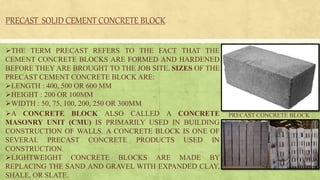

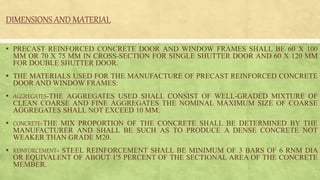

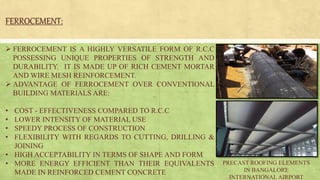

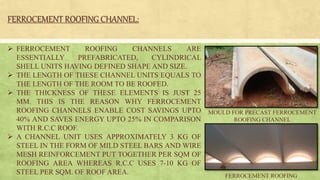

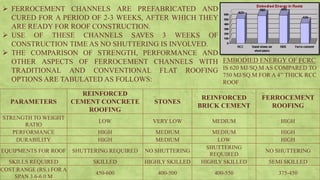

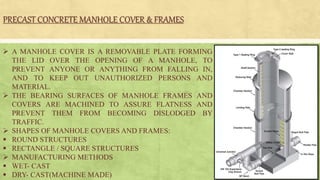

This document provides information on various low cost building components that can be used for construction. It discusses precast solid cement concrete blocks, precast concrete stone masonry blocks, hollow and solid lightweight concrete masonry units, precast reinforced concrete door and window frames, ferrocement roofing channels, and other components. These alternative materials provide benefits like reduced cost, improved strength and durability, thermal efficiency, and environmental sustainability compared to traditional building materials.