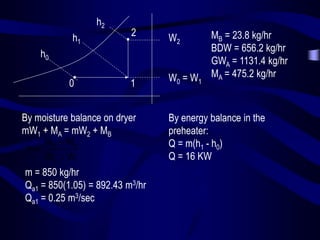

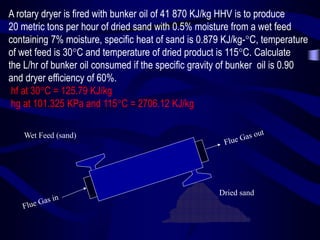

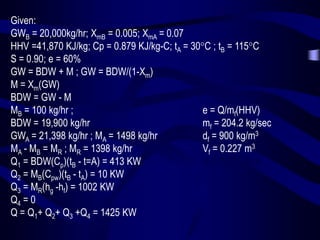

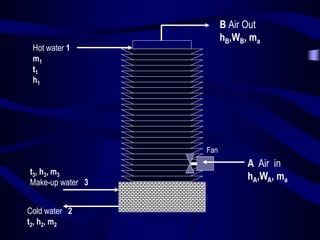

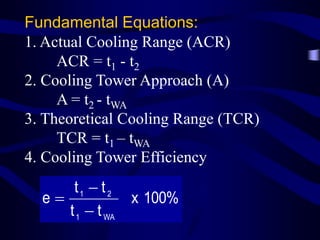

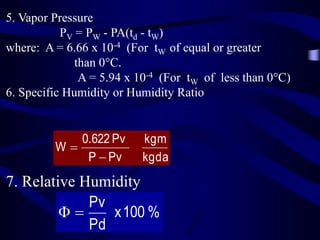

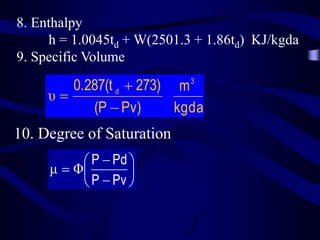

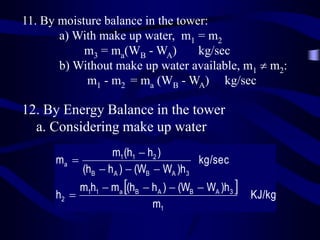

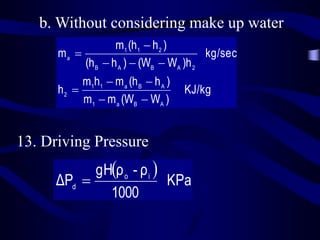

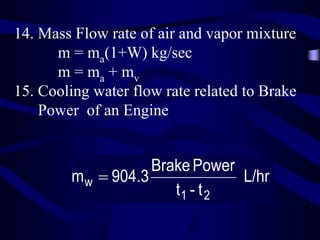

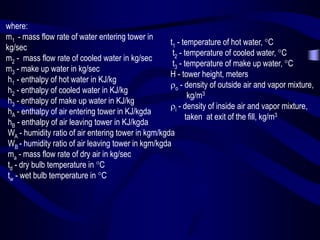

A cooling tower cools water by evaporating a portion of the water as it is exposed to air circulating through the tower. Hot water enters the top of the tower and is cooled as it falls through fillings, exposing new surfaces to the air. Cooled water exits the bottom while moist air exits from the top after partially saturating with evaporated water. The document provides equations for calculating cooling tower performance parameters like actual cooling range, approach, efficiency, enthalpy, humidity ratio, and mass and energy balances.

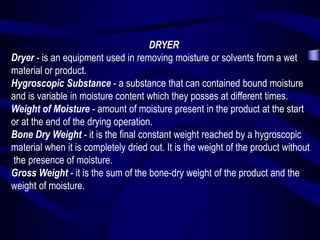

![Continuous Drying - is that type of drying operation in which the material

to be dried is fed to and discharge from the dryer continuously.

Batch Drying - is that type of drying operation in which the material to be

dried is done in batches at definite interval of time.

CLASSIFICATION OF DRYERS

1. Direct Dryers - conduction heat transfer

2. Indirect Dryers - convection heat transfer

3. Infra-red Dryers - radiation heat transfer

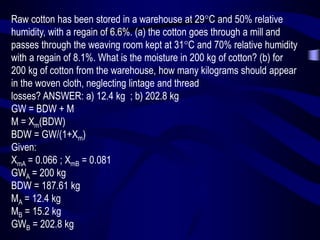

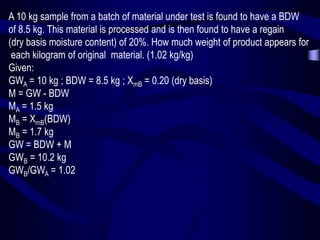

PRODUCT SYMBOLS

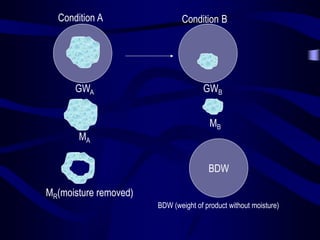

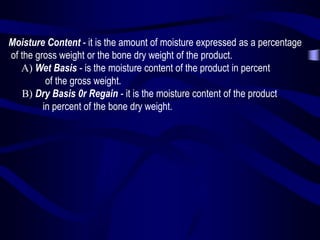

1. GW = BDW + M

2. Xm = [M/GW] x 100% (wet basis)

3. Xm = [M/BDW] x 100% (dry basis or regain)

where: GW - gross weight

BDW - bone dry weight

M - weight of moisture

Xm - moisture content](https://image.slidesharecdn.com/coolingtowerdryer-140208204949-phpapp02/85/Cooling-Tower-Dryer-Fundamentals-13-320.jpg)