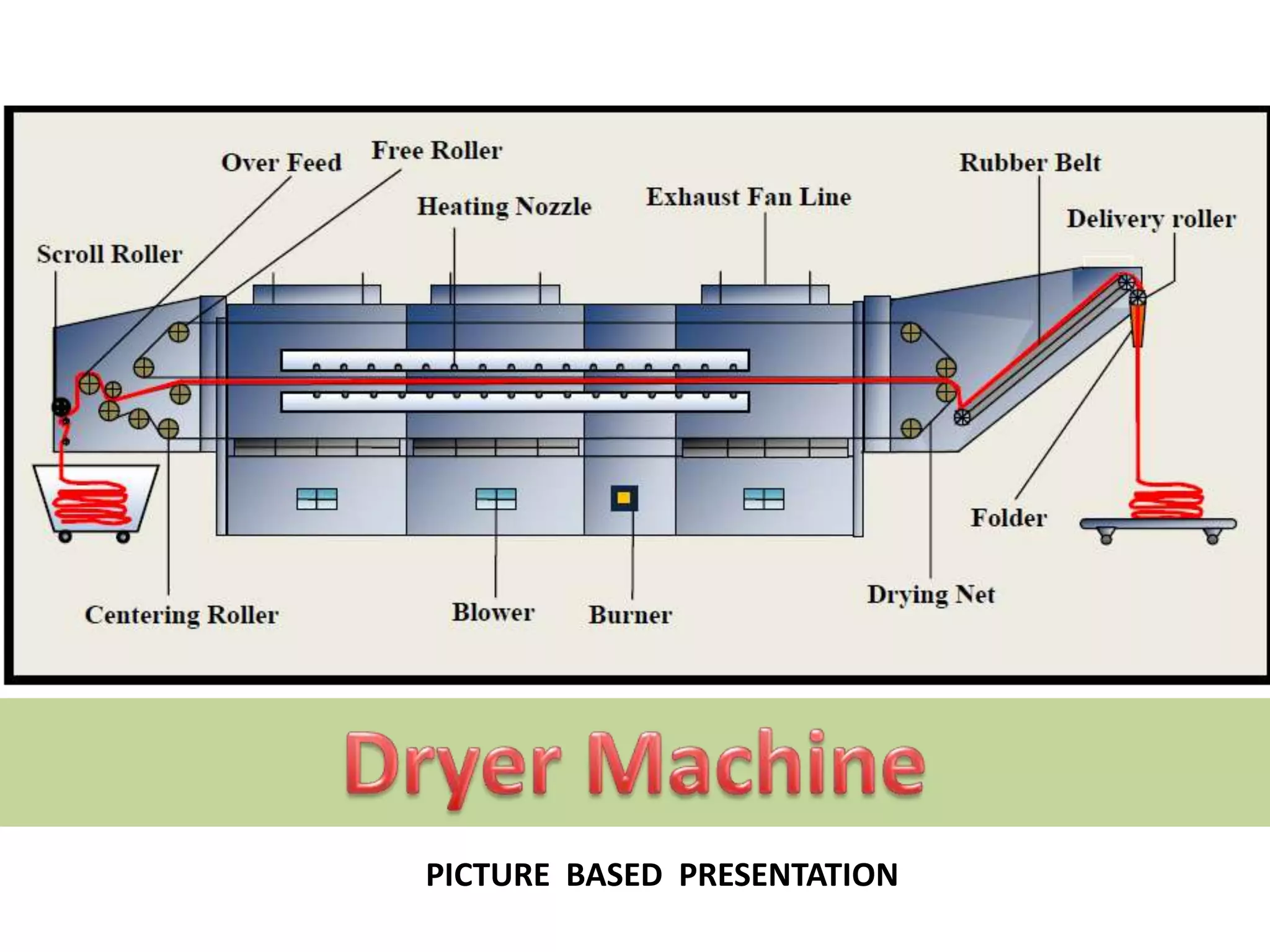

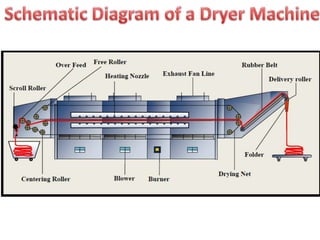

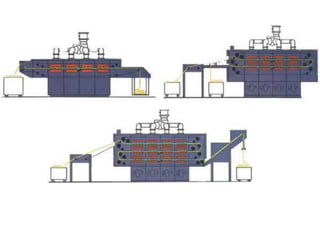

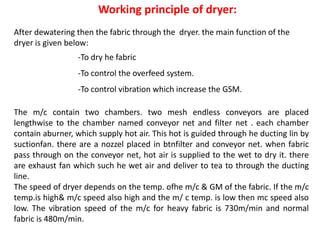

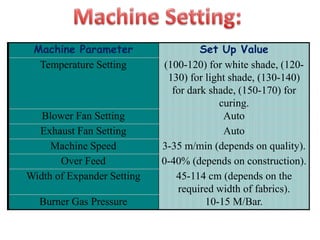

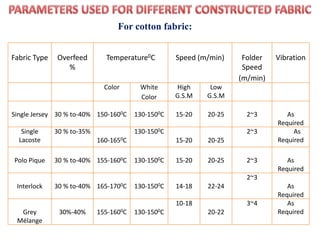

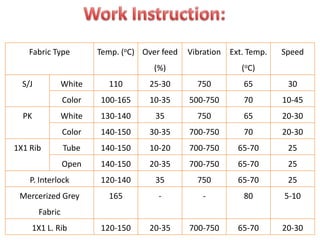

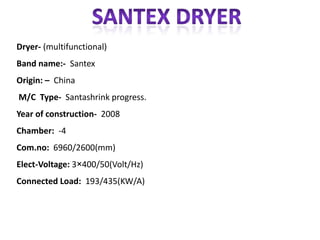

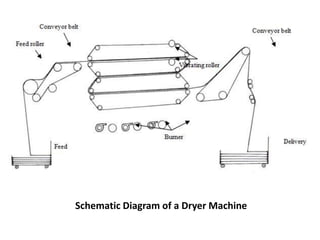

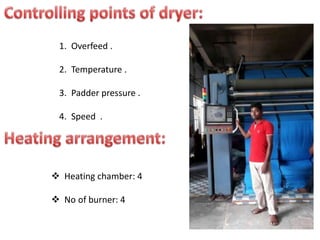

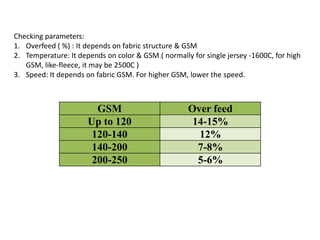

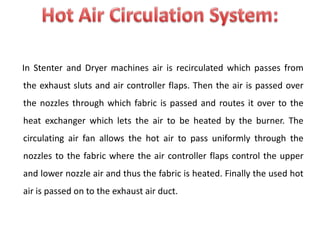

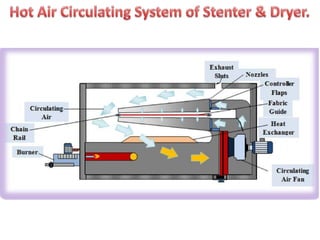

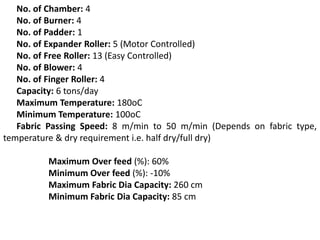

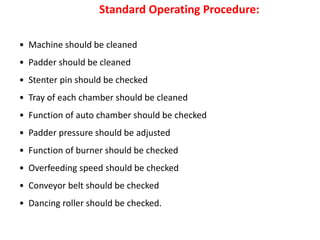

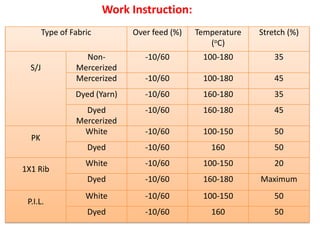

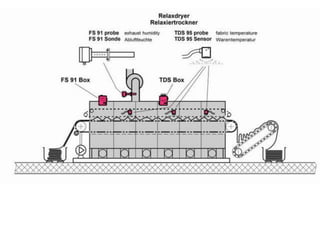

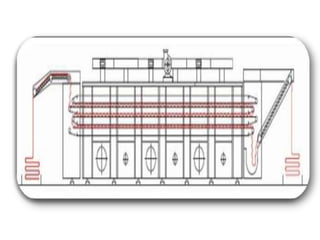

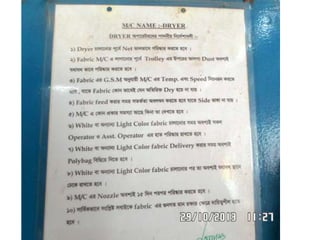

The document provides information about a drying machine used in textile processing. It contains details such as the machine having 2 chambers, 8 blowers, and 2 conveyors. It then explains that the machine removes residual water from fabric by applying heat through burner nozzles while continuously measuring humidity. The document further discusses parameters for operating the machine like temperature, speed, and overfeeding percentage which depend on factors like fabric type and weight. It also lists components of the machine and steps for cleaning and maintenance.