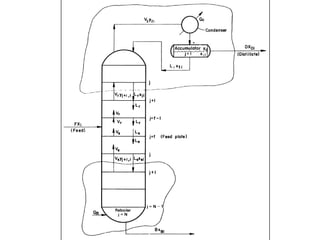

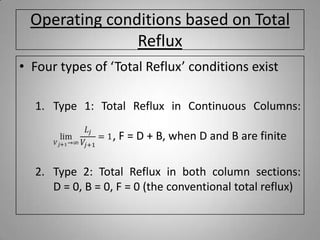

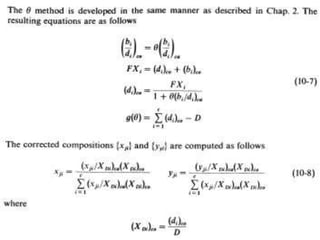

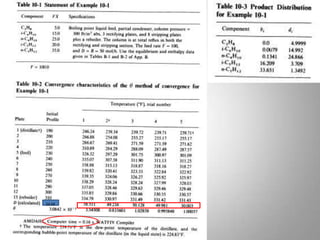

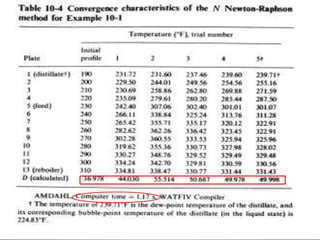

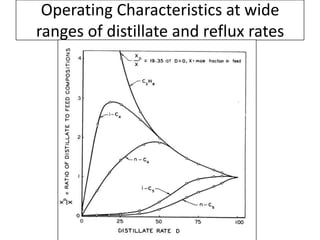

This document discusses different operating conditions of continuous distillation columns under total reflux, including four types of total reflux. It describes total reflux, where no distillate or bottom products leave the column. It also discusses the material balance equation and introduces the Θ method and Newton Raphson method for determining column specifications under Type 1 total reflux conditions, where distillate and bottom rates are finite as reflux ratio approaches infinity. The document provides an example application of the Θ method and compares it to the Newton Raphson method.