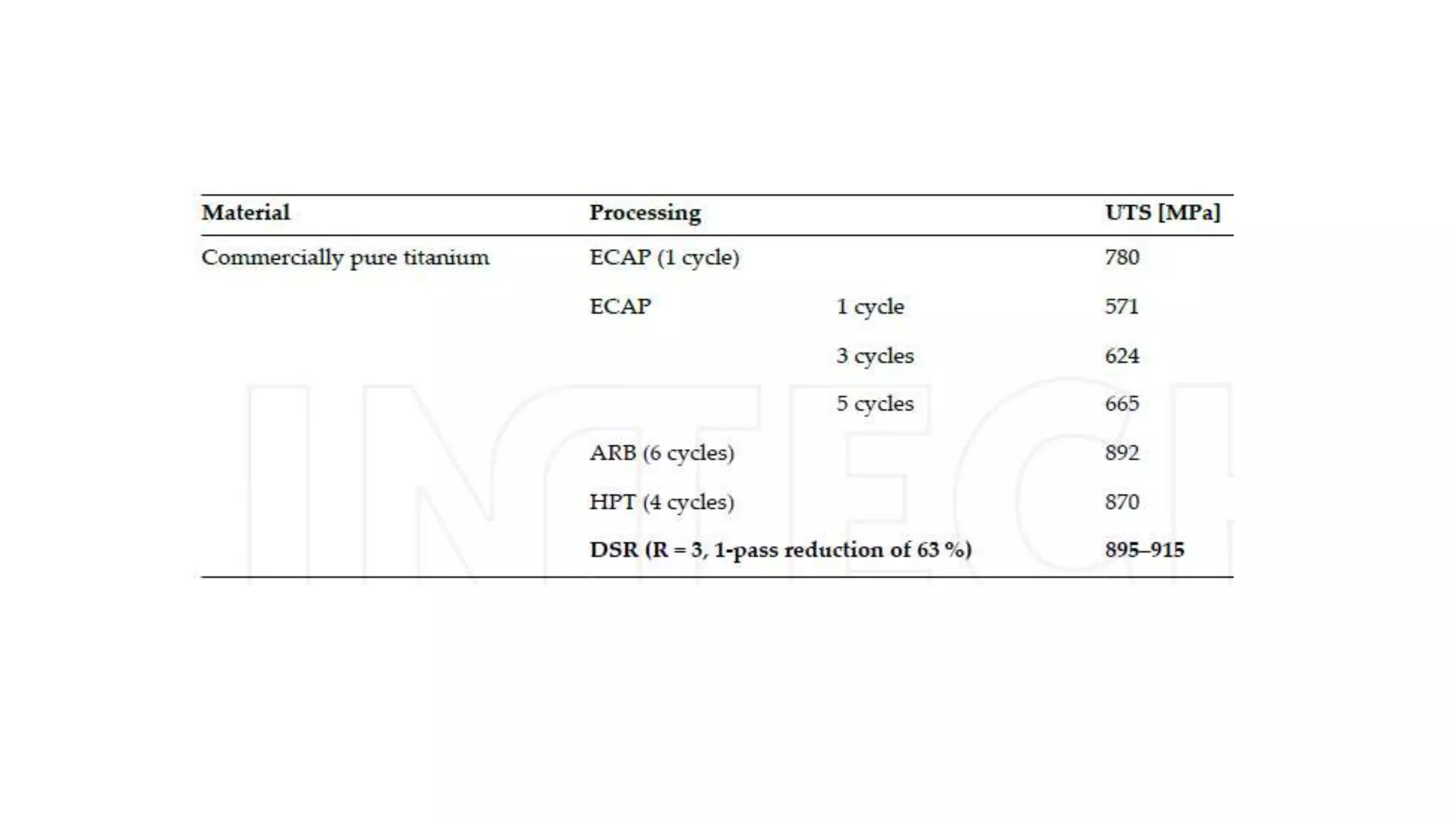

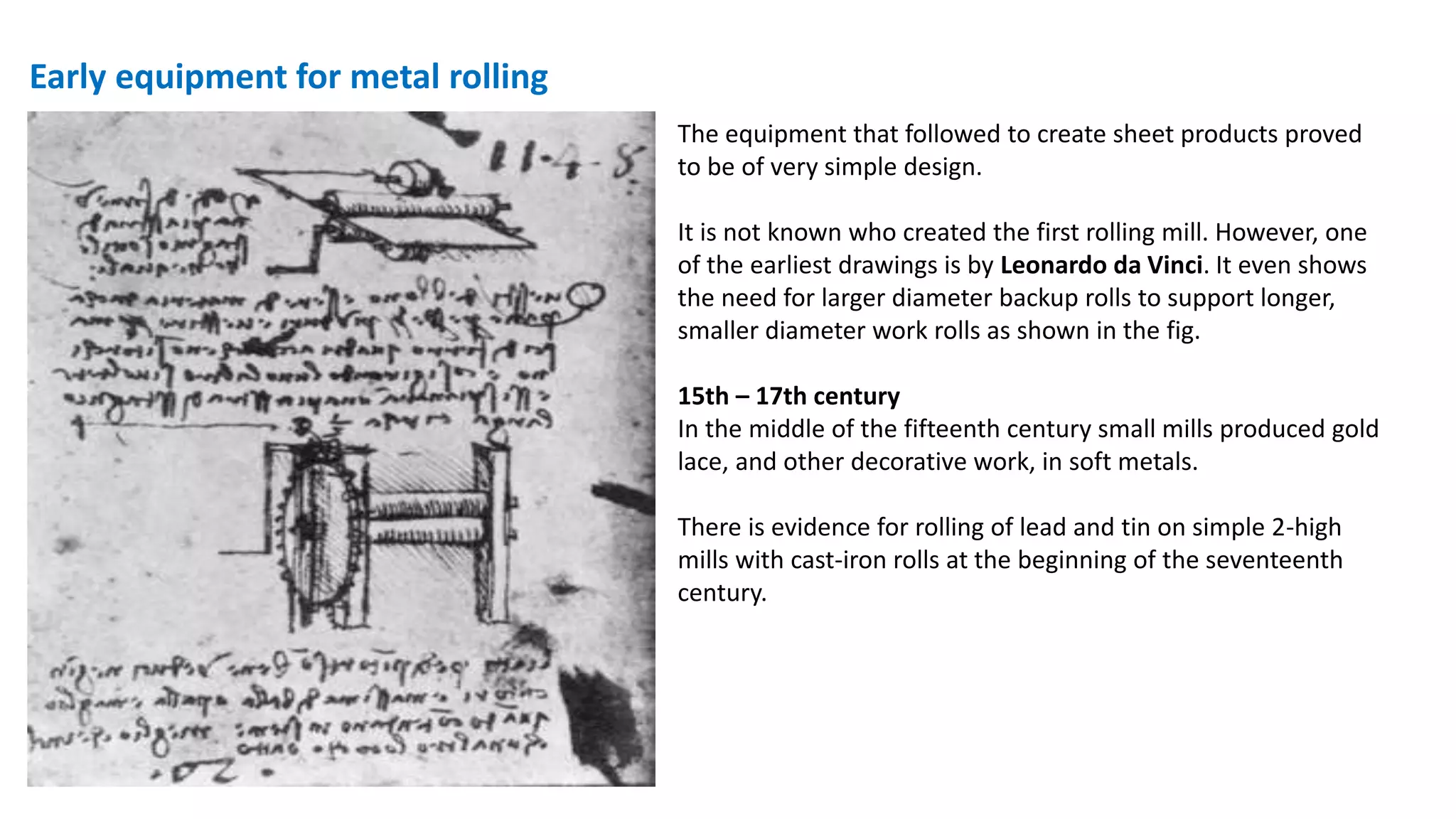

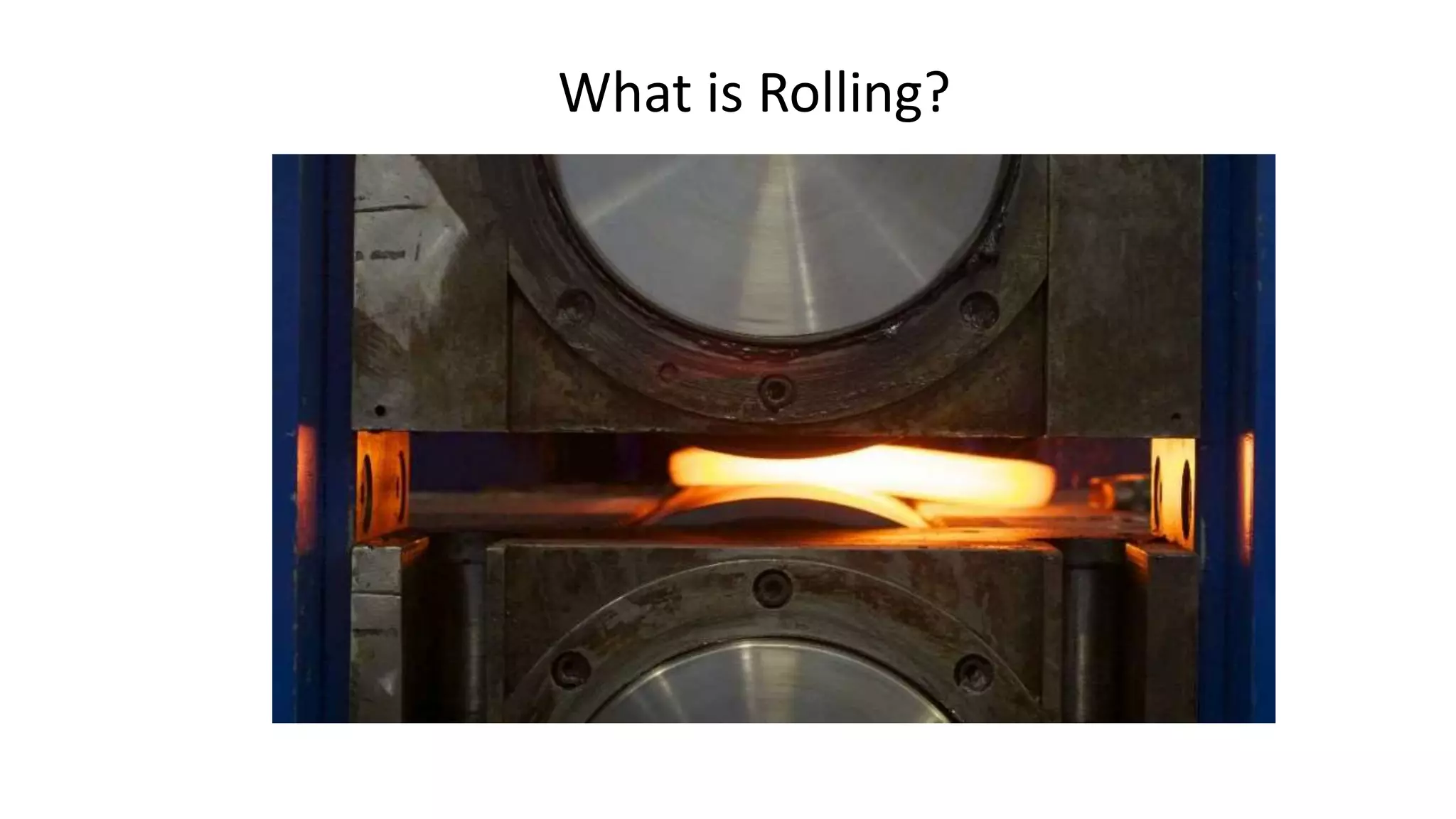

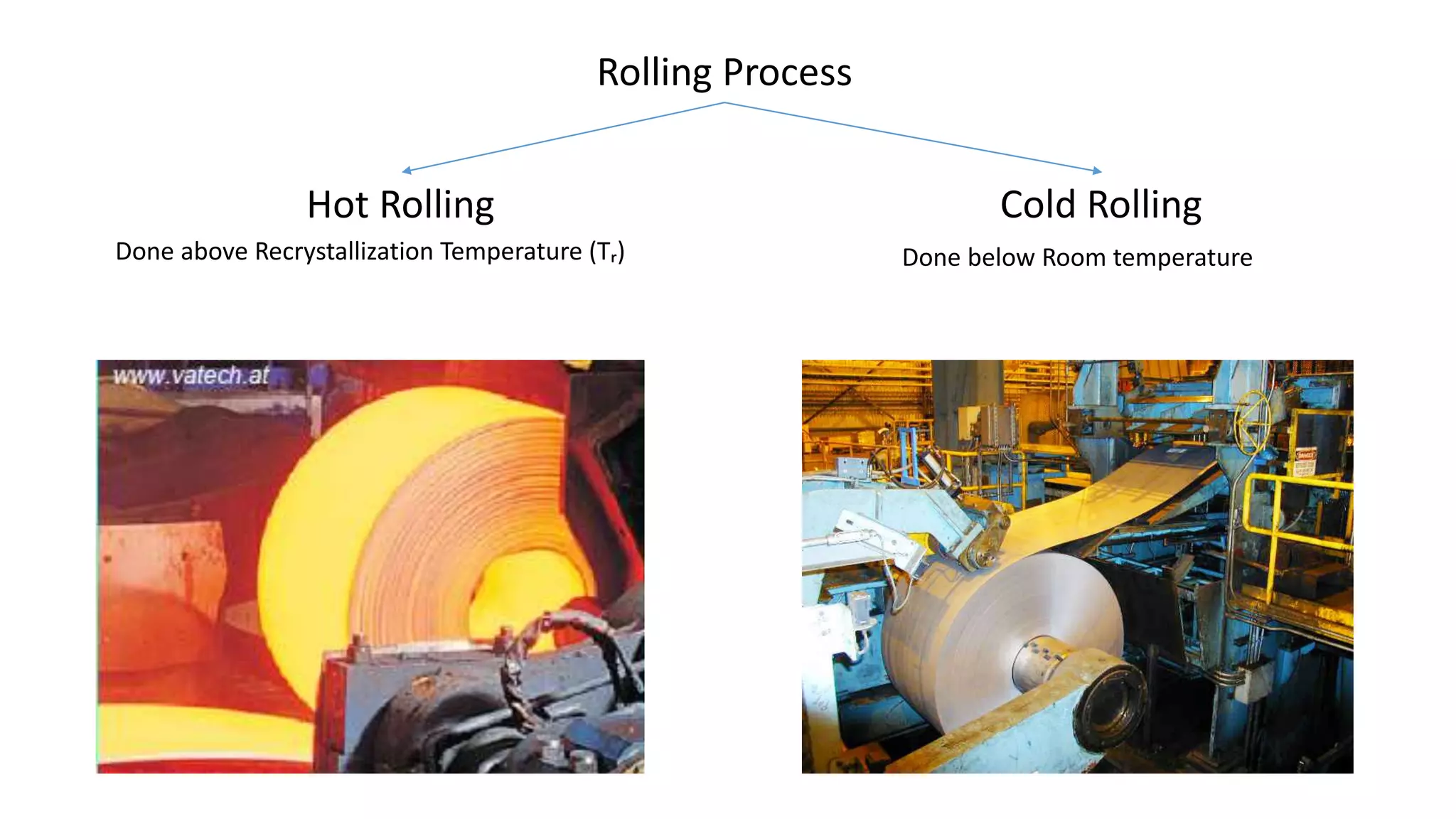

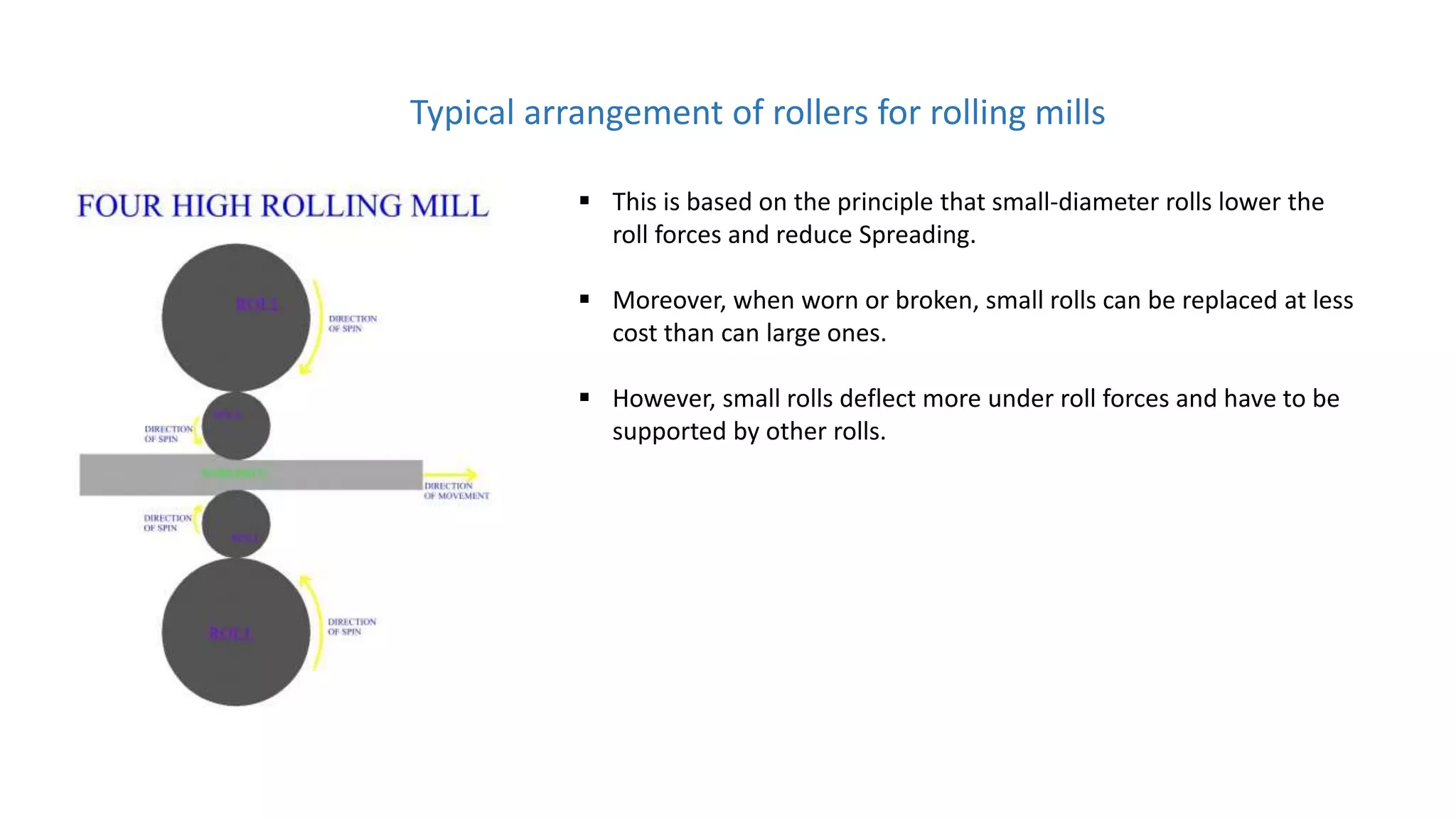

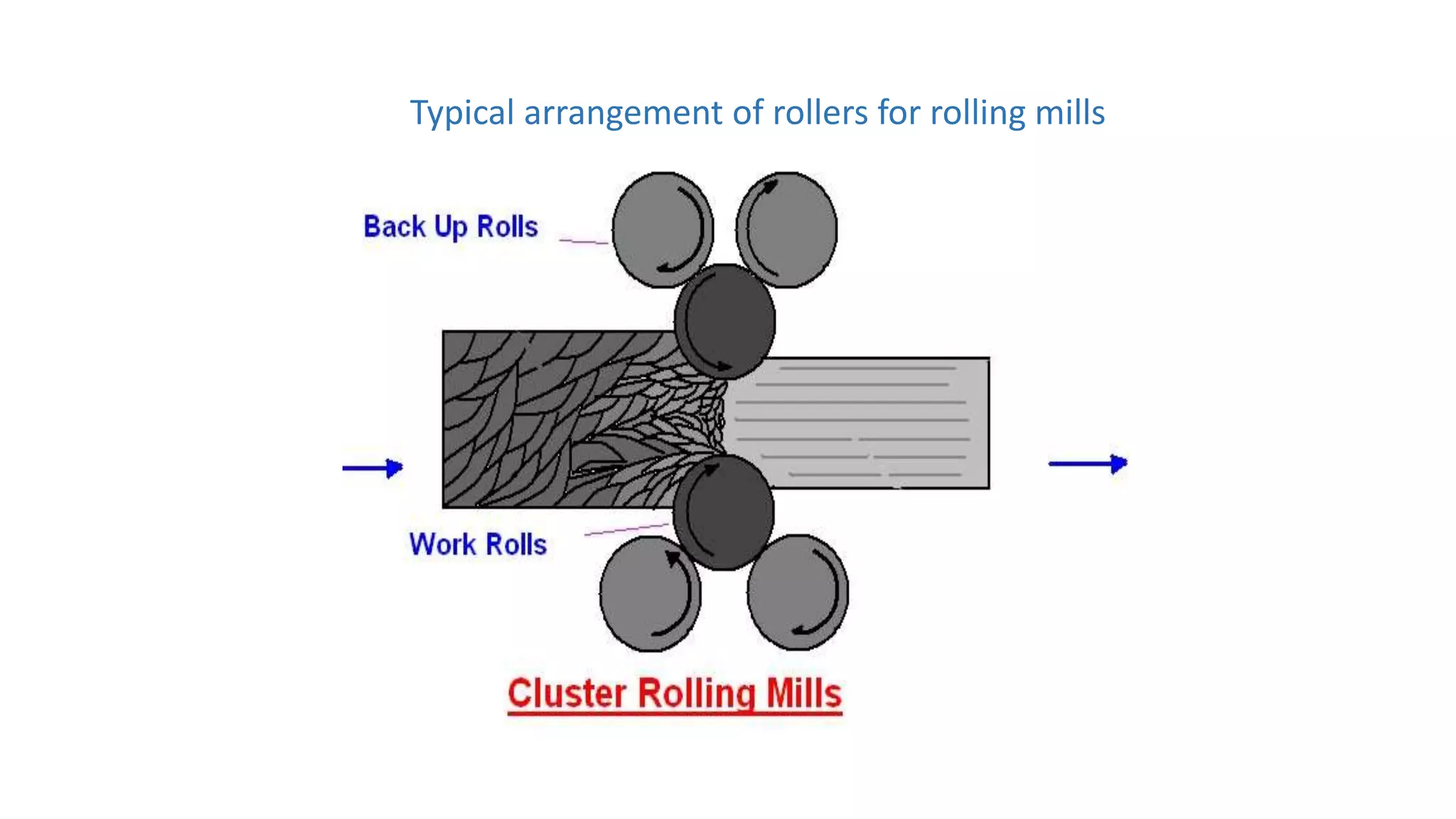

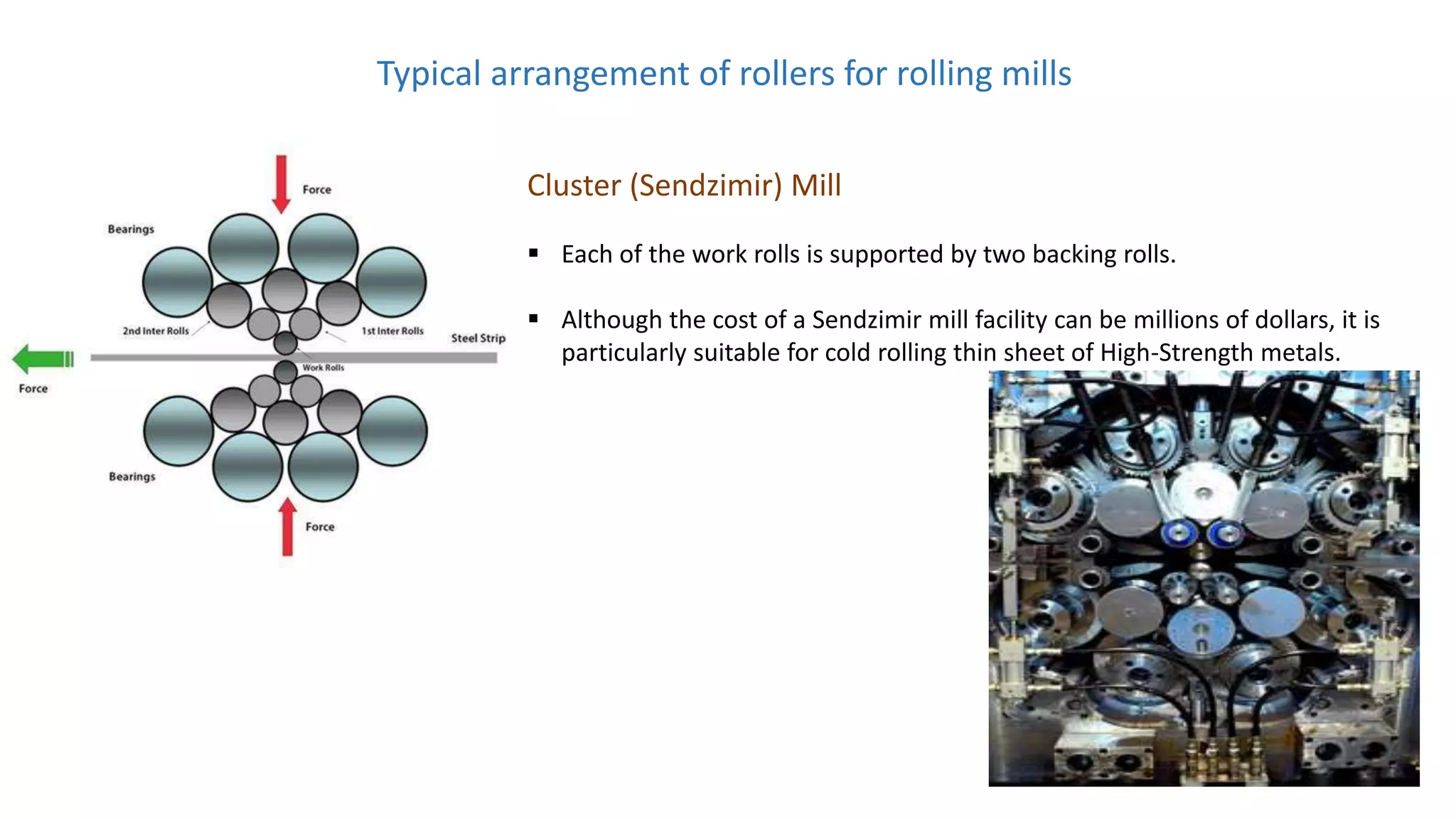

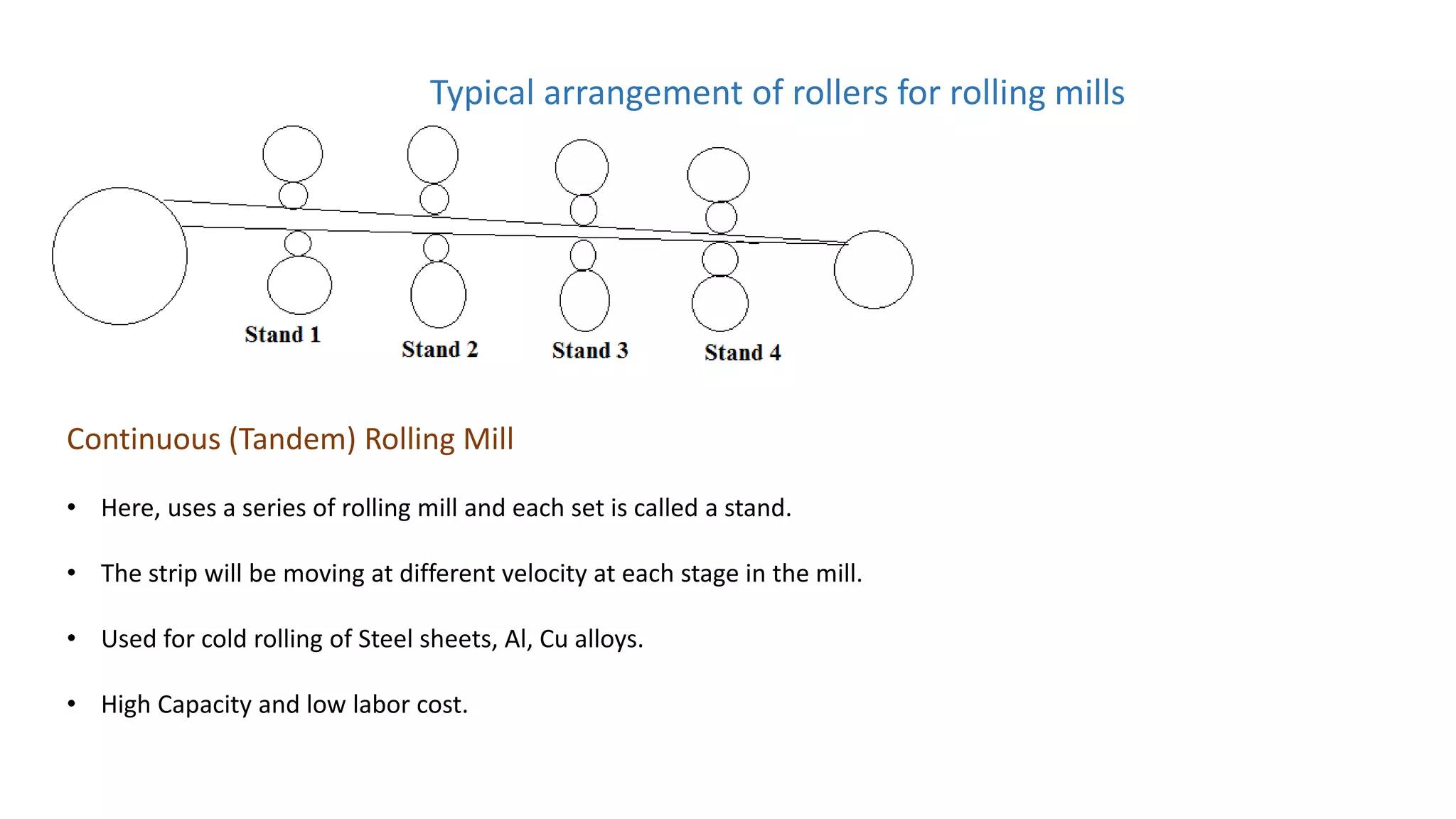

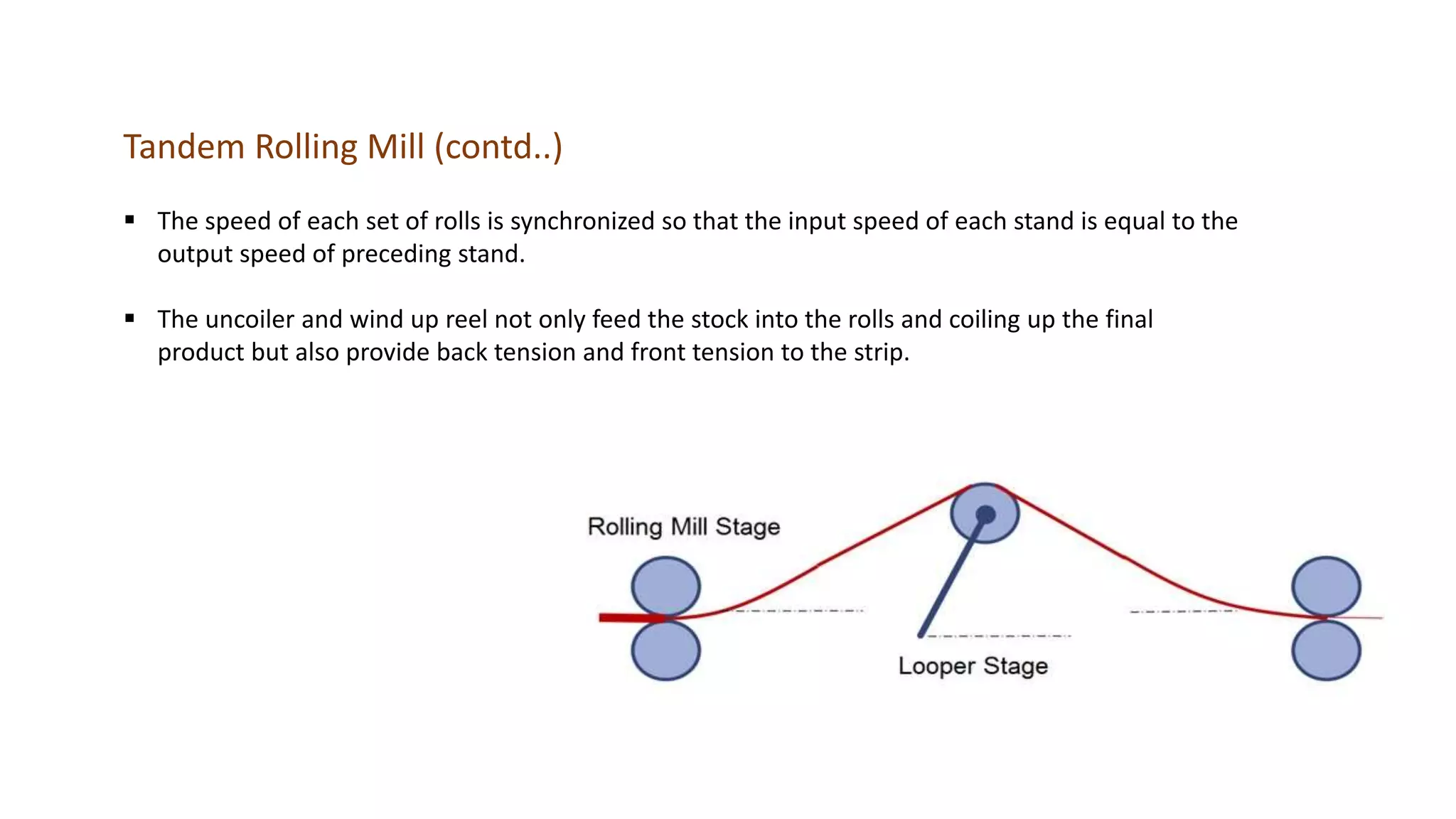

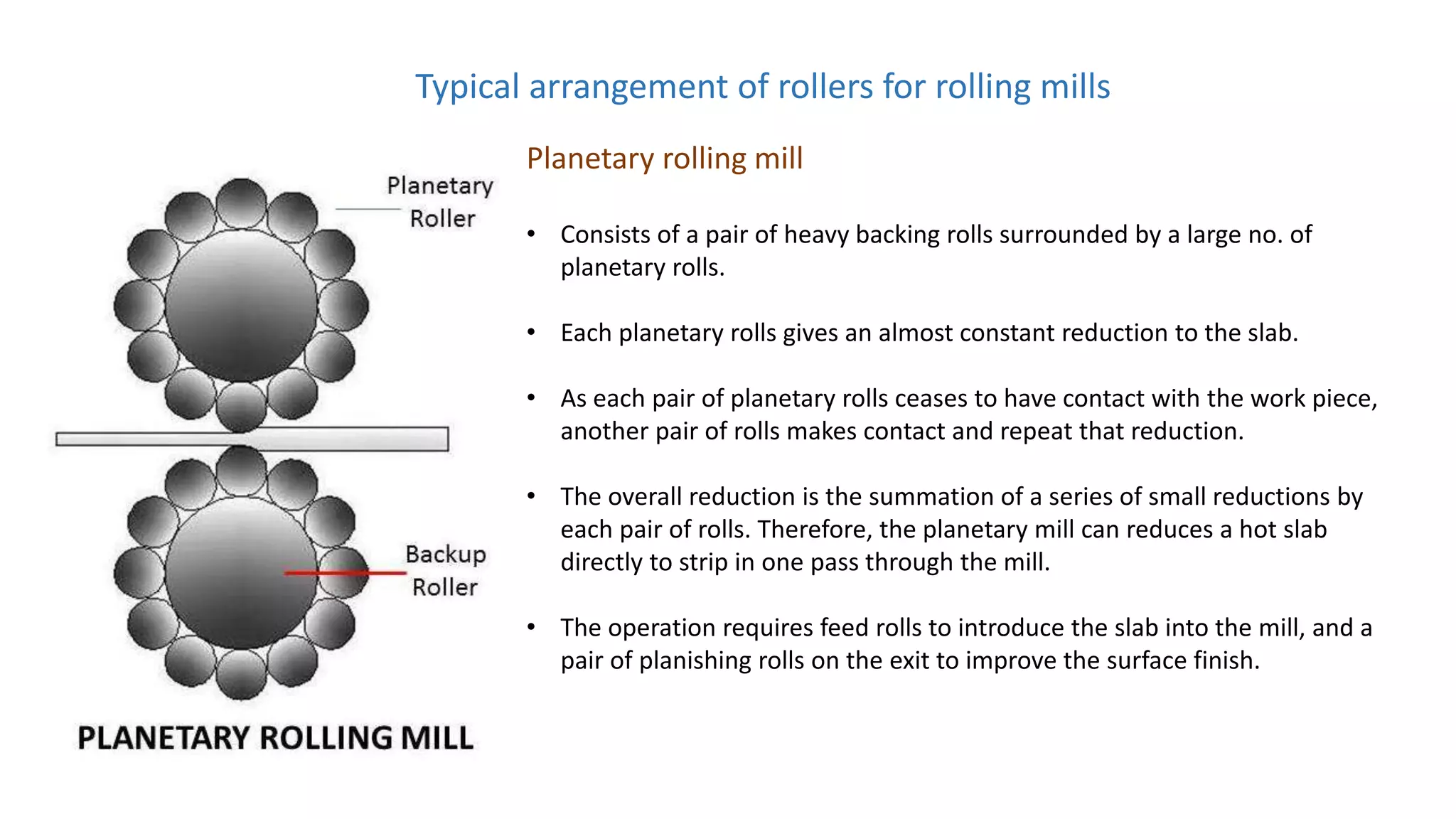

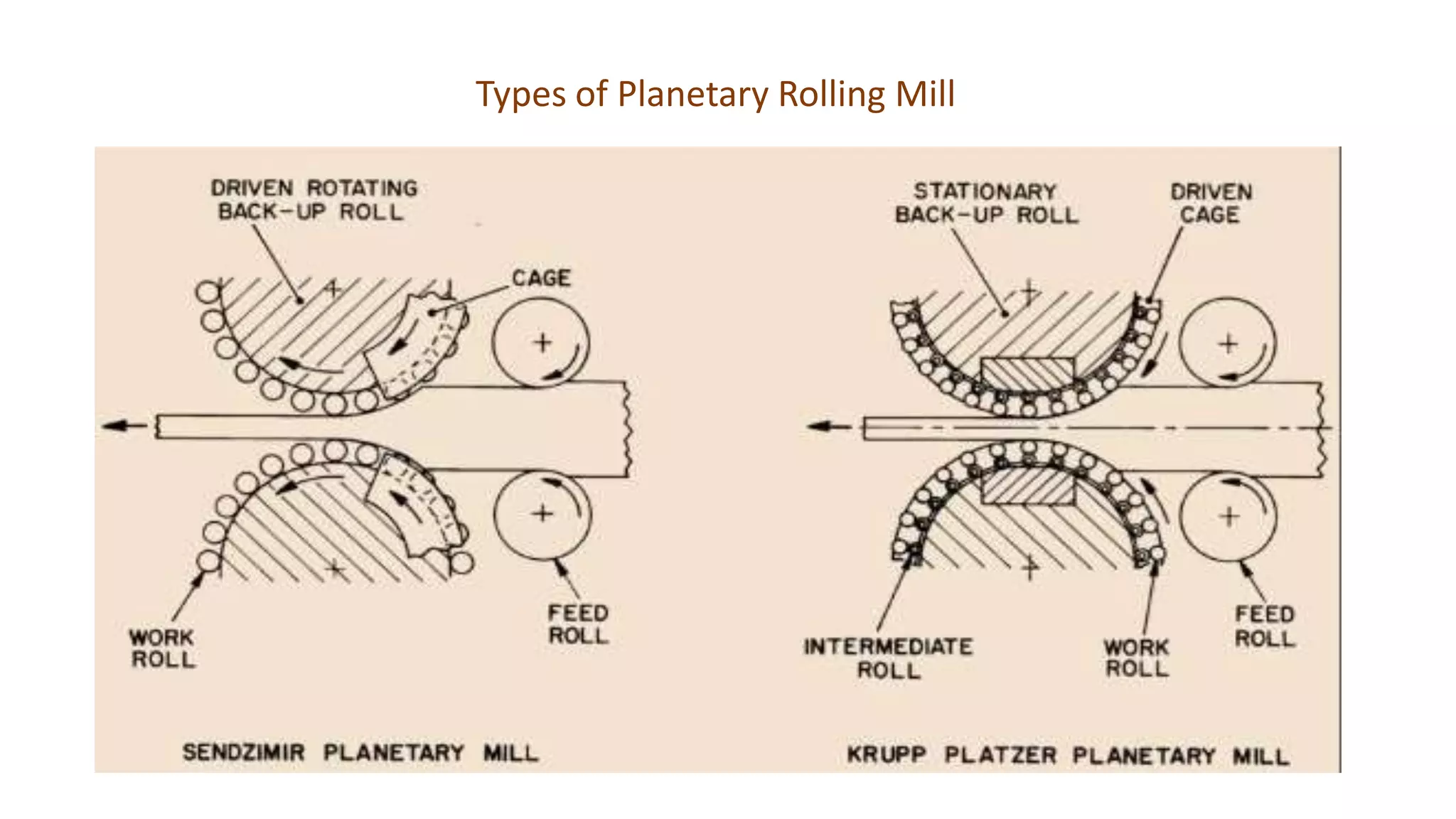

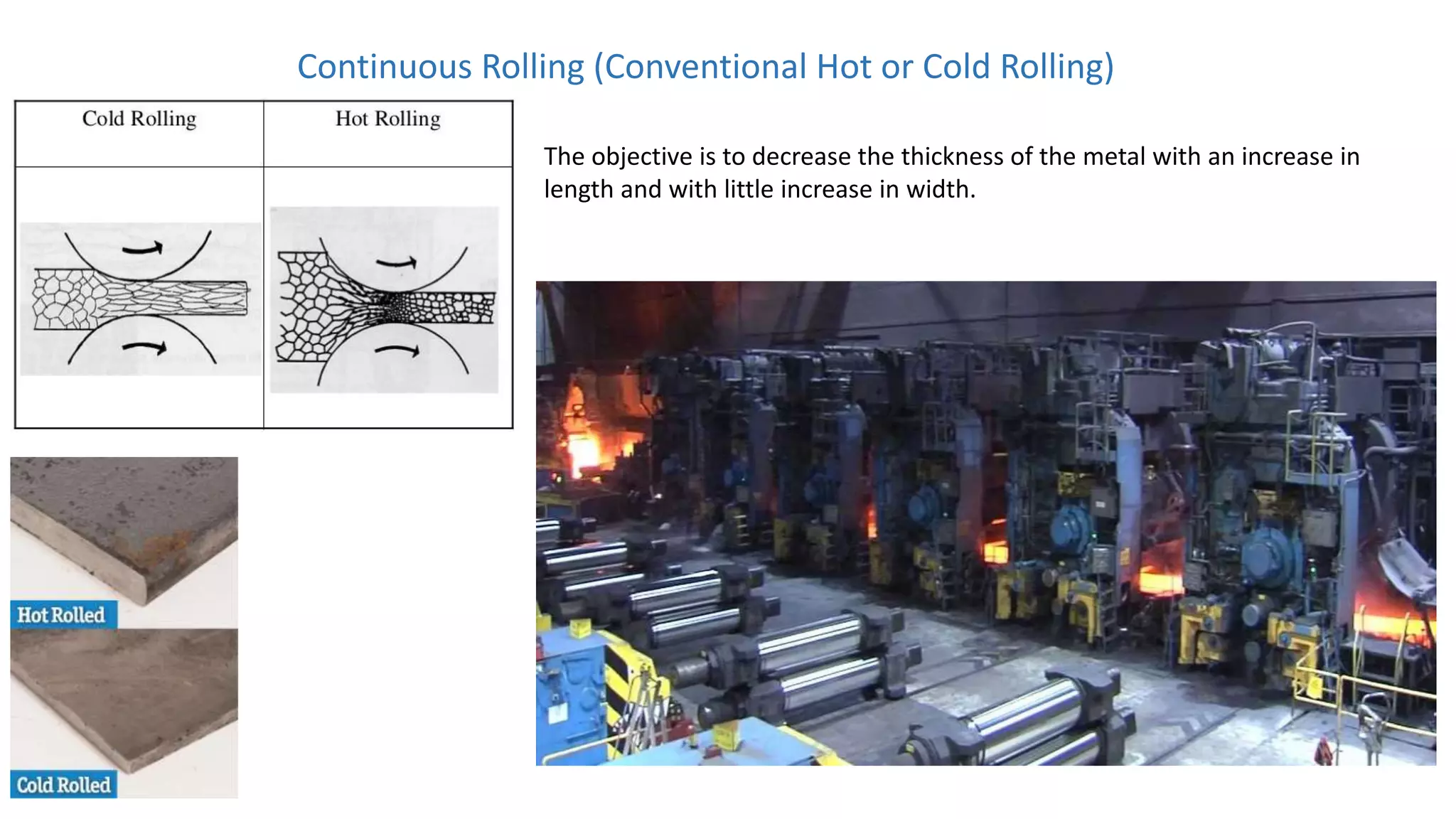

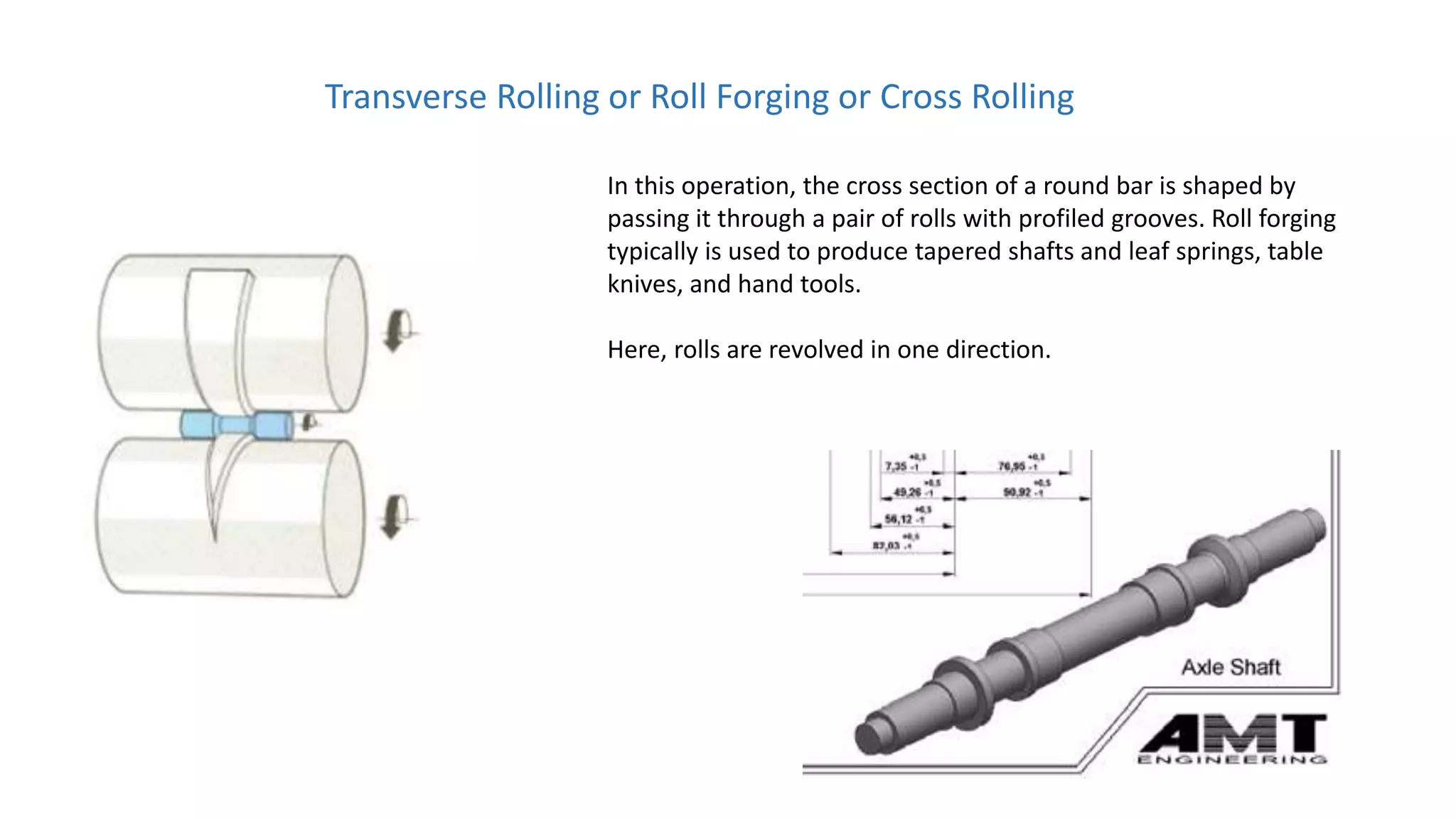

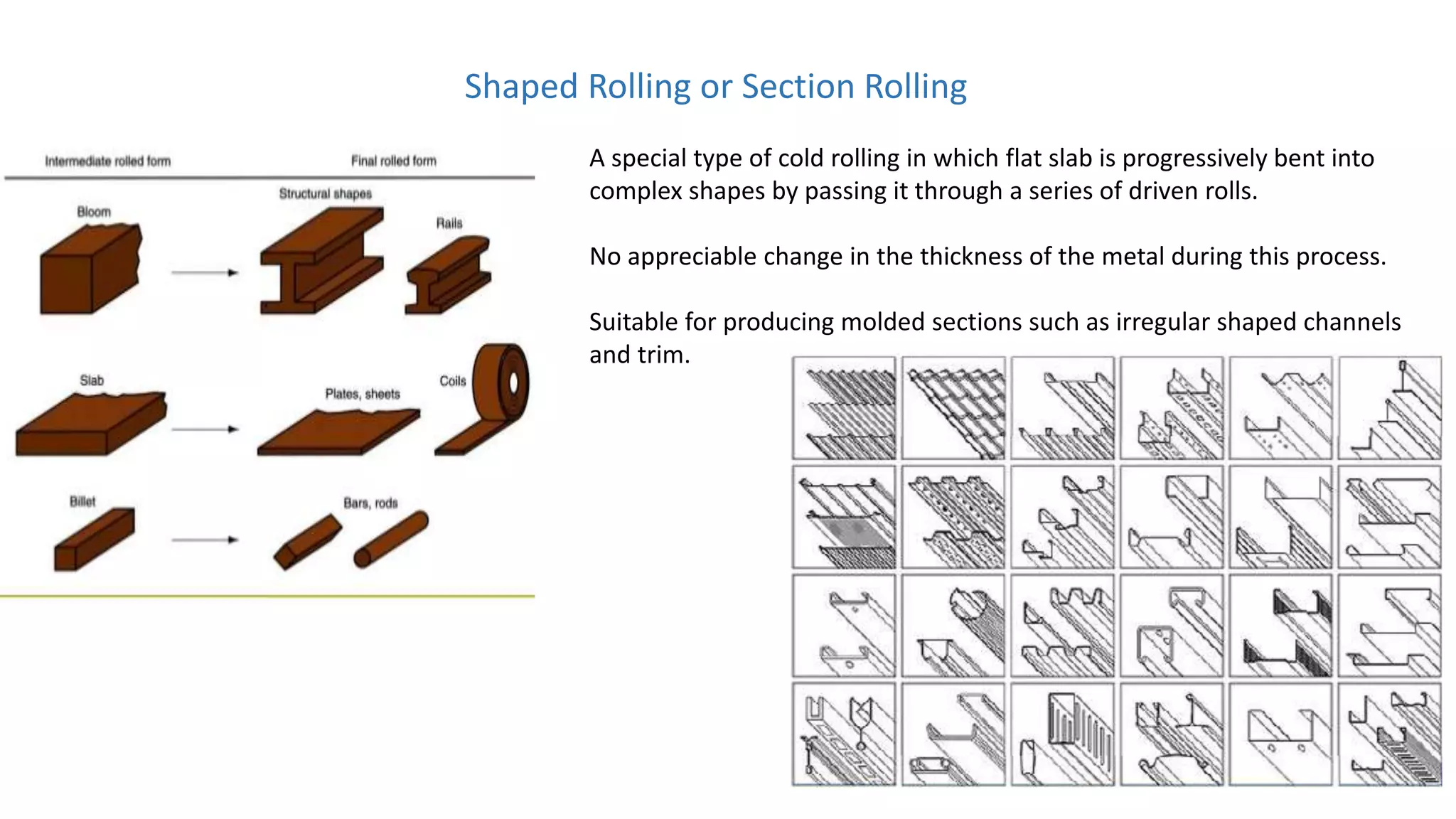

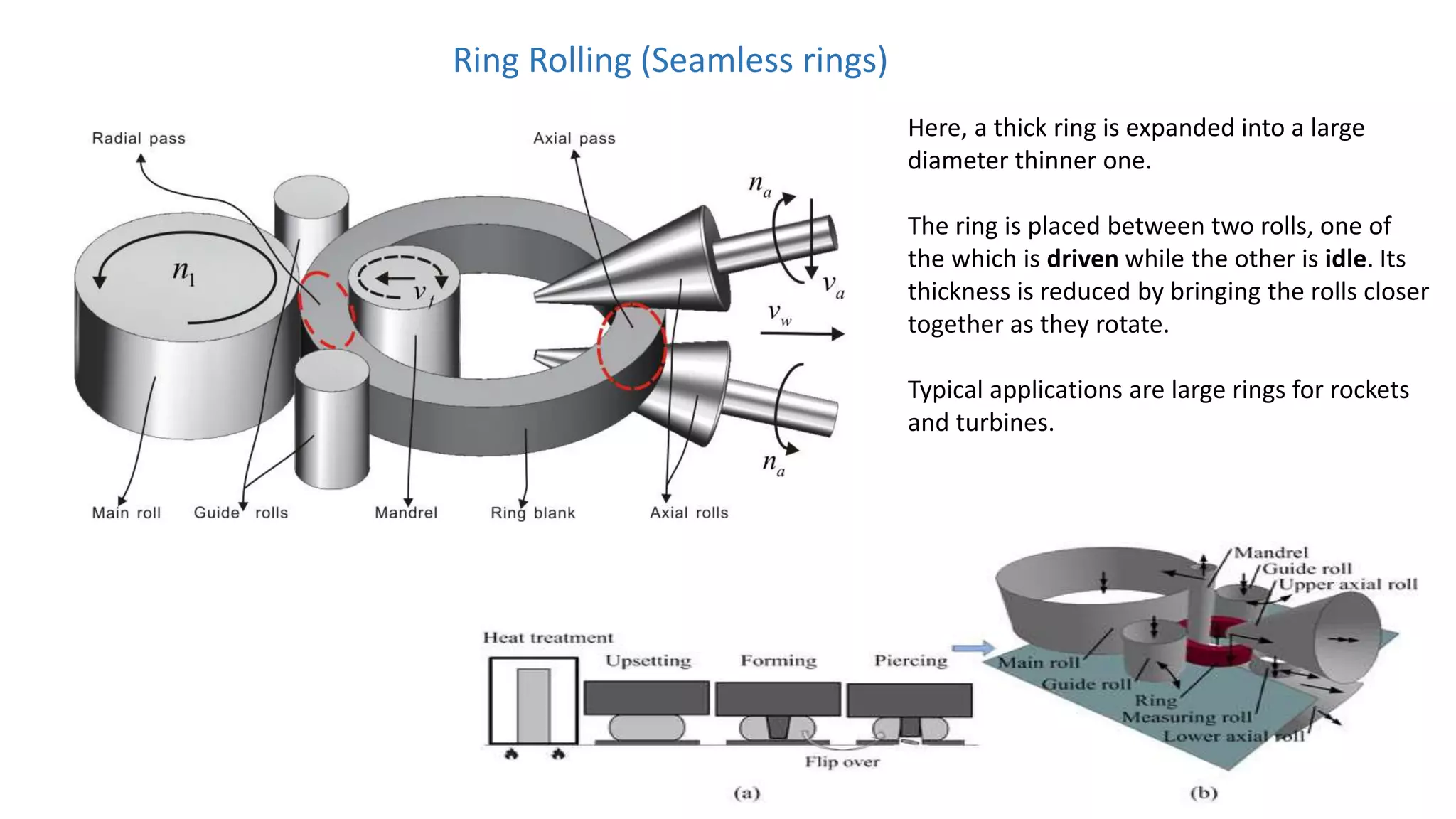

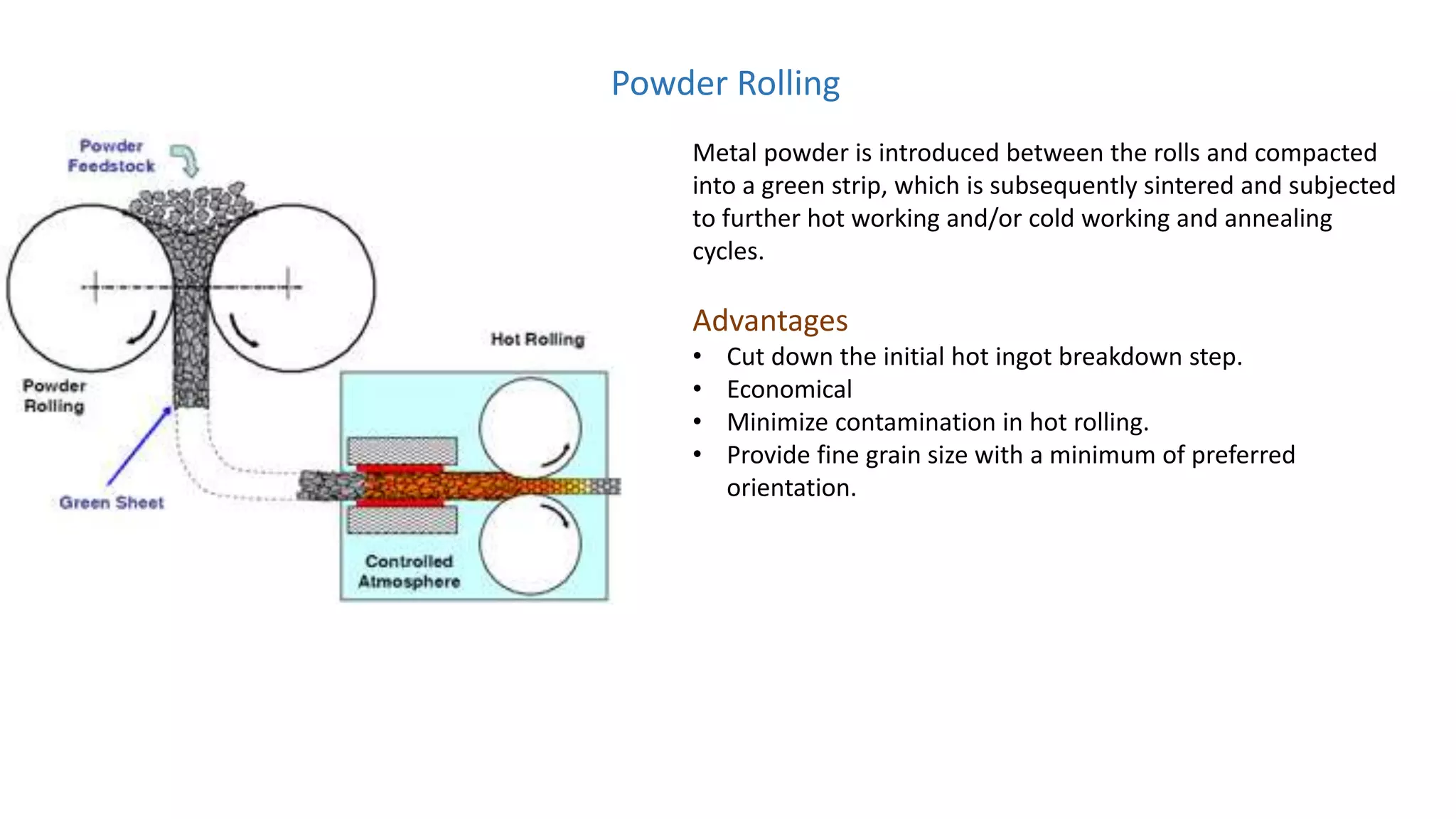

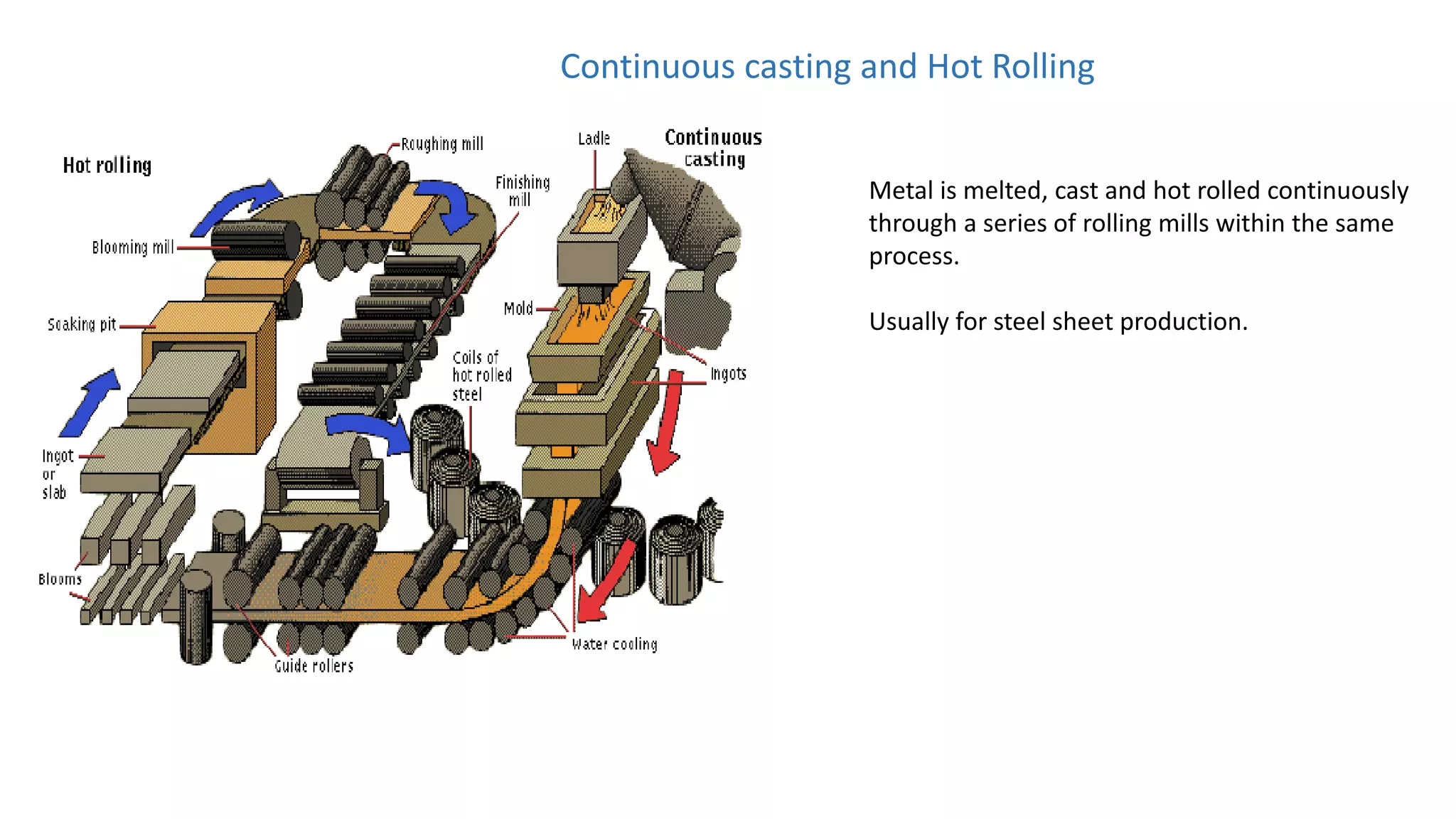

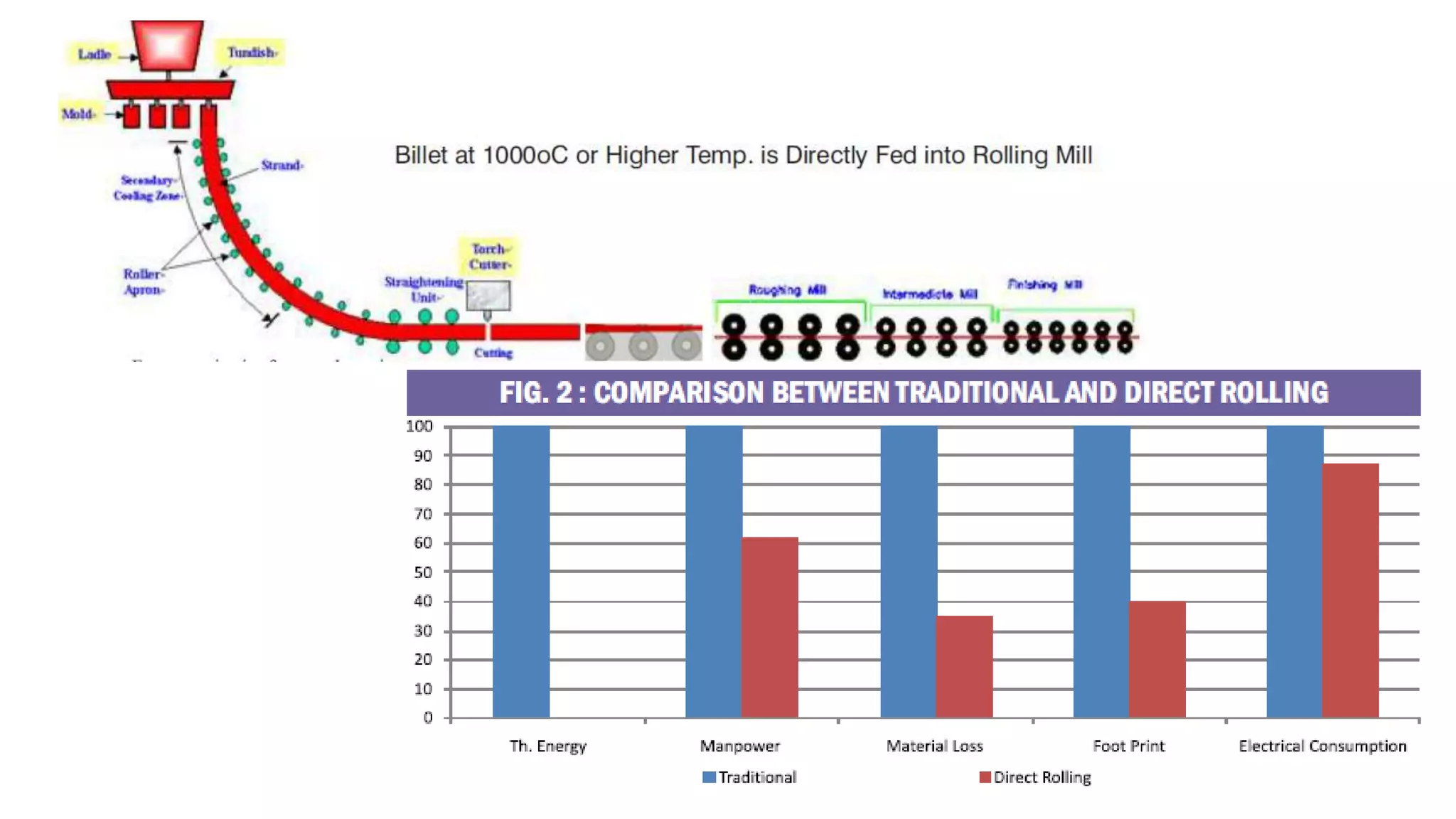

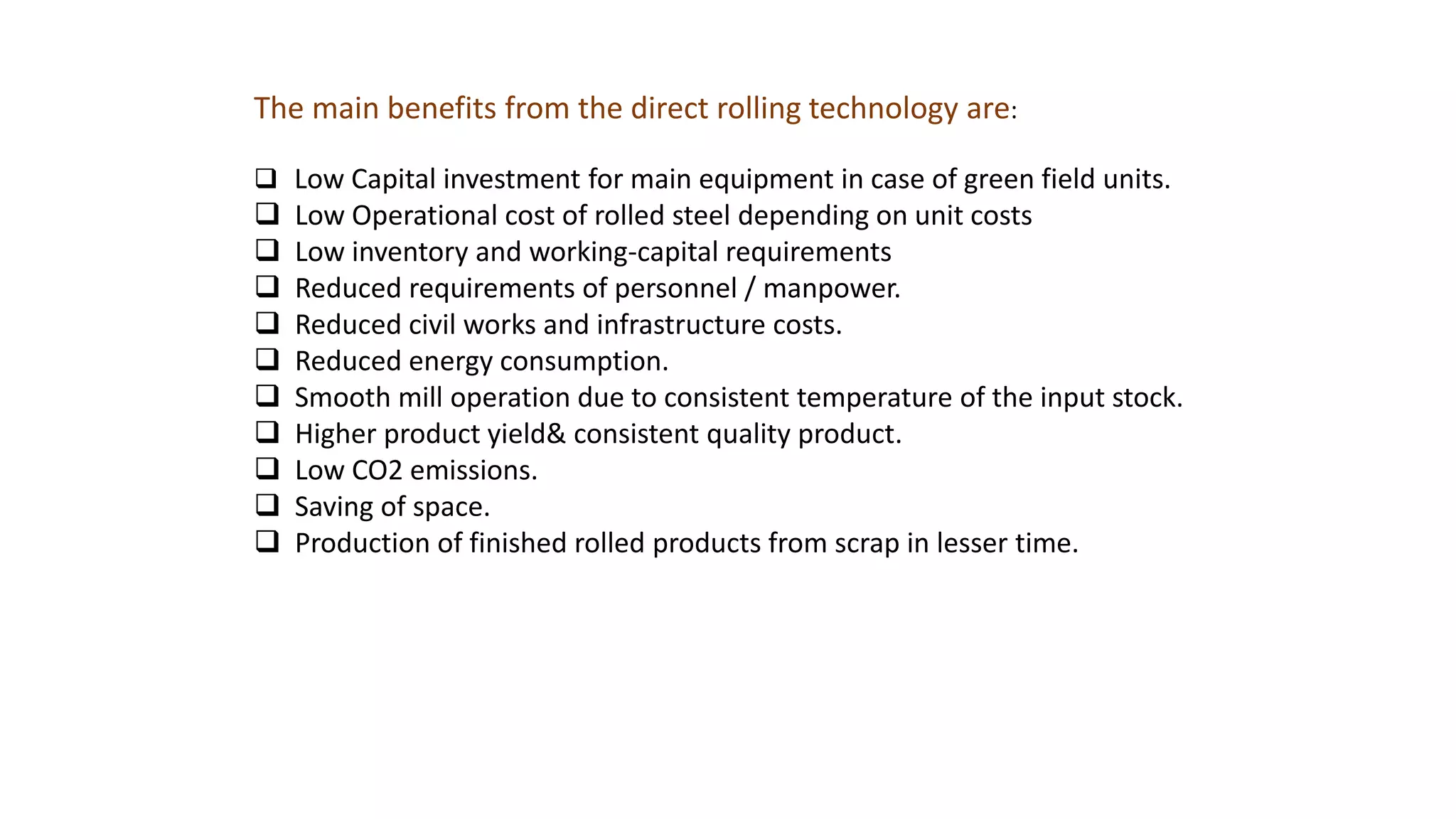

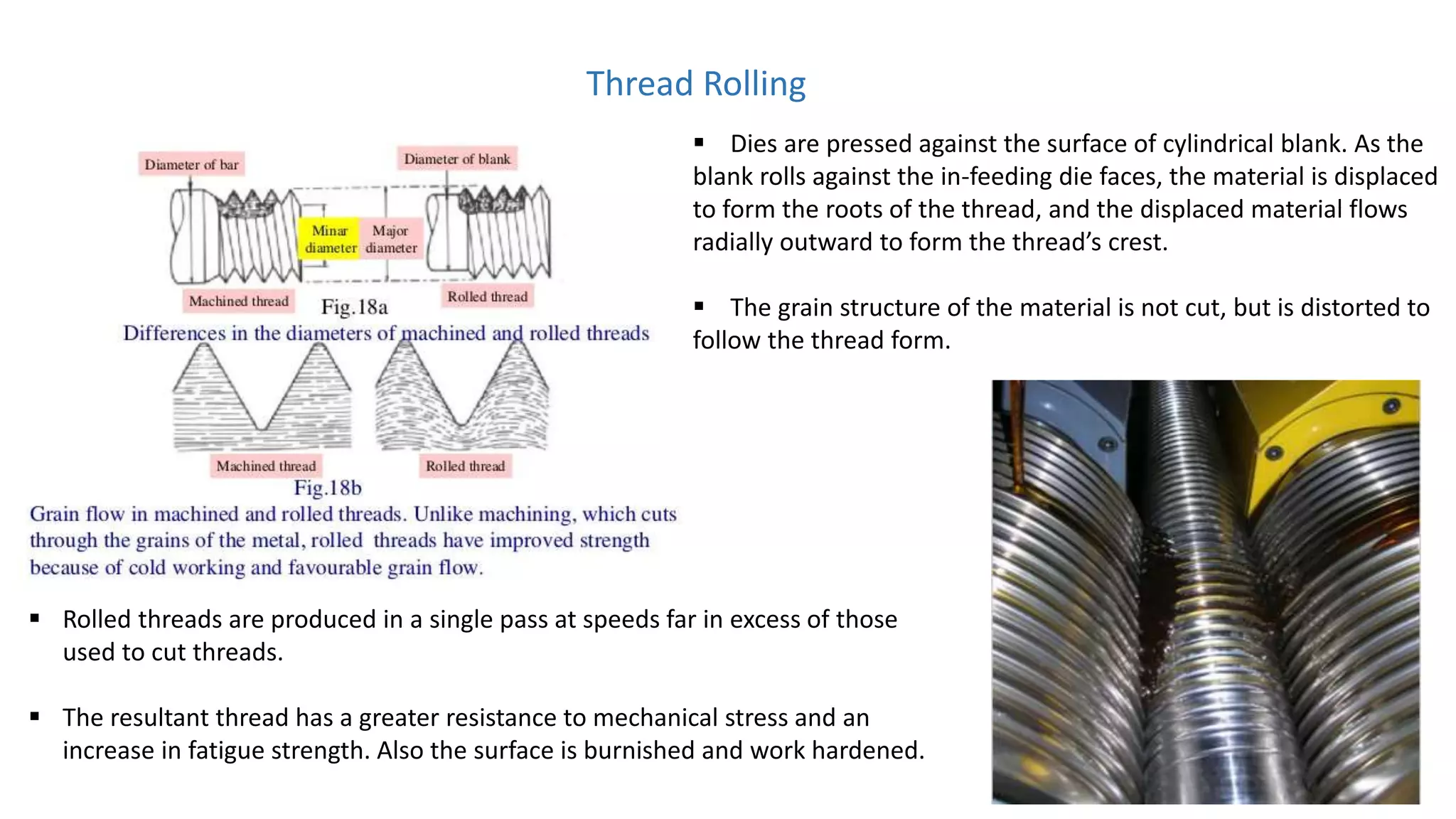

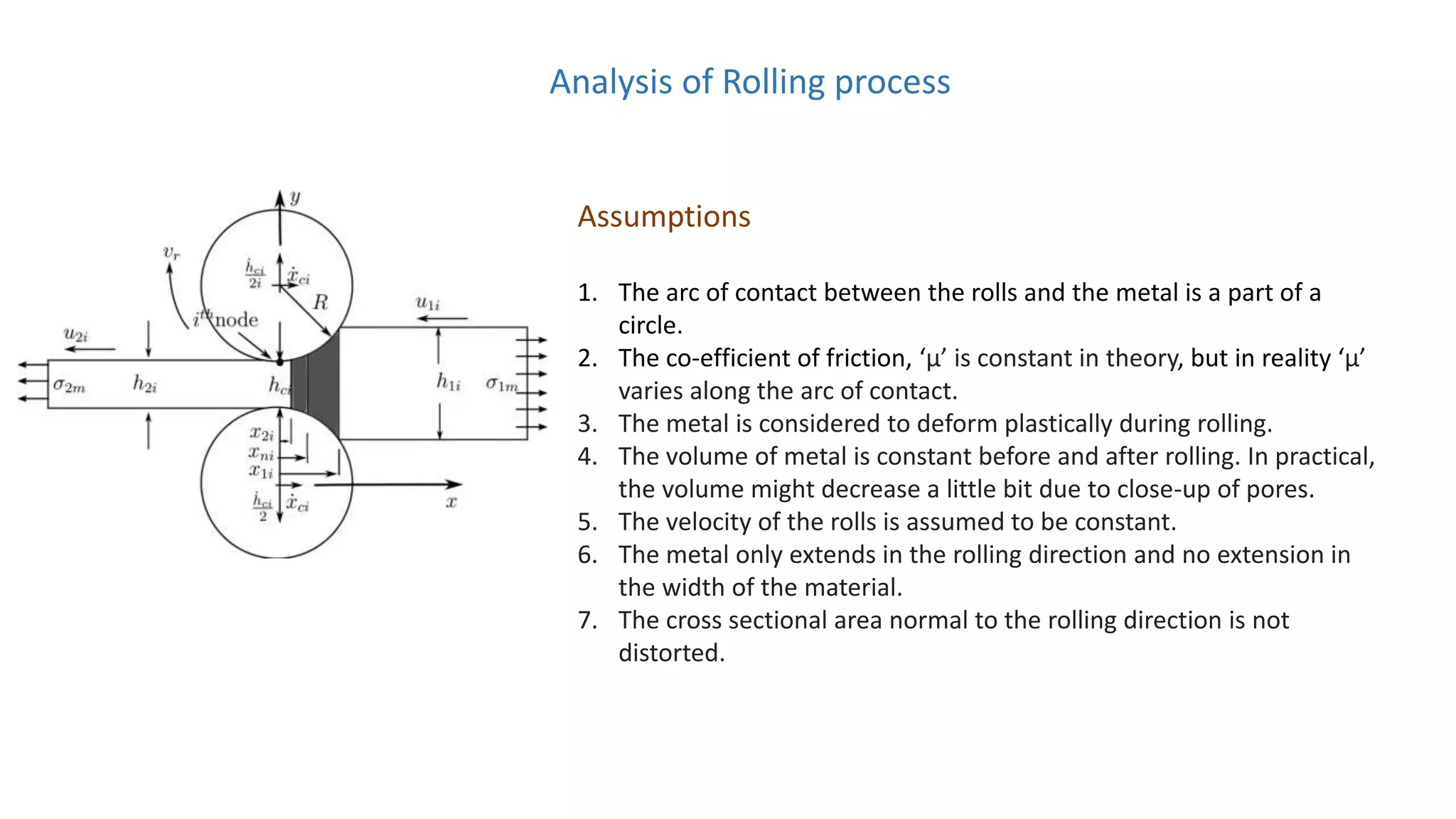

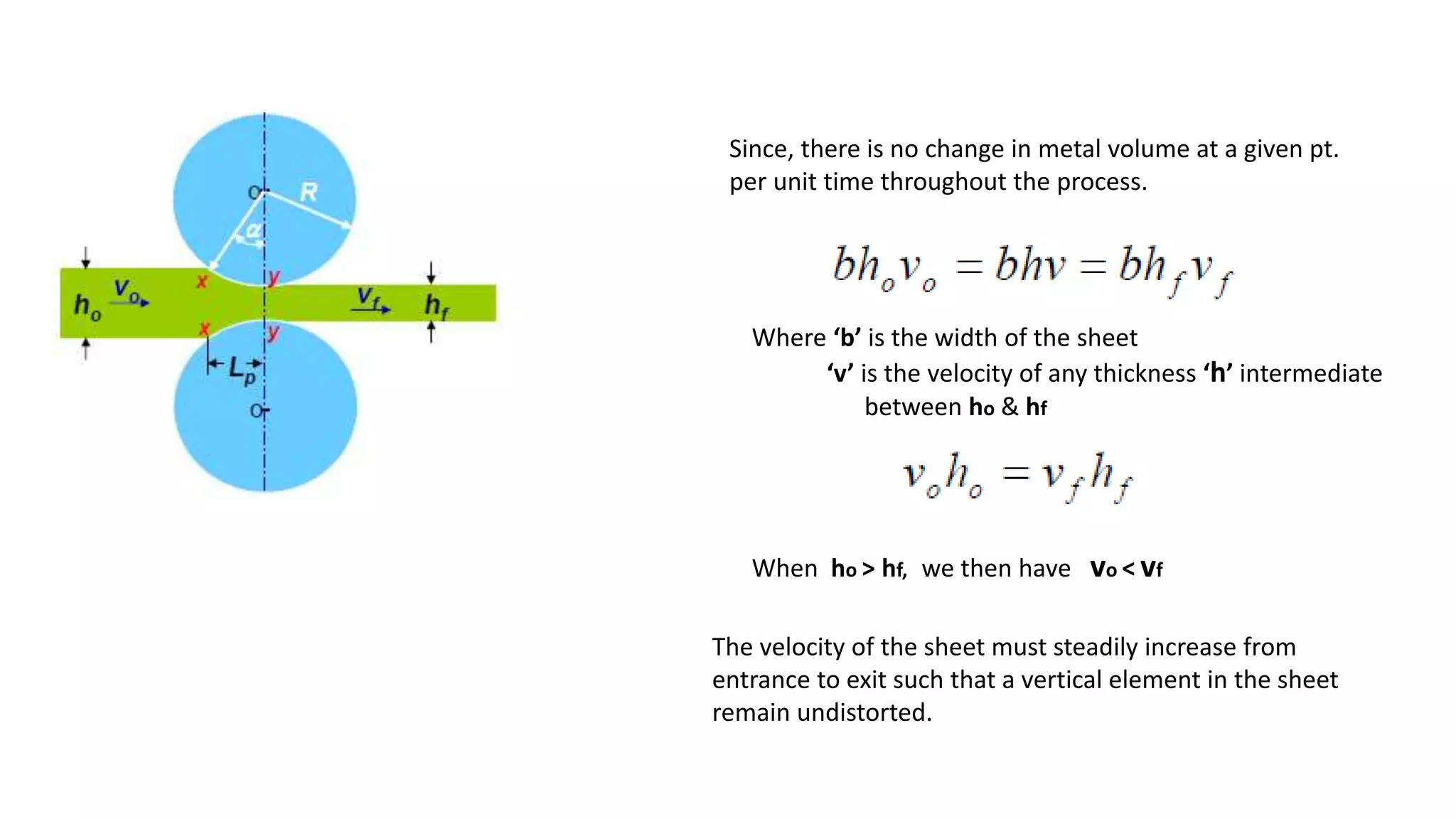

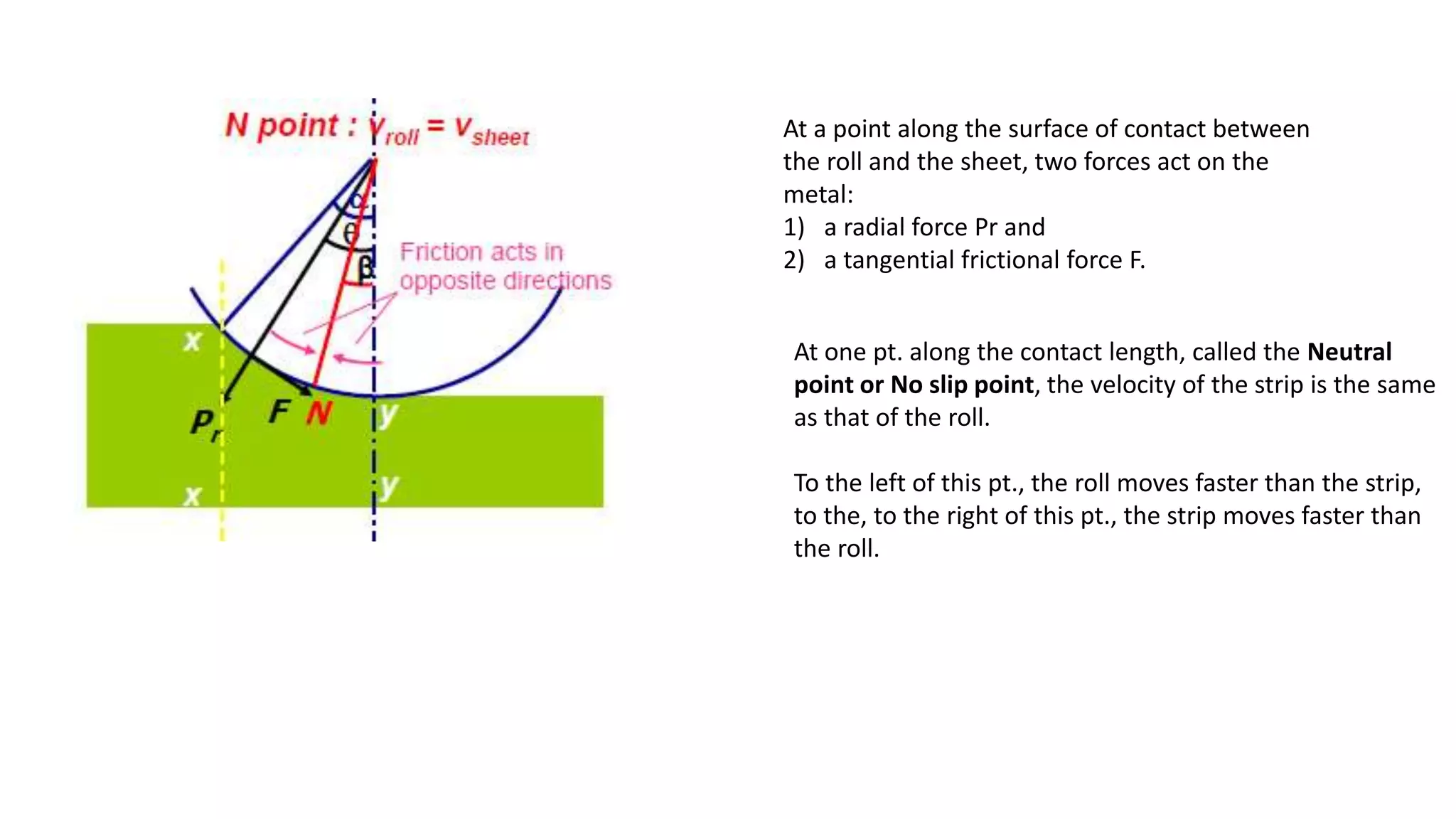

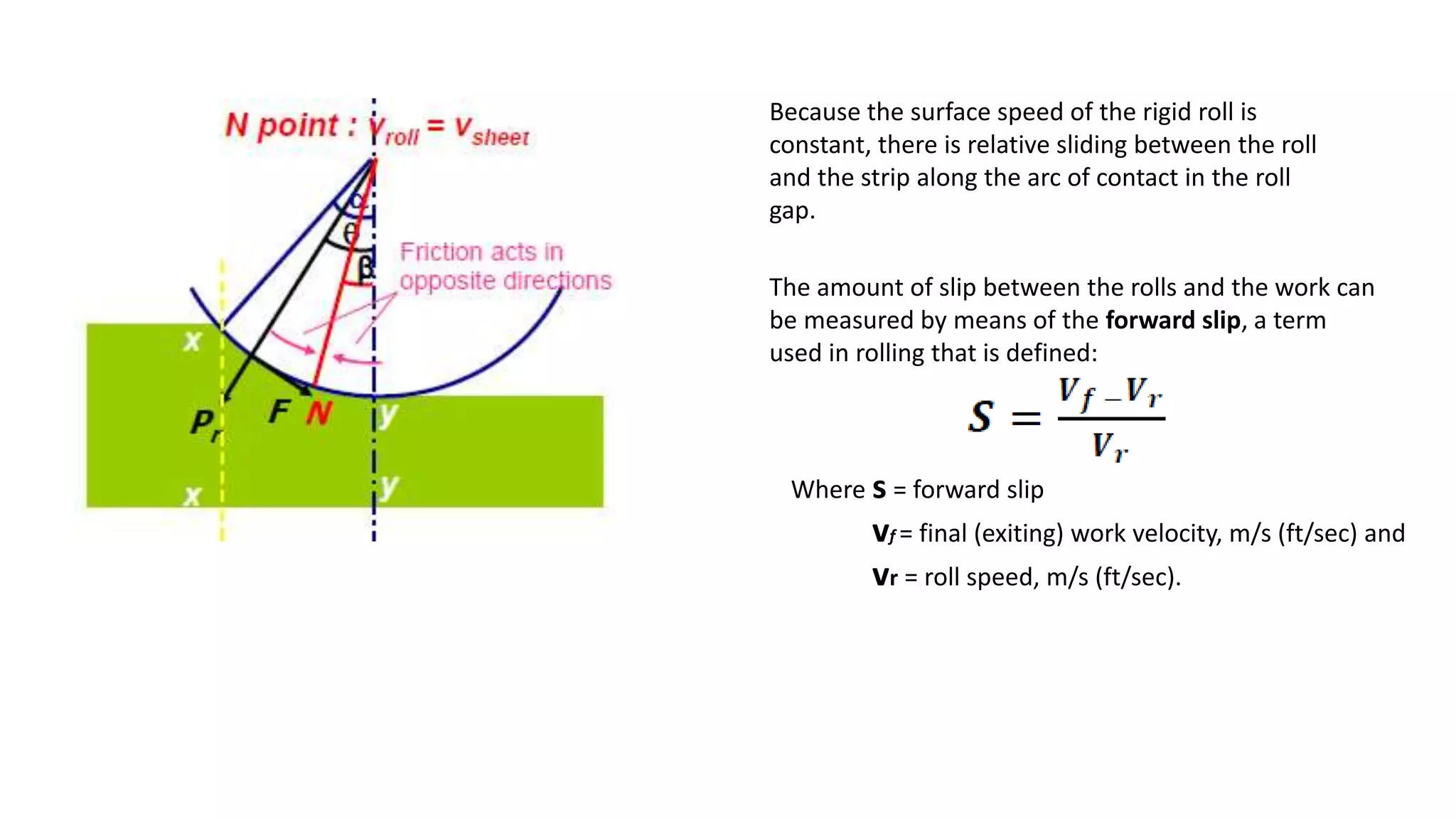

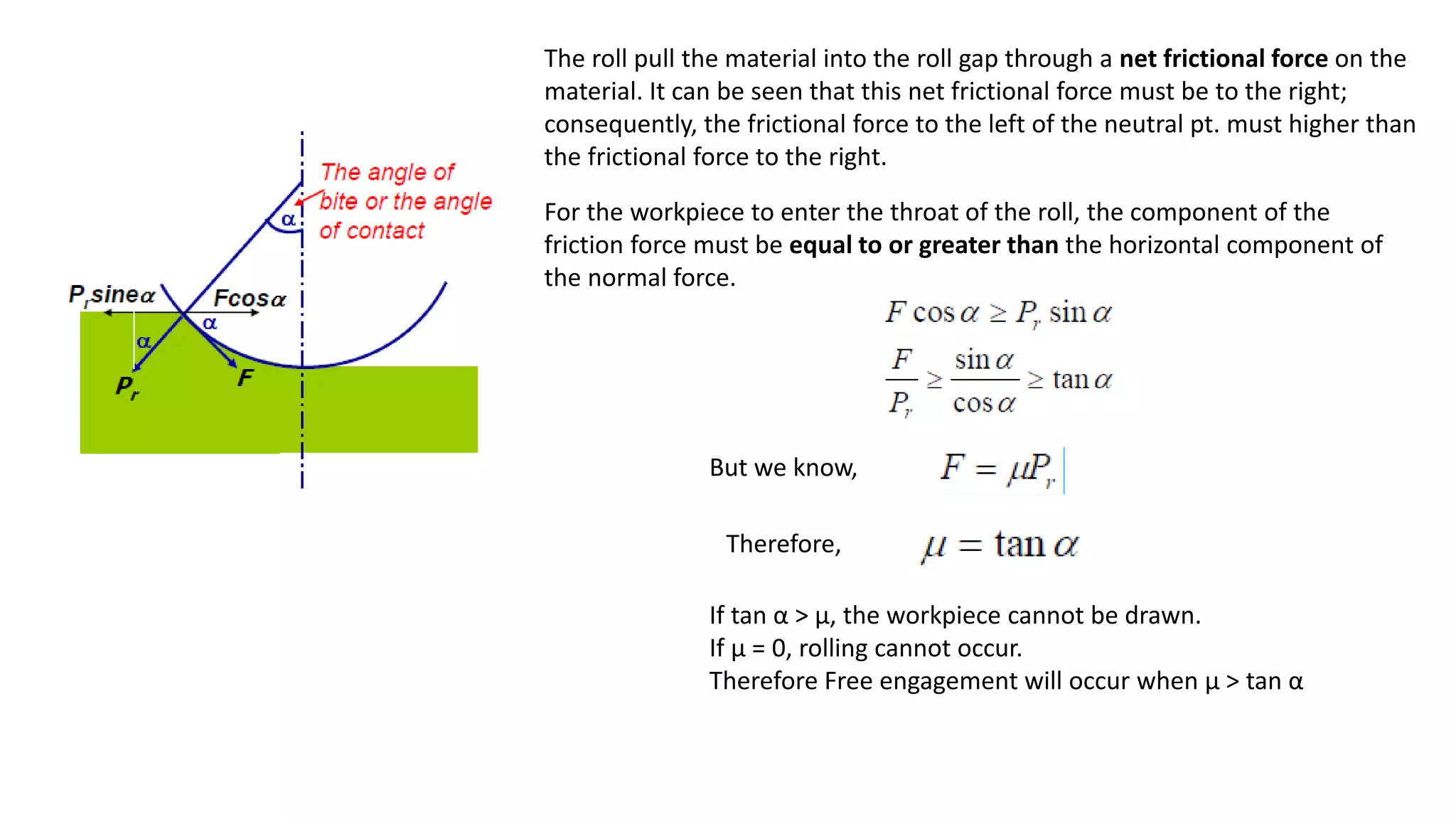

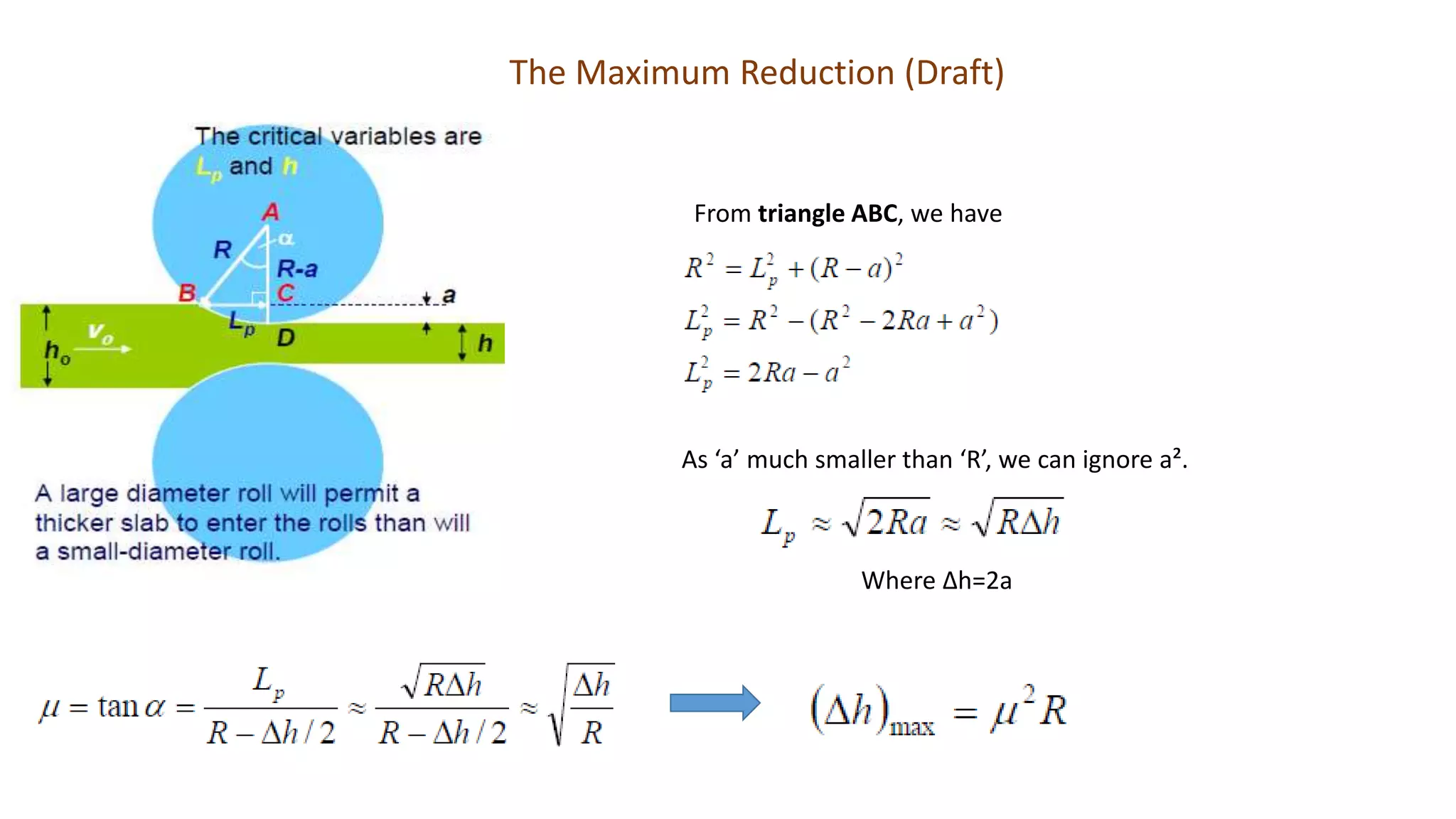

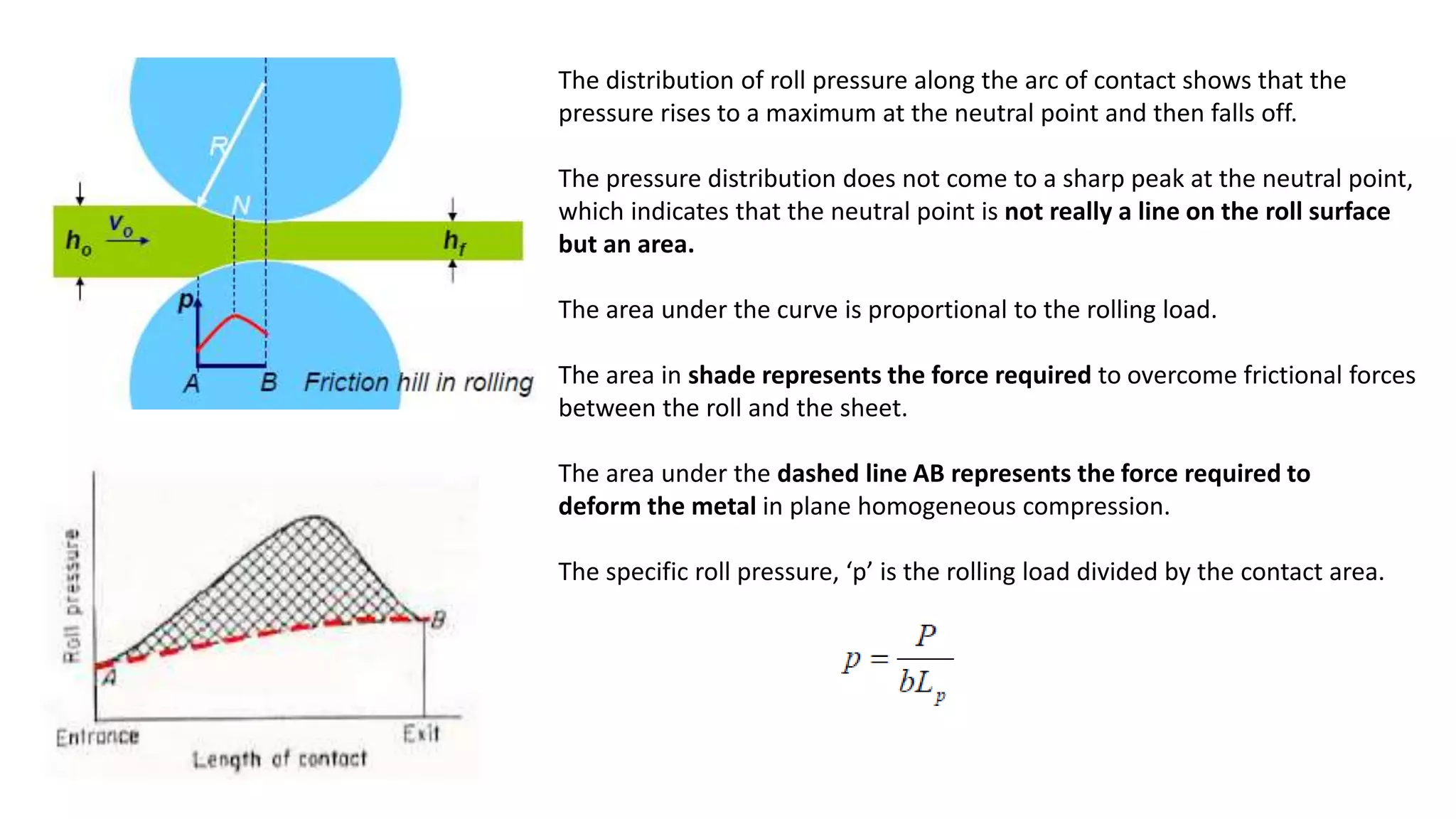

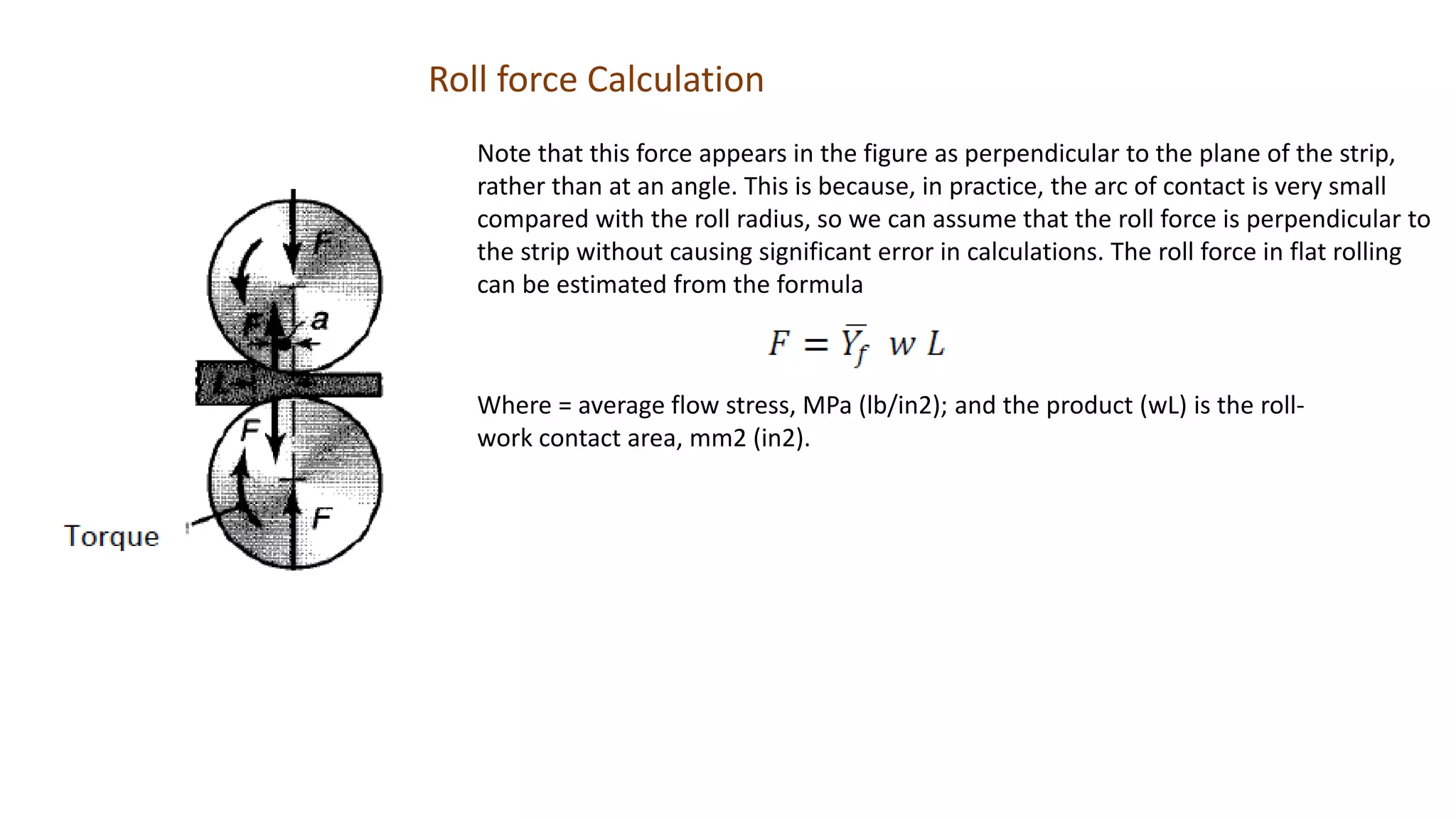

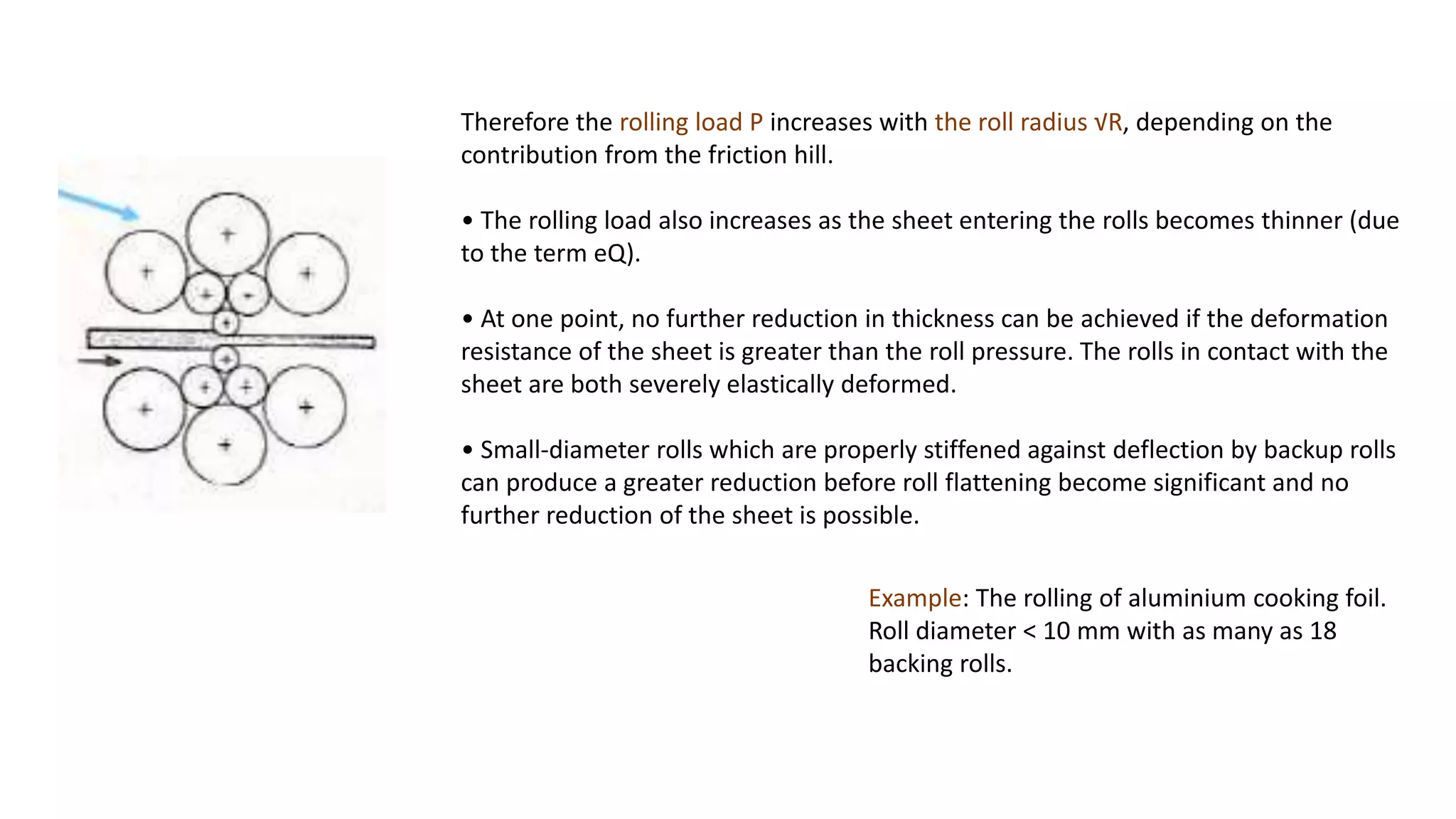

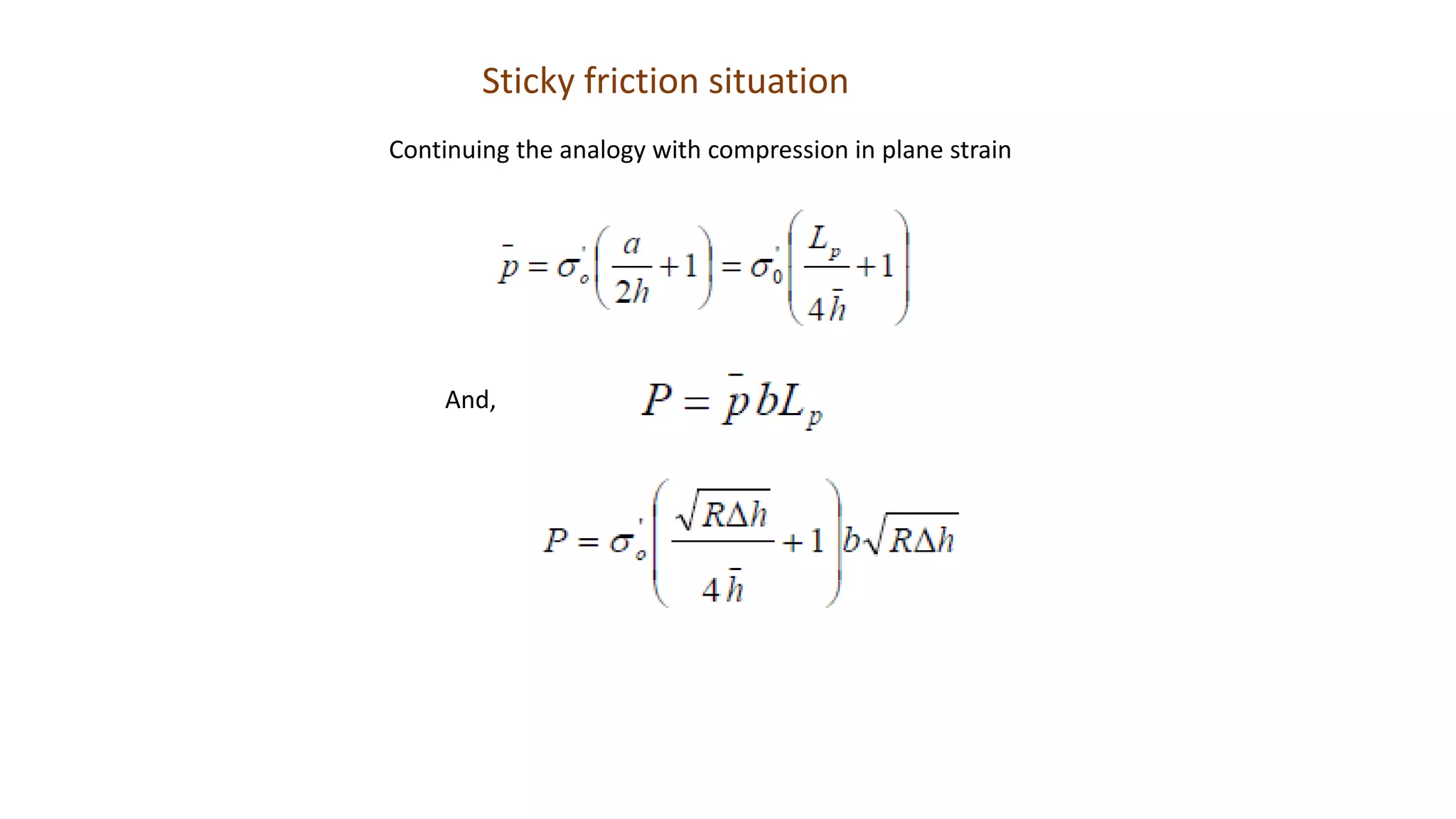

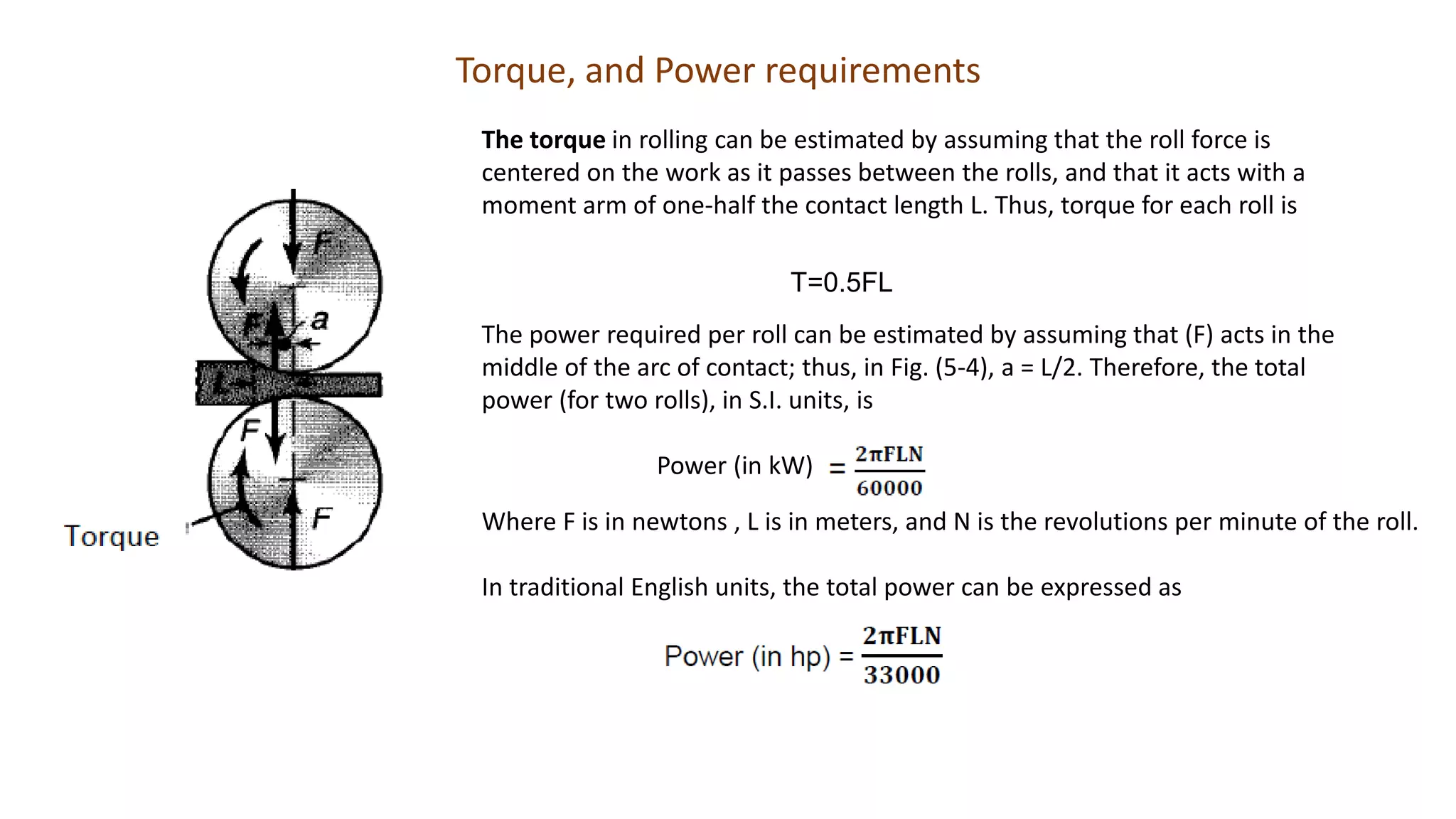

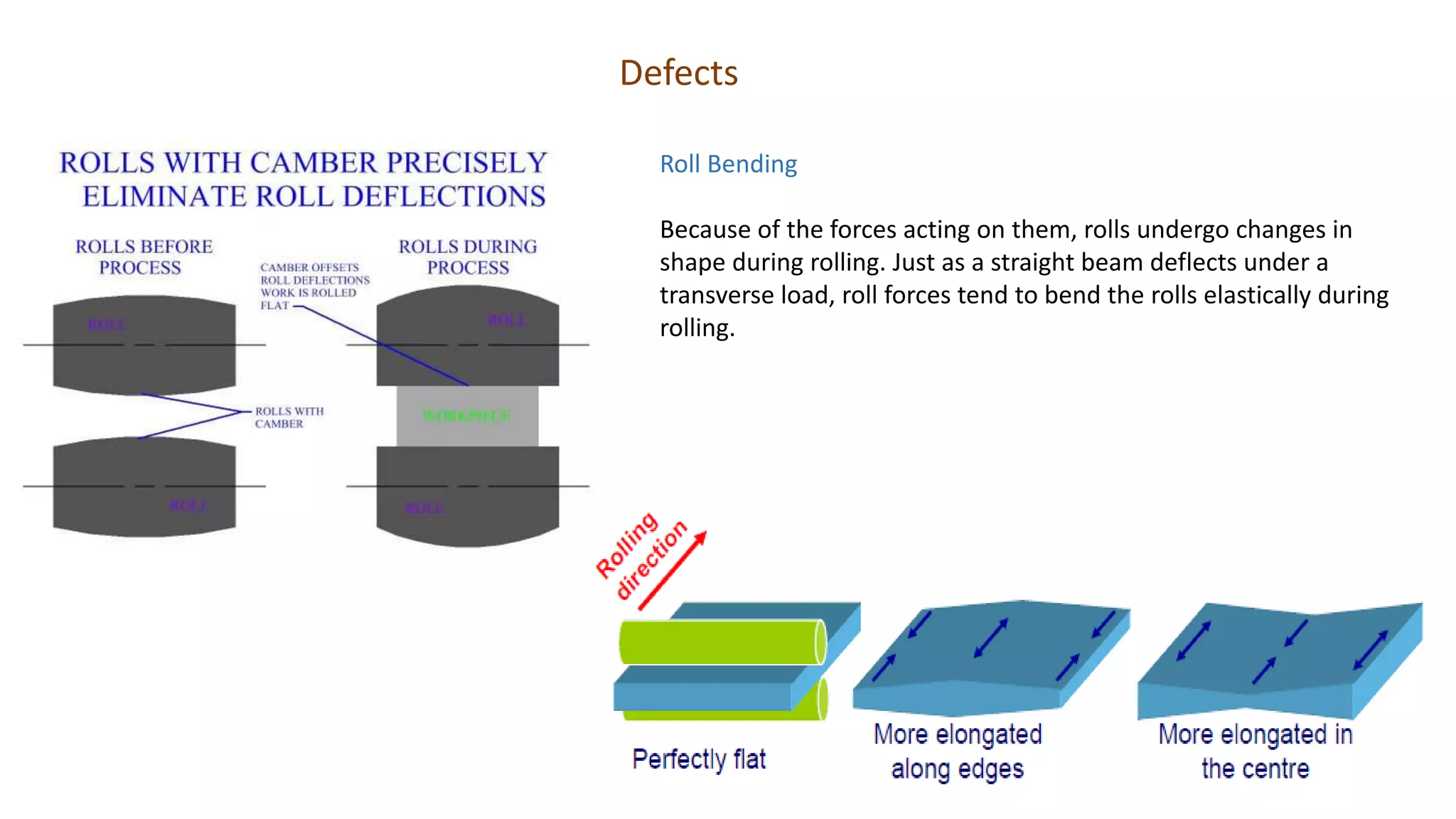

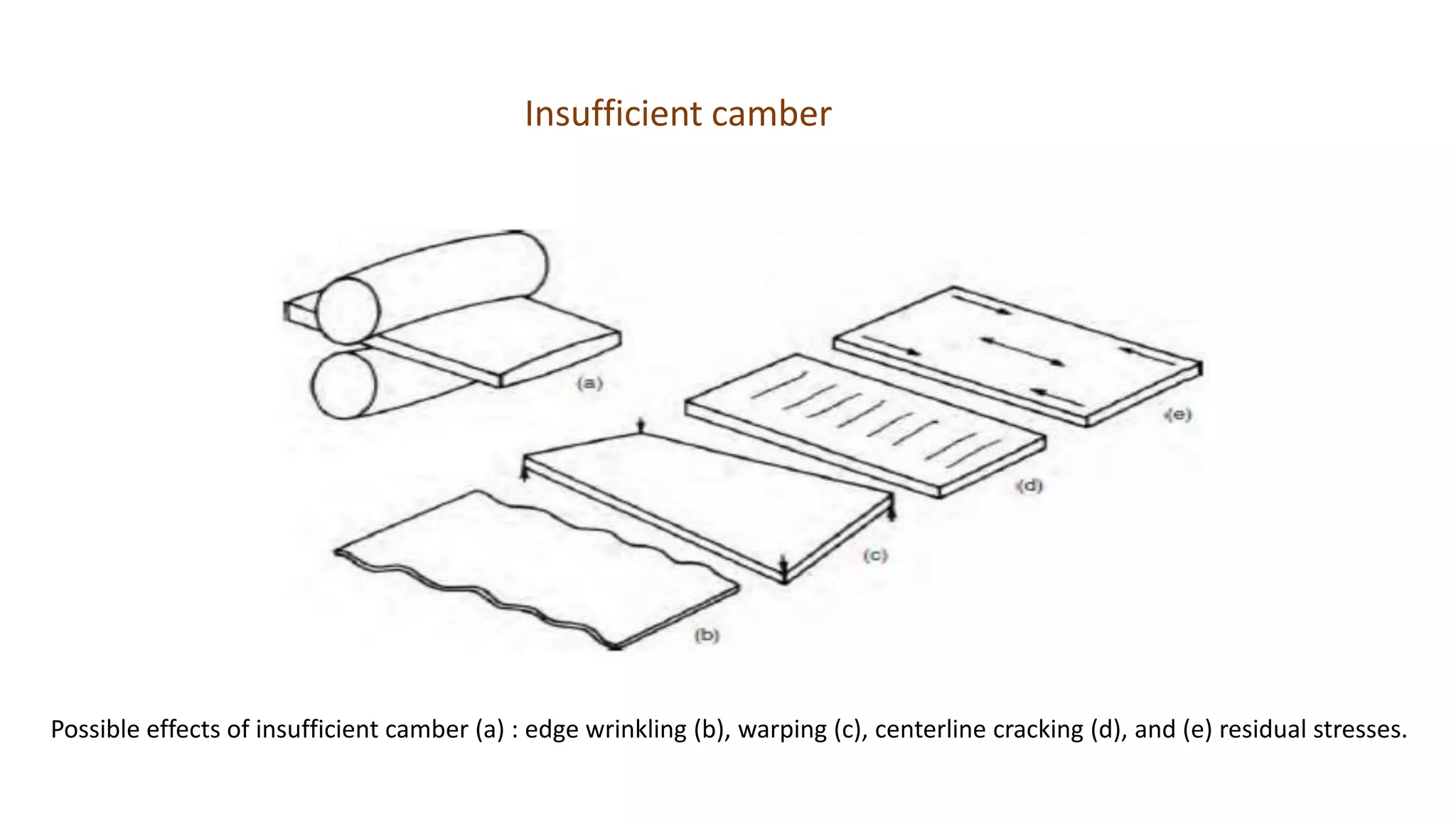

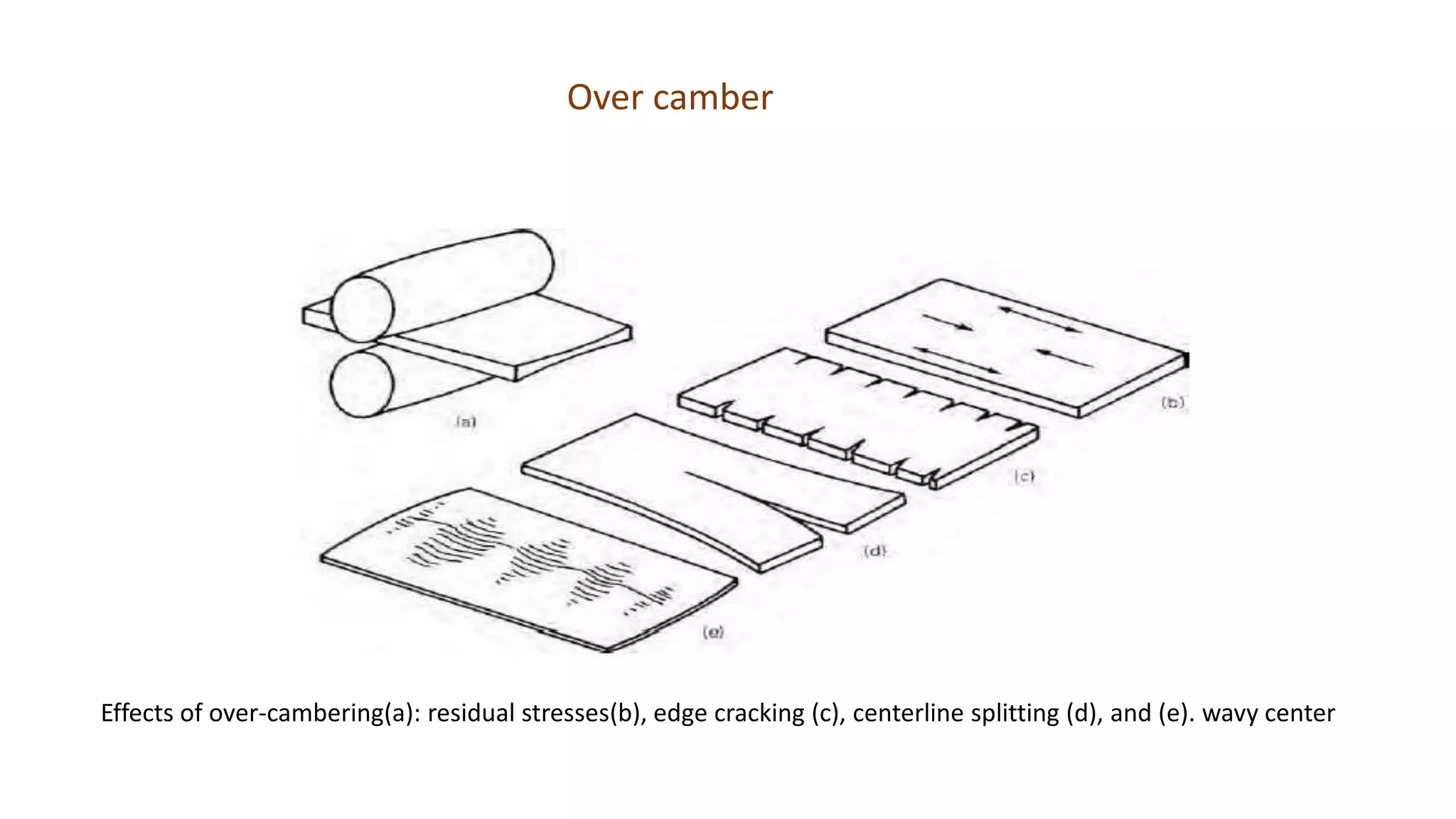

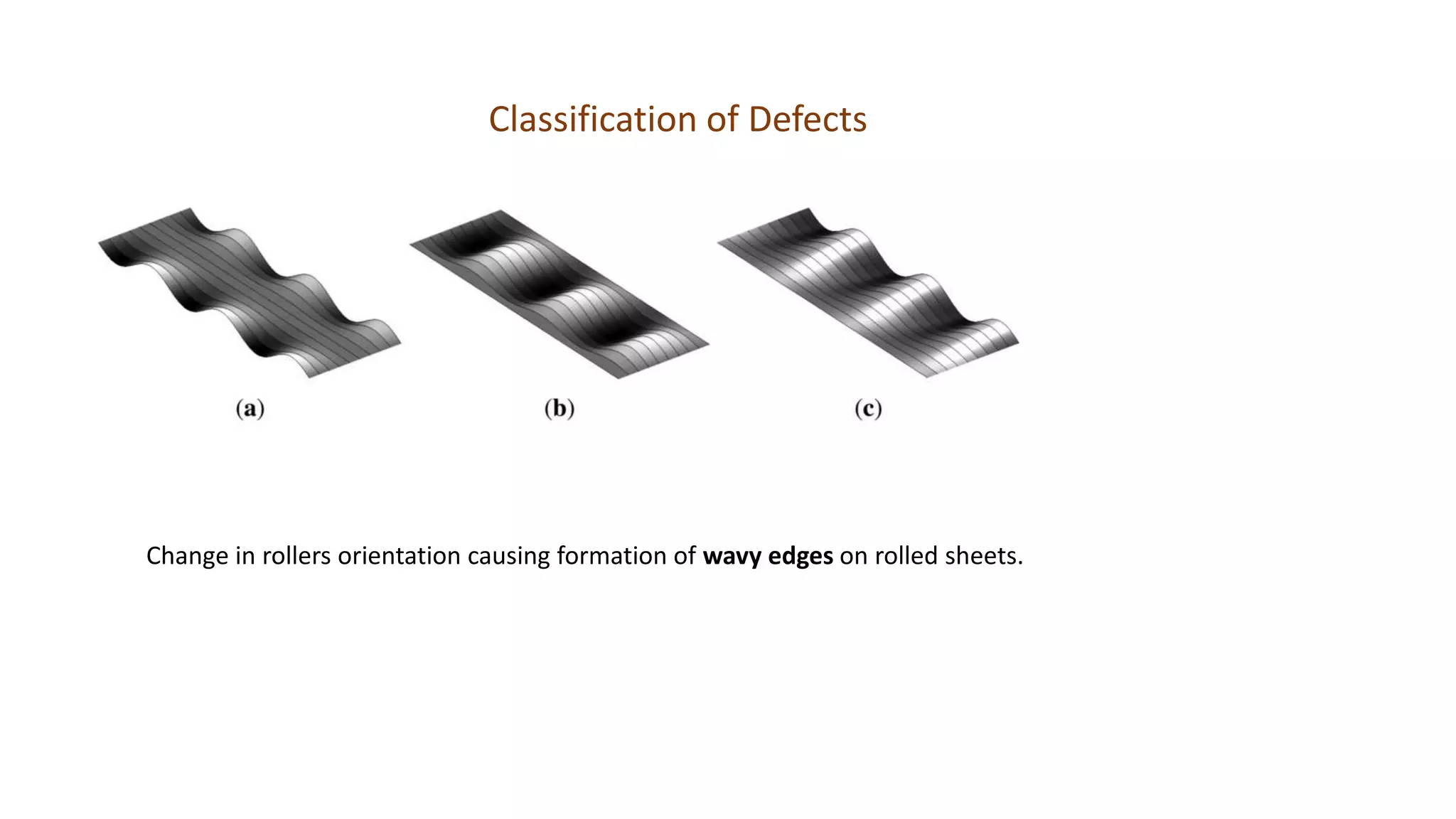

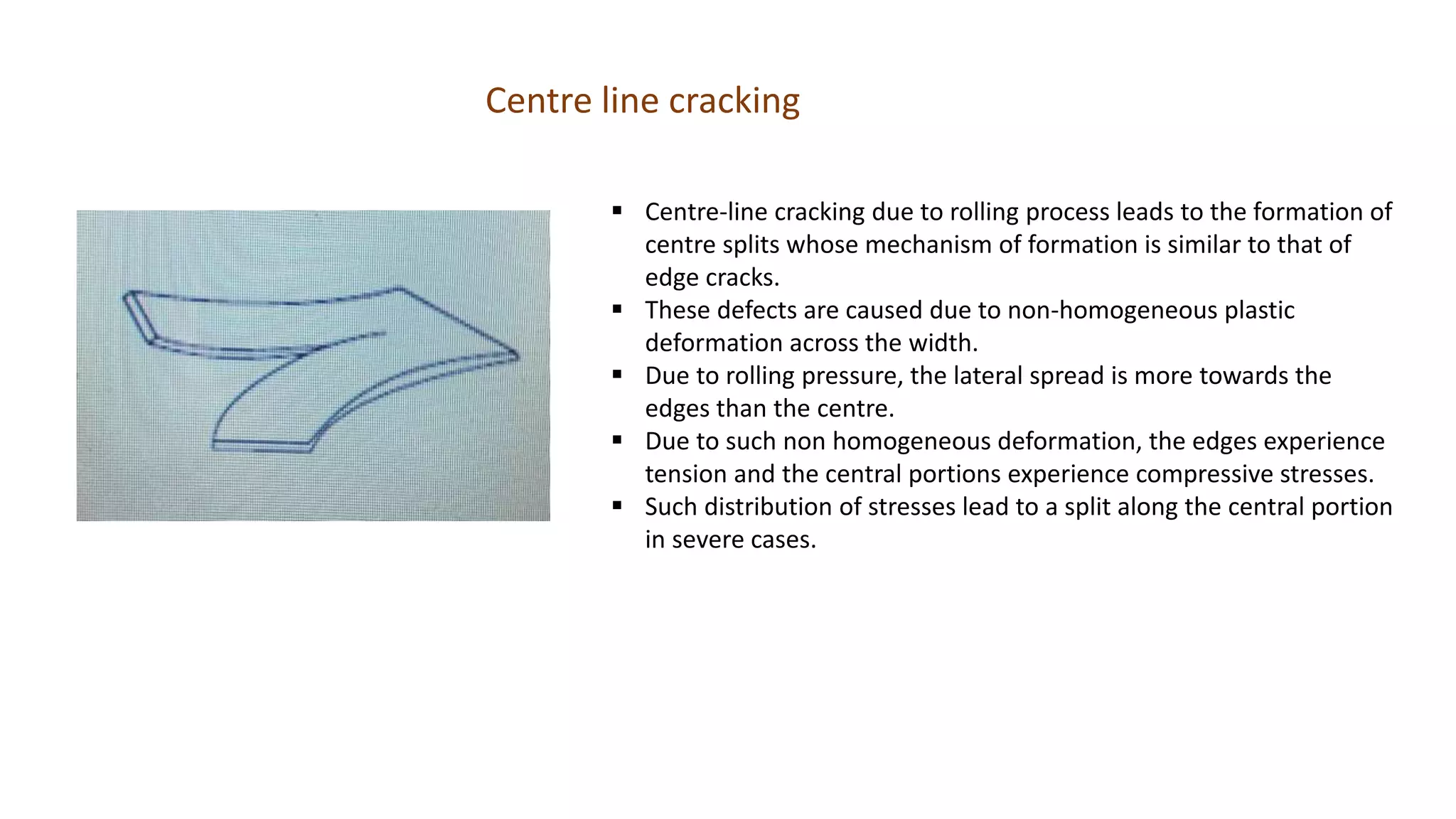

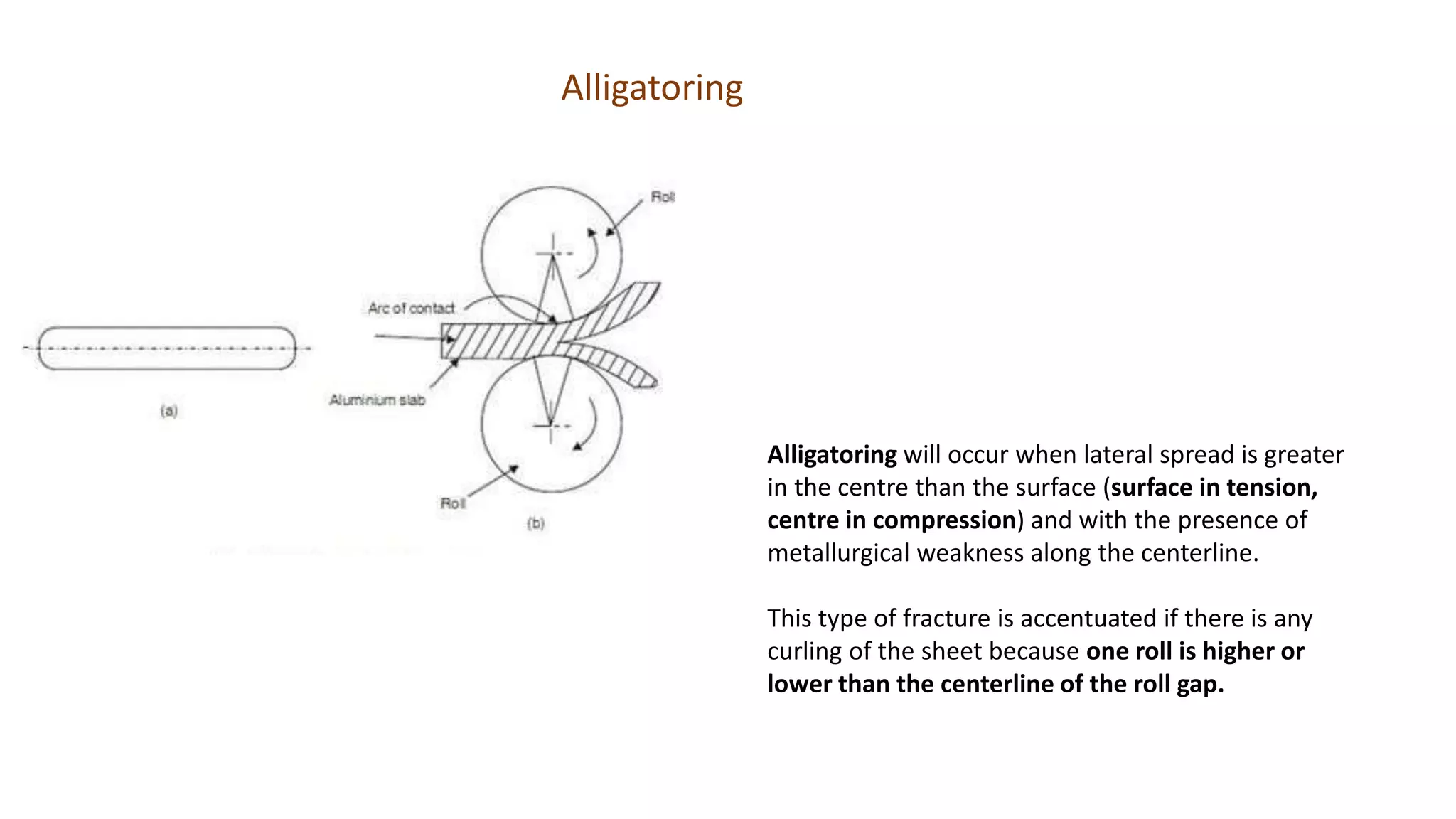

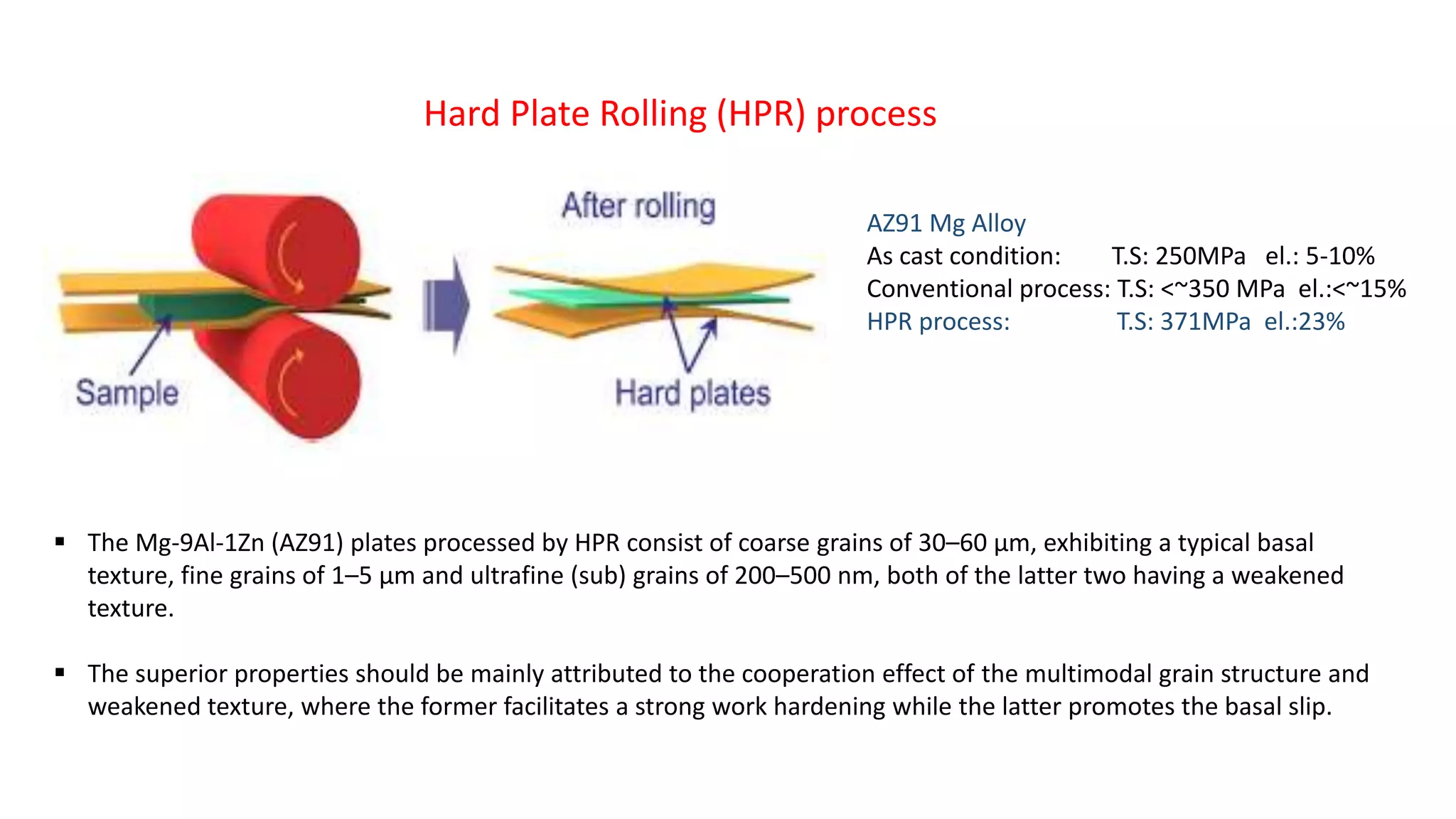

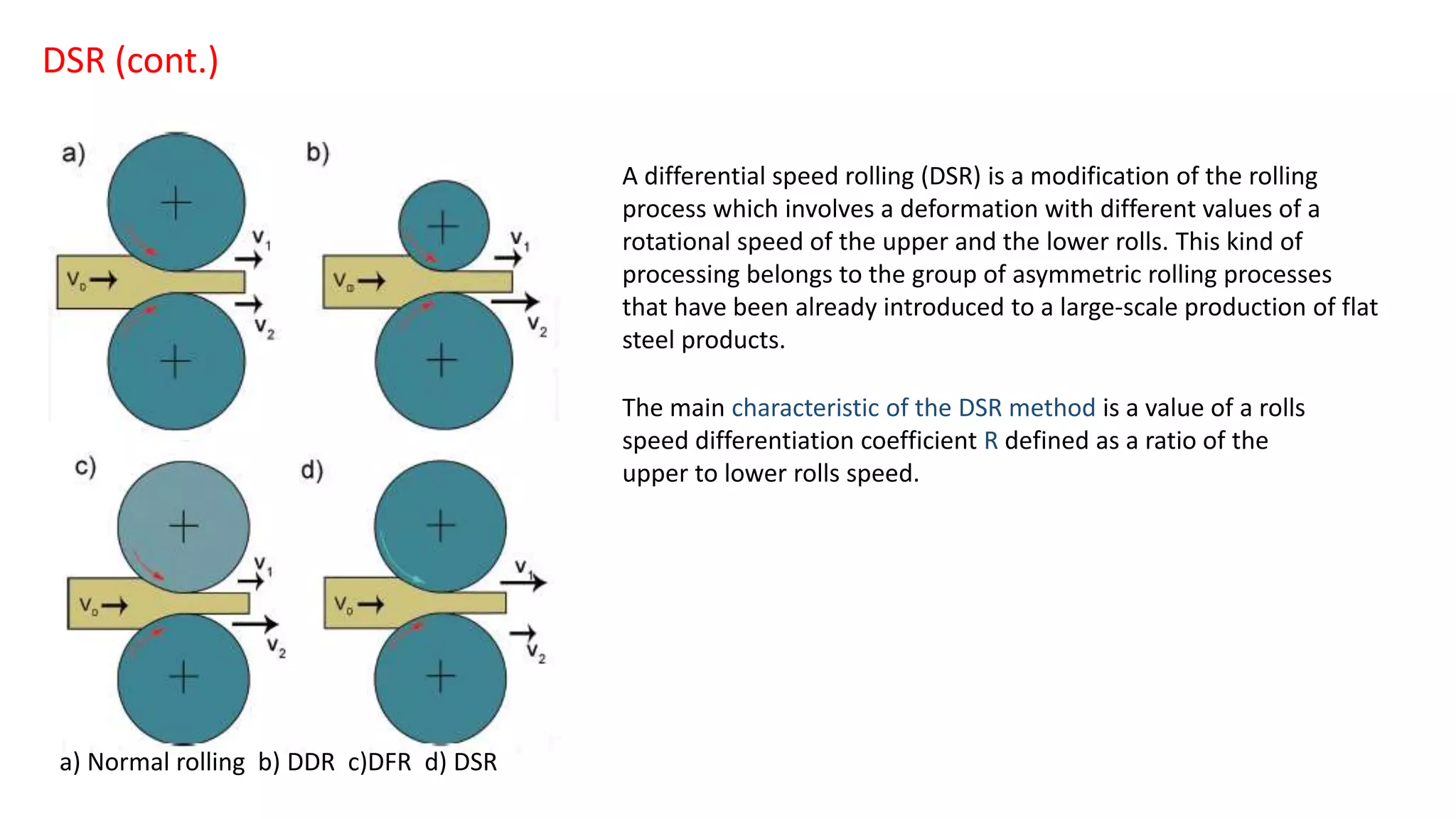

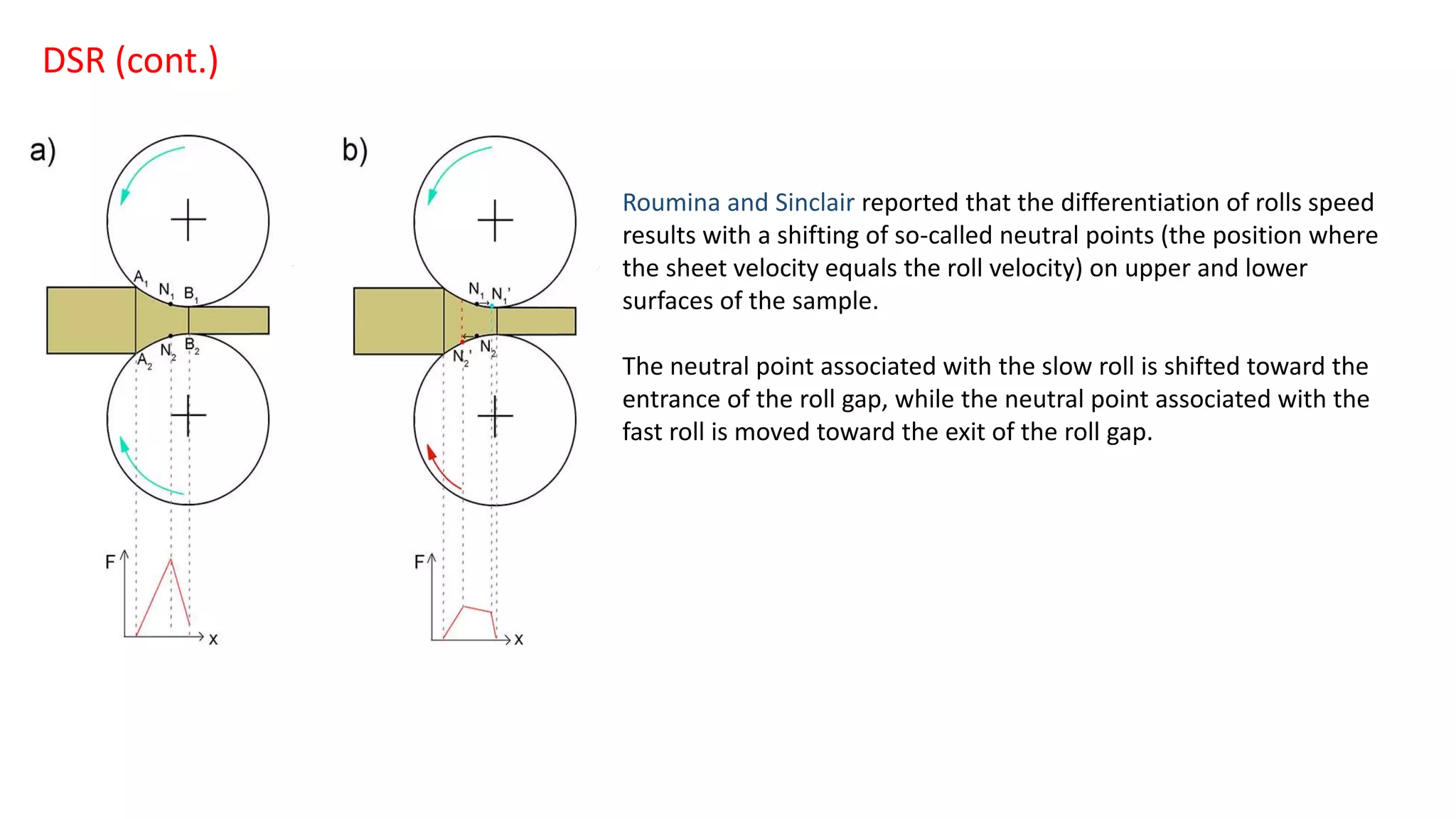

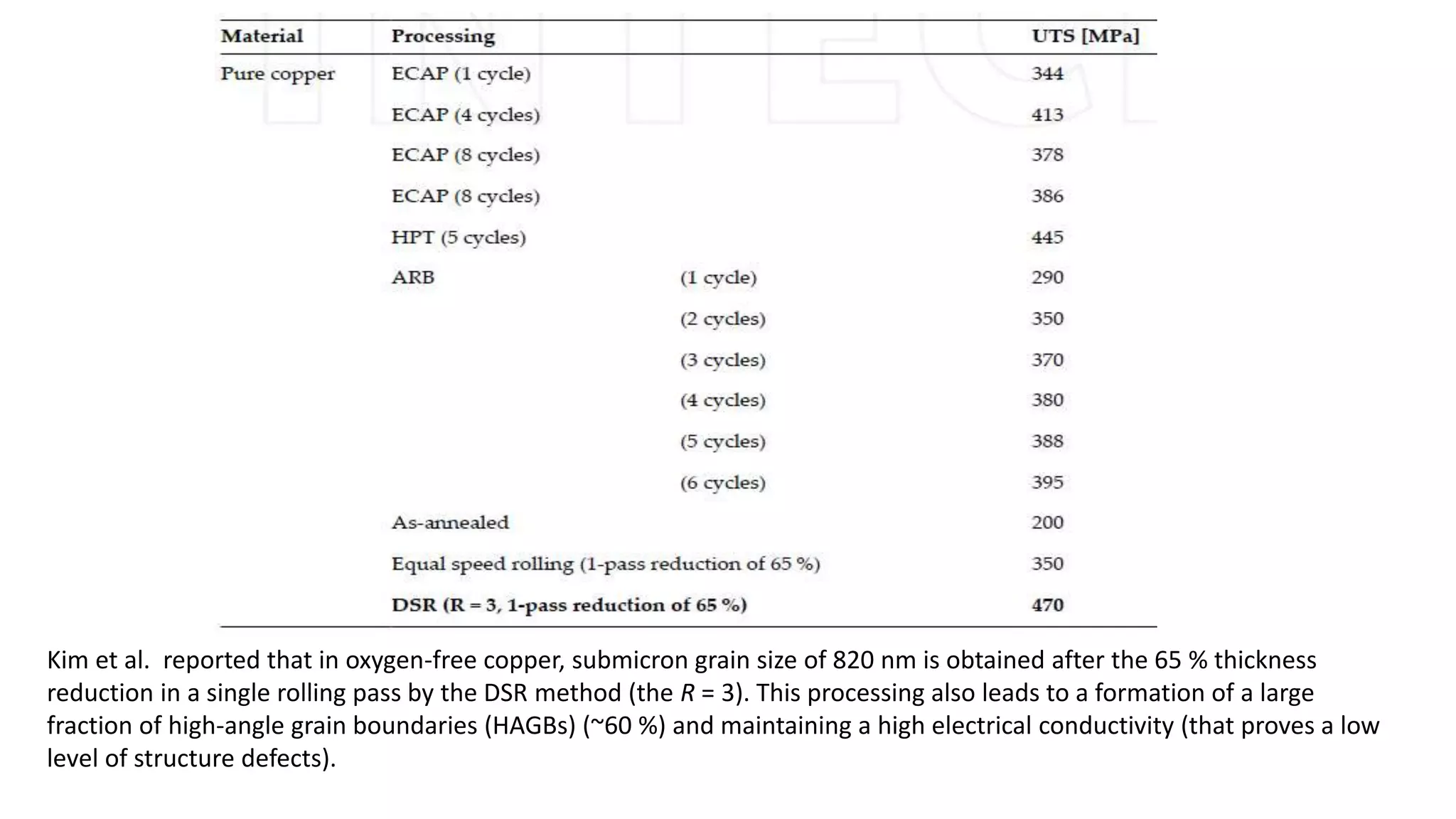

The document discusses the historical and technical aspects of metal rolling processes, including the definitions, types, and arrangements of rolling mills. It covers topics such as hot and cold rolling, various rolling techniques, advantages, and defects associated with rolling, along with advancements in rolling technology. The analysis includes mathematical considerations and practical implications of rolling loads, specific roll pressures, and defect formations.

![Jiang et al. [22] on pure aluminum subjected to the DSR process. The authors found that the cold rolling (with the R = 3)

of commercially pure aluminum to 90 % of thickness reduction leads to a formation of microstructure composed of

submicron-equiaxed grains and a high fraction of HAGBs (~50 %).](https://image.slidesharecdn.com/rollingpresentation-180123060545/75/Conclave-of-rolling-processs-56-2048.jpg)