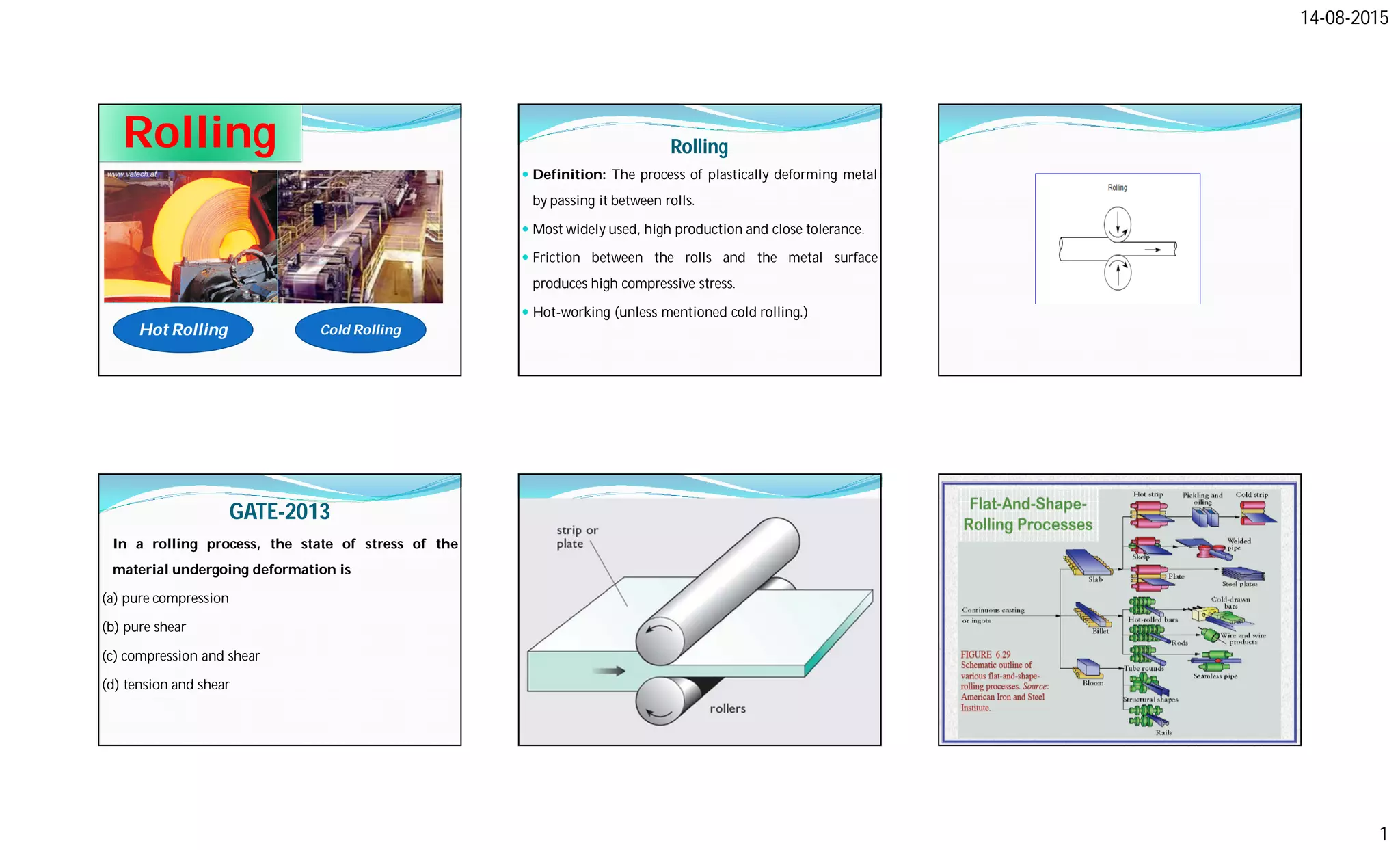

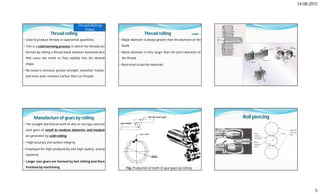

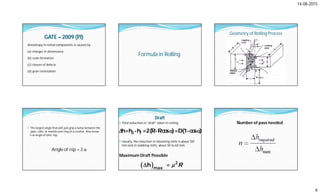

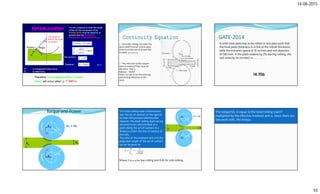

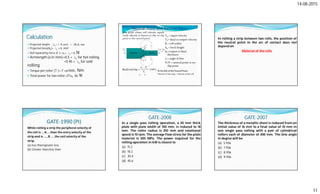

The document discusses various types of rolling processes including hot rolling, cold rolling, ring rolling, sheet rolling, roll forming, roll bending, shape rolling, pack rolling, thread rolling, roll piercing, and planetary mill rolling. It provides definitions and descriptions of each process. It also discusses related topics like geometry of rolling processes, lubrication, defects in rolling, and formulas used in rolling calculations.