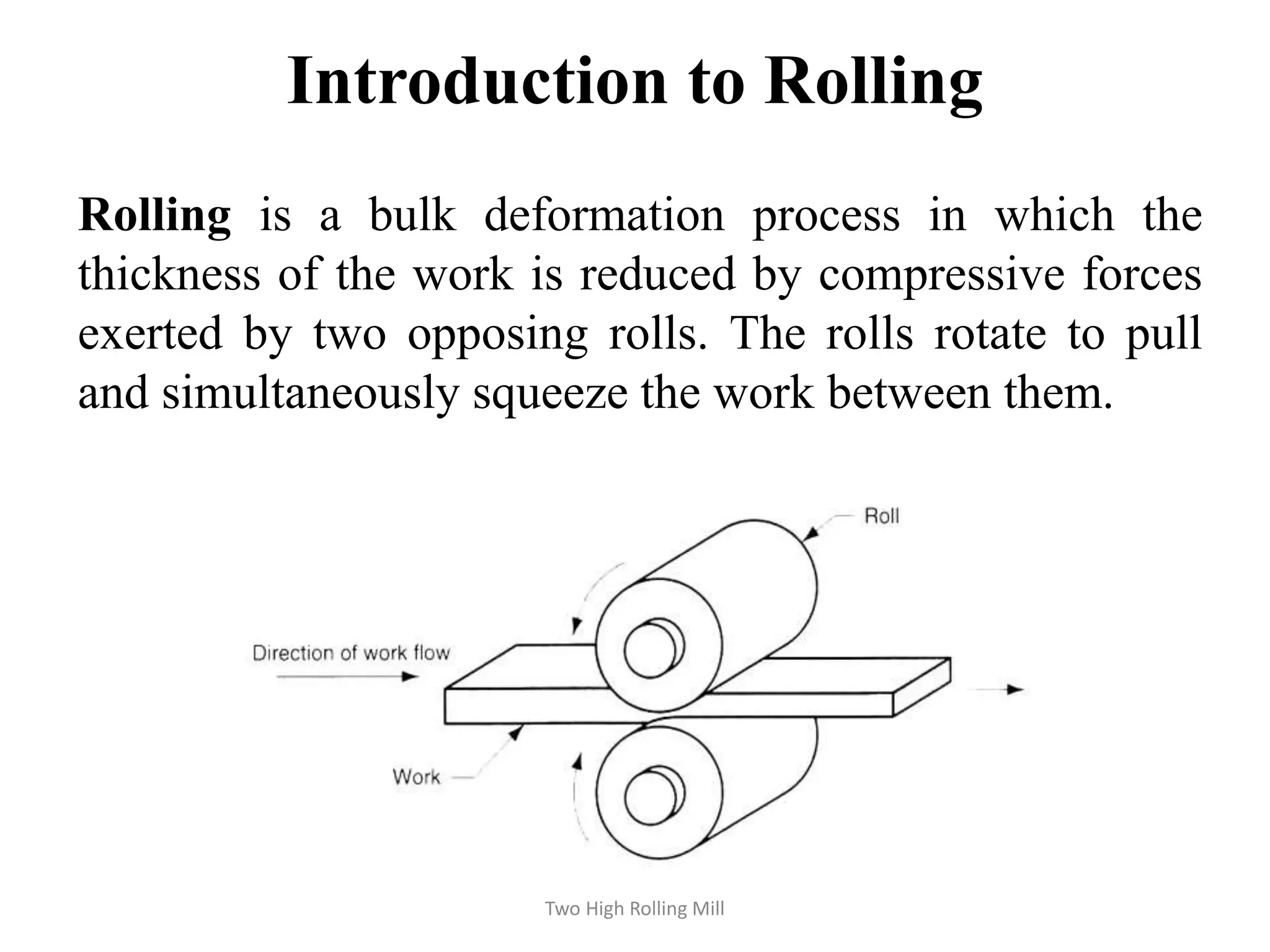

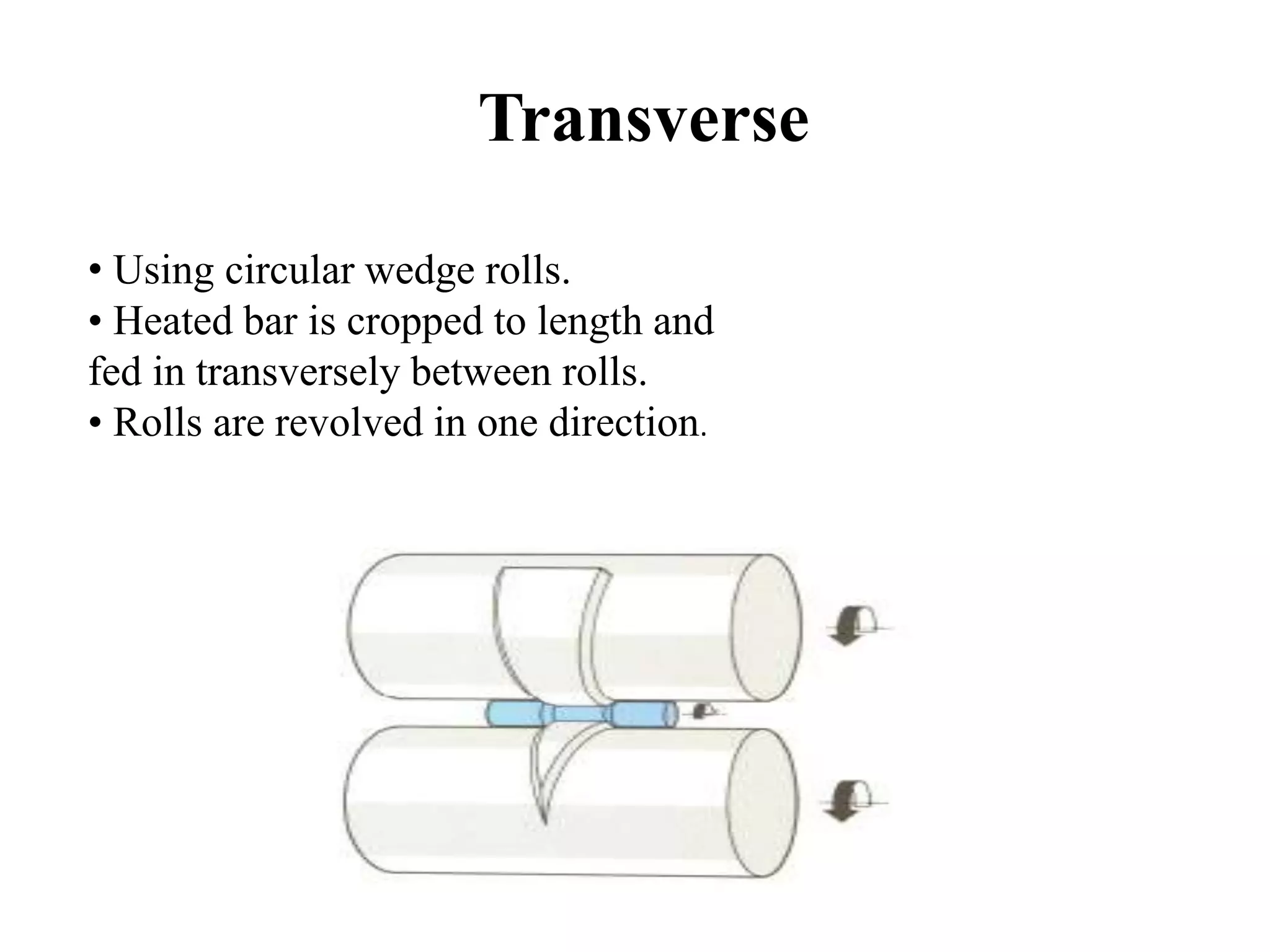

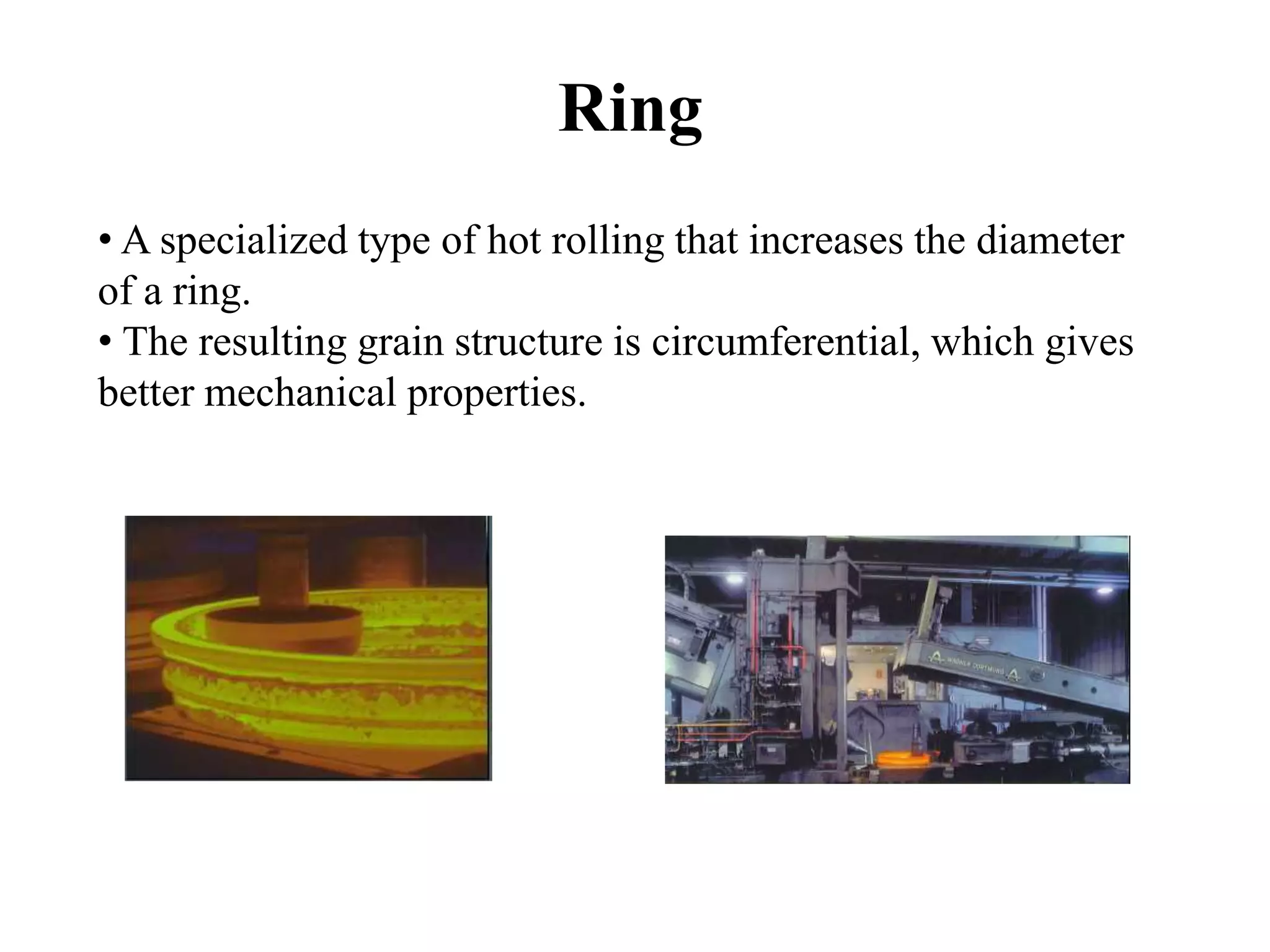

The document discusses the rolling process used in metal forming. It describes rolling as a process where the thickness of metal is reduced by compressive forces from two opposing rolls. Rolling can be used for flat rolling to reduce thickness of rectangular cross-sections or shape rolling to form square cross-sections into shapes like I-beams. The document outlines different types of rolling like hot rolling, cold rolling, continuous rolling and shape rolling and describes the purposes and processes for each type.