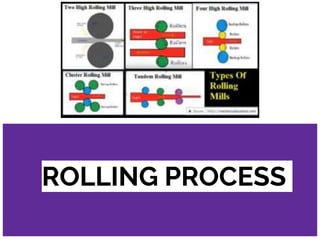

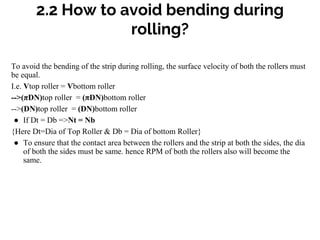

Rolling is a metal forming process where metal stock is passed through one or more pairs of rotating rollers to reduce the thickness and change the cross-section of the metal. There are two main types of rolling: hot rolling, where the temperature of the metal is above the recrystallization temperature, and cold rolling, where the temperature is below the recrystallization temperature. To avoid bending during rolling, the surface velocity of the top and bottom rollers must be equal. There are several types of rolling mills including two high, three high, four high, cluster, and tandem mills which differ in their roller configurations and applications. Rolling is used to mass produce a variety of products like sheets, rods, tubes, bol