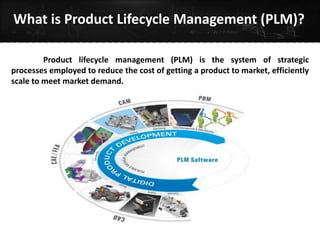

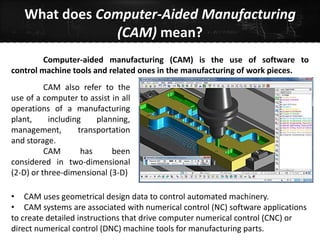

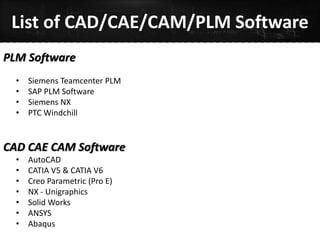

This document provides information on Swapnil Shahade's career and education background, as well as summaries of key engineering software topics - Product Lifecycle Management (PLM), Computer Aided Design (CAD), Computer Aided Engineering (CAE), and Computer Aided Manufacturing (CAM). It outlines Swapnil's experience as Assistant Manager at two companies, and defines PLM as strategic processes to reduce product costs and scale production. CAD uses computer technology to design and document products, while CAE simulates performance to improve designs. CAM uses design data to control automated machinery for manufacturing. The document concludes with examples of popular CAD/CAE/CAM and PLM software.

![PLM

Date – 06 March 2018

Swapnil Shahade

B.E. [Mechanical Engg]

M.Tech [CAD/CAM]

Career

Assistant Manager – CEAT Ltd, Mumbai

(R & D Department)

Assistant Manager – Naissance Ltd, Pune](https://image.slidesharecdn.com/cadlecture-180307135400/75/CAD-CAE-CAM-Lecture-1-2048.jpg)