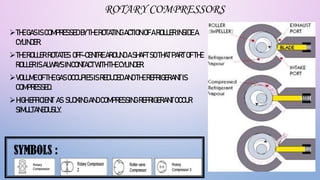

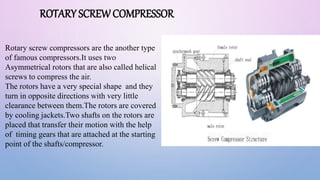

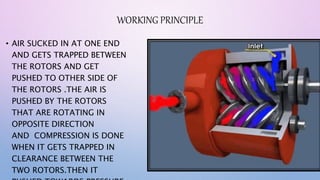

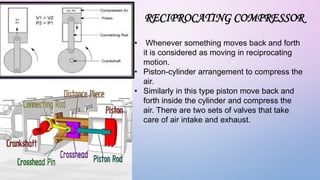

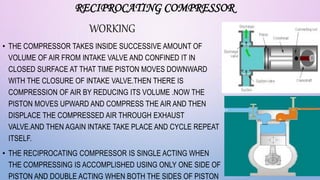

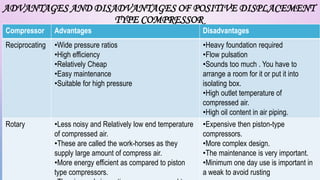

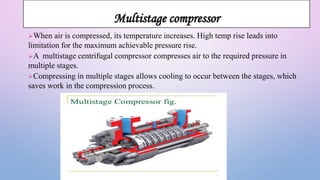

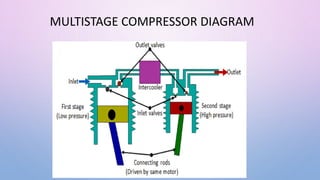

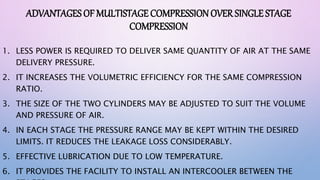

The document compares rotary compressors and reciprocating compressors, detailing their operating principles, advantages, and disadvantages. Rotary compressors utilize rotating actions for gas compression, while reciprocating compressors use a piston-cylinder arrangement for back-and-forth motion. Additionally, it discusses multistage compressors, highlighting their efficiency and benefits over single-stage compressors.