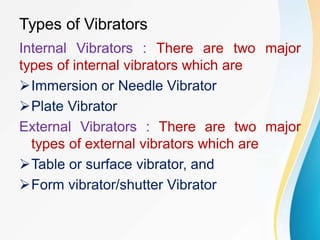

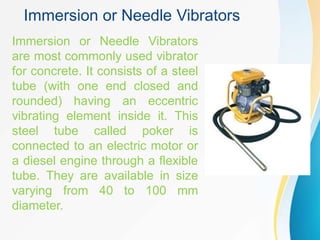

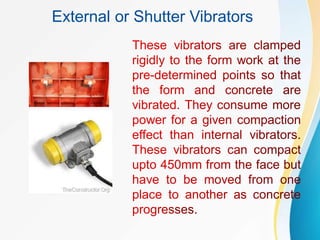

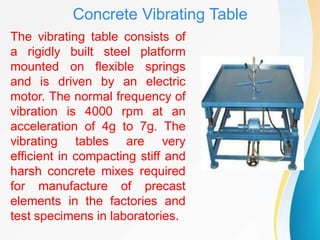

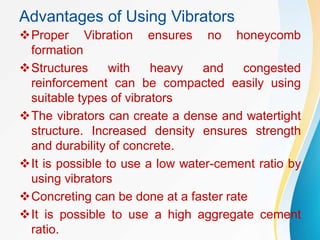

The document explains the compaction of fresh concrete, detailing its importance in eliminating entrapped air to enhance strength and durability, and prevent defects like honeycombing. It outlines types of compaction methods, including hand and machine techniques, as well as various types of concrete vibrators used to achieve proper consolidation. The advantages of using vibrators include improved density, strength, and efficiency in concrete application.