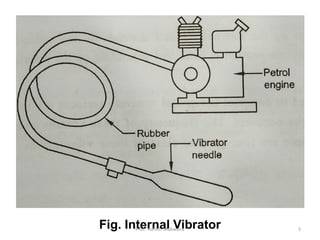

This document discusses different types of vibrators used in concrete construction. It describes internal vibrators, also called needle vibrators, which are inserted directly into wet concrete to consolidate it. Surface vibrators are used to compact horizontal concrete surfaces and include vibrating screeds, pan vibrators, plate tampers, and rolling screeds. Form vibrators are external vibrators attached to formwork that transmit vibrations to the concrete through the forms. The document provides details on the components, operation, and use of internal vibrators for effective concrete consolidation.