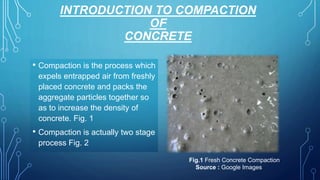

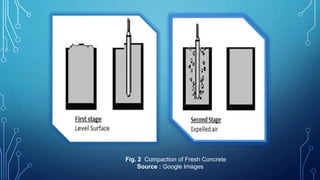

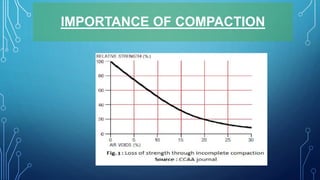

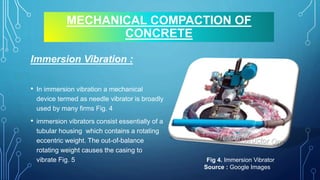

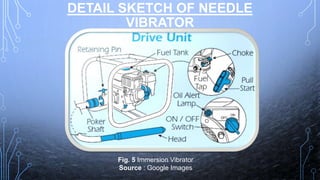

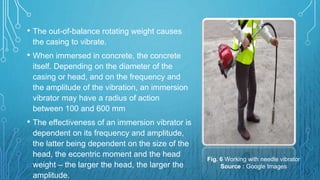

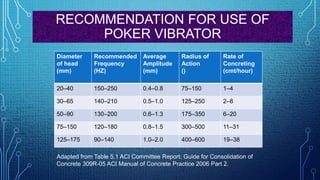

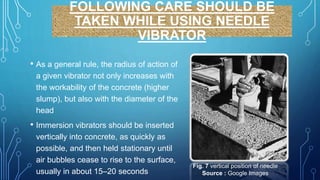

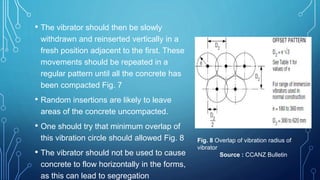

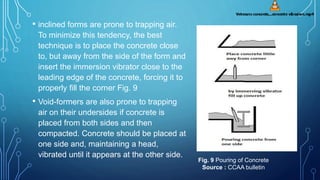

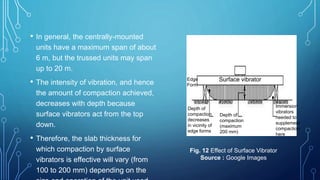

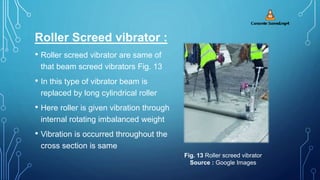

The document discusses the mechanical compaction of concrete, emphasizing its importance for enhancing strength and durability by removing air voids through various vibration techniques, including immersion, surface, and form vibration. It details different types of vibrators, their effective usage, and guidelines for achieving optimal compaction. The conclusion highlights that complete compaction significantly improves concrete properties crucial for construction.