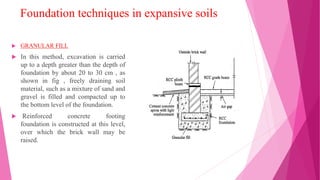

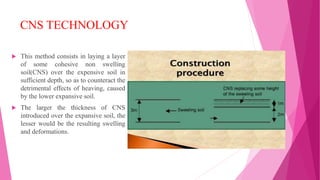

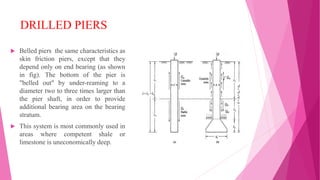

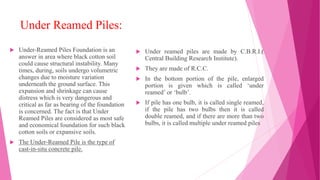

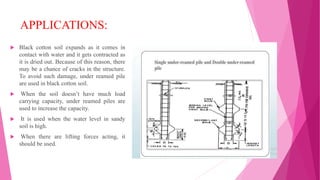

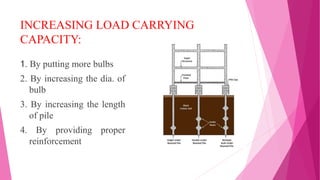

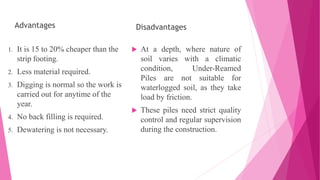

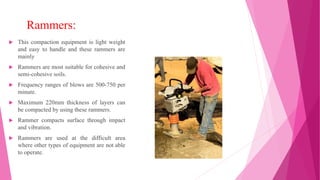

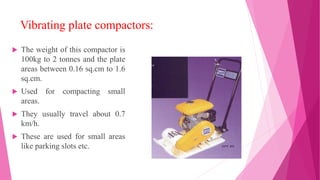

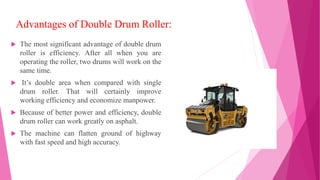

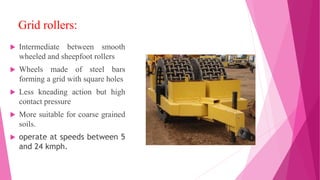

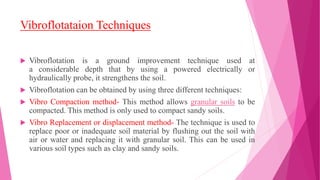

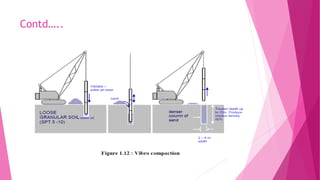

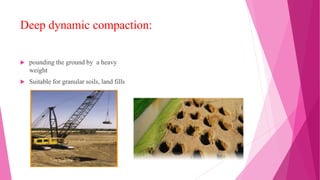

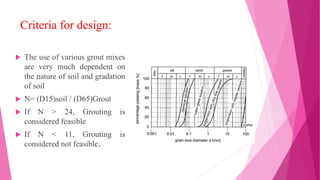

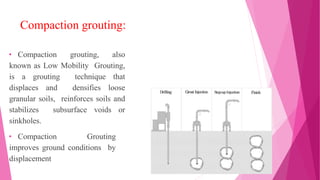

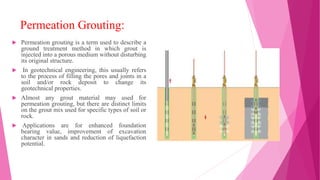

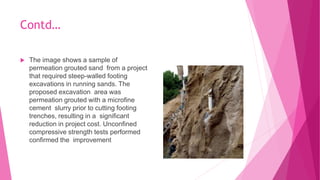

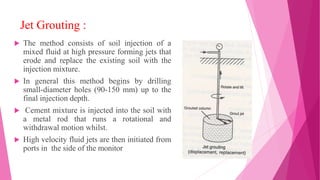

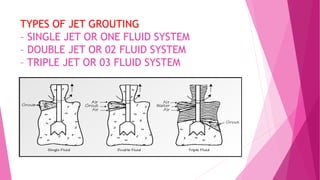

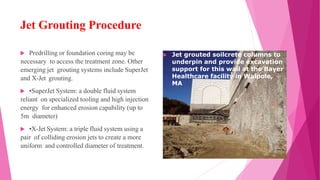

The document discusses various ground improvement techniques targeting expansive soils that expand when wet and shrink when dried, posing challenges for construction. It covers methods such as mechanical modification through compaction, chemical modification via grouting, and foundation techniques like under-reamed piles to enhance soil stability and load-bearing capacity. Additionally, it outlines the properties of expansive soils, their challenges, and types of compaction equipment suitable for different soil conditions.