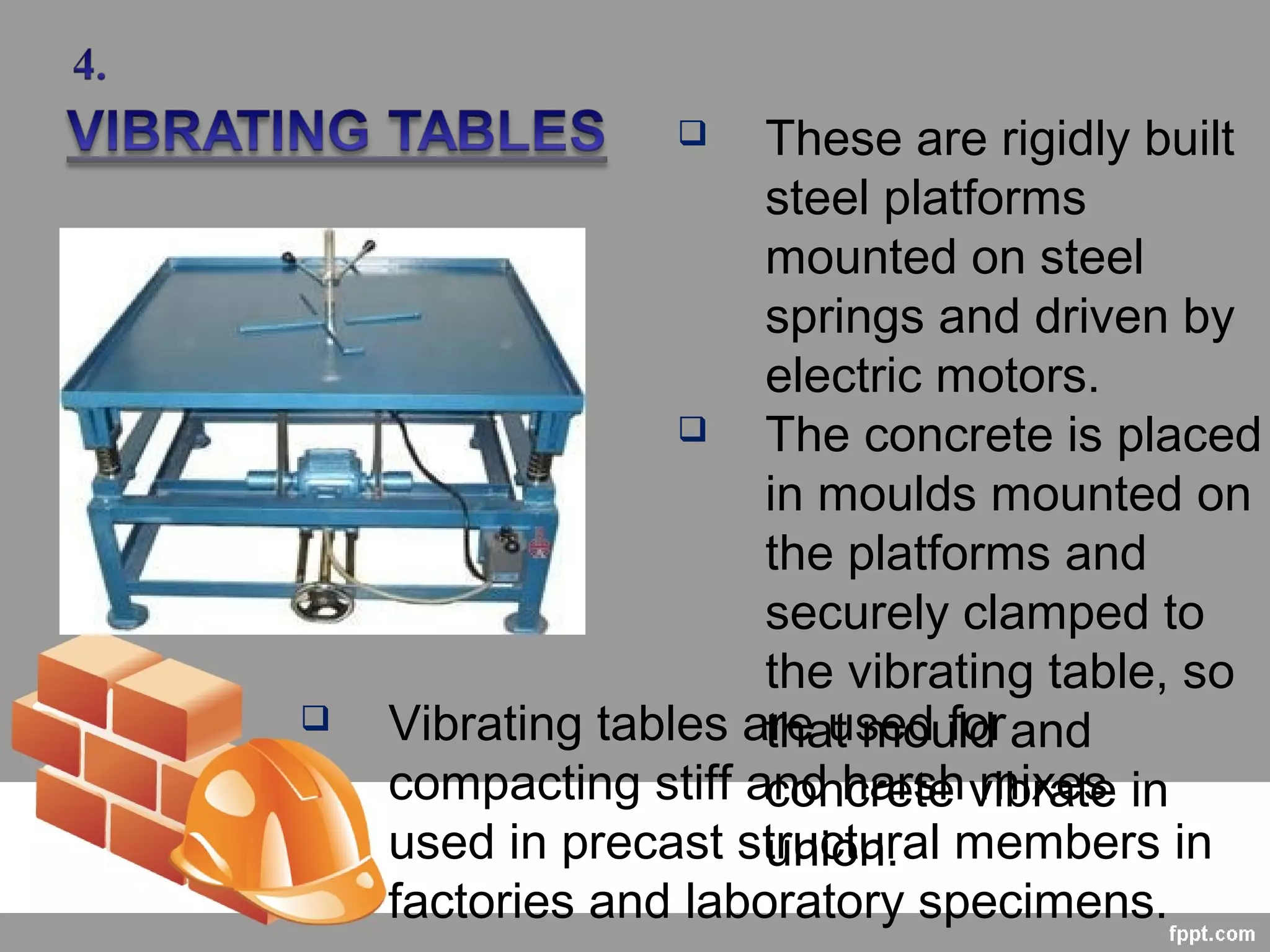

Concrete vibrators are tools used on construction sites to eliminate air bubbles and ensure a smooth finish in concrete pouring, particularly in large load-bearing projects. They come in various sizes and types, from battery-powered wands to larger units for deep pours, and typically consist of a power unit and a vibrating head. Additional equipment, such as vibrating tables, are used for compacting stiff concrete mixes in precast applications.