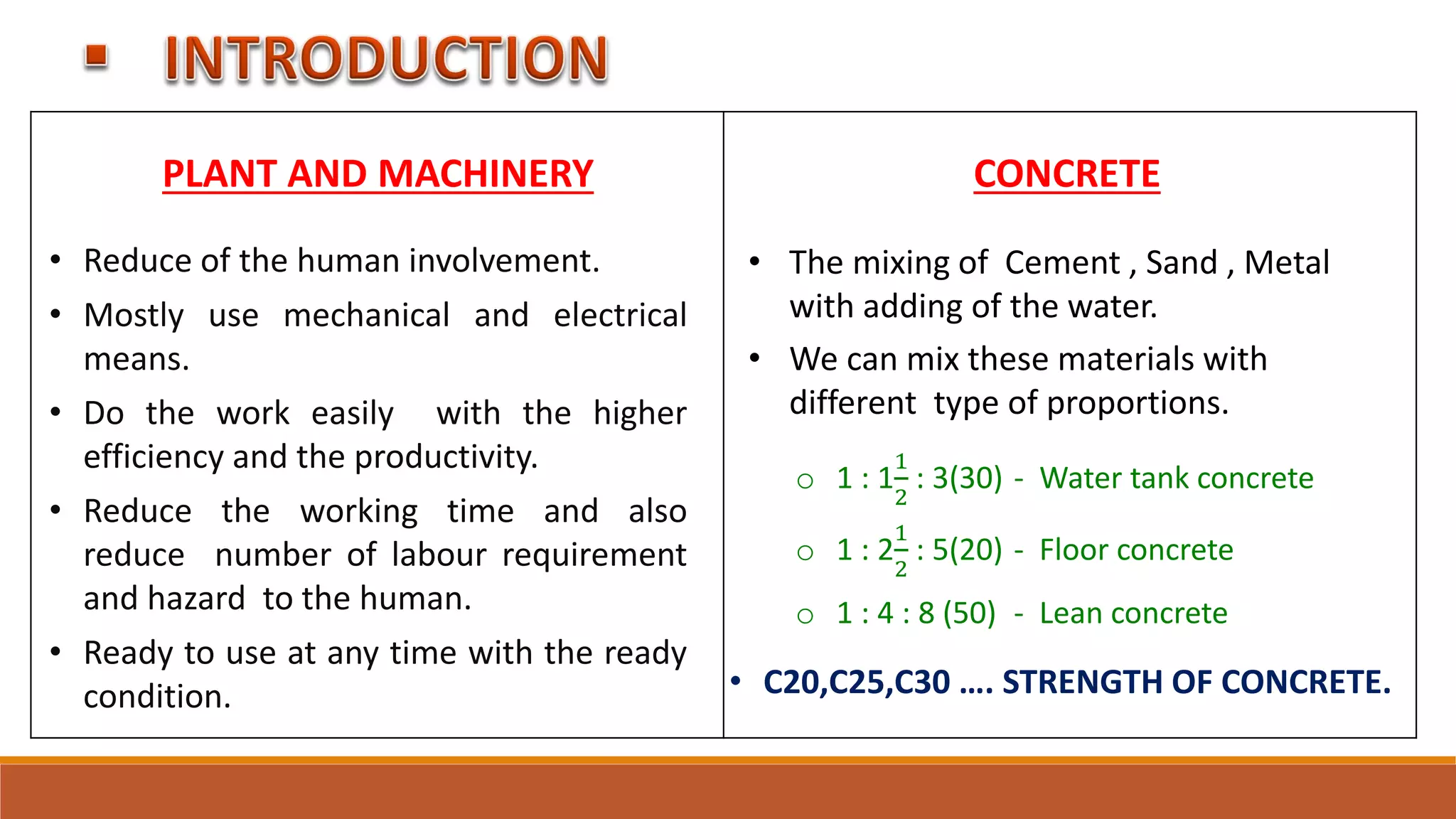

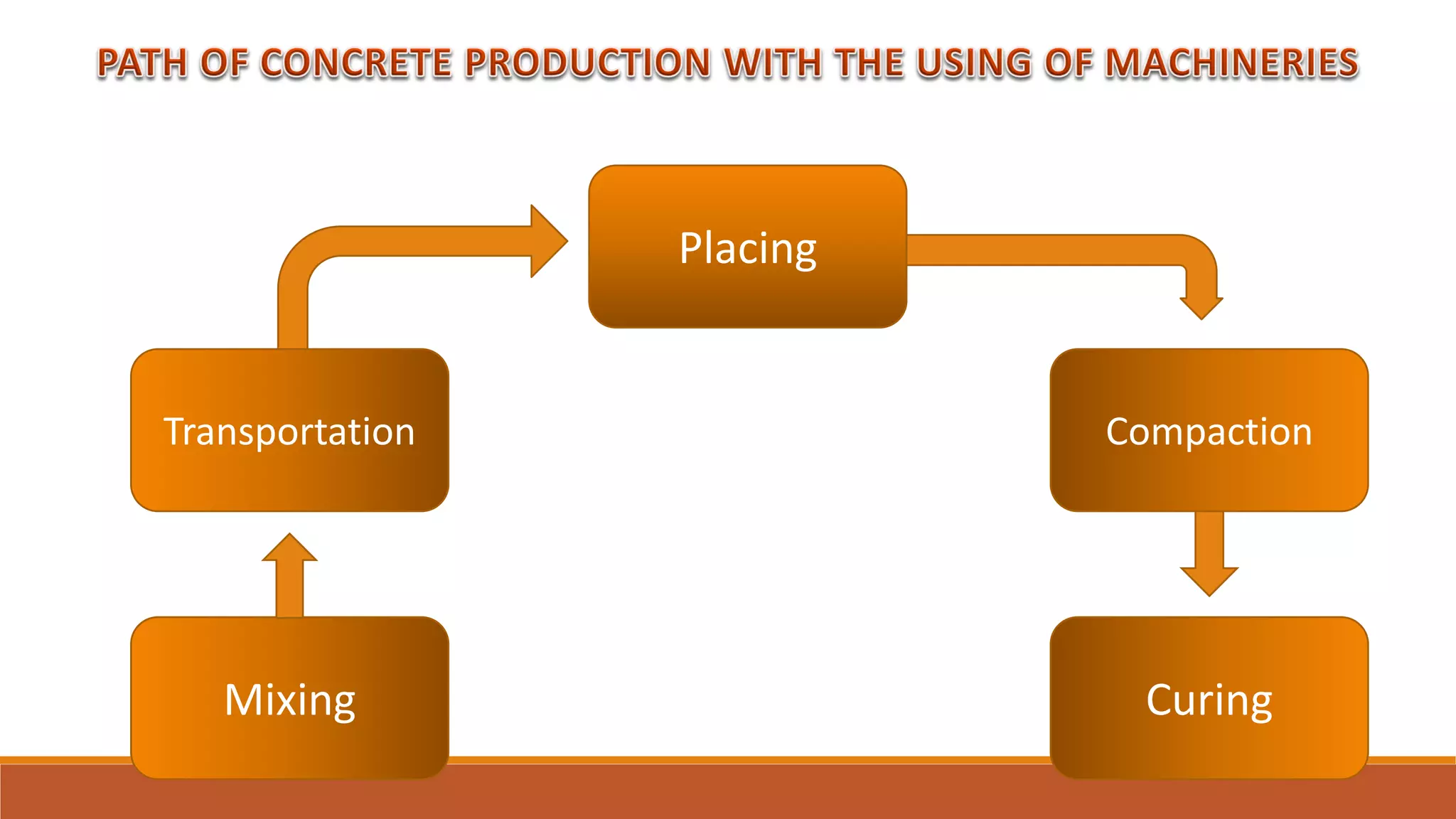

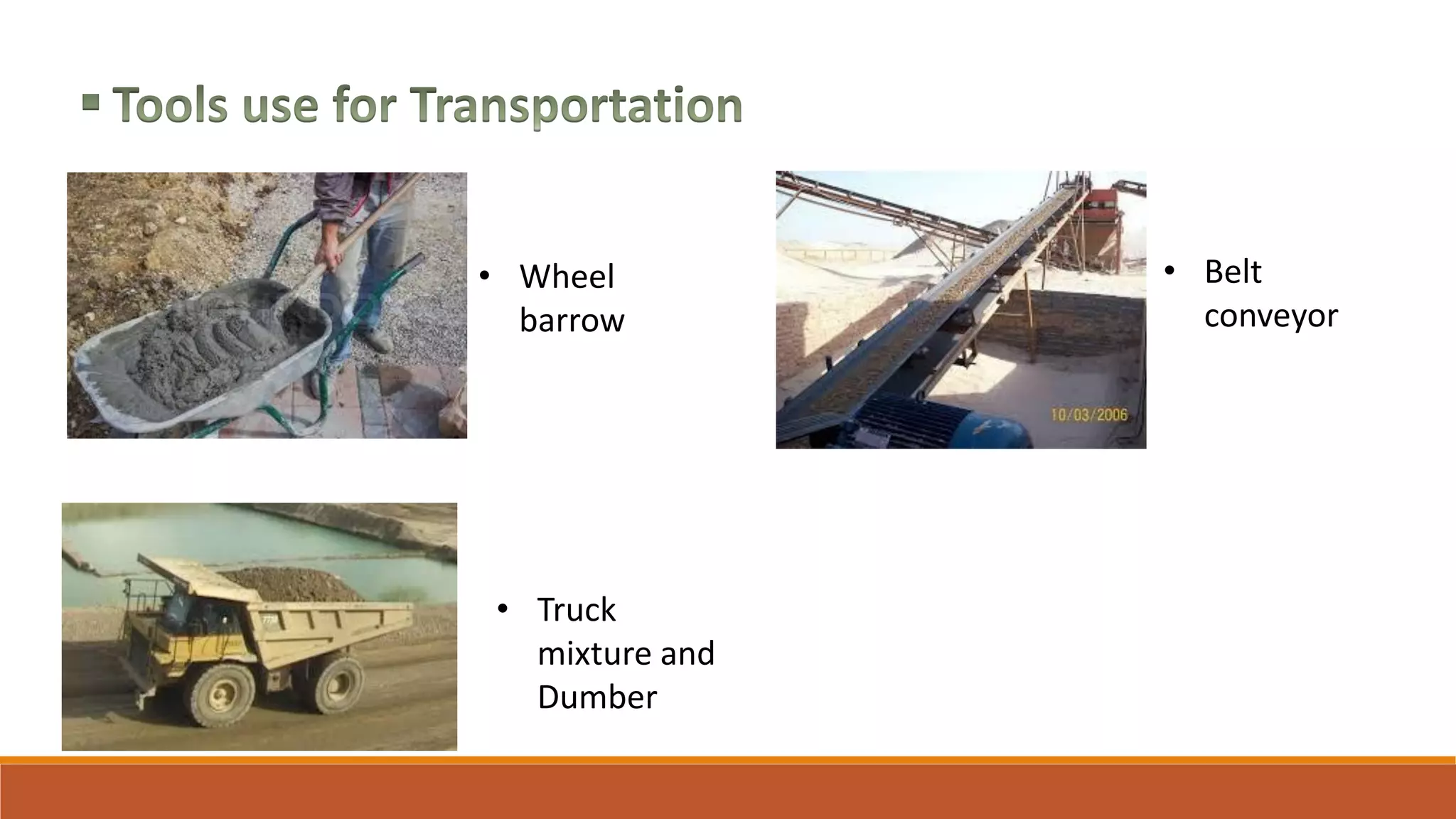

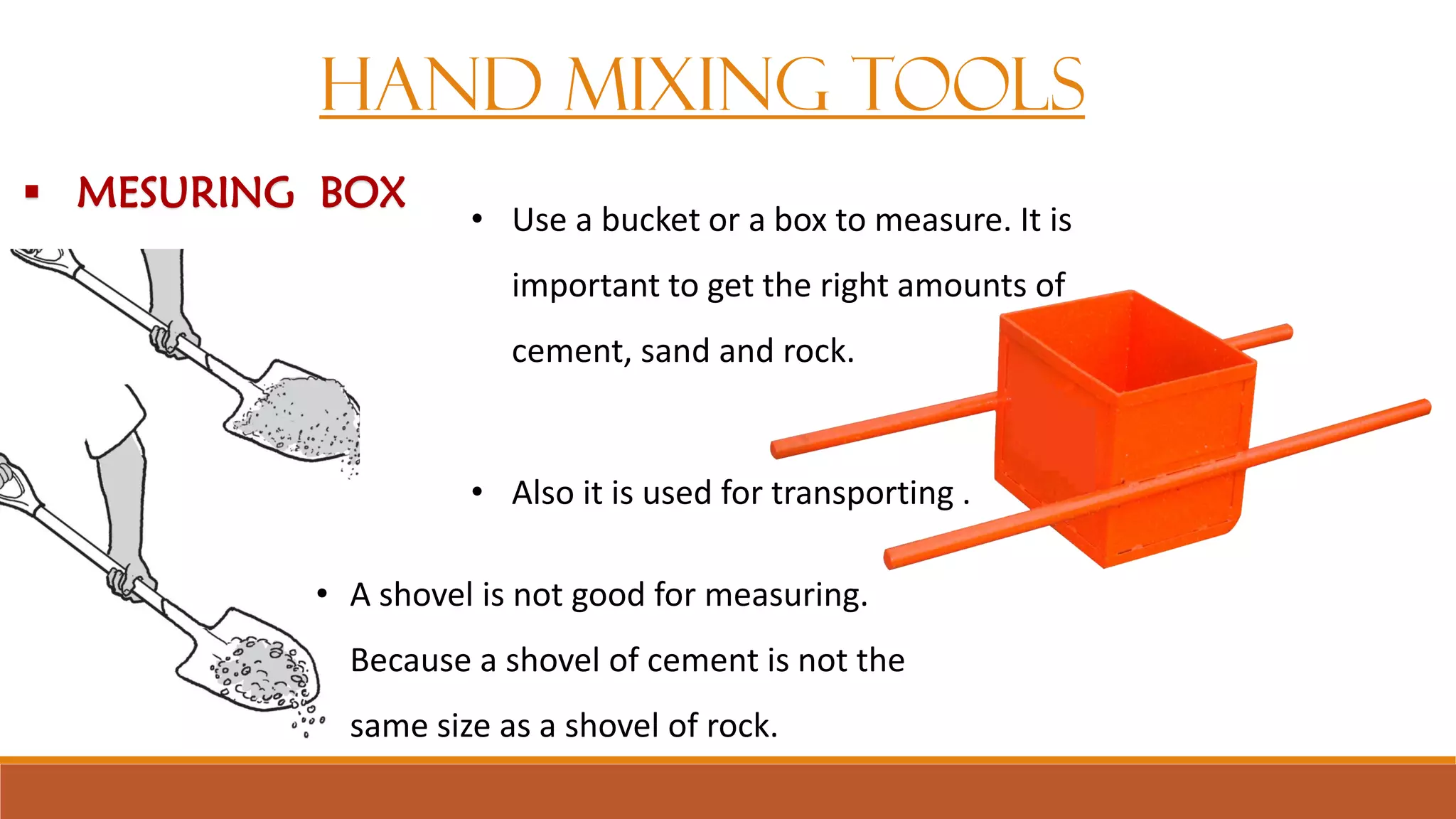

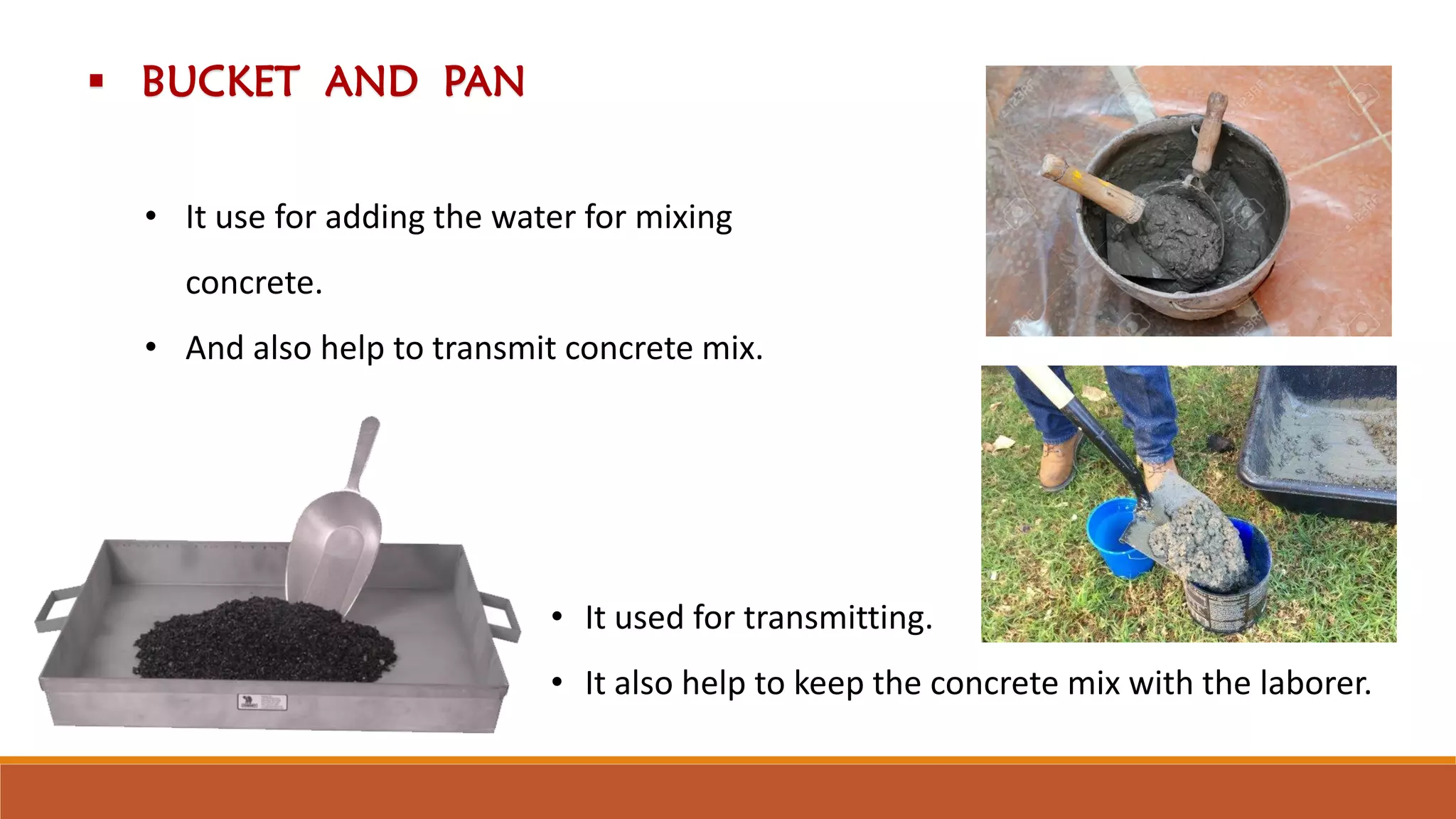

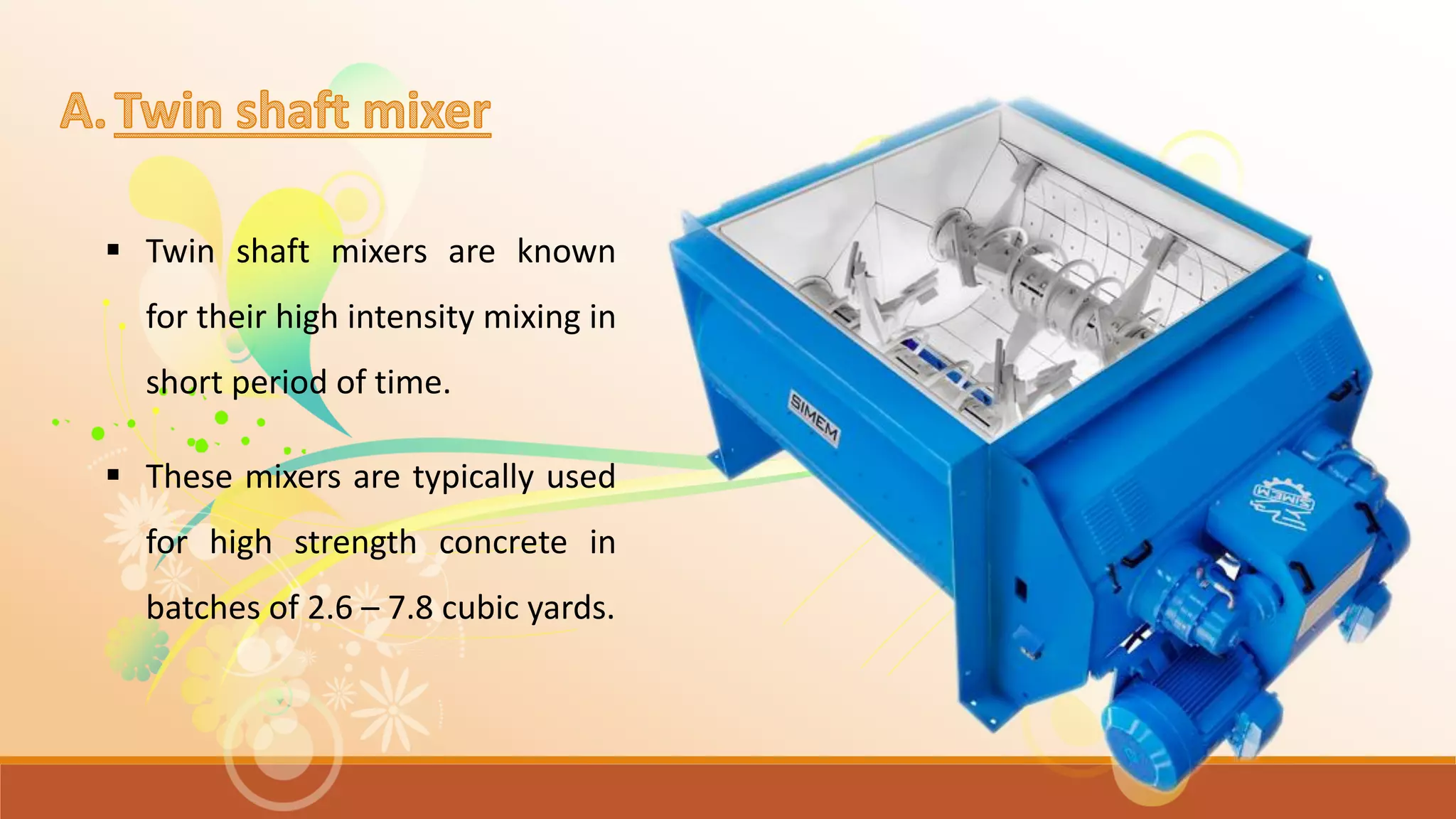

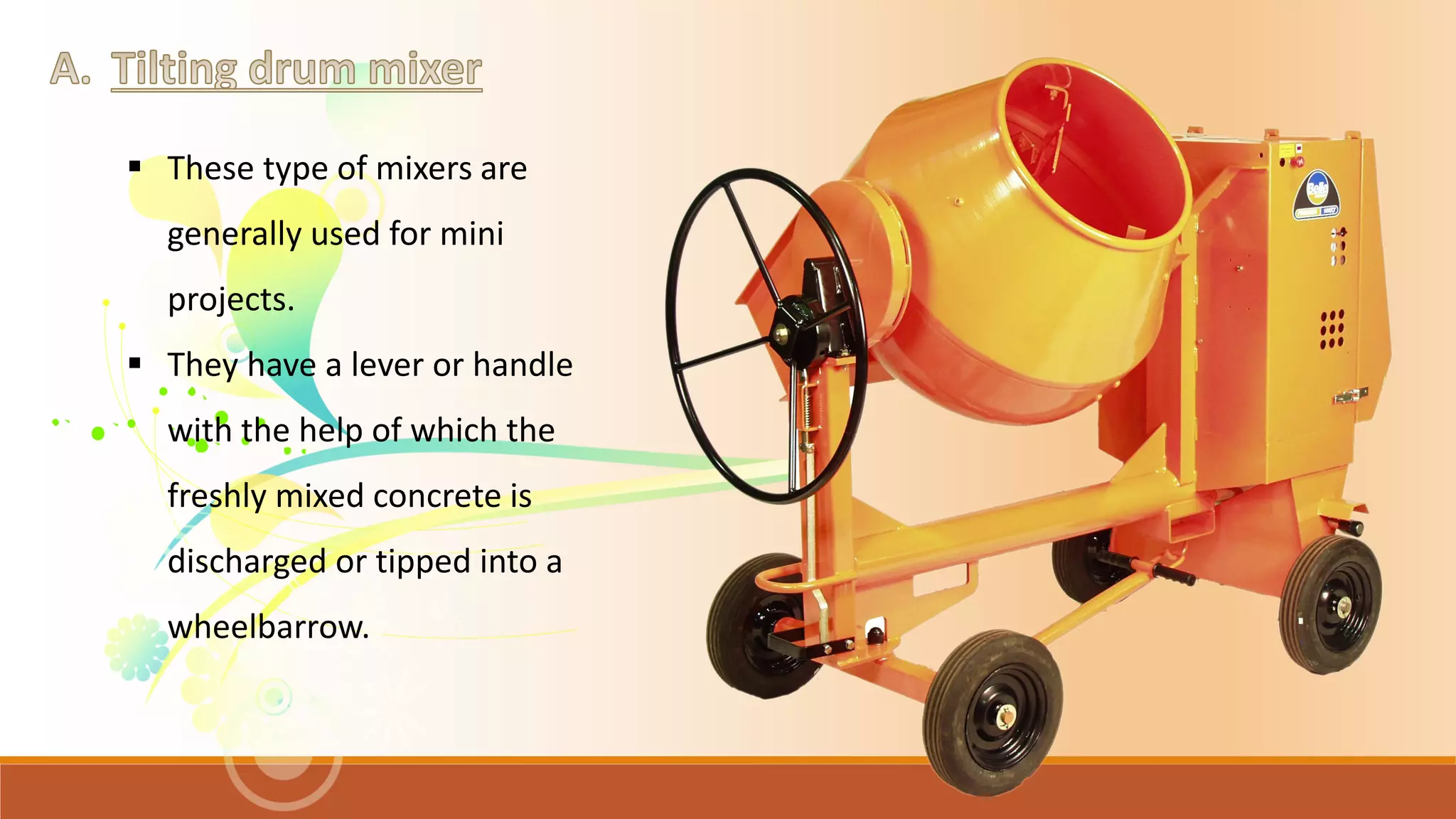

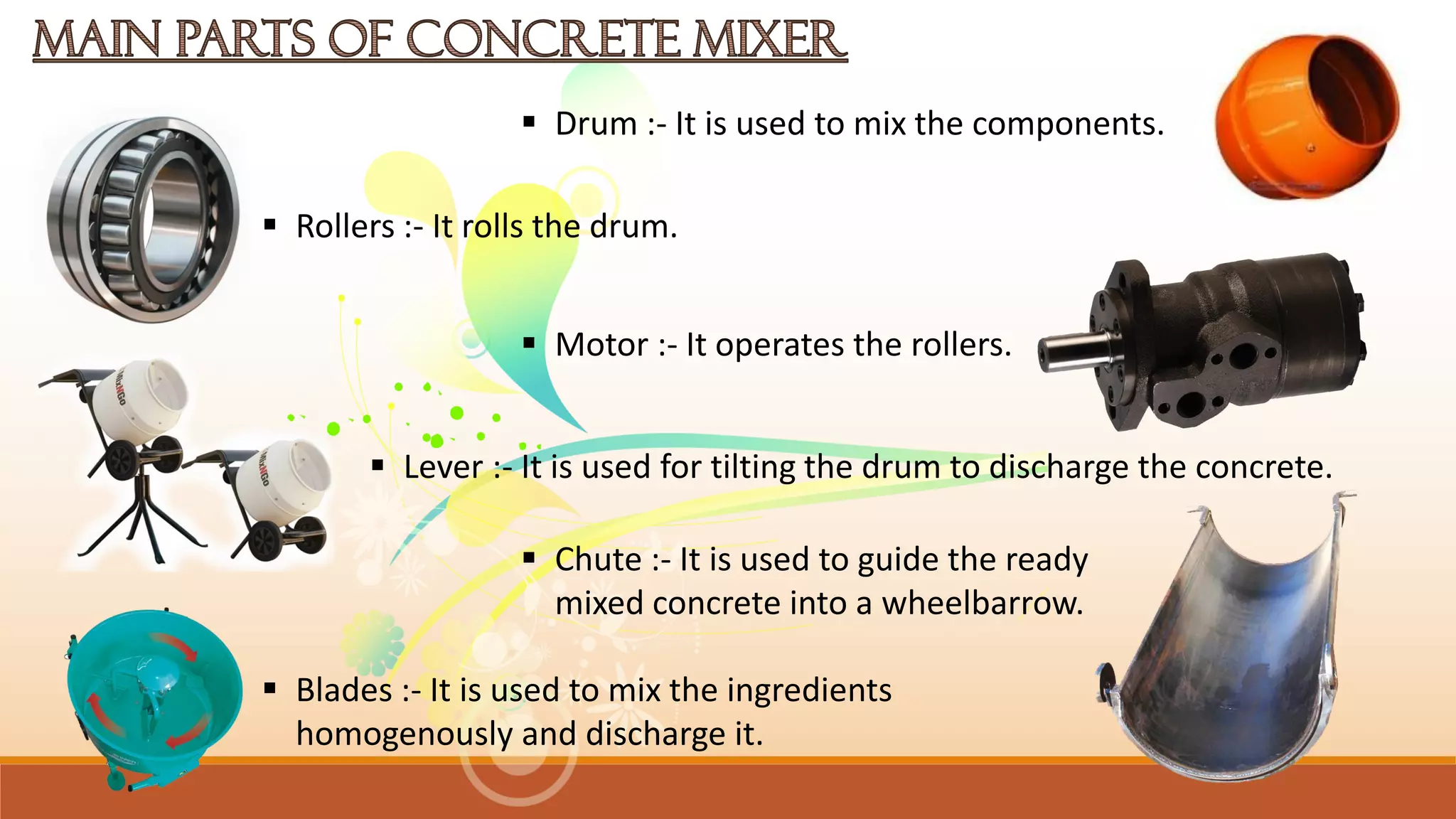

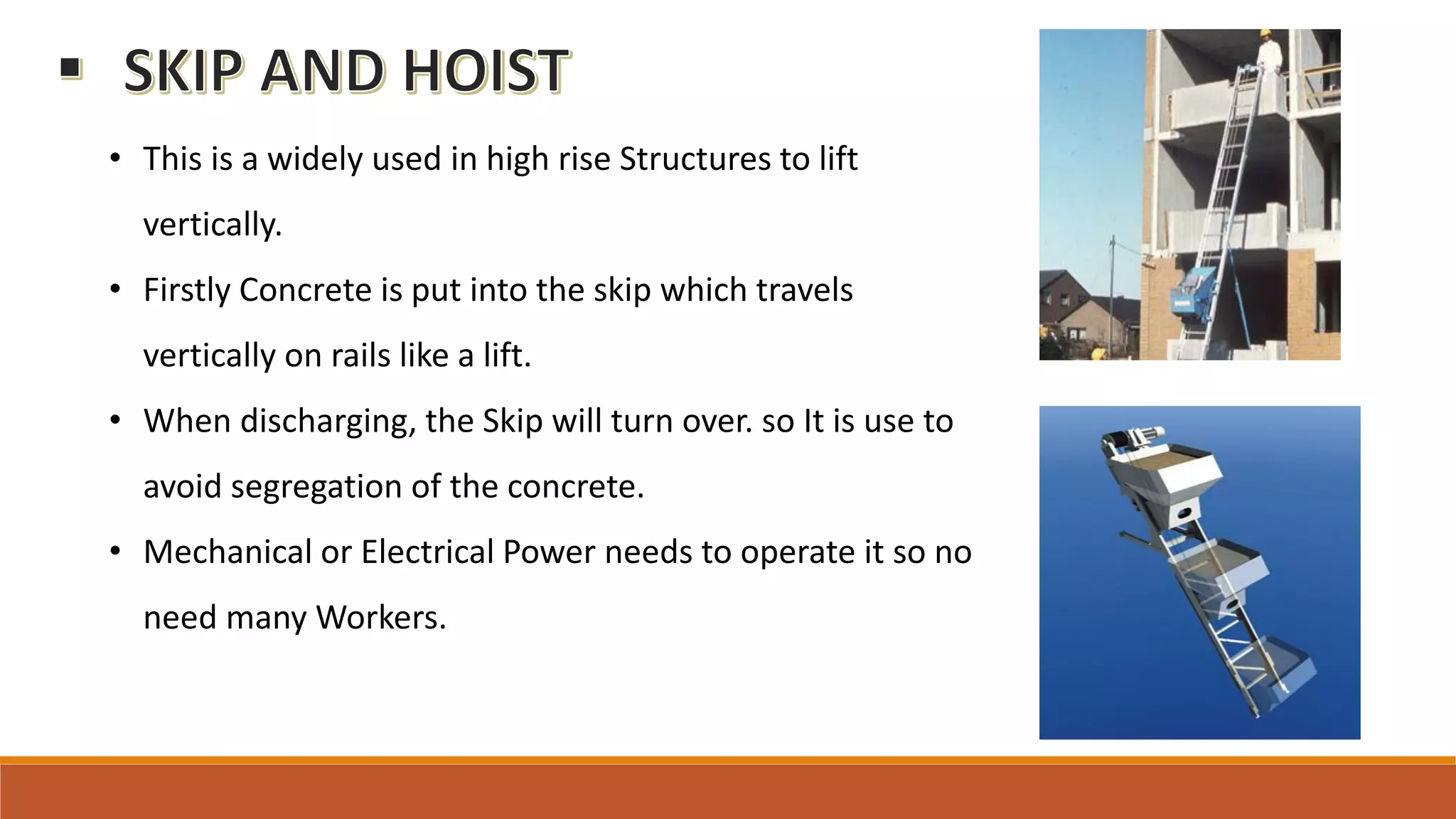

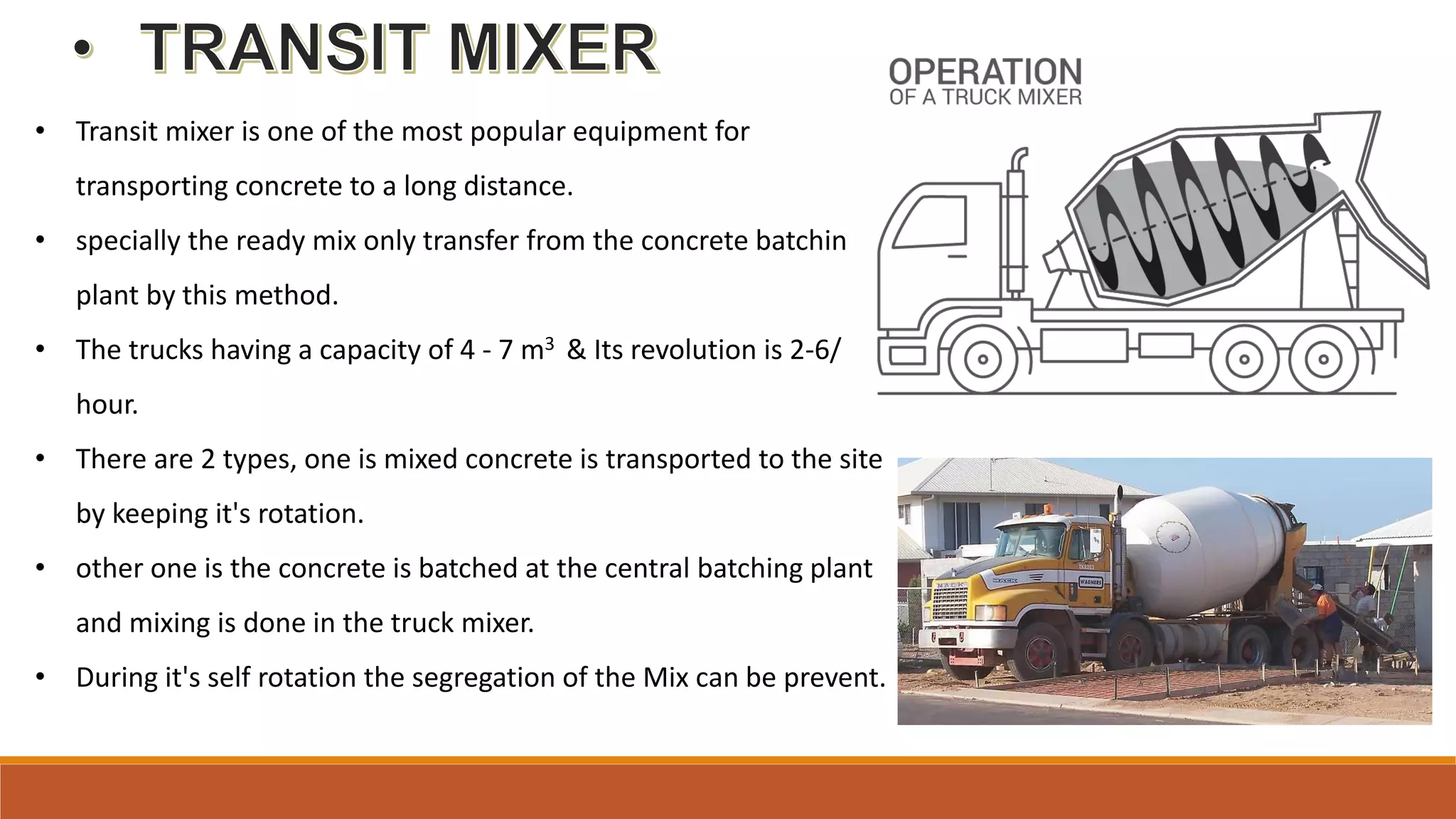

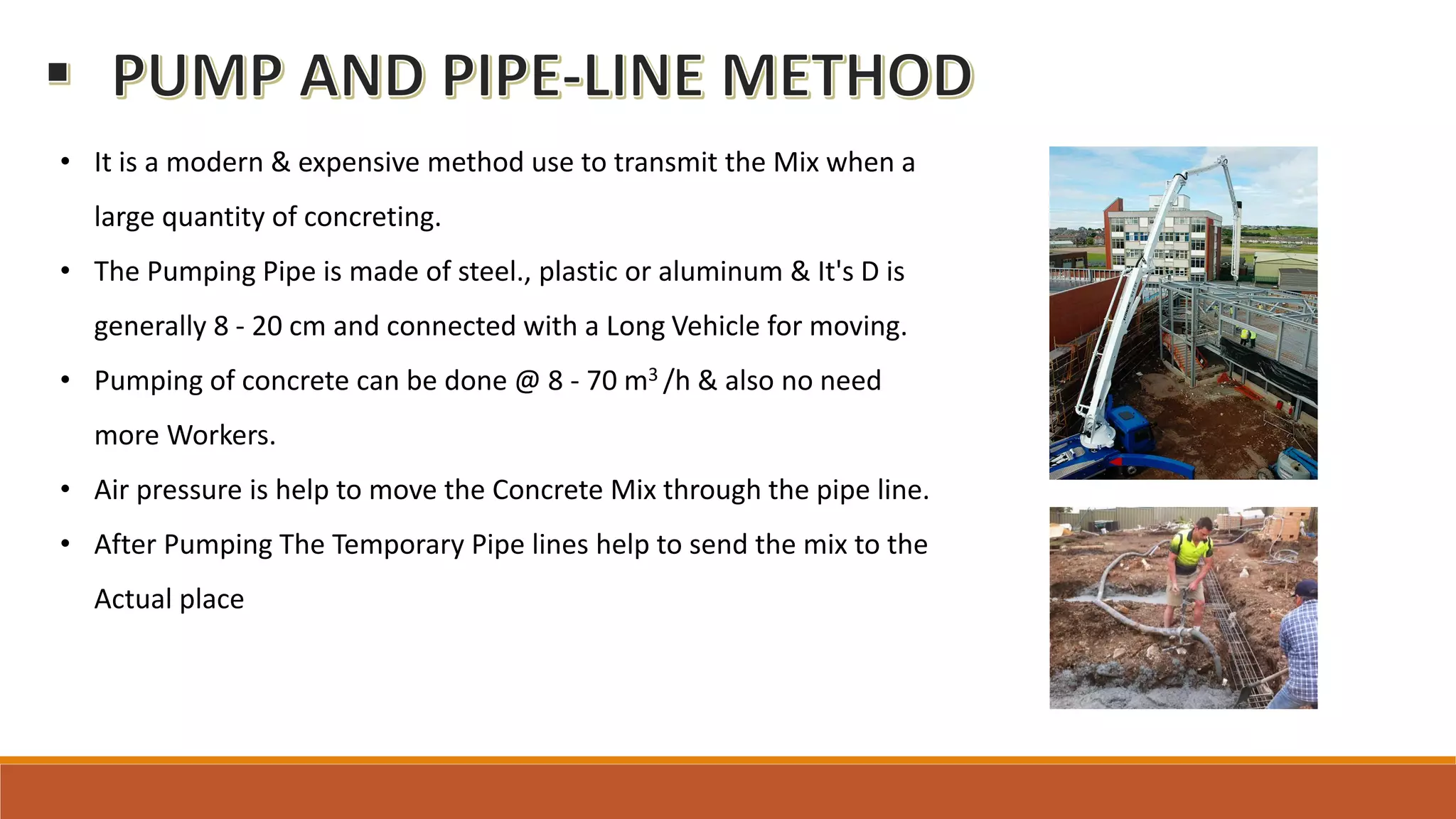

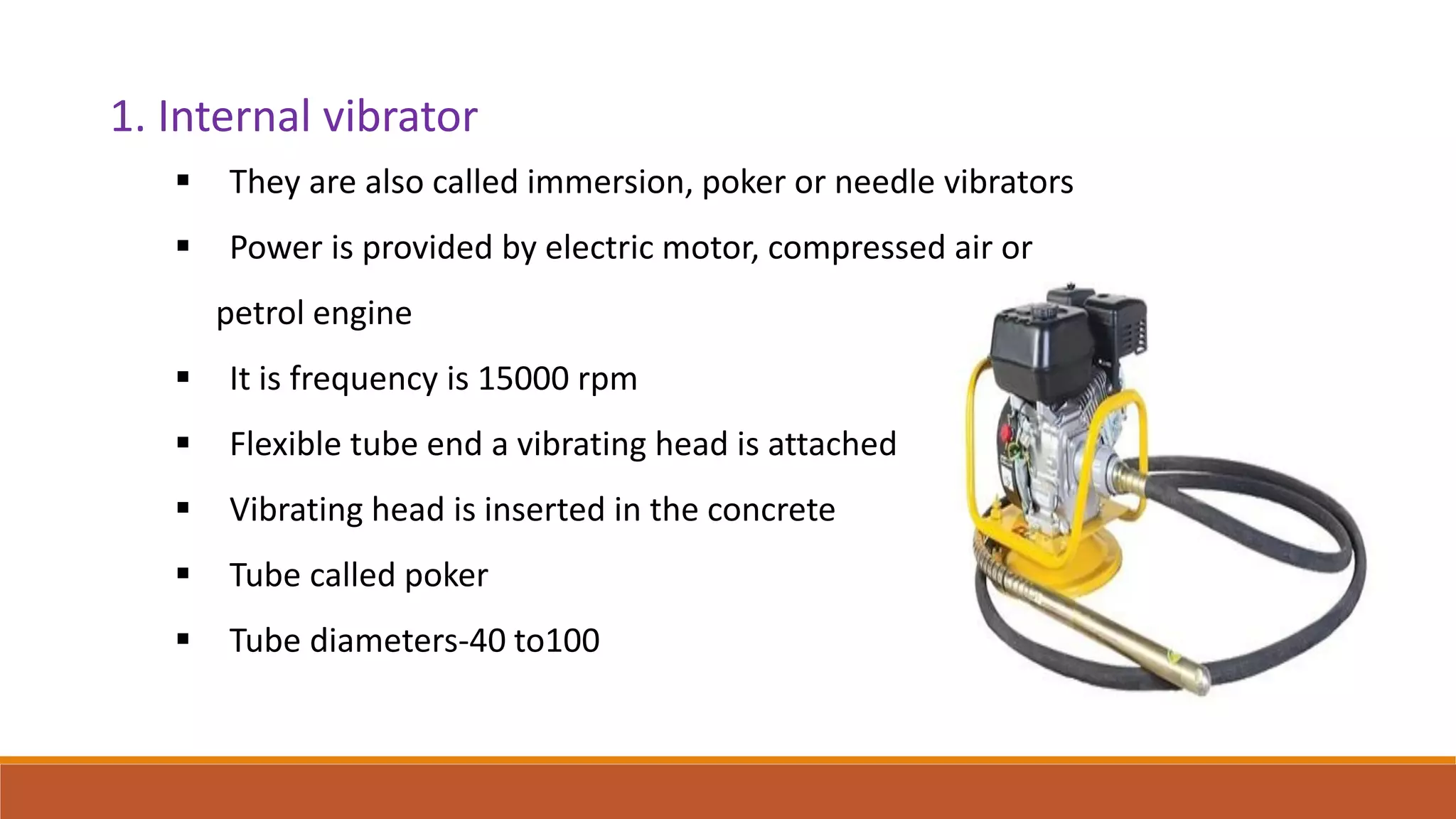

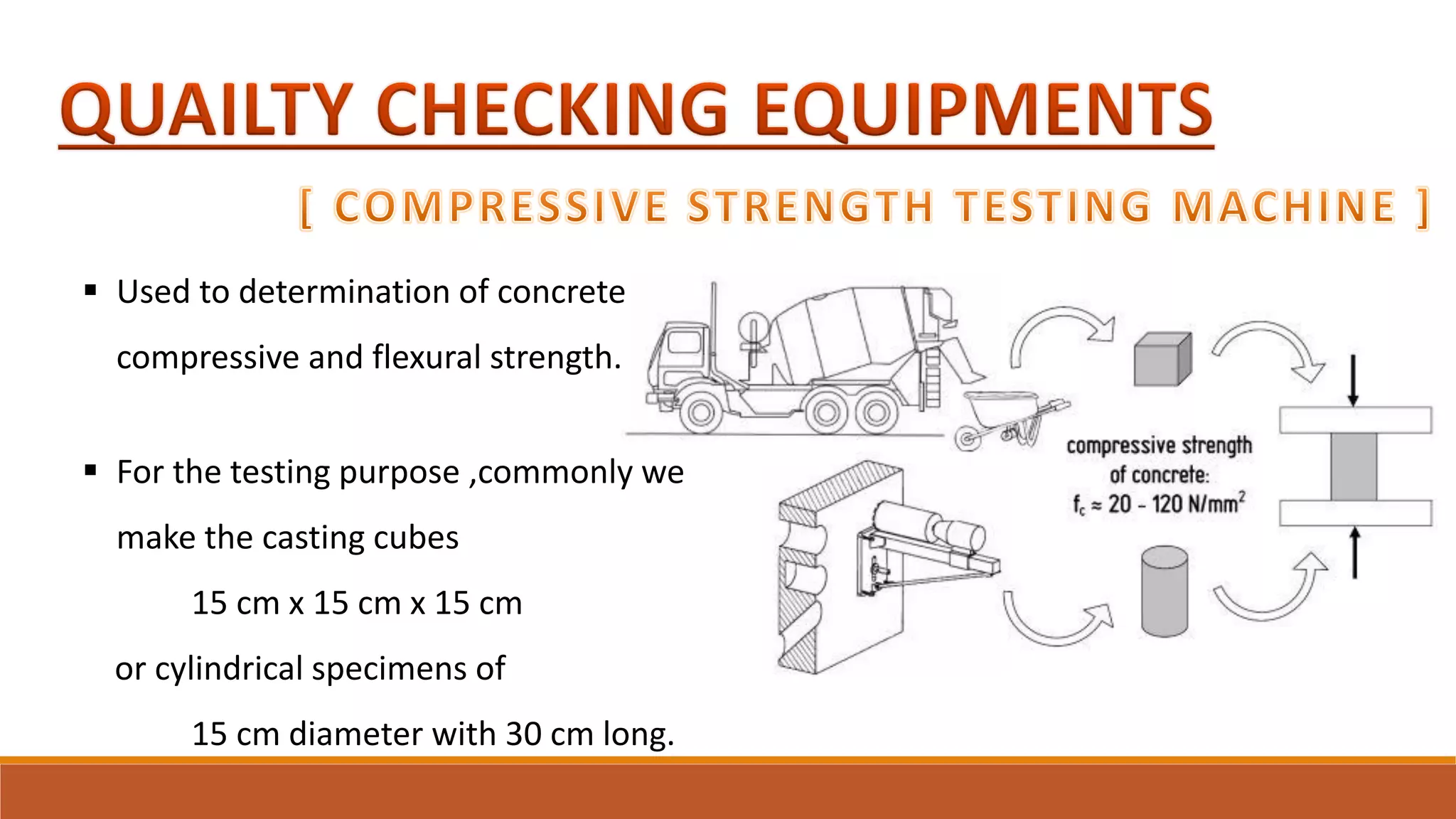

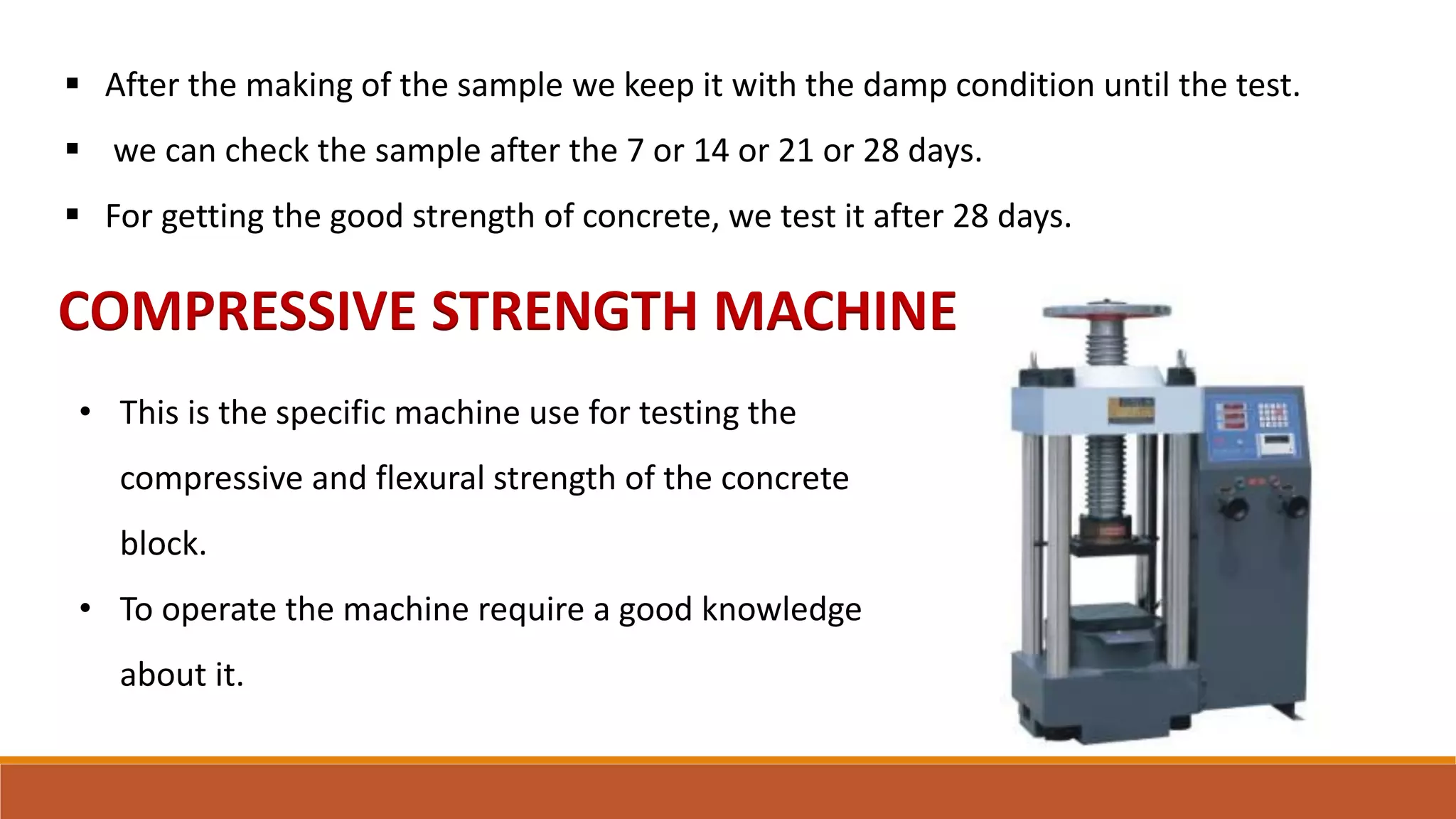

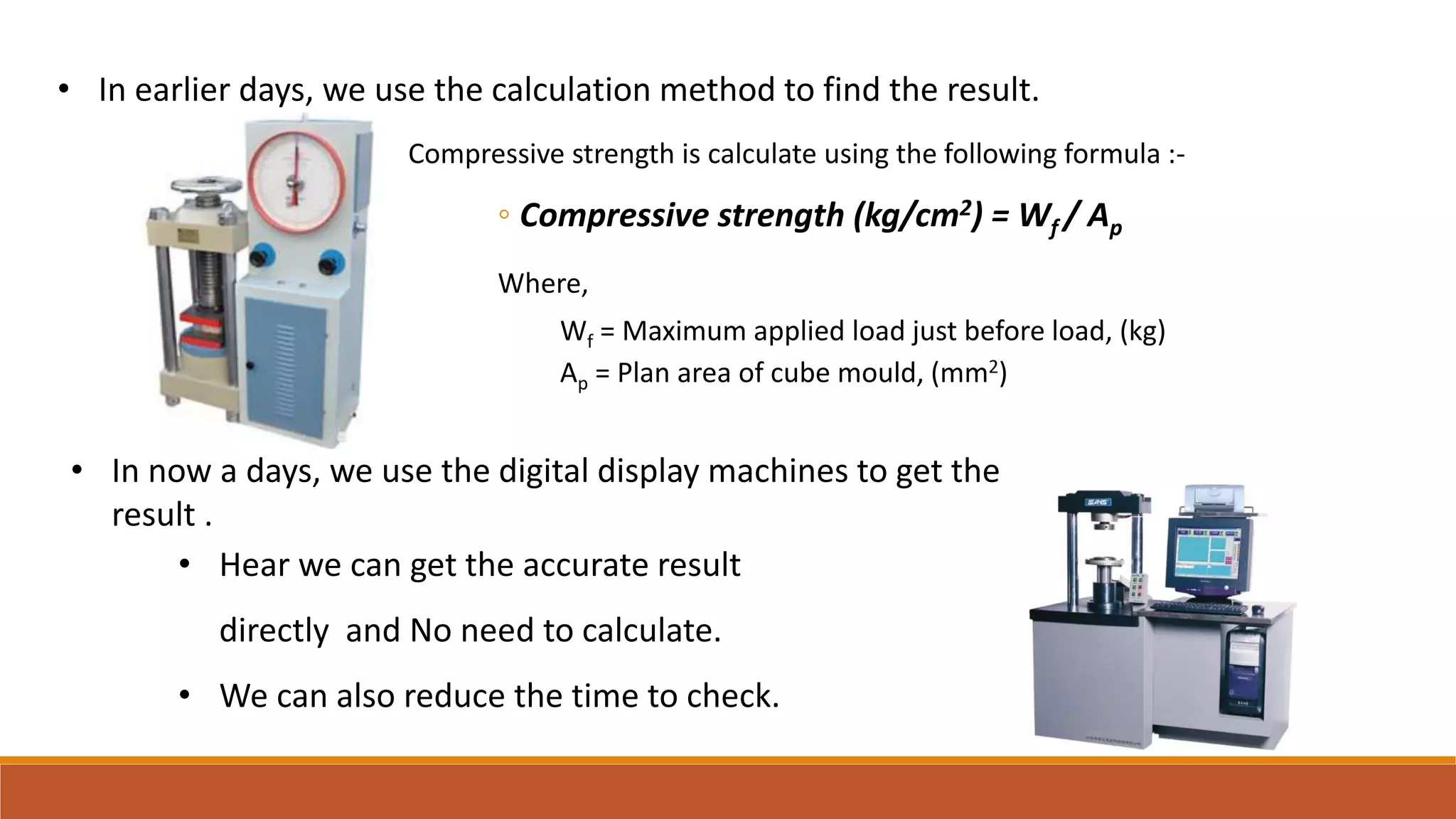

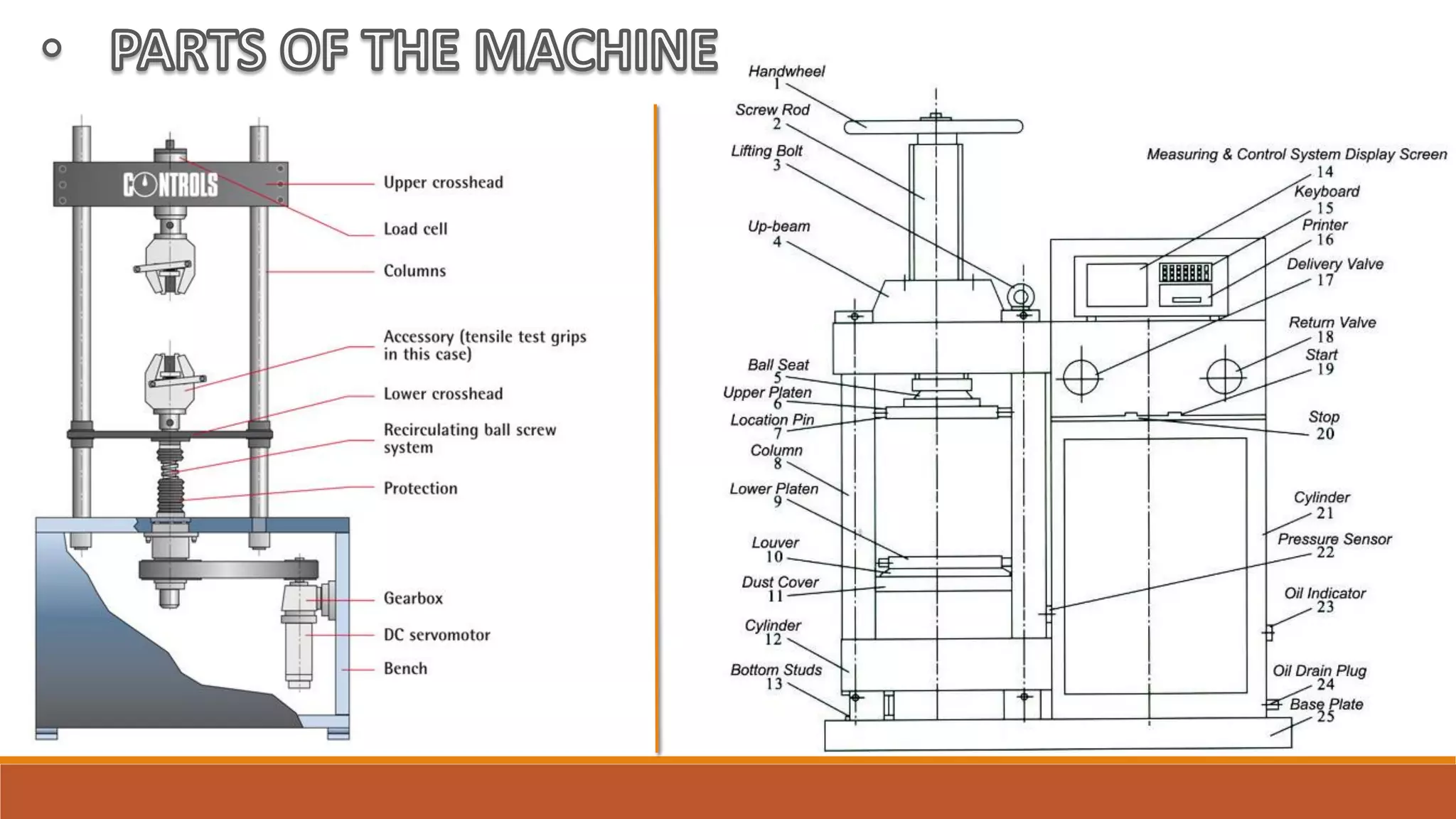

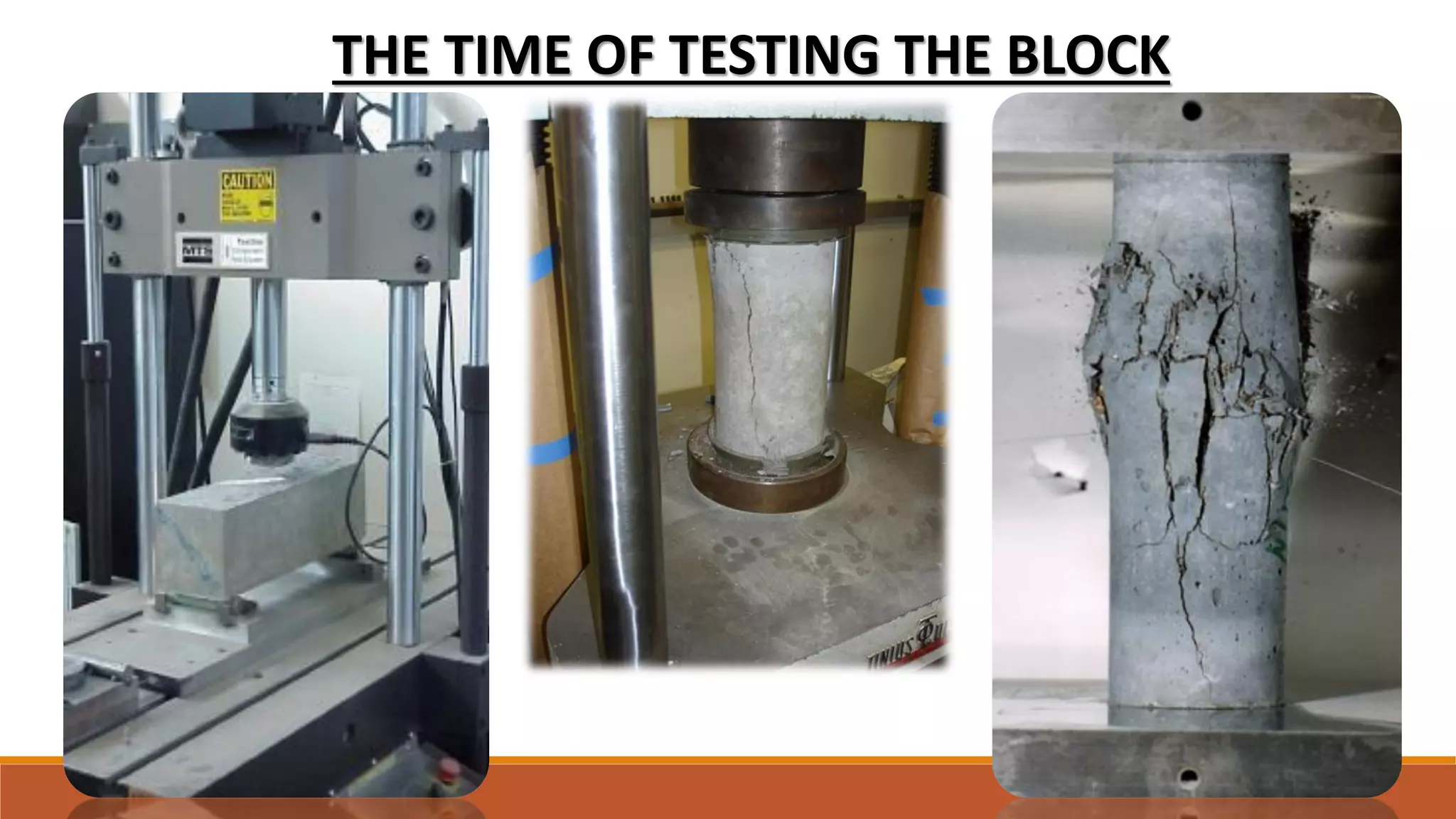

The document discusses various tools and machinery used in concrete construction. It describes hand mixing tools like measuring boxes, boards, shovels and buckets. It also describes different types of concrete mixers like twin shaft mixers, vertical axis mixers, and drum mixers. Transportation equipment like pans, chutes, belt conveyors, and dump trucks are mentioned. Compaction tools include internal vibrators, form vibrators, surface vibrators, and vibrating tables. Quality checking equipment includes compressive strength testing machines.