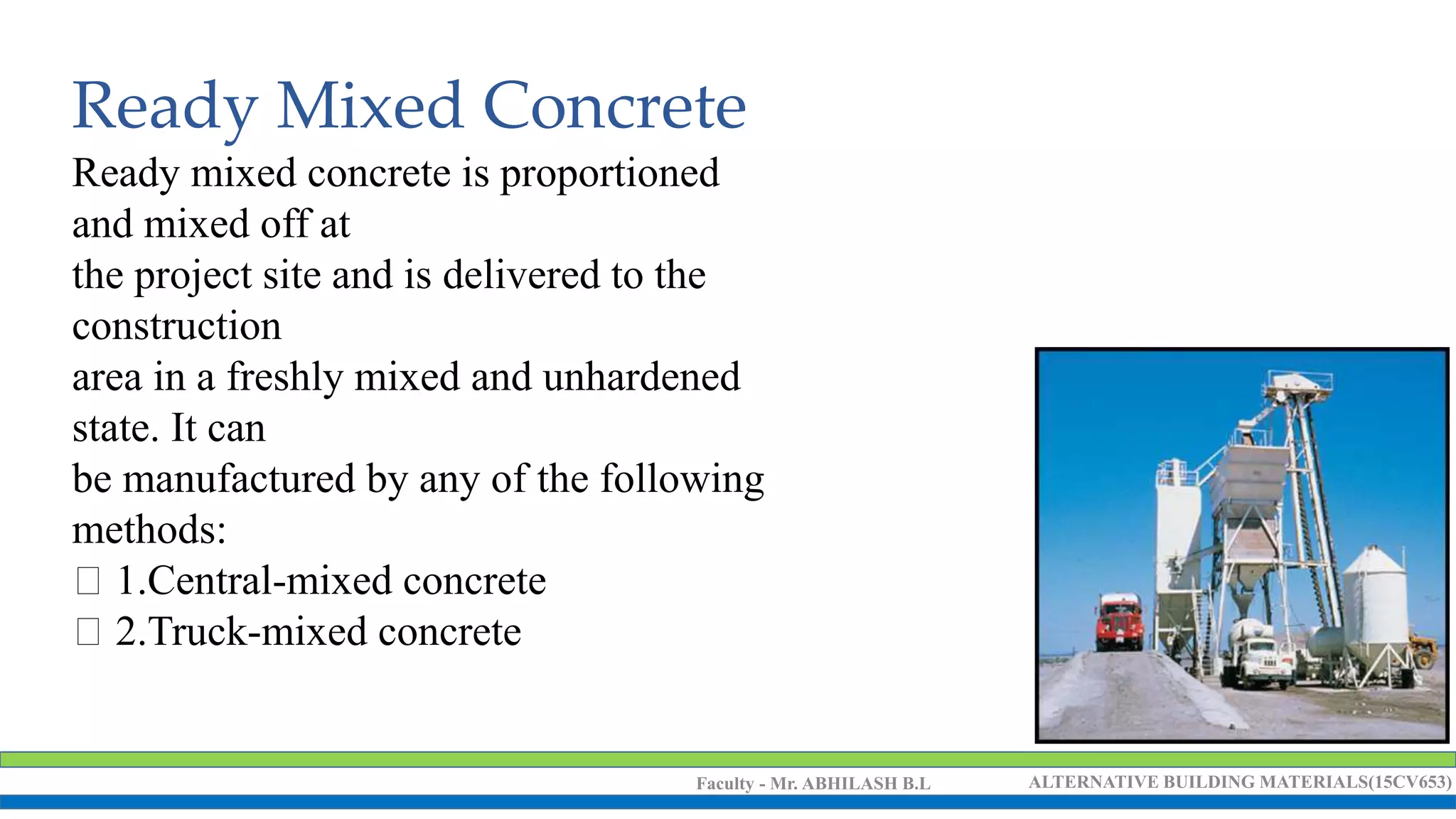

The document outlines the curriculum for a course on alternative building materials led by Mr. Abhilash B.L. It covers topics including the production and mixing of concrete, equipment for alternative materials, cost concepts in building construction, and methods for improving cost efficiency. Key processes such as batching, mixing, transporting, and compaction of concrete are also detailed.