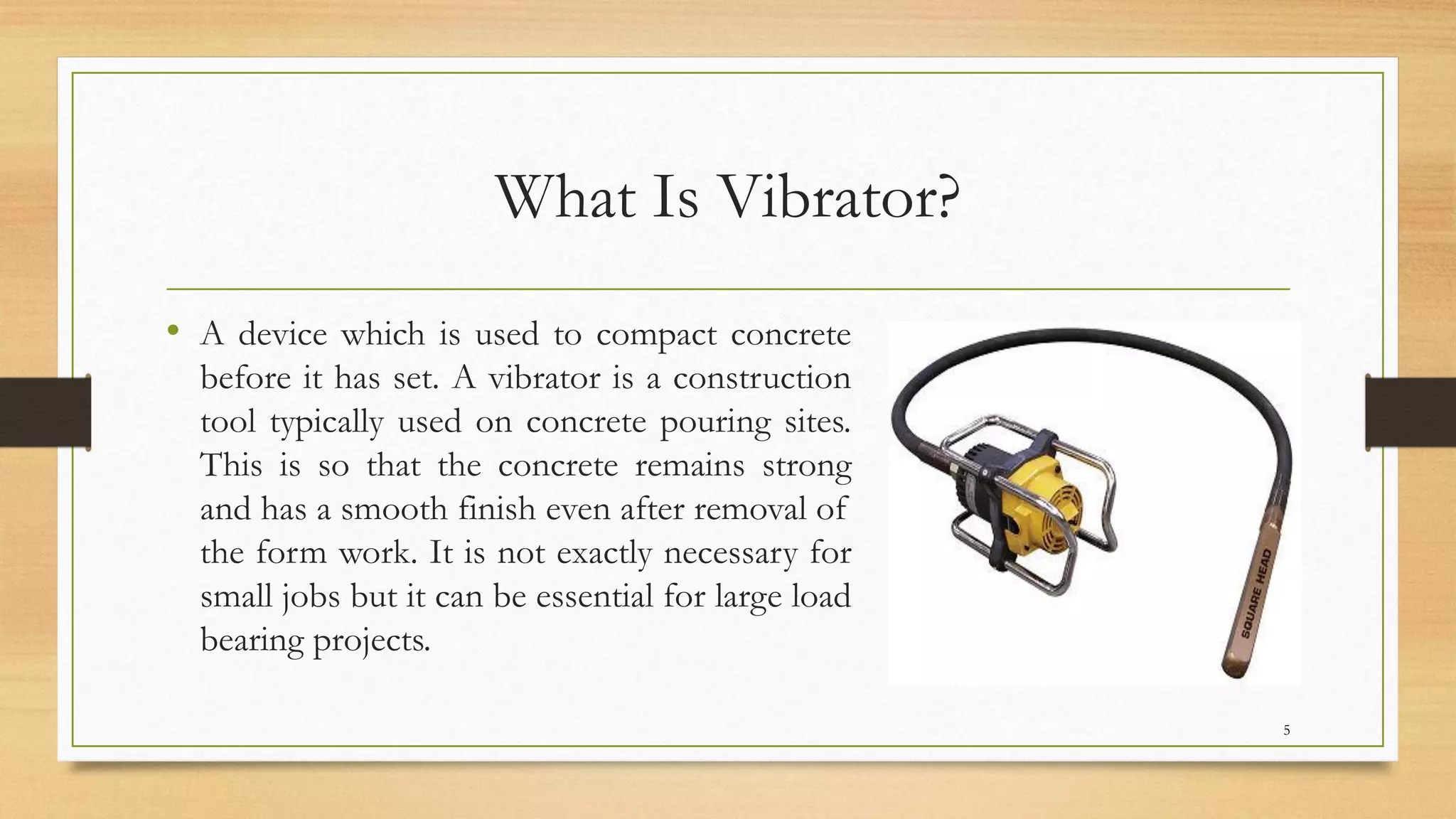

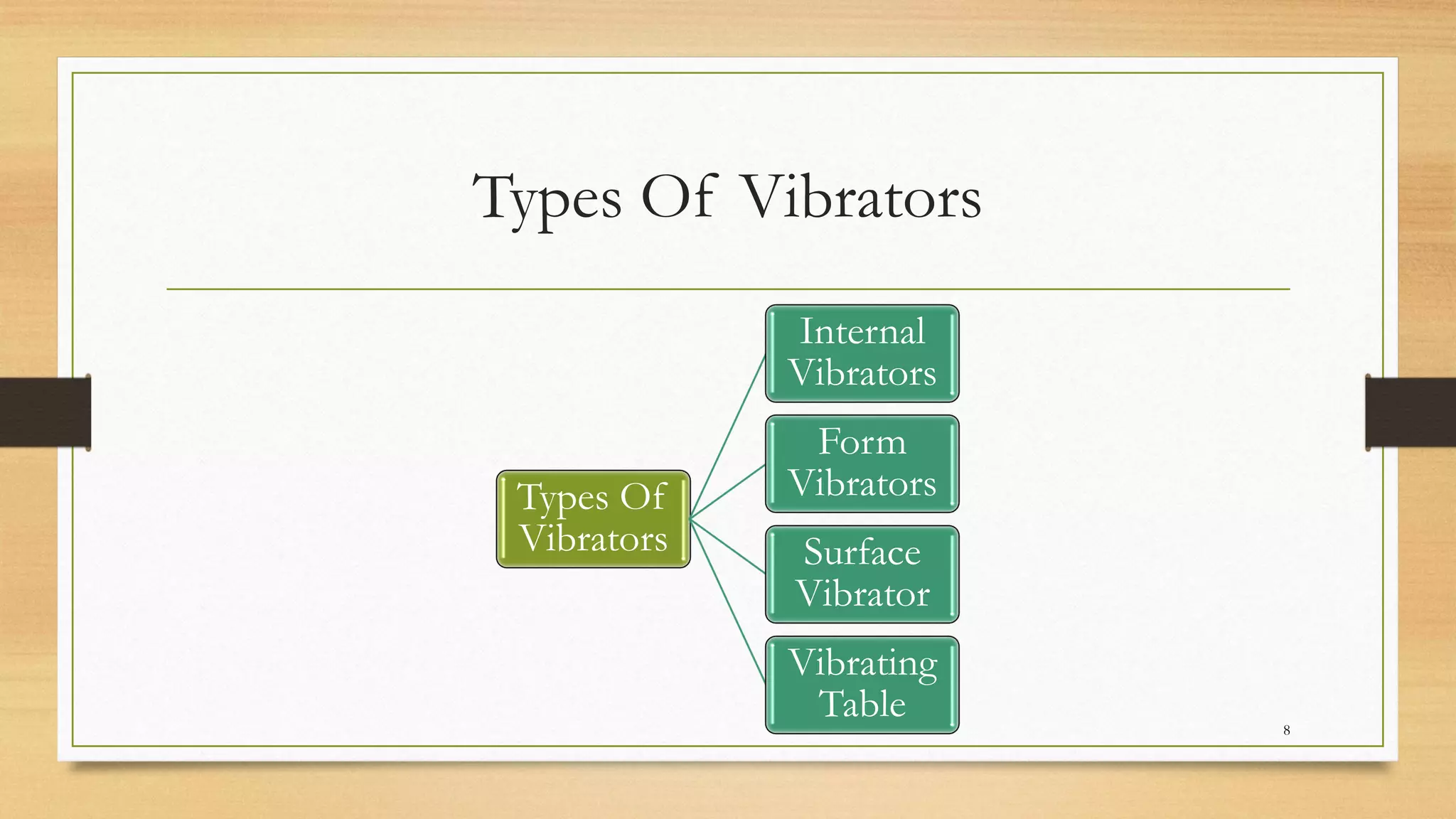

The document presents an overview of vibrators used in concrete compaction, including their definition, functions, types, and applications. It outlines various types of vibrators such as internal, form, and surface vibrators, detailing their specific uses and effectiveness in different scenarios. The importance of proper vibration duration for concrete consolidation to achieve maximum density and strength is also emphasized.