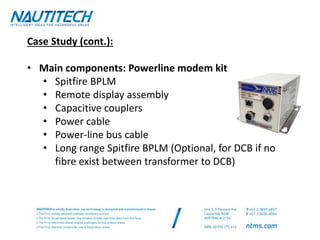

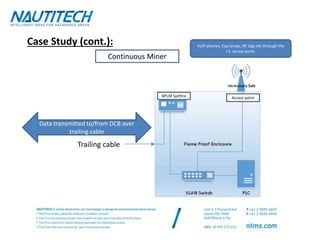

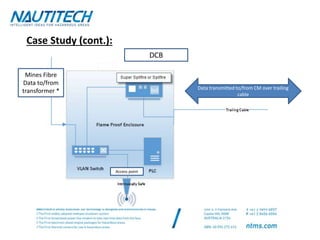

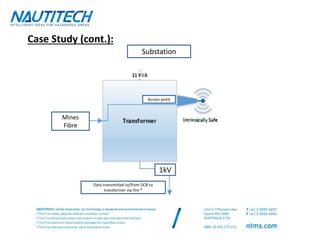

This document discusses using broadband power line modems for data communication in underground coal mines. It describes current communication solutions like wired and wireless networks and their challenges in providing reliable, high-bandwidth coverage everywhere needed. It then presents a case study where a combination of broadband power line modems and wireless access points were used together to provide reliable network access to equipment on a continuous miner. This solved challenges of running a wireless network the entire distance and provided better bandwidth than existing solutions. The system was successfully implemented and demonstrated at a mine, and they are looking to expand its use to other applications.