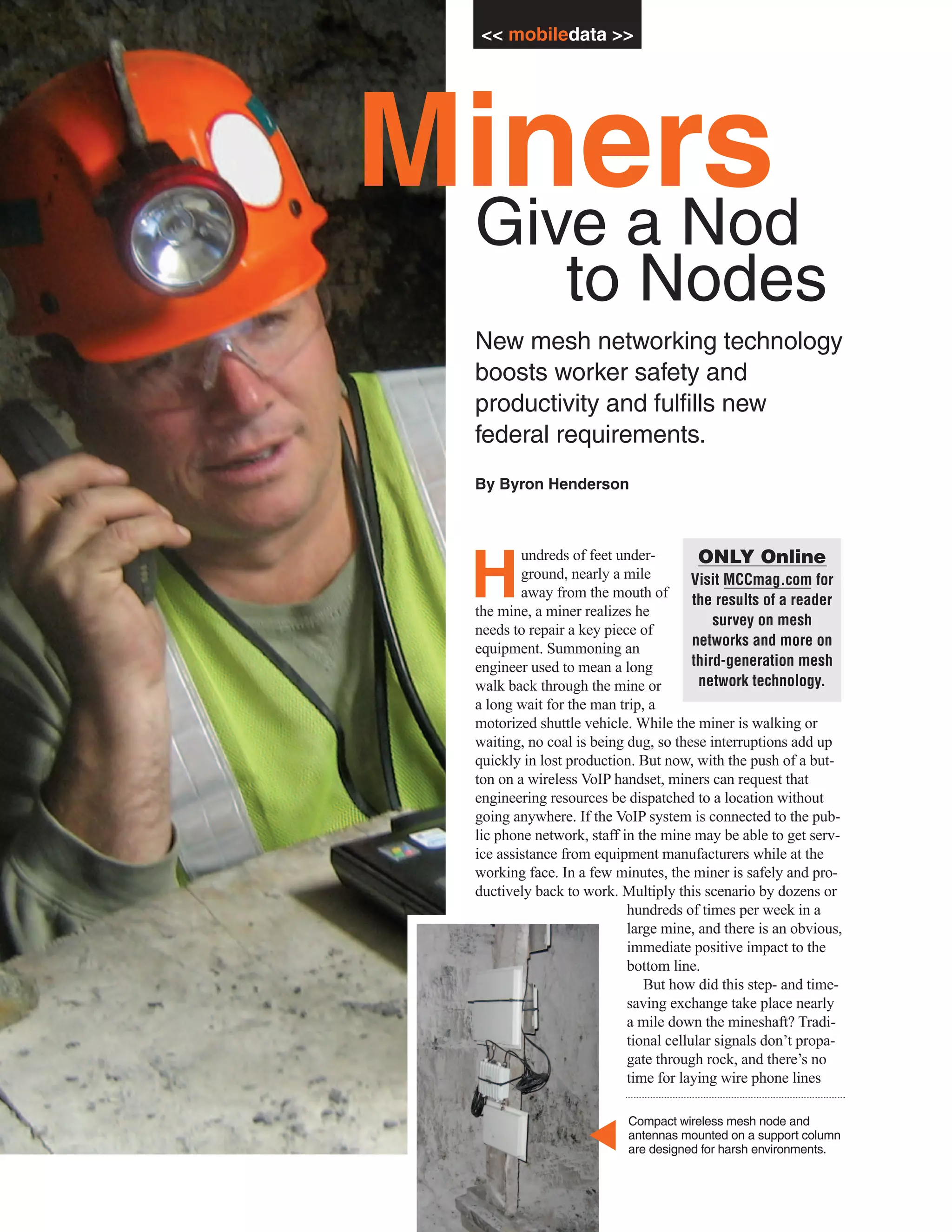

The document discusses the implementation of wireless mesh networking technology in underground coal mines to improve safety and productivity, meeting federal requirements. This new system allows miners to communicate and summon engineering assistance via wireless VoIP handsets, significantly reducing downtime and enhancing operational efficiency. The technology is adaptable to the dynamic mining environment and supports features such as location tracking and video monitoring to ensure quick responses in case of emergencies.