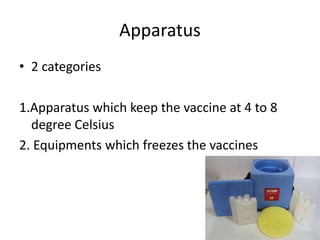

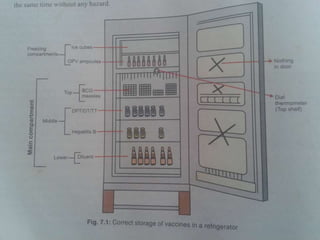

The cold chain is a system for storing and transporting vaccines at low temperatures from manufacture to point of vaccination. It is important to maintain the potency of vaccines by keeping them within specific temperature ranges and protecting them from sunlight exposure. The cold chain involves equipment like vaccine carriers, cold packs, refrigerators, and walk-in coolers, as well as supplies, transportation, communication, and manual efforts to ensure vaccines are properly stored and distributed. Proper control and maintenance of the cold chain is essential for effective vaccination programs.