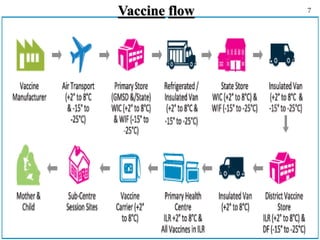

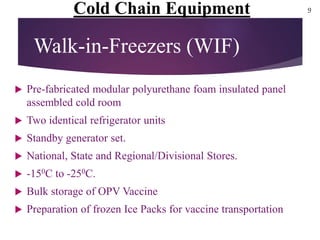

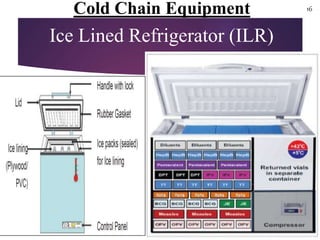

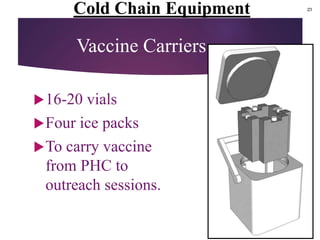

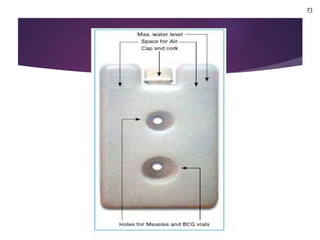

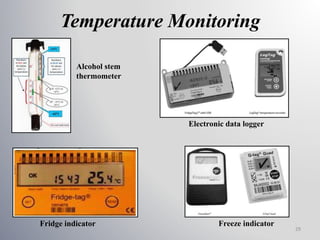

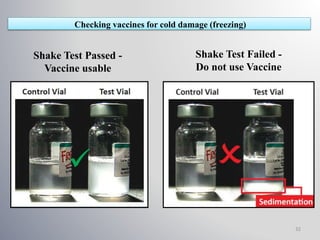

The document discusses the cold chain system for storing and transporting vaccines. It describes key elements like personnel, equipment, and procedures to ensure vaccines are safely stored and transported within the recommended temperature range. Various types of cold chain equipment are outlined, including walk-in freezers and coolers, deep freezers, ice-lined refrigerators, vaccine carriers, and cold boxes. Placement of vaccines, temperature monitoring, and checking vaccine potency are also covered. The cold chain system is crucial for maintaining vaccine effectiveness from the point of manufacture to administration.