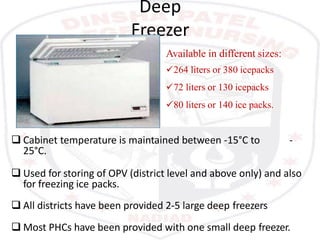

This document discusses India's Universal Immunization Programme (UIP) and the importance of maintaining a proper cold chain for vaccine storage and transport. It outlines the key components of India's cold chain system, including walk-in freezers, walk-in coolers, deep freezers, ice-lined refrigerators, cold boxes, and vaccine carriers. It describes how each component works and its role in storing or transporting vaccines at the appropriate temperatures from national to sub-center levels to ensure vaccine potency. Maintaining an unbroken cold chain is essential for effective immunization.