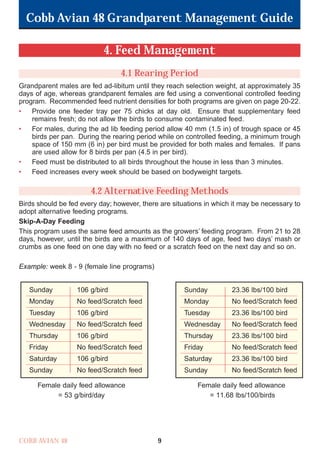

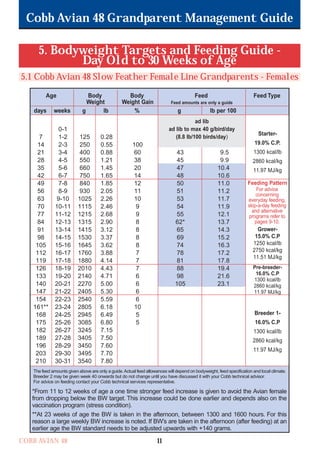

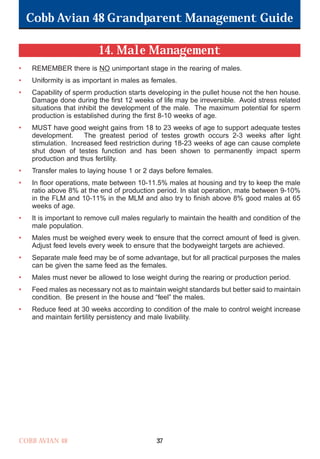

This document provides guidelines for managing Cobb Avian 48 grandparent breeders. It discusses preparing facilities before chick arrival, planning chick placement including stocking densities and equipment setup. It also covers chick placement procedures, brooding methods including temperature profiles, and lighting recommendations. The guidelines are intended to help attain genetic potential and consistent flock production through implementing a good management program.