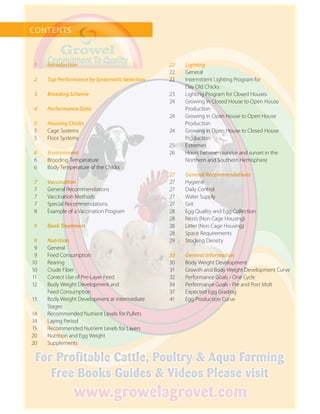

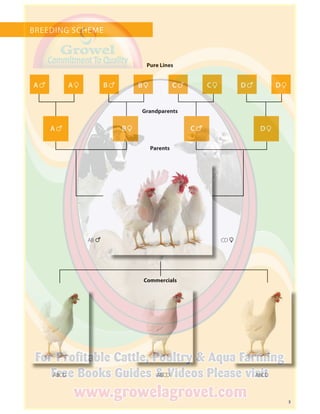

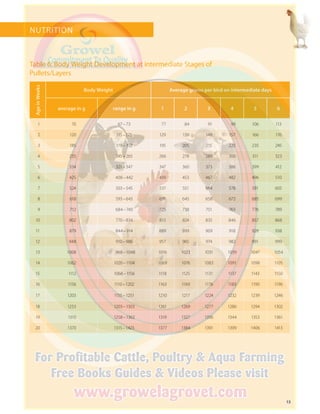

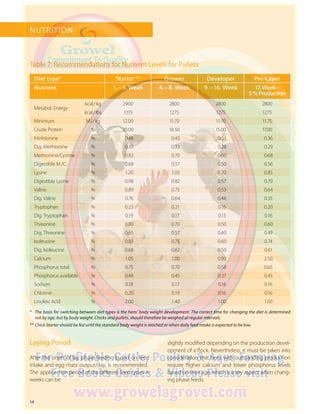

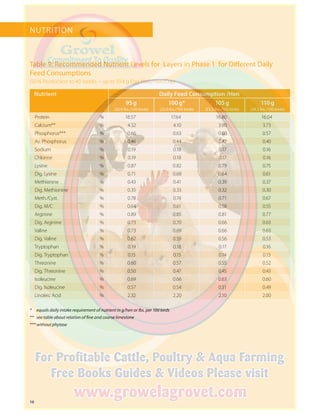

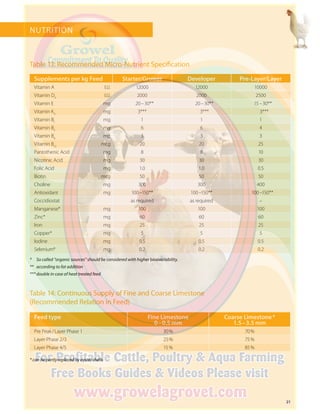

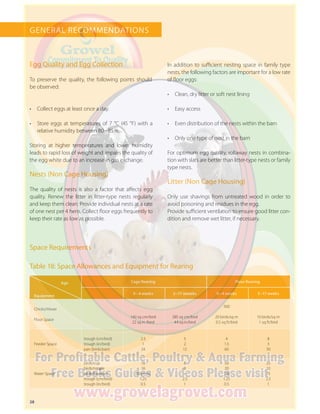

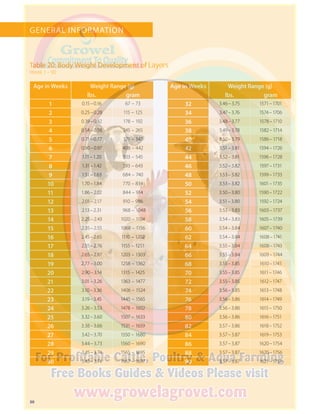

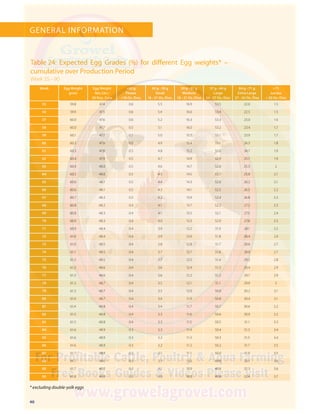

The document outlines a comprehensive guide for commercial egg production, covering key aspects such as breeding, housing, nutrition, and management practices to optimize egg production. It includes detailed recommendations on environmental conditions, vaccination protocols, and feeding strategies essential for the development and health of poultry. The aim is to provide valuable insights for both newcomers and experienced producers in the egg industry to enhance productivity and ensure the well-being of chickens.