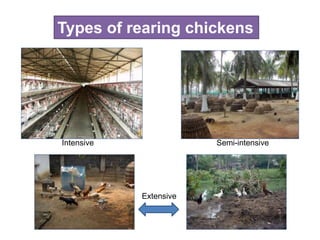

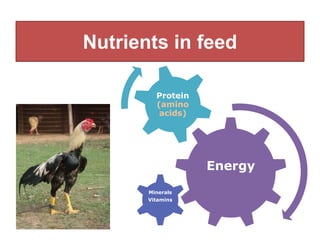

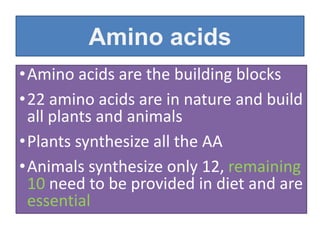

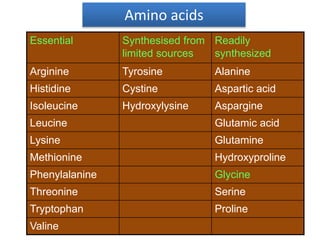

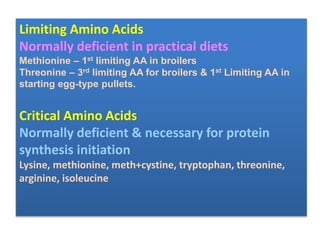

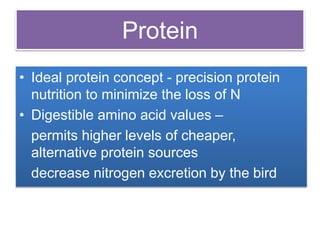

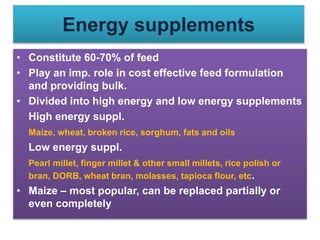

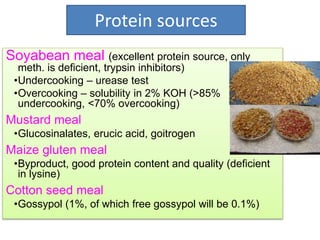

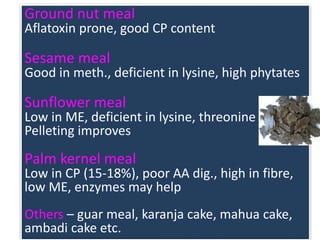

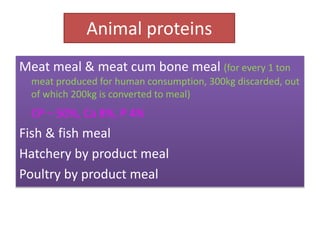

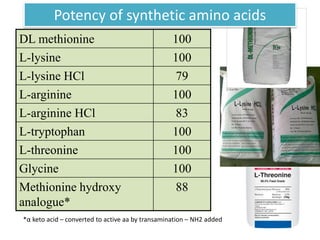

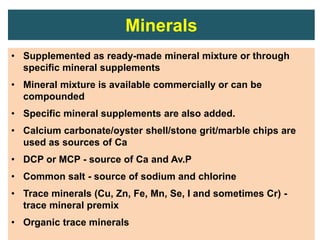

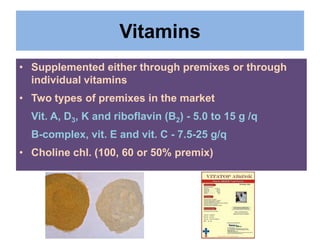

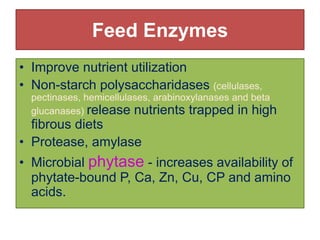

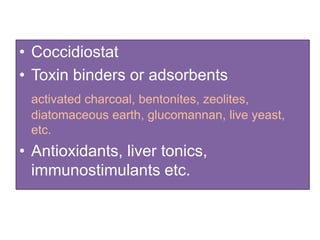

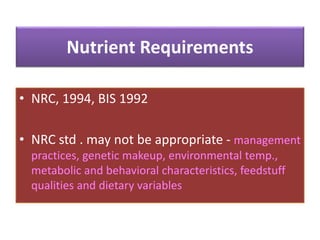

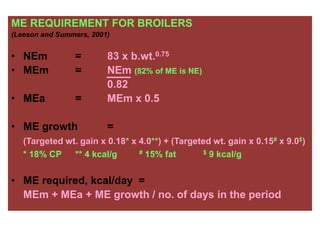

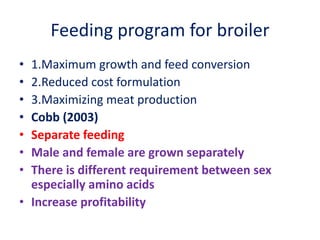

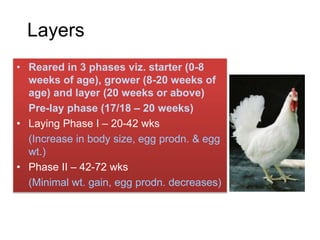

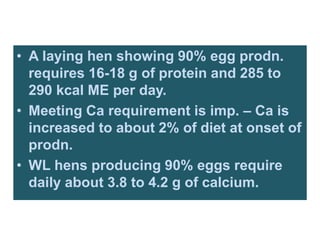

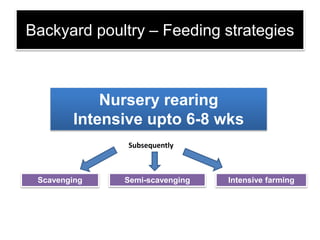

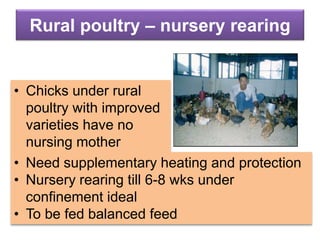

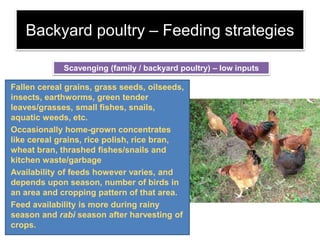

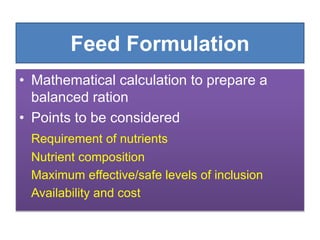

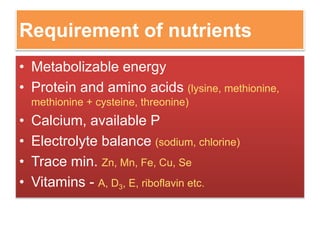

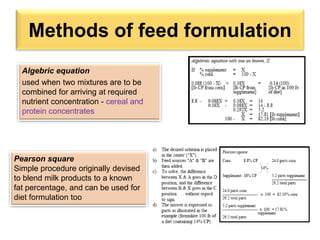

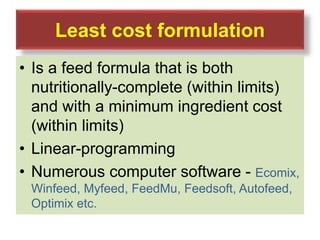

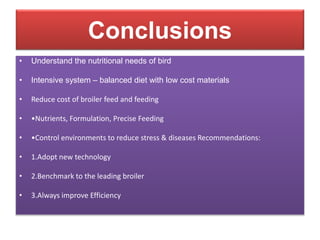

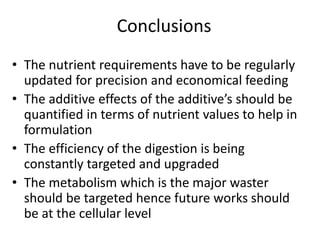

The document outlines poultry feeding procedures and management, emphasizing the importance of balanced diets tailored to different growth stages and production types to optimize efficiency, profitability, and welfare. It details the nutritional requirements for energy, amino acids, vitamins, and minerals, along with feeding strategies for various poultry production systems including intensive, semi-intensive, and backyard farming. Additionally, it highlights the use of feed additives and computer applications for formulating cost-effective and nutritionally complete rations.