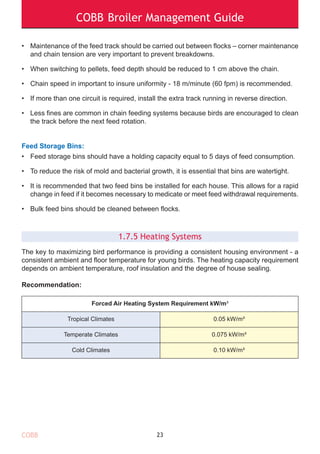

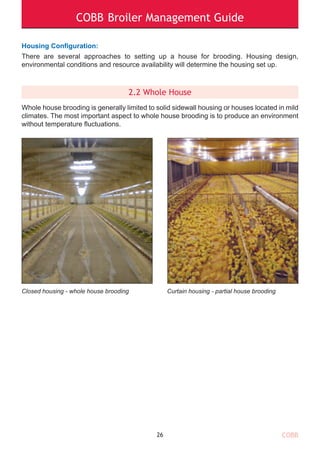

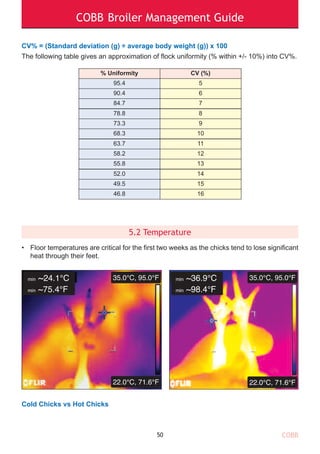

The Cobb Broiler Management Guide provides essential guidelines for optimizing broiler and broiler breeder production through effective management practices tailored to various housing and environmental conditions. It emphasizes the significance of a well-designed housing structure, including considerations for insulation, ventilation, and water management, to maximize the genetic potential of the birds. This guide serves as a comprehensive reference, incorporating key points and best practices based on scientific research and practical experience to help managers achieve consistent and optimal results.