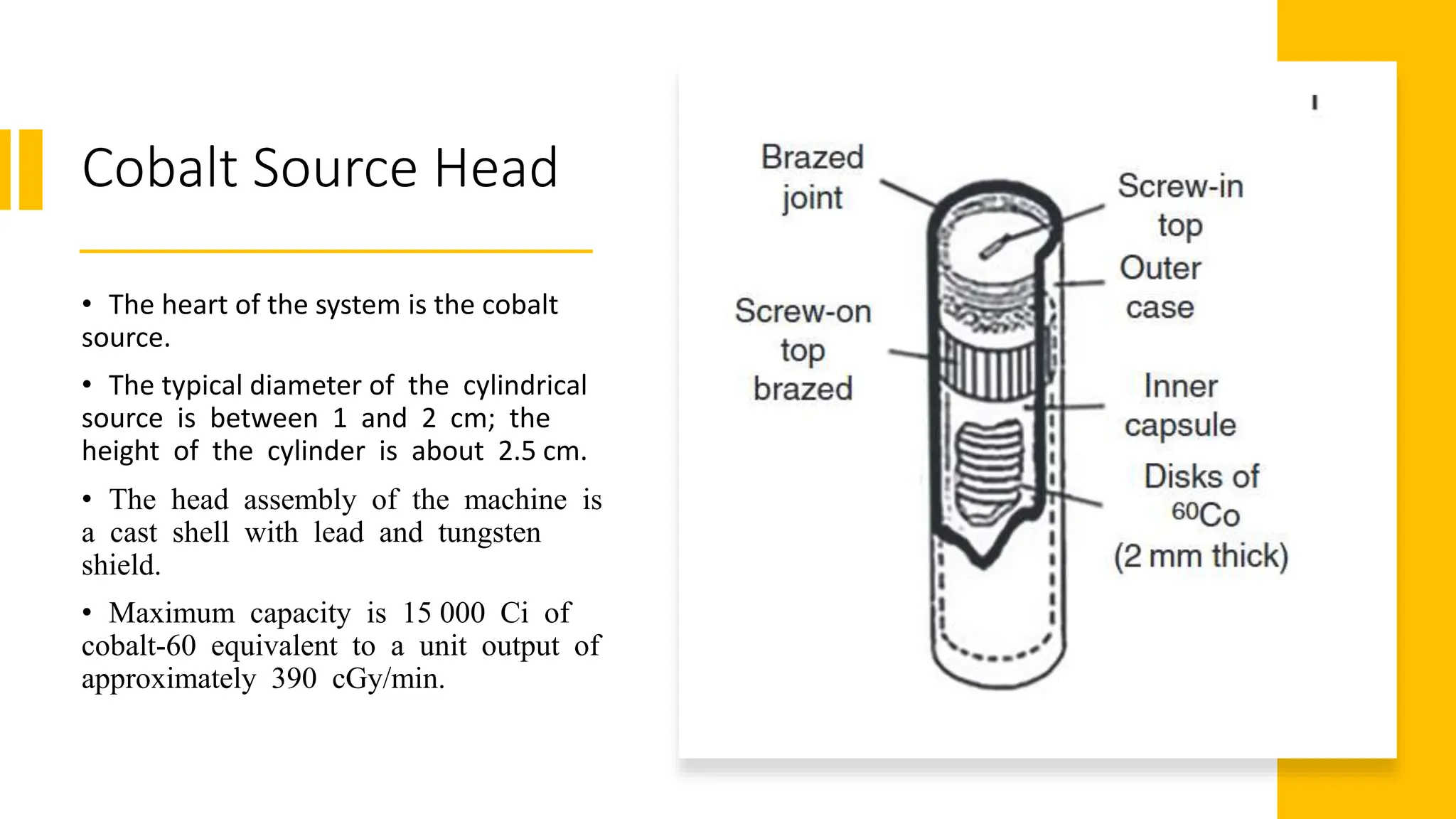

Cobalt-60 machines use a radioactive cobalt-60 source to emit gamma rays for external beam radiation therapy. They consist of a cobalt source head that can rotate around the patient on a gantry. Collimators are used to shape the radiation beam and a treatment table positions the patient. Controls allow adjusting beam angles and sizes from a shielded room. Cobalt-60 is widely used for cancer treatment due to its precision and effectiveness.