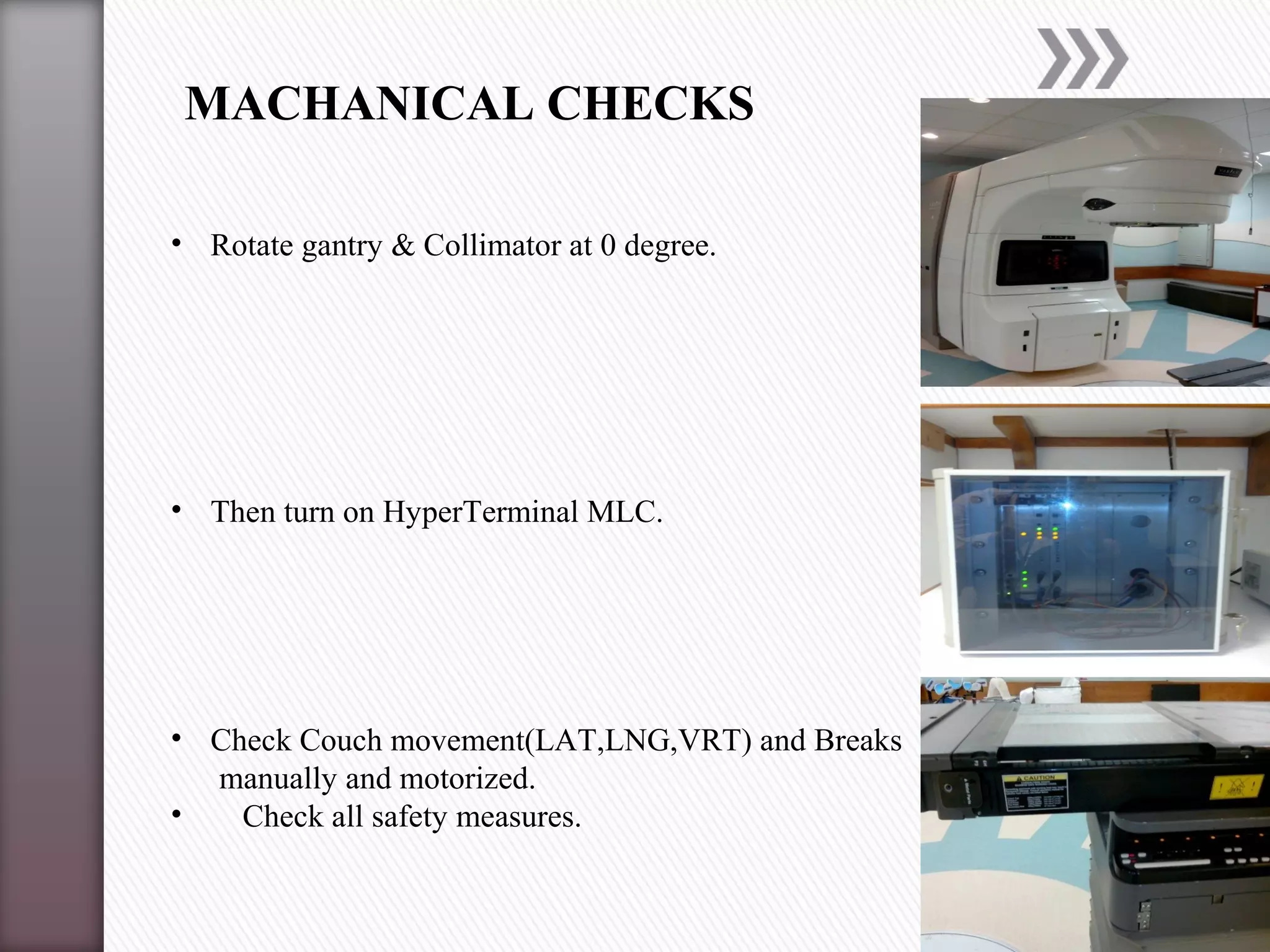

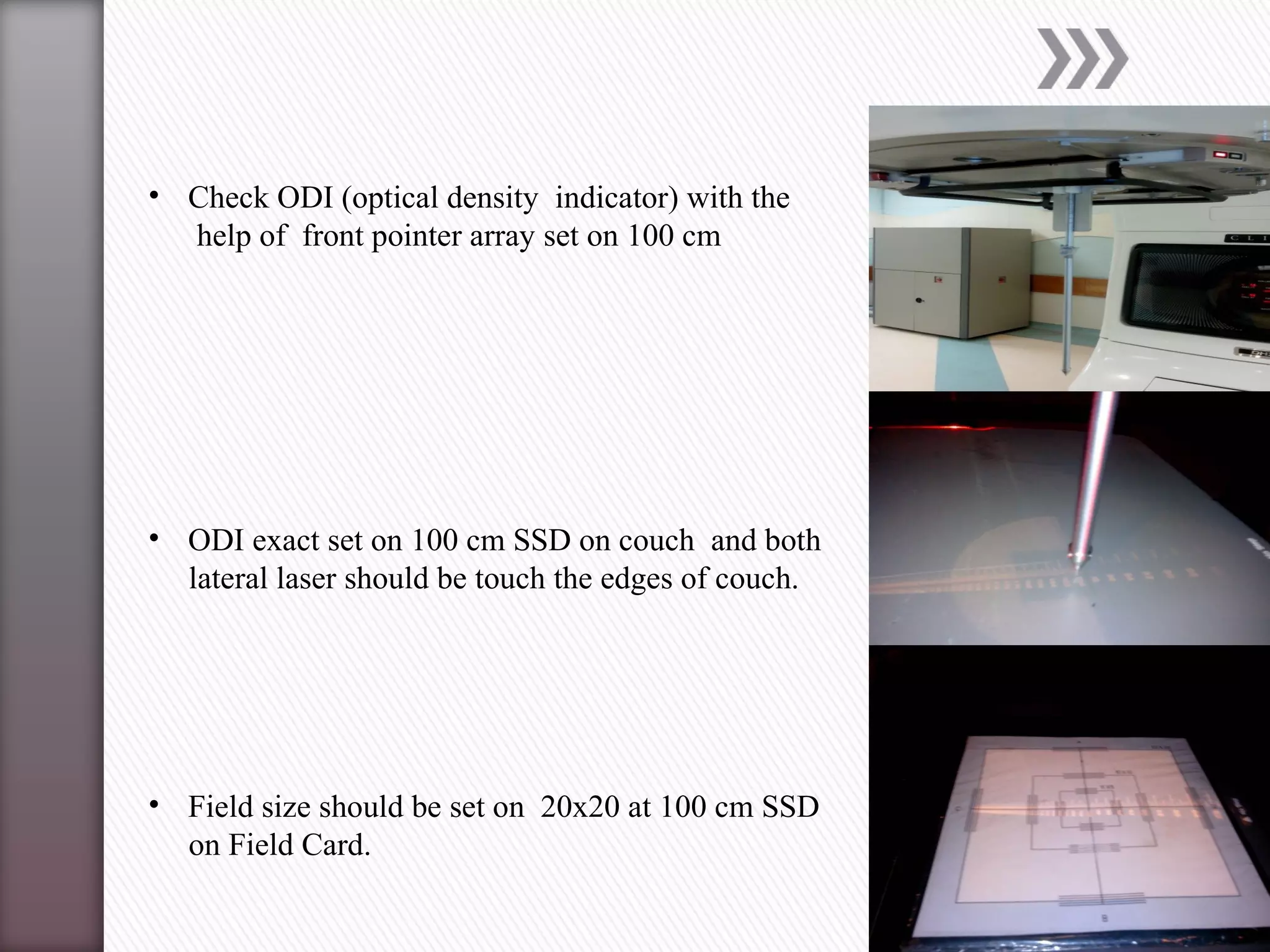

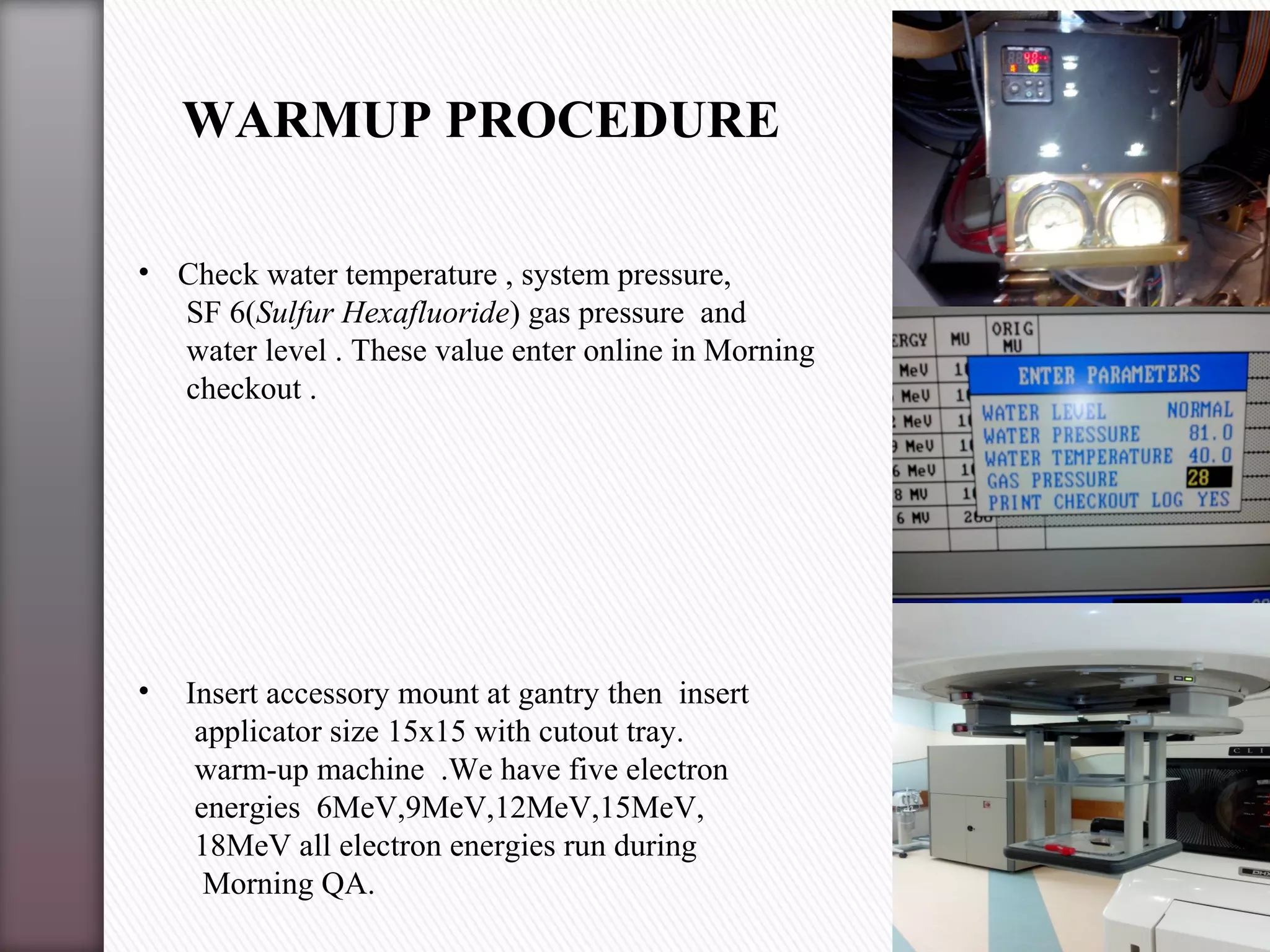

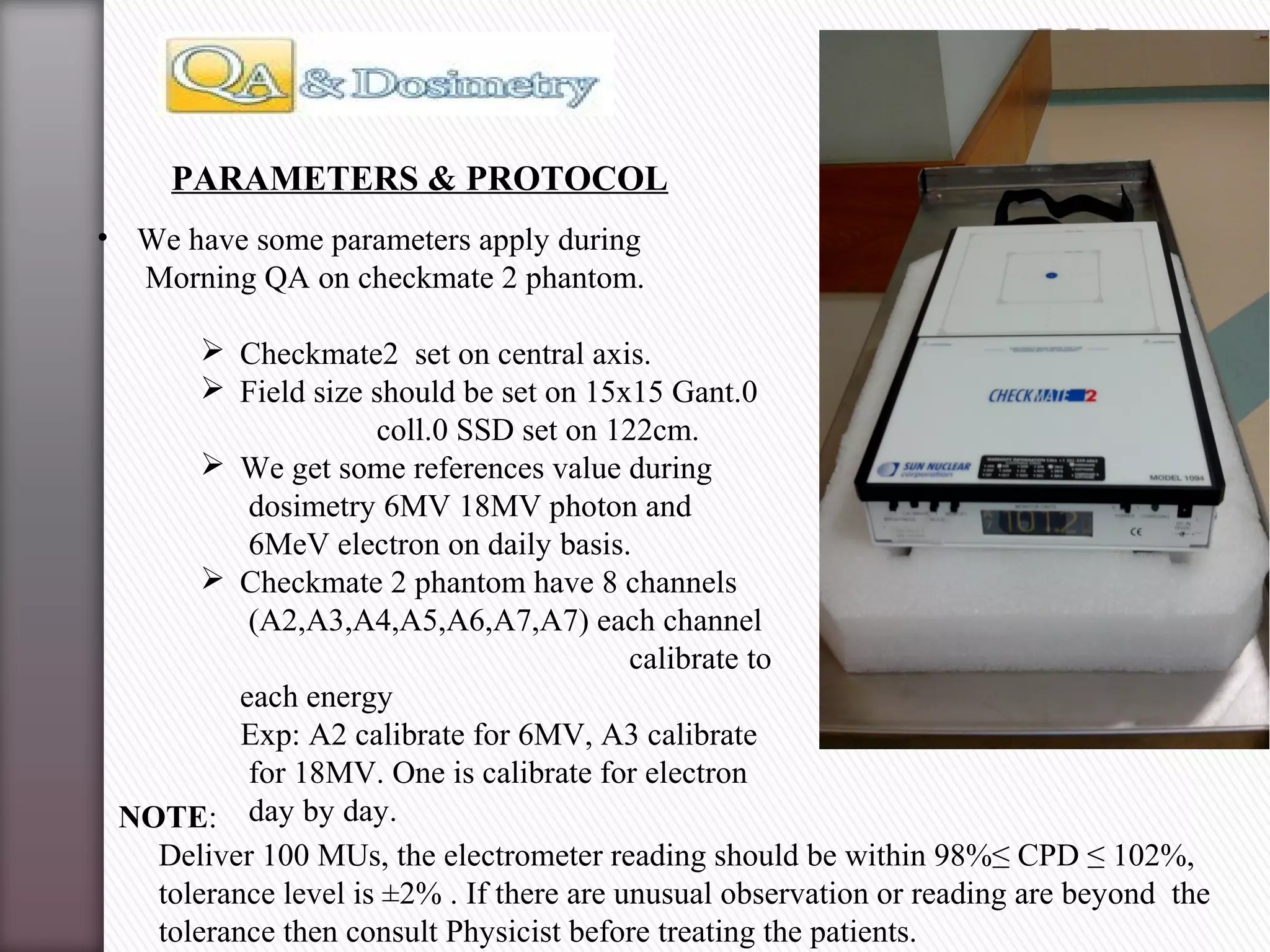

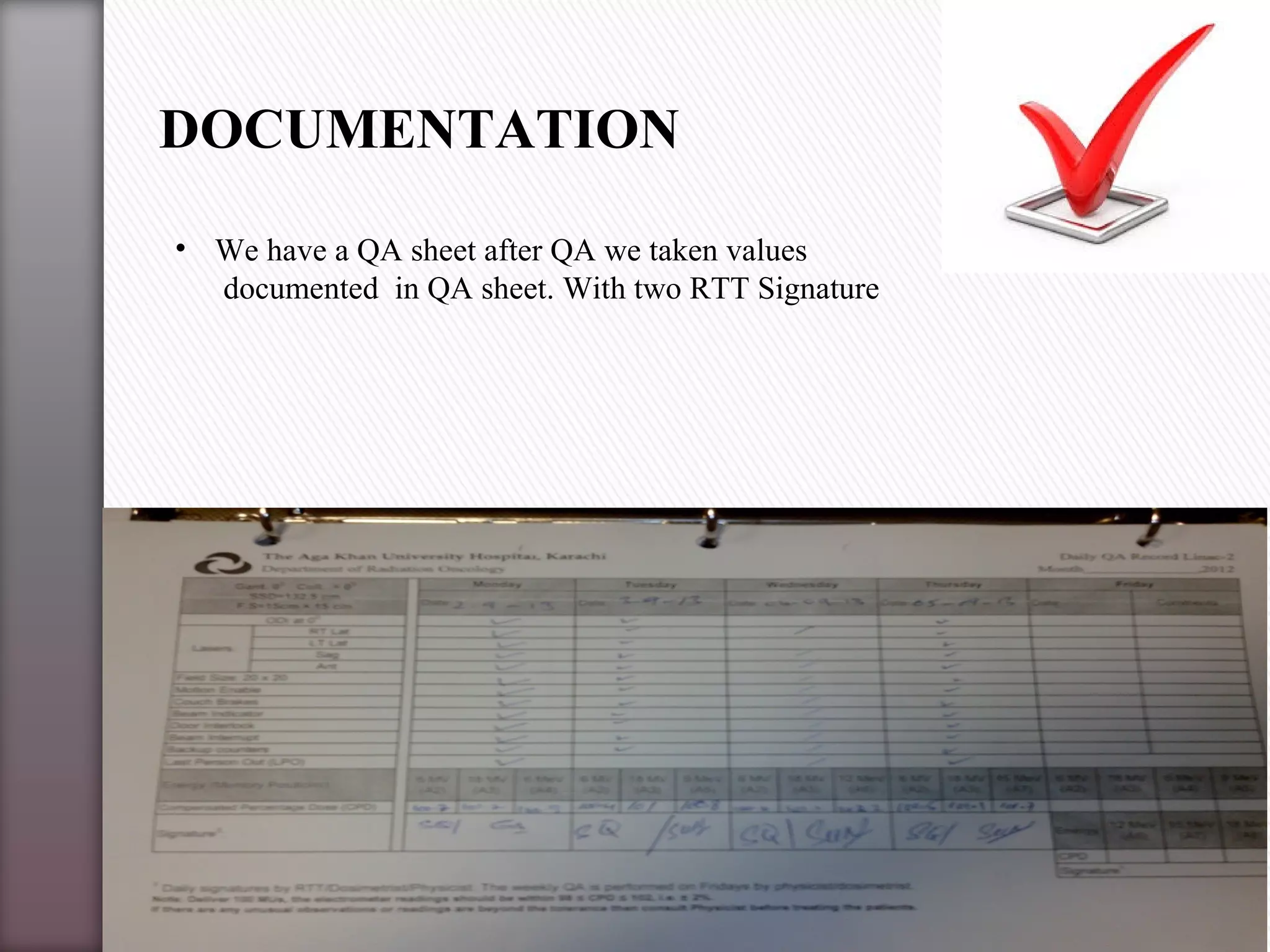

This document outlines the daily quality assurance procedure for a linear accelerator. It describes turning on the machine, performing mechanical checks like gantry and couch movement tests, warming up the machine using various electron and photon energies, and performing dosimetry measurements to ensure parameters are within tolerance levels. Results are documented in a QA sheet for record keeping. The purpose is to ensure consistent machine quality and patient safety by verifying proper dose delivery and checking for any mechanical or software errors.