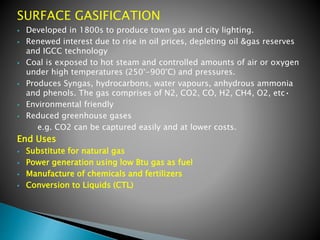

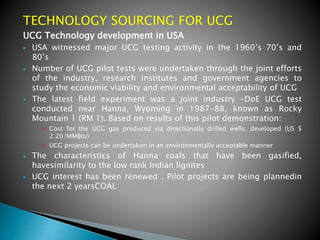

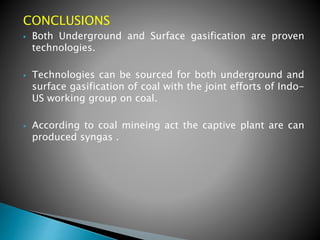

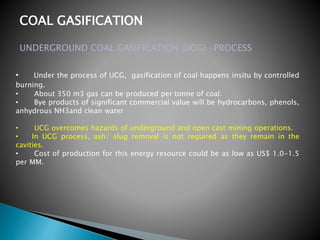

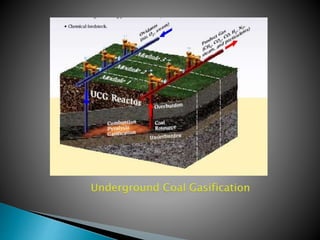

The document discusses coal gasification, including underground coal gasification (UCG) and surface coal gasification. UCG involves injecting oxygen and steam into underground coal seams to produce synthesis gas. Surface gasification involves exposing coal to steam and controlled oxygen on the surface. Both technologies produce a mixture of hydrogen, carbon monoxide, and other gases that can be used as fuel or processed further. The document examines the advantages of UCG such as accessing deep coal reserves and reduced environmental impacts compared to mining. It also discusses sourcing gasification technologies and the need for regulatory frameworks to allow gasification of coal resources.

![POTENTIAL END USE MARKETS FOR UCG

RESOURCES INSITU

UCG

AIR INJECTION

STEAM / OXYGEN

INJECTION

Nitrogen50% CO, H2, CH4,

CO2100-180 BTU/ SCF

COAL

100% CO, H2, CH4, CO2200-

300 BTU/ SCF

Electrical power generation

&Industrial Fuel100-180 BTU / SCF

CO2Removal CO shift and

Methanation

Synthesis

Gas(Chemical

Feedstock)300-400

BTU / SCF

]

Synthetic Pipeline

Gas900 -1000 BTU /

SCF50](https://image.slidesharecdn.com/coalgasificationsimanchal-170222101028/85/Coal-gasification-9-320.jpg)