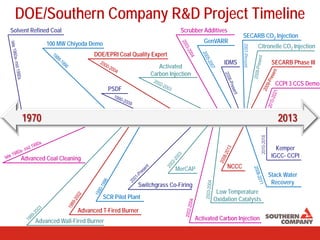

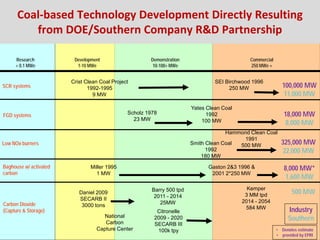

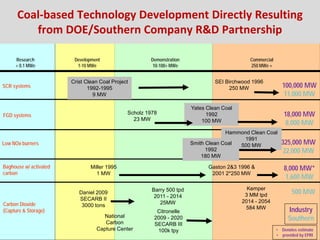

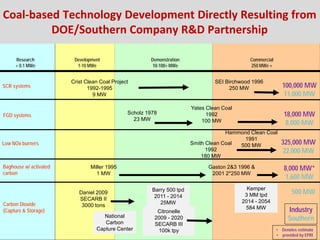

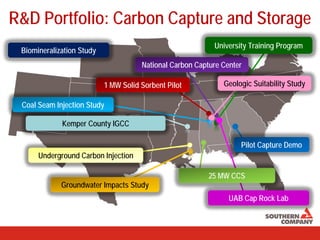

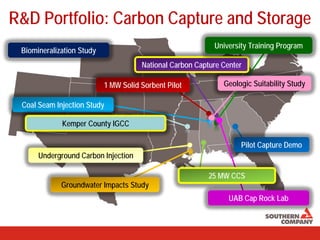

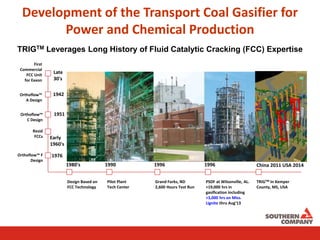

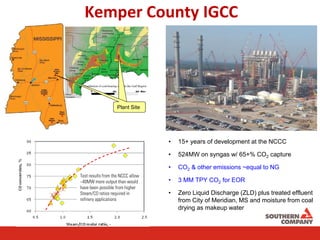

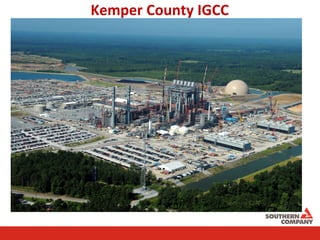

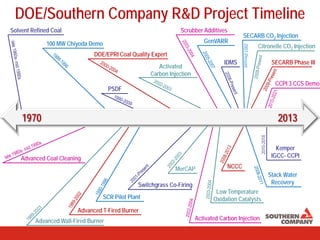

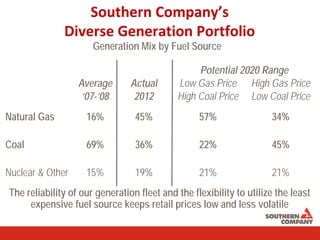

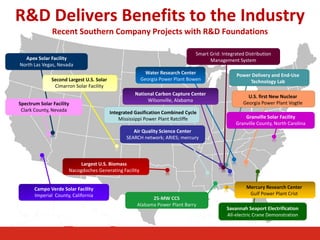

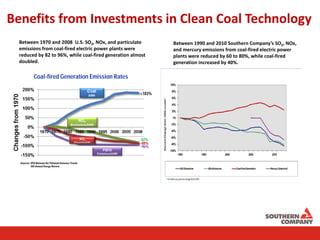

The document outlines Southern Company's advancements in fossil energy technologies through collaborations and a diversified research and development (R&D) portfolio focused on clean coal and carbon capture. It highlights key projects from 1970 to 2013, showcasing various technologies and their impact on reducing emissions and optimizing energy generation. Southern Company's efforts have significantly lowered emissions while increasing coal-fired generation capacity.