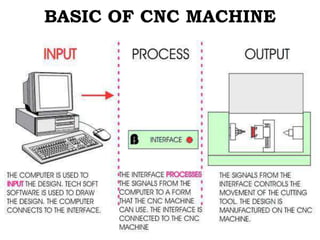

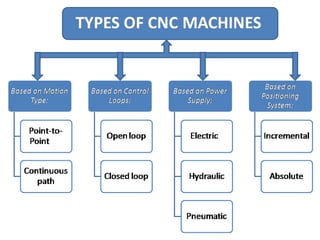

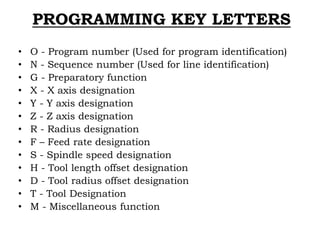

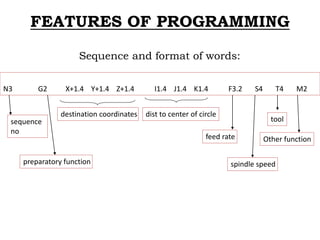

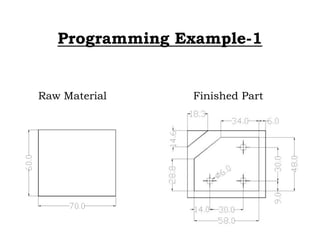

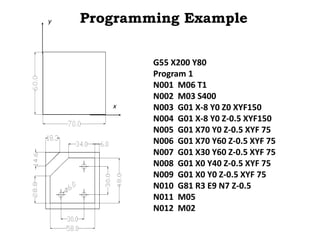

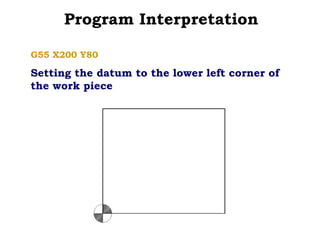

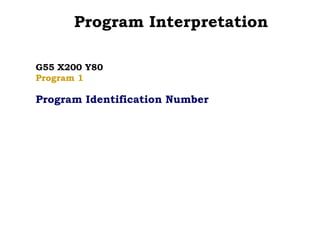

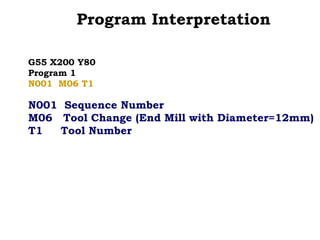

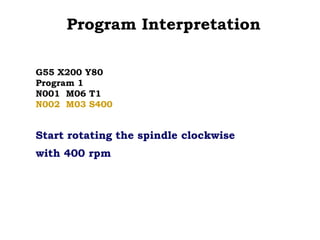

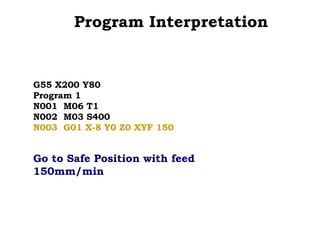

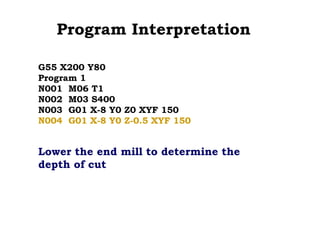

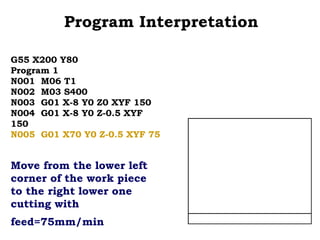

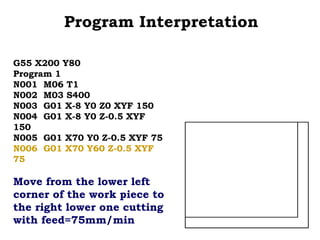

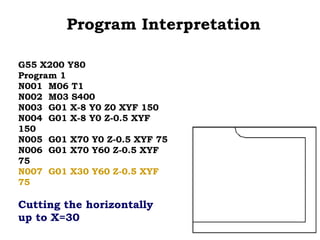

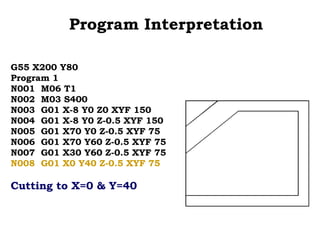

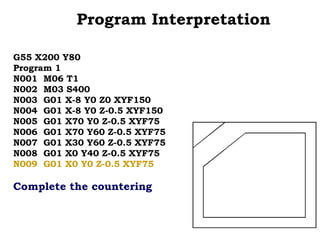

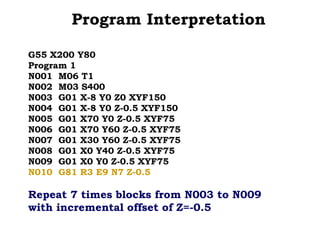

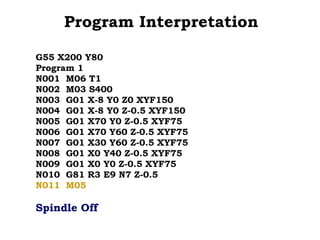

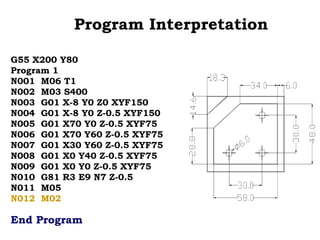

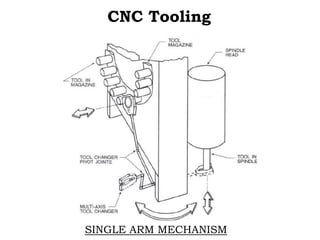

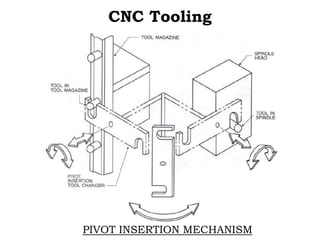

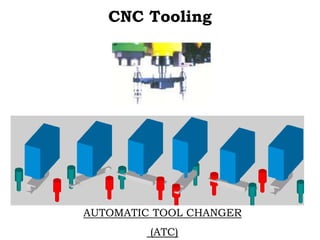

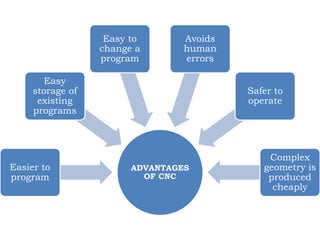

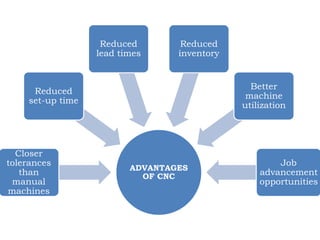

The document explains the fundamentals of CNC (Computer Numerical Control) machines, detailing their programming structure and key functions for controlling the cutting and shaping of materials. It describes various programming commands, their meanings, and includes a programming example with interpretations for clarity. Additionally, it highlights the advantages of CNC technology, such as improved tolerances, reduced setup times, and enhanced machine utilization.