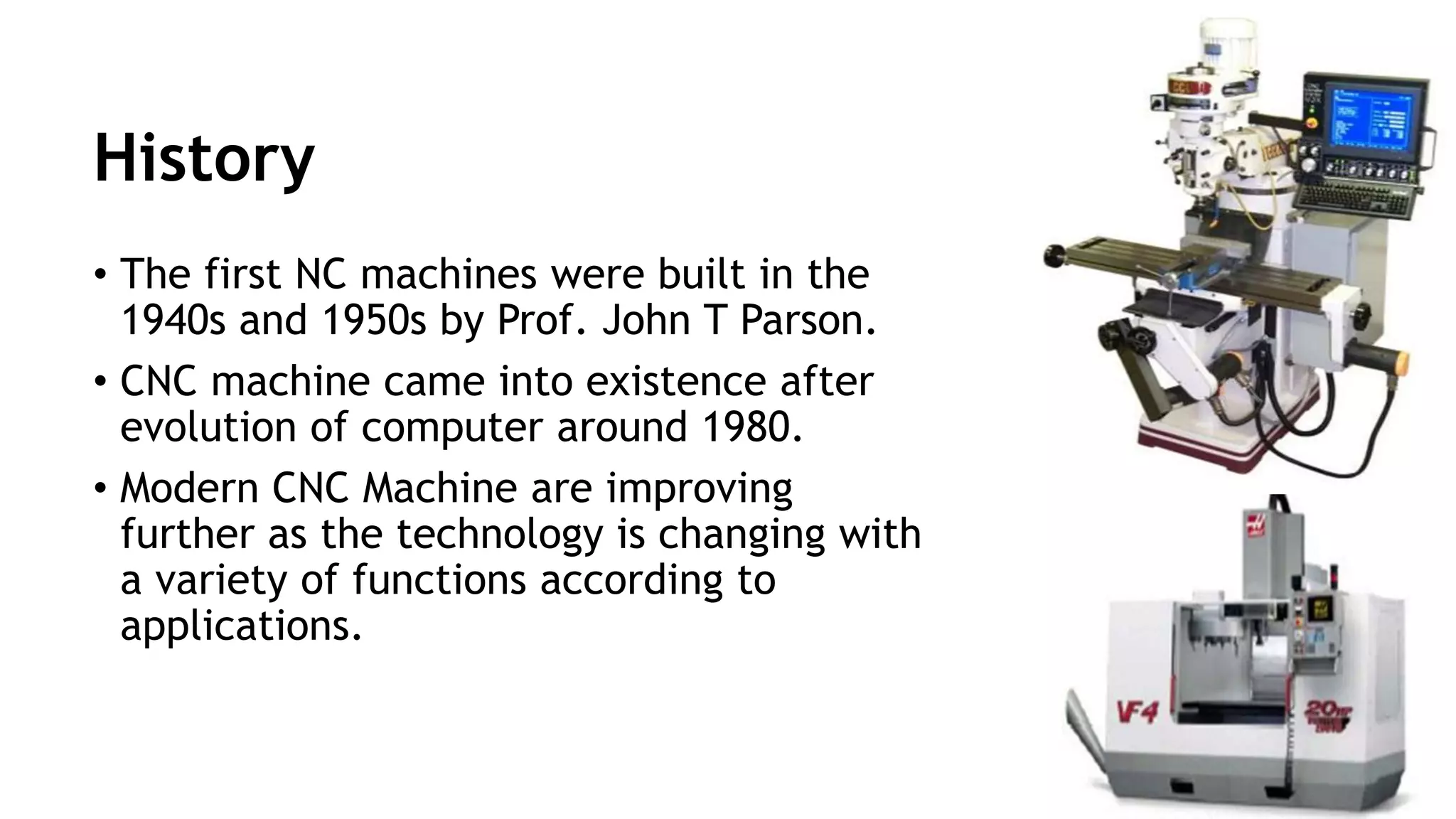

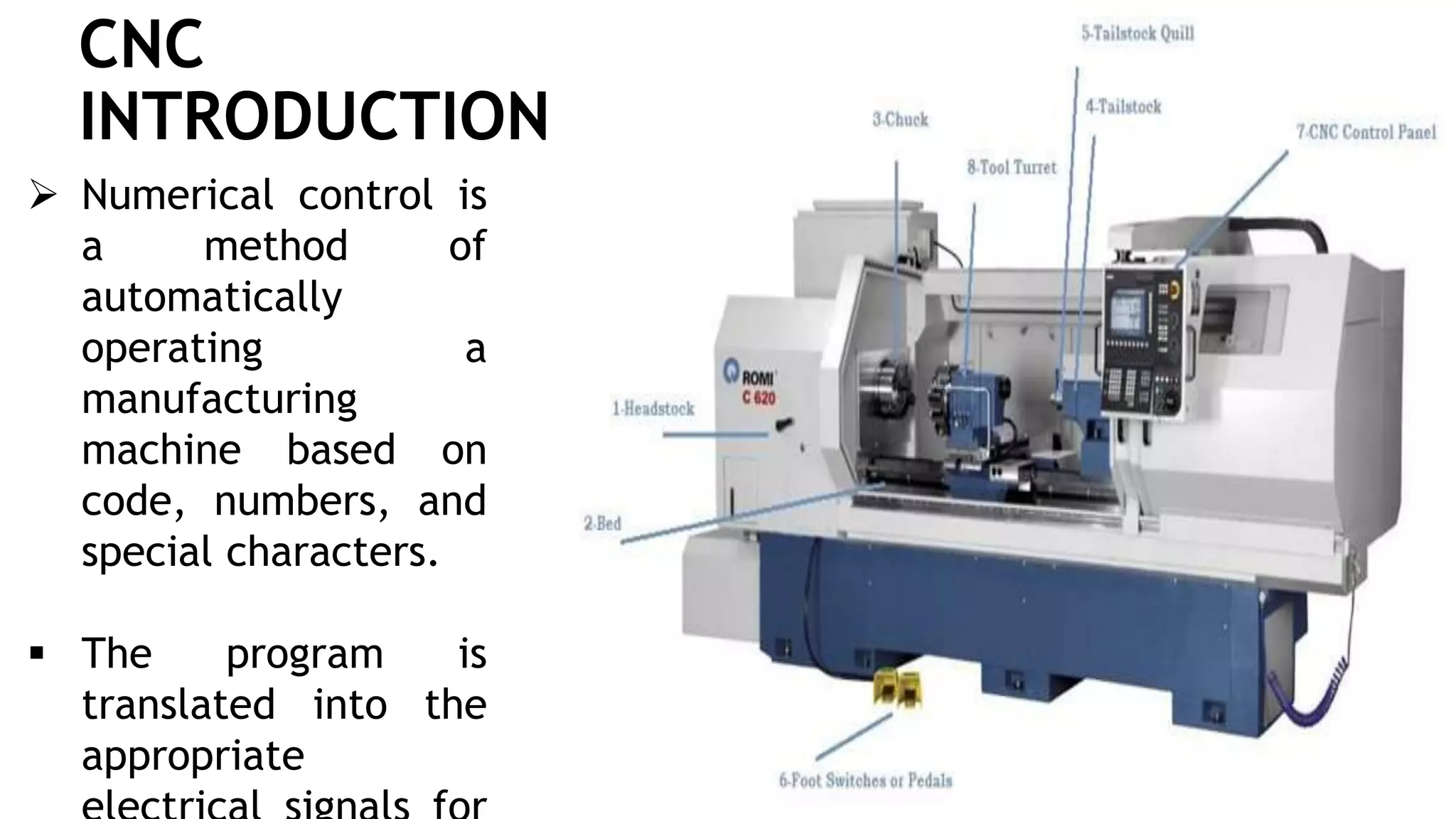

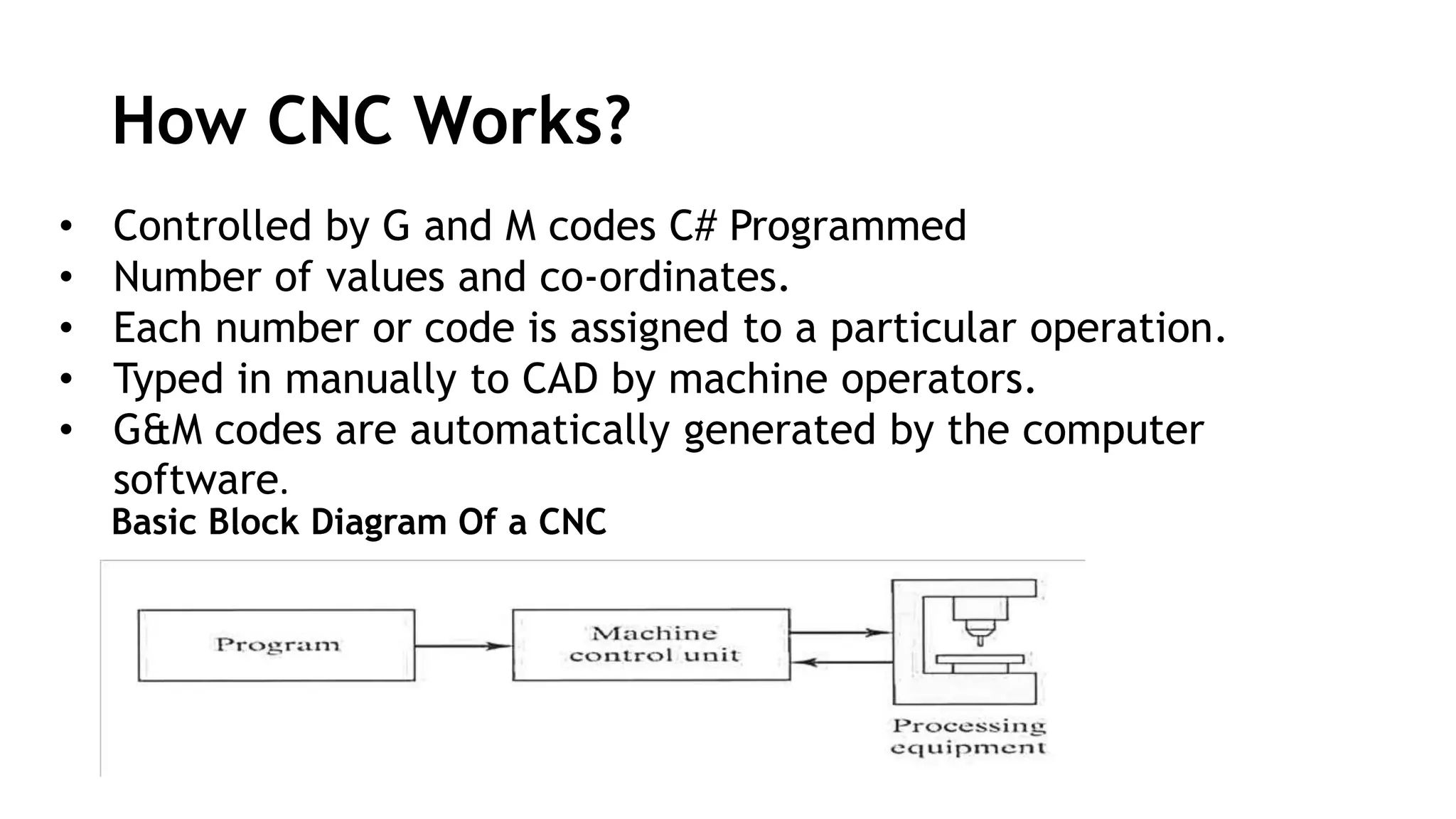

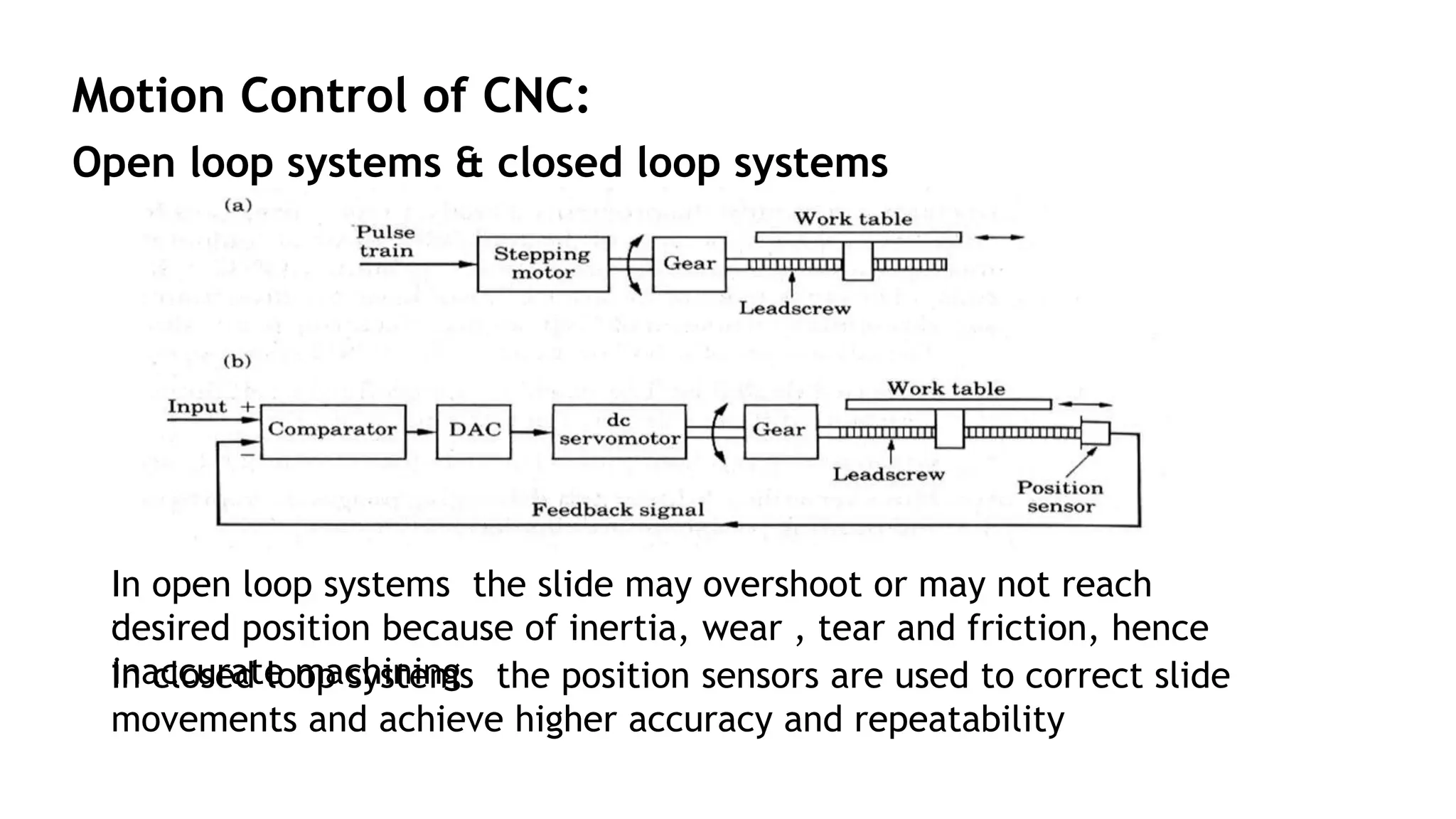

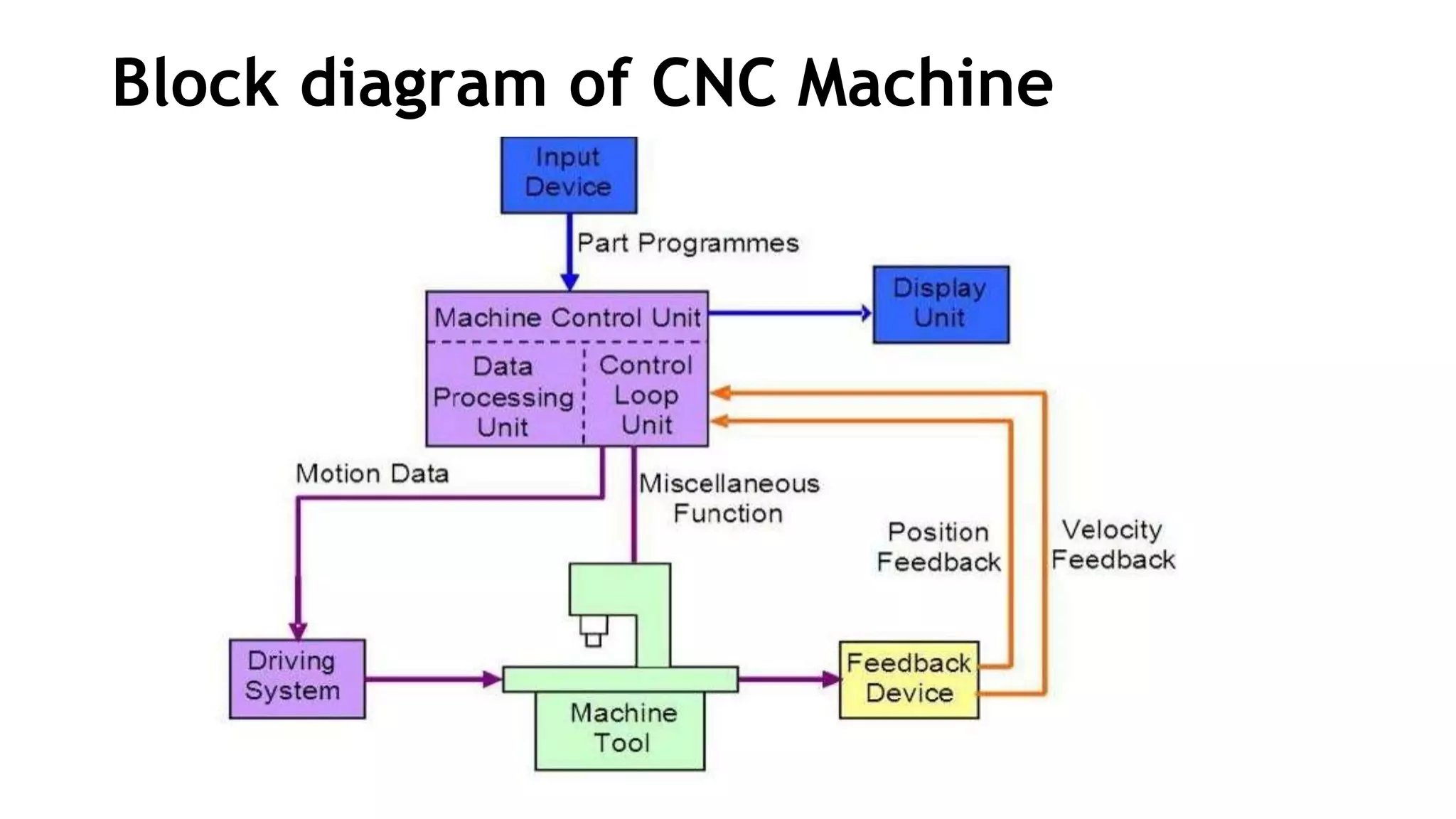

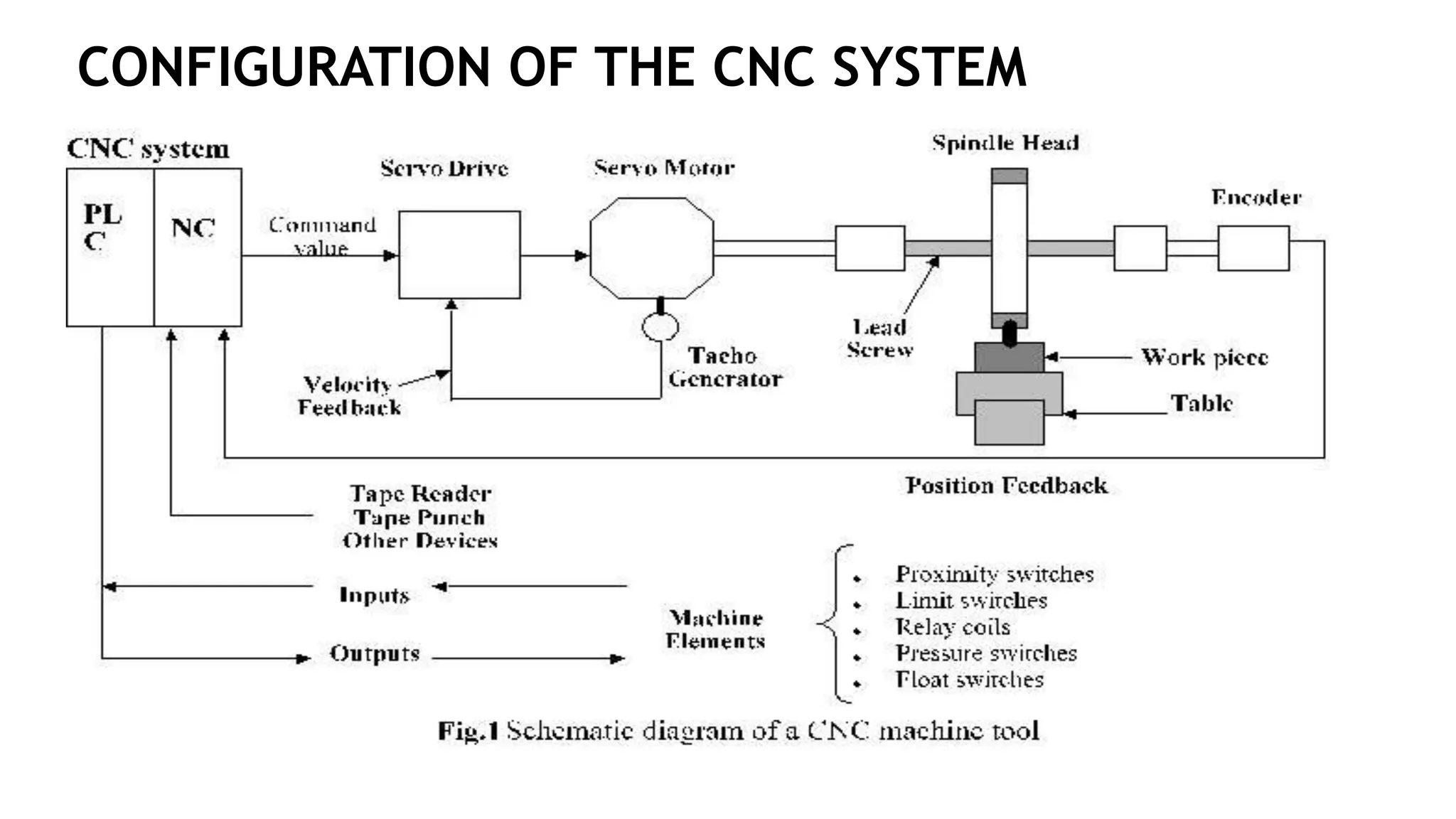

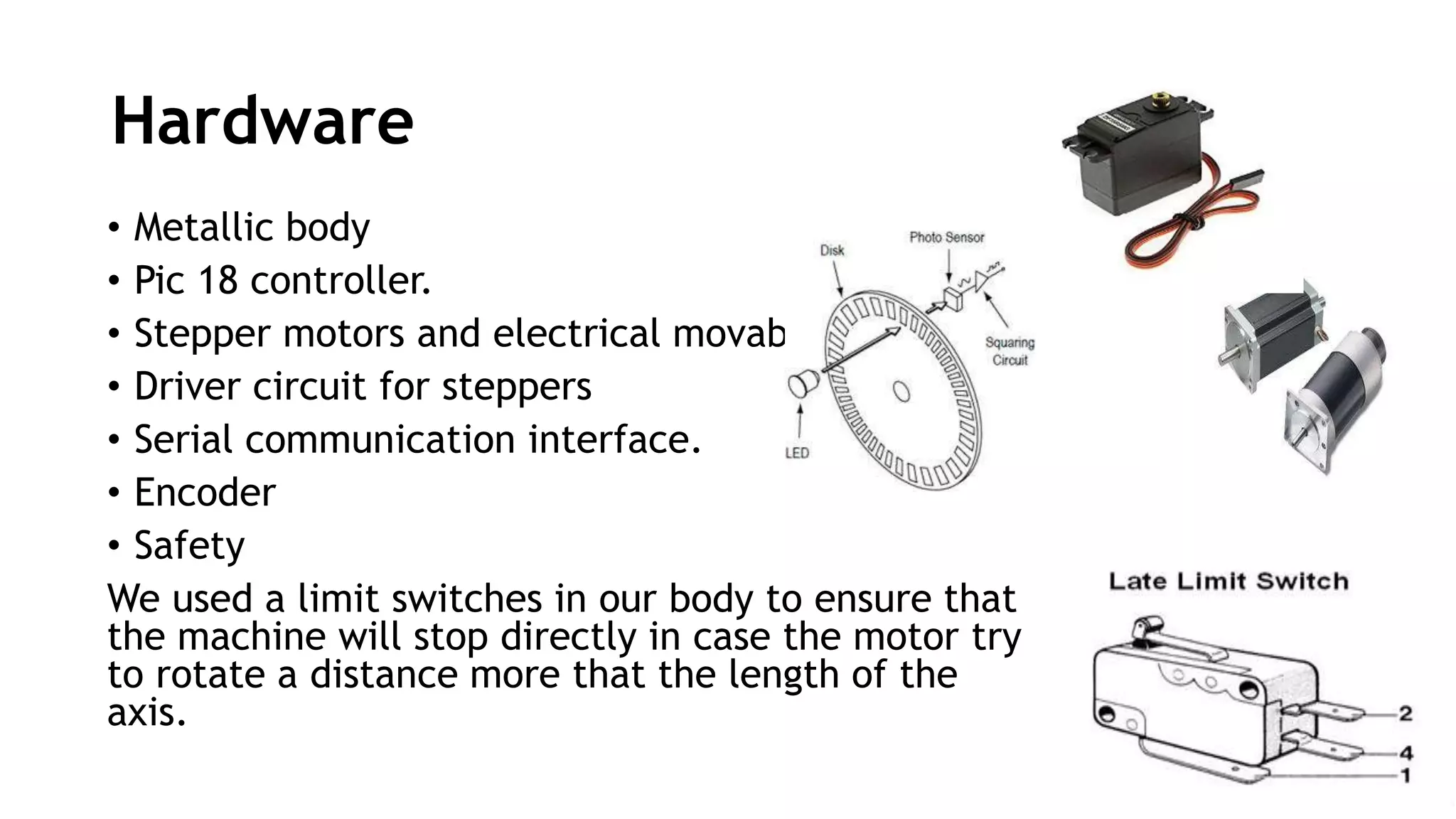

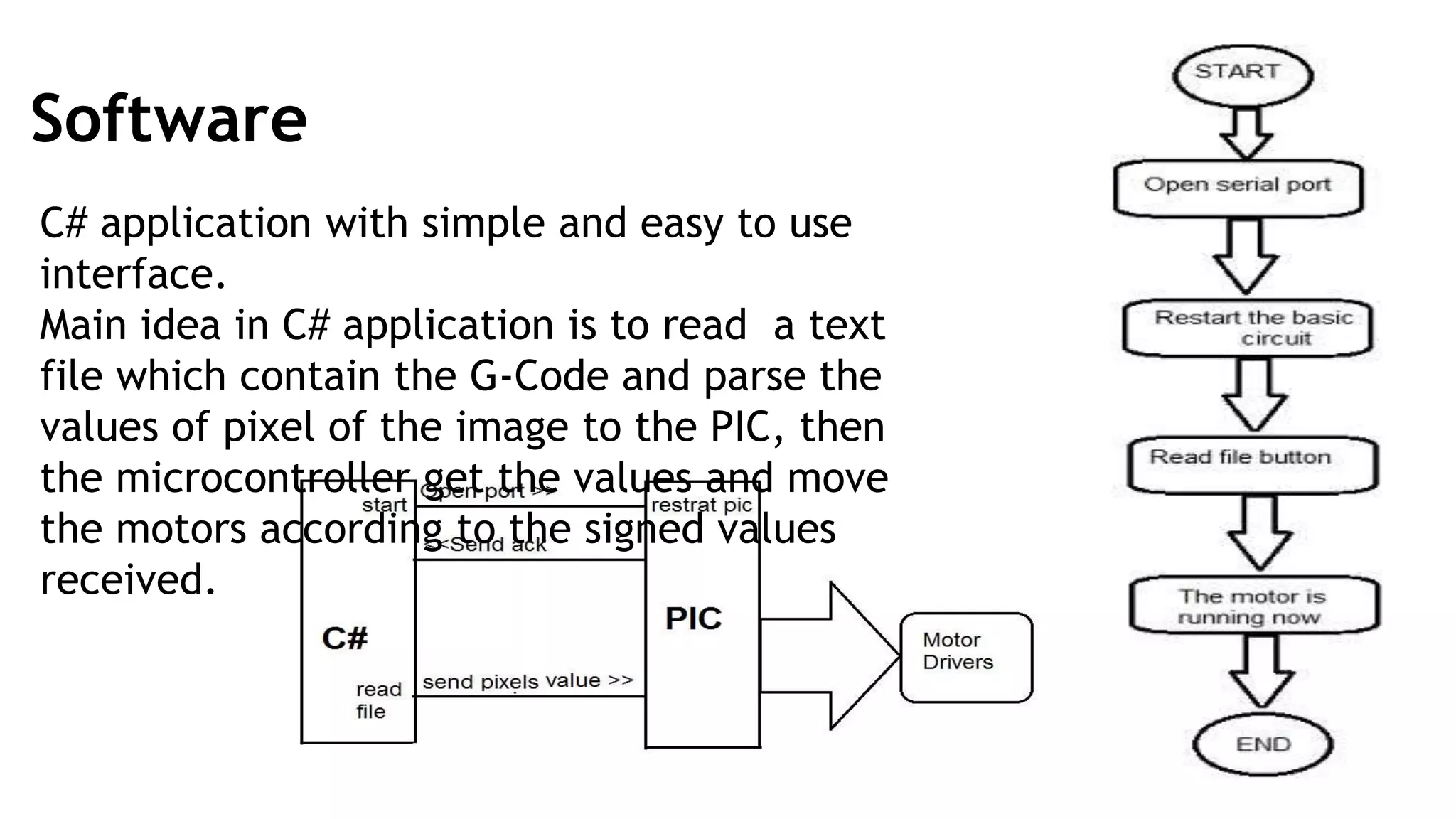

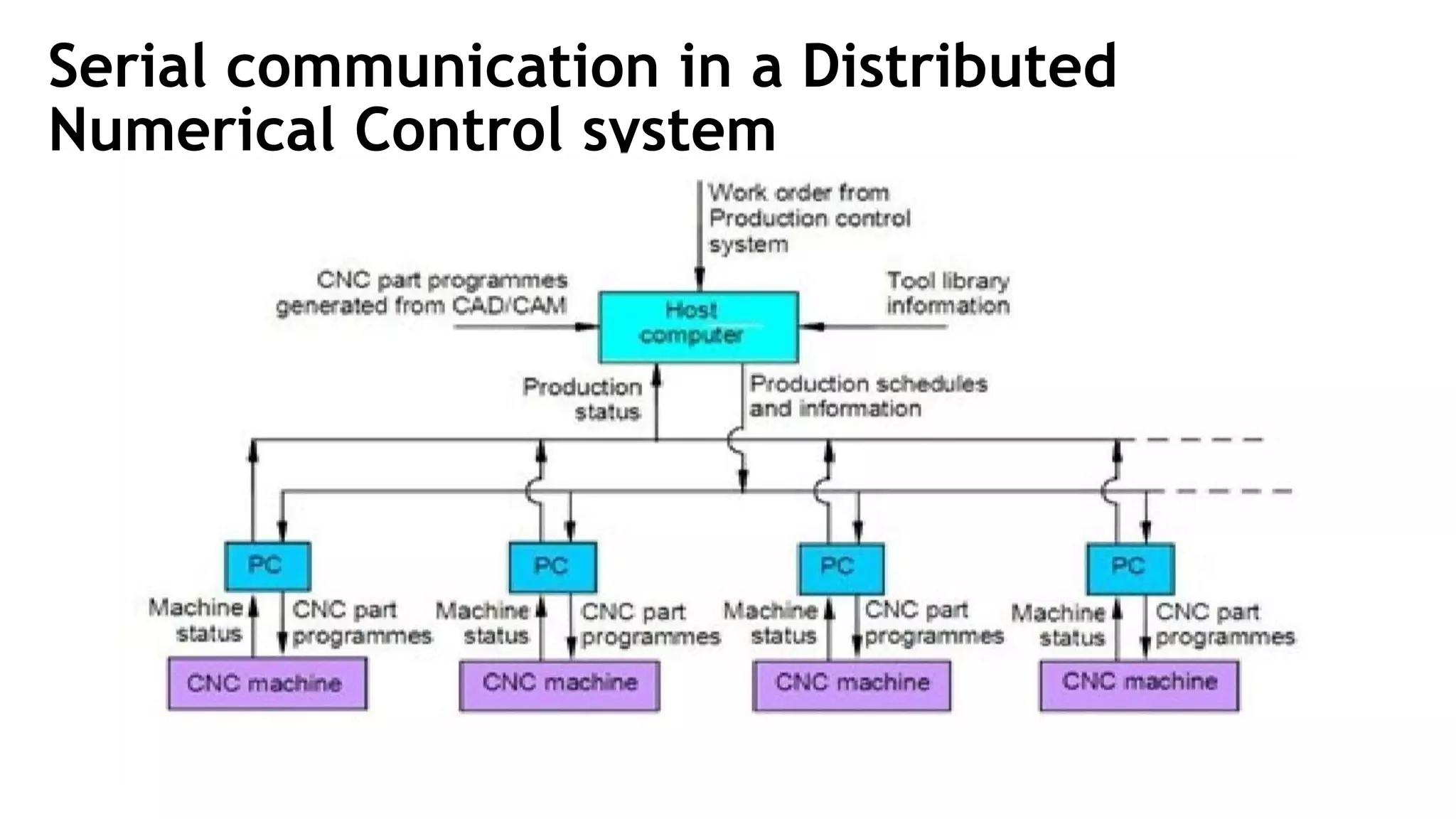

This presentation discusses Computer Numeric Control (CNC) machines, detailing their history, functionality, key components, and advantages and disadvantages. CNC machines, which evolved from numerical control in the mid-20th century, enhance production efficiency and accuracy while offering flexibility in manufacturing. The presentation underscores the importance of CNC in modern factories for achieving precise and high-volume production goals.

![References:

[1]

http://www.brighthubengineering.com/manufacturing-

technology/55787-what-is-the-cnc-machine-how-cnc-

machine-works/

[2] https://www.okuma.com/cnc-machine-tool-lineup

[3] http://hongyumold.en.made-in-china.com/

[4] https://wiki.mcneel.com/rhino/cncbasics

[5] https://www.mmsonline.com/articles/key-cnc-

concept-9the-key-sequences-of-operation](https://image.slidesharecdn.com/cncpresentationps-180417134349/75/CNC-Presentation-18-2048.jpg)