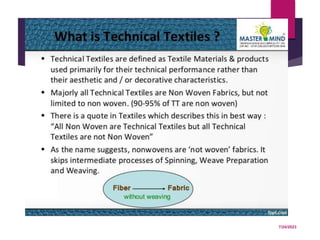

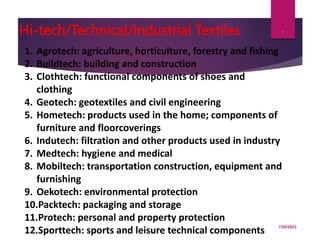

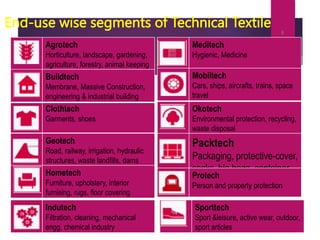

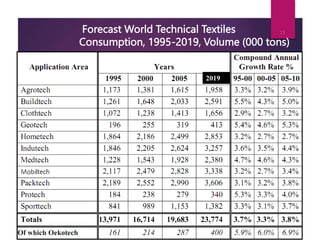

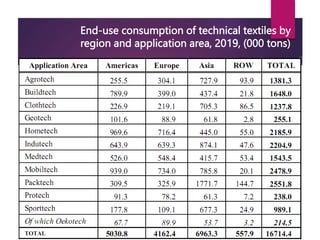

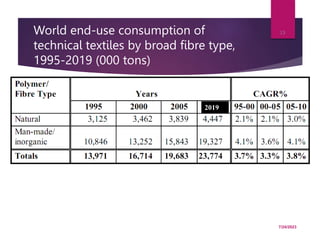

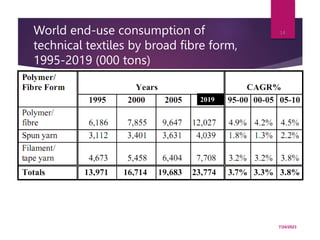

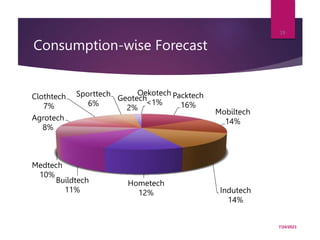

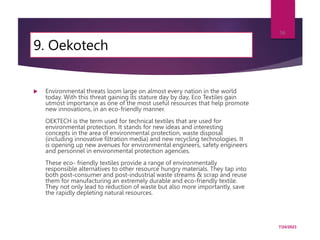

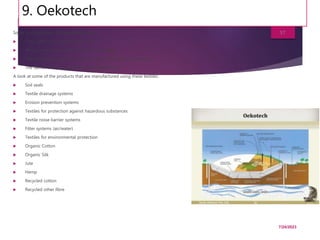

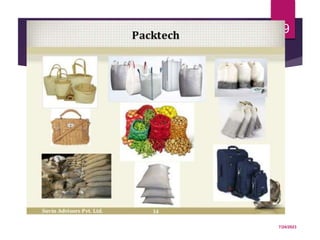

The document discusses various categories and applications of technical textiles. It begins by defining technical textiles as textile products used principally for their performance characteristics rather than aesthetics. It then describes 12 categories of technical textiles including agrotech, buildtech, clothtech, geotech, hometech, indutech, medtech, mobiltech, oekotech, packtech, protech and sporttech. Each category is used for different industrial and non-consumer applications. The document provides examples of applications and functional properties for some of these categories.