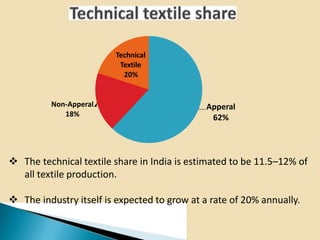

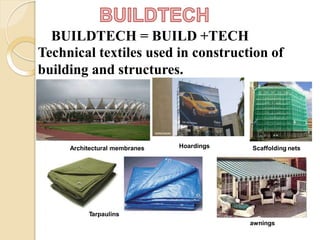

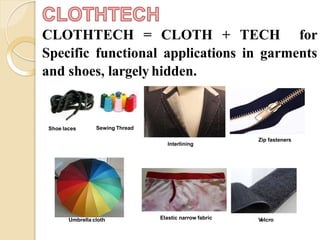

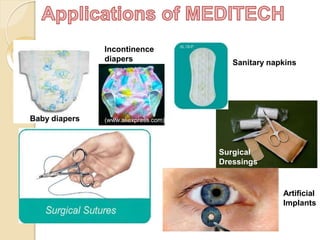

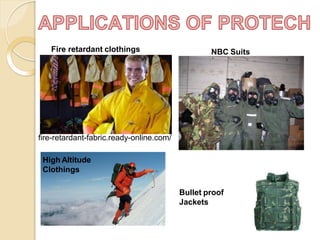

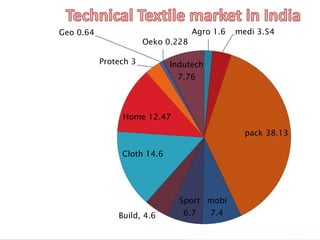

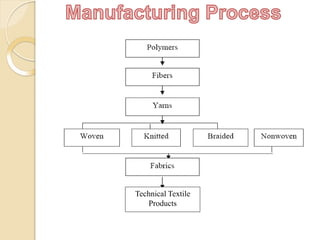

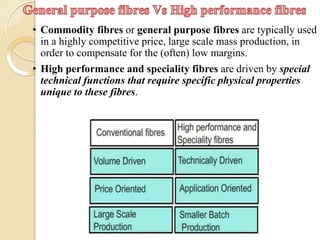

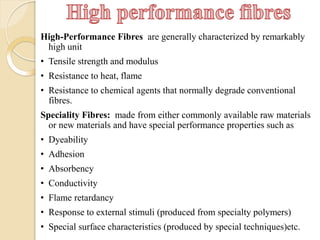

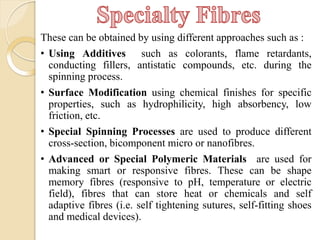

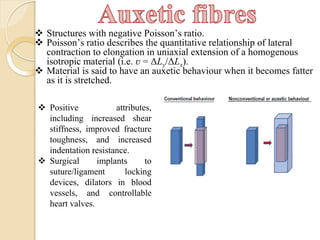

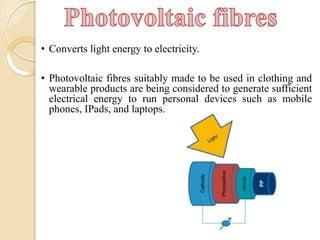

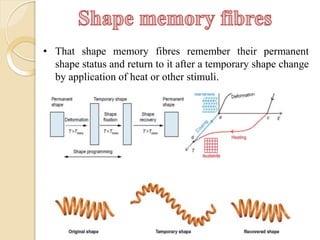

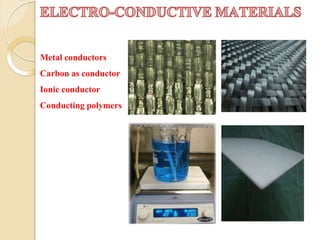

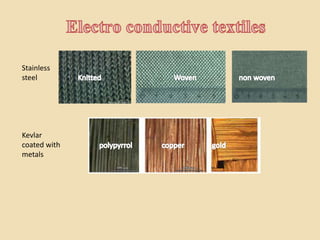

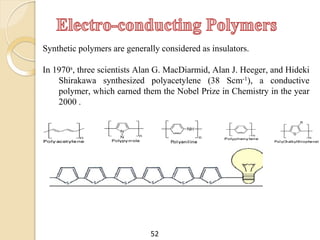

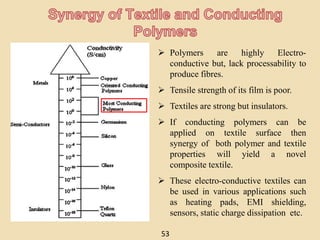

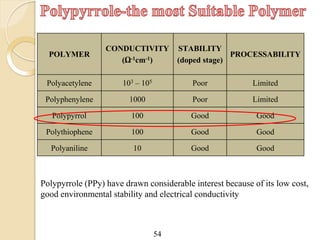

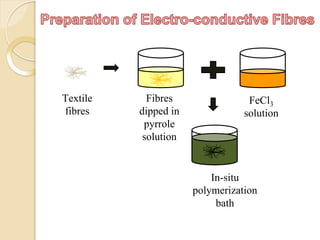

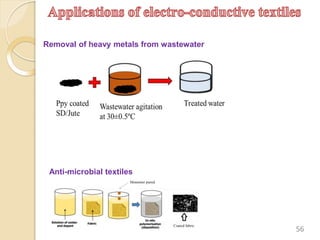

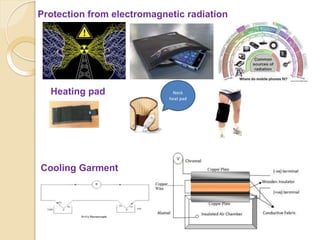

This document discusses technical textiles and their applications. It begins by defining technical textiles as textile materials manufactured for their functional properties rather than aesthetics. It then estimates technical textiles comprise 11.5-12% of Indian textile production. The document categorizes technical textiles into 12 categories including agrotech, buildtech, clothtech, etc. and provides examples for each category. It discusses properties of high-performance fibers and specialty fibers used in technical textiles. The document also covers topics like nanofibers, auxetic materials, conductive fibers, and smart or responsive fibers.