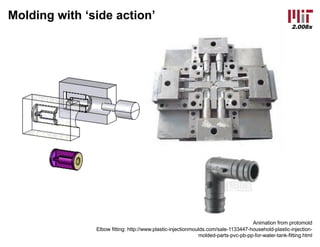

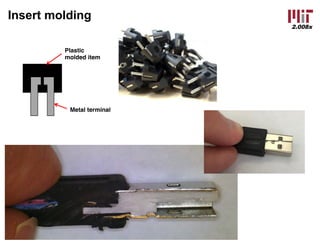

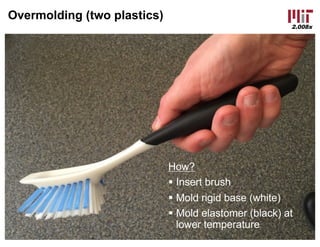

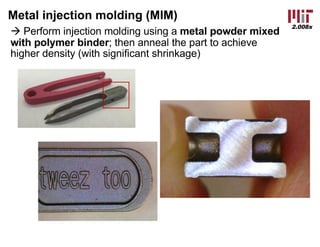

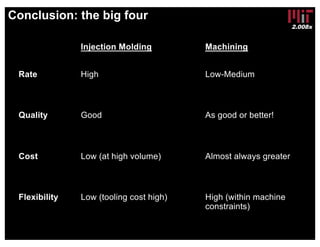

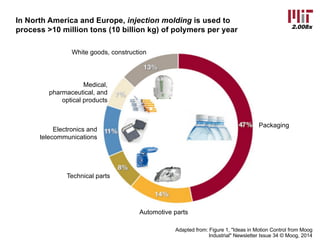

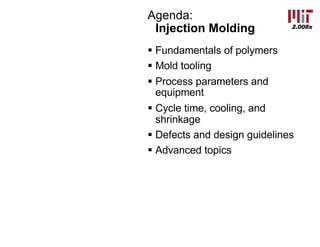

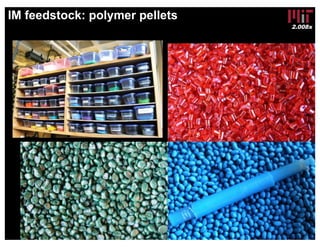

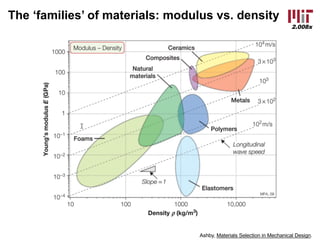

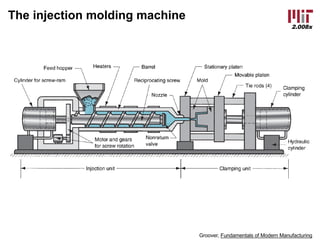

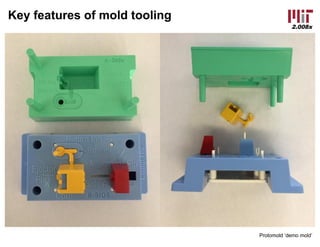

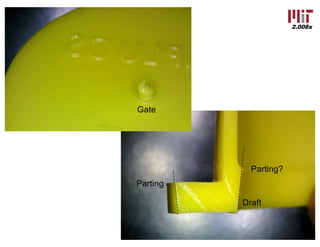

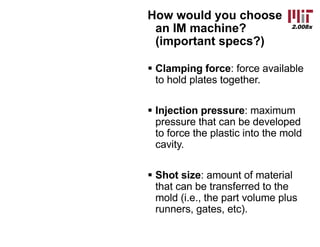

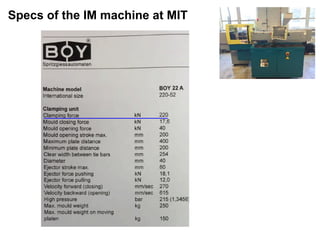

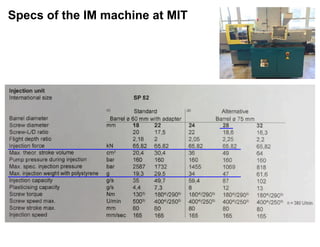

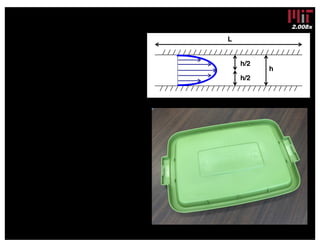

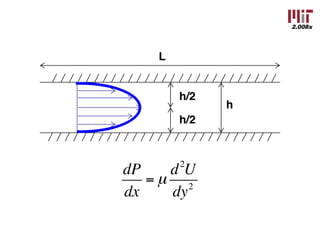

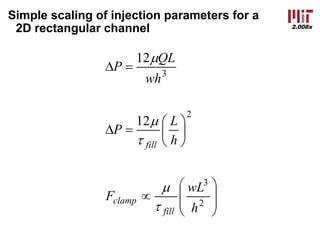

The document discusses injection molding. It begins with an overview of injection molding and the types of products made through the process. It then covers the fundamentals of polymers used in injection molding, including their properties and how they behave under heat and pressure. The document outlines the key components of injection molding machines and mold tooling, and reviews the injection molding process parameters and how they impact the filling and cooling cycles. It also discusses common defects and guidelines for part design. Advanced topics covered include side-action molding, insert molding, and overmolding.

![2.008x

Plastics: 1950-2014

Data from Statista

http://www.statista.com/statistics/282732/global-production-of-plastics-since-1950/

0

50

100

150

200

250

300

350

1950 1960 1970 1980 1990 2000 2010 2020

Volume[millionmetrictons]

Year](https://image.slidesharecdn.com/008xim-compressed-161031140221/85/Injection-Molding-MIT-2-008x-Lecture-Slides-3-320.jpg)

![2.008x

Kalpakjian and Schmid, Manufacturing Engineering and Technology

Groover, Fundamentals of Modern Manufacturing

Poly (many) + mer (structural unit)

-[C2H4]n- = poly[ethylene]](https://image.slidesharecdn.com/008xim-compressed-161031140221/85/Injection-Molding-MIT-2-008x-Lecture-Slides-11-320.jpg)

![2.008x

Viscosity: resistance to shear

*at typical injection shear rate and melt temperature

Material Dynamic viscosity

Water (room temp) 1×10-3 kg/m-s [Pa-s]

Honey 10

Liquid thermoplastic* 102-103

Molten aluminum (600 C) 3×10-3

y

U

¶

¶

= µt

Ux(H) = Ux

Ux(y)

Ux(0) = 0

h

Ux

x

y](https://image.slidesharecdn.com/008xim-compressed-161031140221/85/Injection-Molding-MIT-2-008x-Lecture-Slides-20-320.jpg)

![2.008x

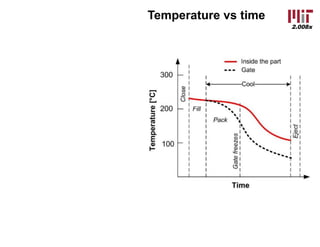

Pack

Close

Fill

Eject

Gatefreezes

Time

Pressure[MPa] 5

10

15

Cool

Cycle time

Pressure vs time](https://image.slidesharecdn.com/008xim-compressed-161031140221/85/Injection-Molding-MIT-2-008x-Lecture-Slides-55-320.jpg)