The document discusses stores management in hospitals. It covers key topics like the functions and importance of stores, factors to consider for location and layout of stores, storage methods, and codification of items. The main points are:

1. Stores play a vital role in hospital operations by providing supplies to user departments and ensuring uninterrupted services. Proper storage, inventory management, and issue of items are some core functions.

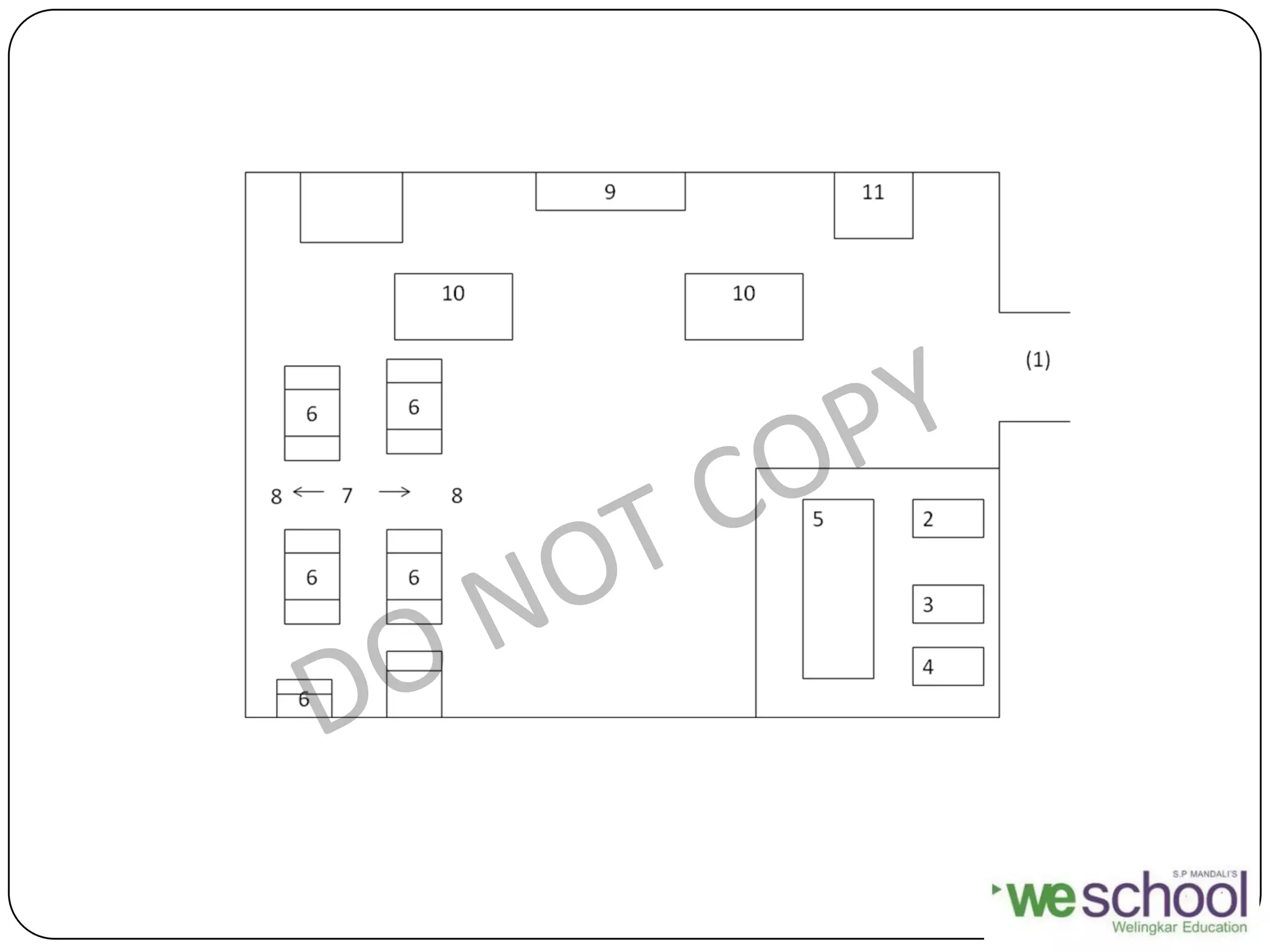

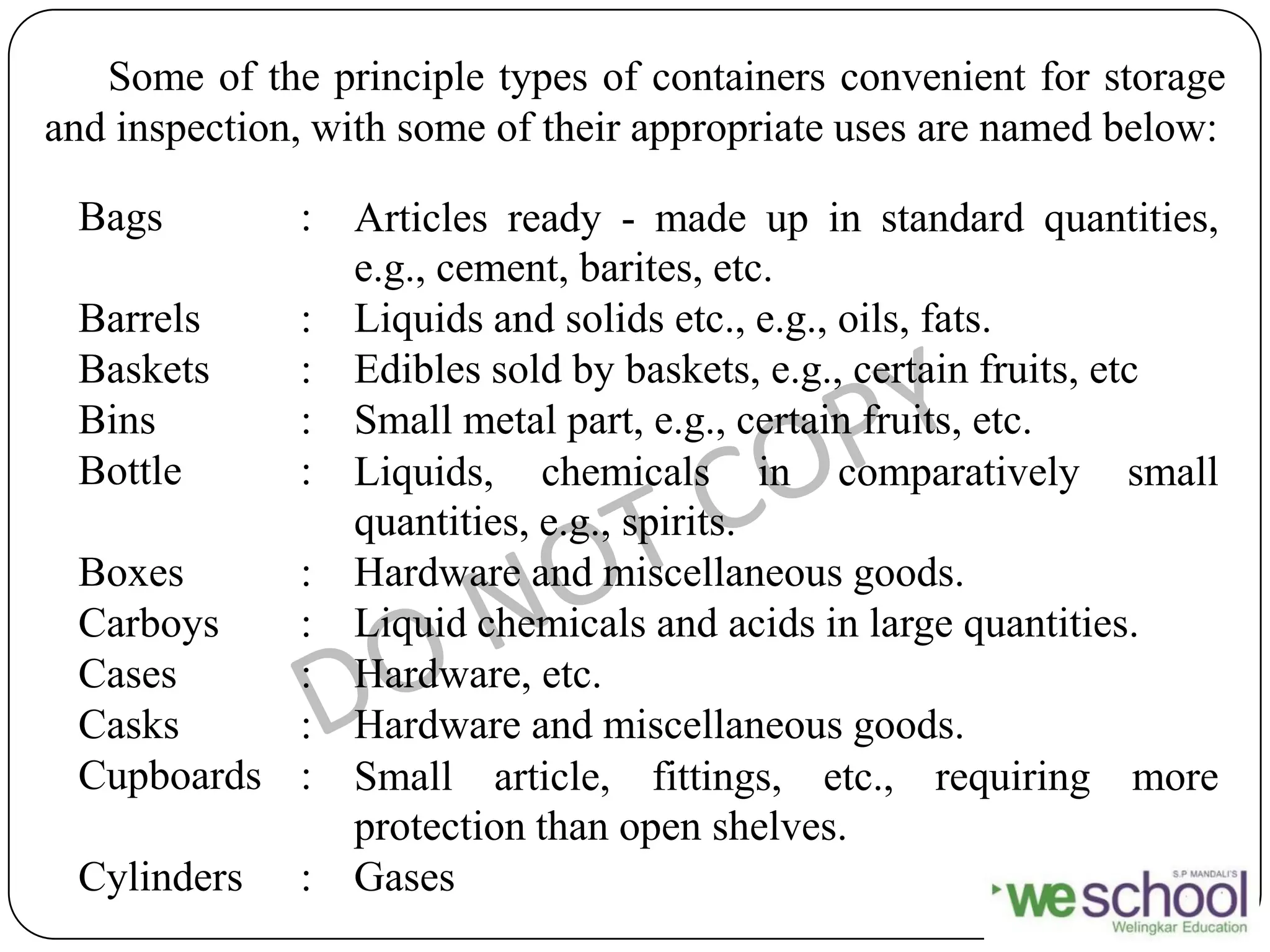

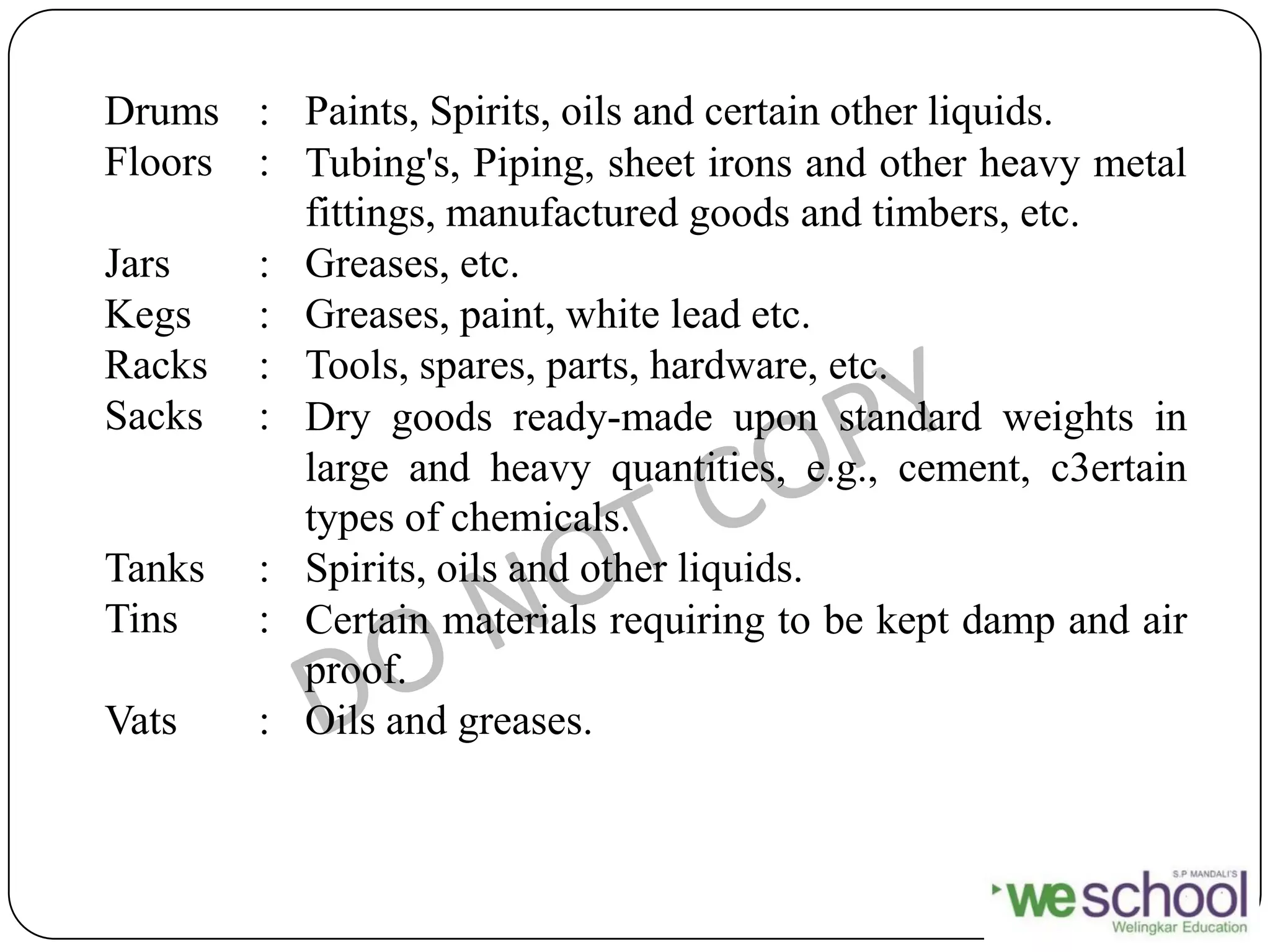

2. Important factors for stores location include proximity to user departments, volume and variety of goods, and accessibility. The layout should allow for easy movement of materials and optimal space utilization.

3. Codification involves representing each stored item with a unique code for identification. Various systems group items