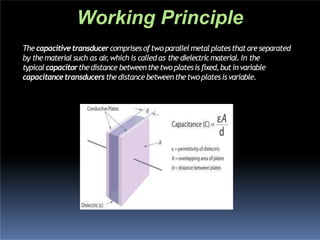

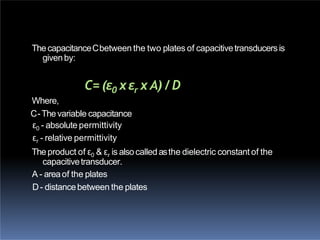

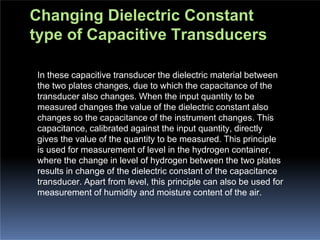

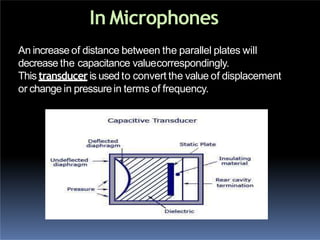

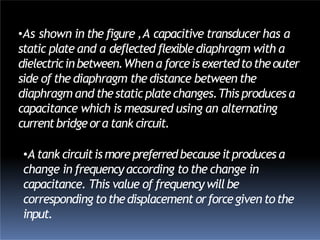

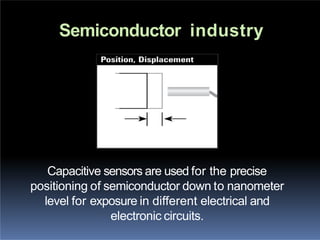

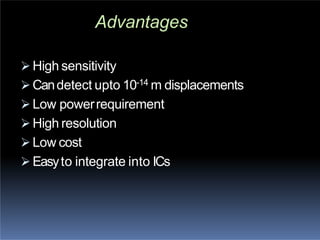

Capacitive transducers work by varying the capacitance between two conductive plates based on changes in dielectric material, plate area, or distance between plates. They are used to measure displacement, pressure, humidity, and other variables. Capacitive transducers have advantages like high sensitivity, low cost, and easy integration into circuits, but also have disadvantages like sensitivity to contaminants, temperature/humidity, and non-linearity. They have a wide range of applications in microphones, semiconductor manufacturing, and detecting dynamic motion.