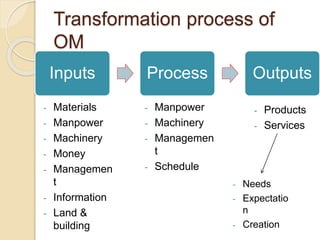

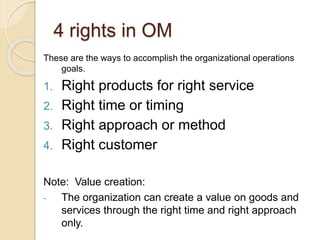

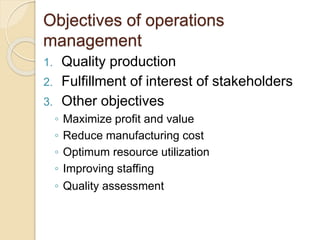

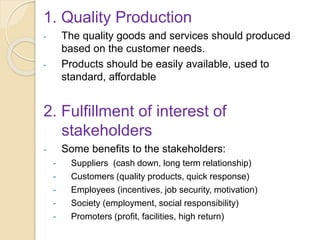

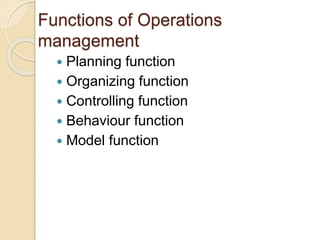

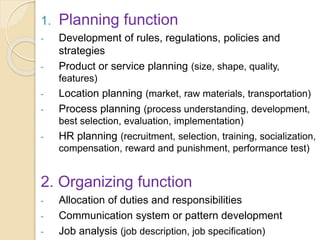

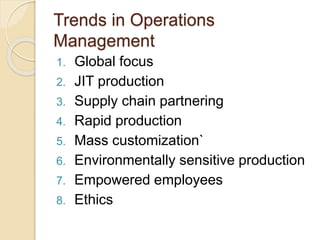

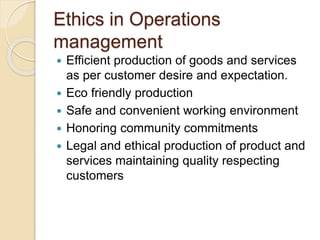

Operations management involves activities that enhance value through transforming resources into goods and services. It focuses on ensuring quality production, stakeholder fulfillment, and achieving organizational goals by managing inputs, processes, and outputs effectively. Recent trends emphasize global focus, just-in-time production, supply chain partnerships, rapid production, mass customization, employee empowerment, environmentally sensitive production, and ethical considerations.