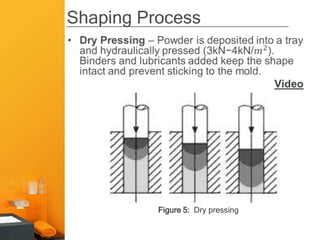

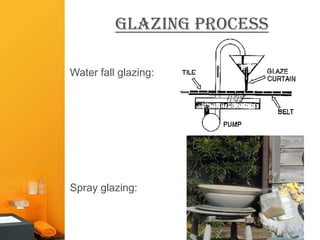

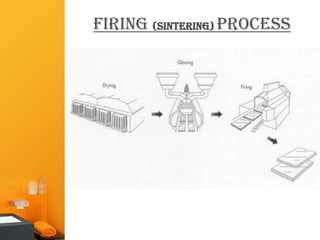

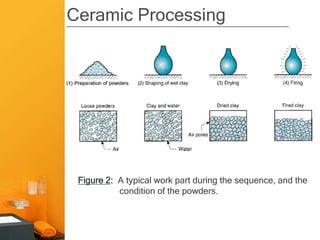

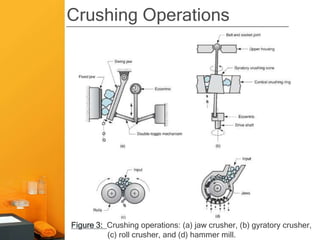

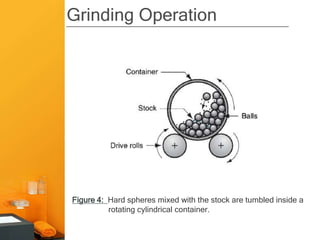

Ceramic tiles are made from clay that is formed, glazed, and baked. The process begins with crushing and grinding raw materials like sand, clay, and feldspar into a fine powder. This powder is mixed with water and other ingredients to form a slurry that is dried and then shaped. The tiles are then glazed by applying a glass-like coating and fired at high temperatures to strengthen them. Additional firing may be done after glazing to further harden the glaze. Finishing steps like grinding can be done to improve dimensional accuracy or the surface.