This document summarizes key aspects of centrifugal pumps, including:

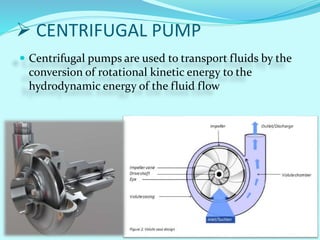

1. Centrifugal pumps use rotational kinetic energy to transport fluids by converting it to hydrodynamic energy.

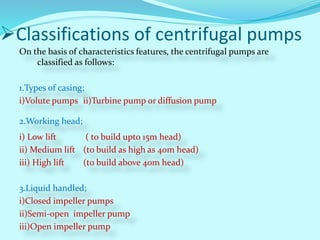

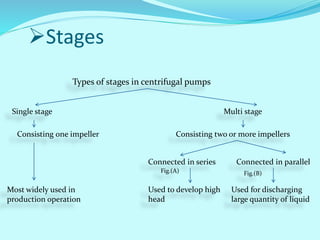

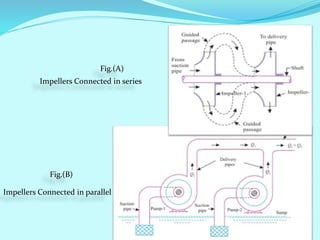

2. Centrifugal pumps are classified based on casing type, working head, liquid handled, number of impellers/shafts, and impeller flow direction.

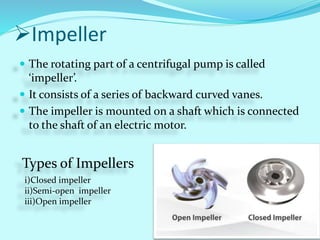

3. The impeller is the rotating part that consists of backward curved vanes mounted on a shaft connected to a motor. Impellers can be closed, semi-open, or open.