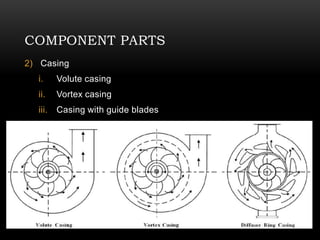

Centrifugal pumps work by using a rotating impeller to increase the velocity and pressure of a liquid. They operate in the opposite direction of turbines. Centrifugal pumps can handle liquids with some amount of gases or vapor but are susceptible to cavitation at low pressures. Centrifugal pumps are classified based on factors like casing type, head, liquid handled, number of impellers, and flow direction through the impeller. Key components include the impeller, casing, suction pipe, and delivery pipe. Cavitation can occur if low pressure allows vapor bubbles to form and collapse in the pump, reducing performance.