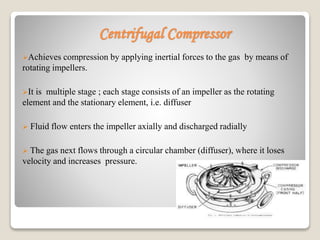

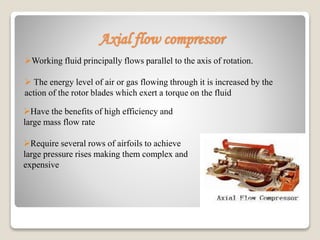

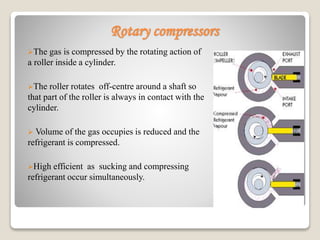

Compressors are mechanical devices that compress gases and have various applications. They are widely used in industries to compress air or refrigerants. Compressors can be classified as centrifugal compressors, axial flow compressors, or positive displacement compressors. Centrifugal compressors achieve compression by applying inertial forces via rotating impellers to force the gas outward, while axial flow compressors increase energy by rotor blades acting on the fluid flowing parallel to the axis of rotation. Positive displacement compressors work by trapping a fixed amount of air and forcing it into the discharge pipe, which can be further broken down into rotary compressors that use a rotating roller inside a cylinder or reciprocating compressors that use pistons driven by