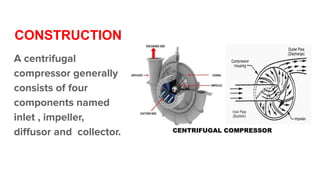

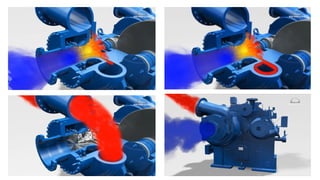

1. A centrifugal compressor uses radial acceleration from an impeller to compress gas, with multiple stages providing greater compression. Air passing through the impeller gains velocity and pressure before entering the diffuser.

2. The diffuser converts the velocity into pressure as the air slows down. Multiple components including the impeller and diffuser work together to increase the pressure.

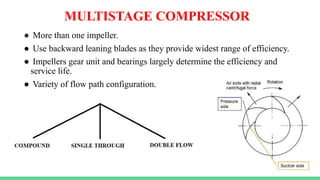

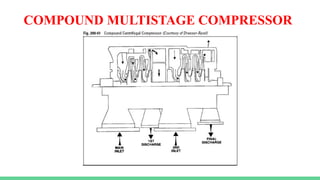

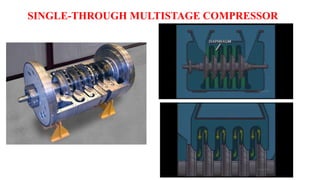

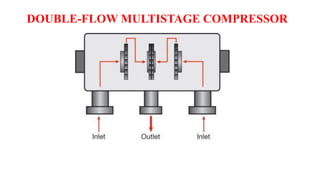

3. Centrifugal compressors come in single stage for lower compression ratios up to 3:1, and multistage versions for higher compression using backward leaning blades for better efficiency. They are used widely in industries like oil/gas, food processing, and refrigeration.