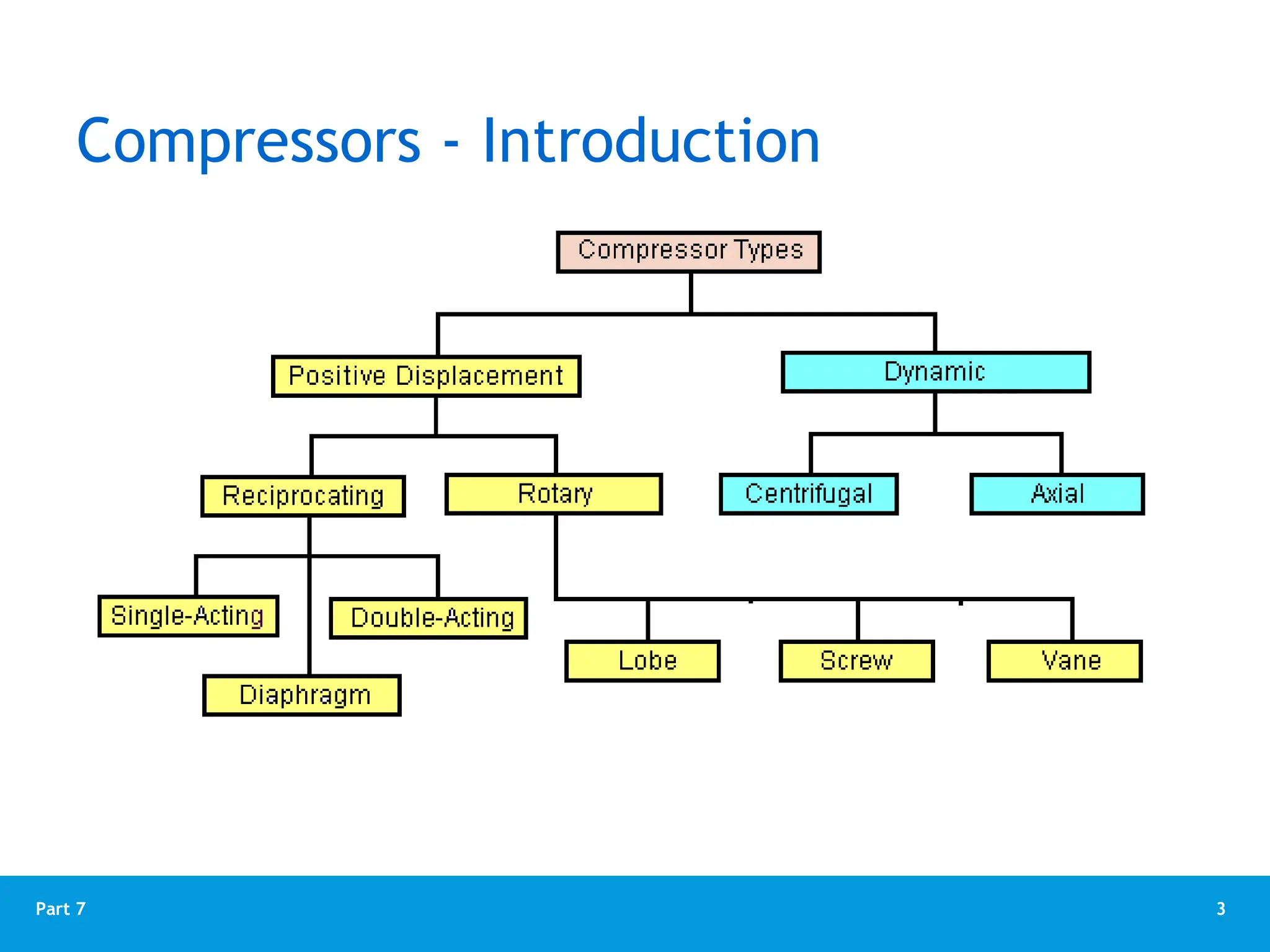

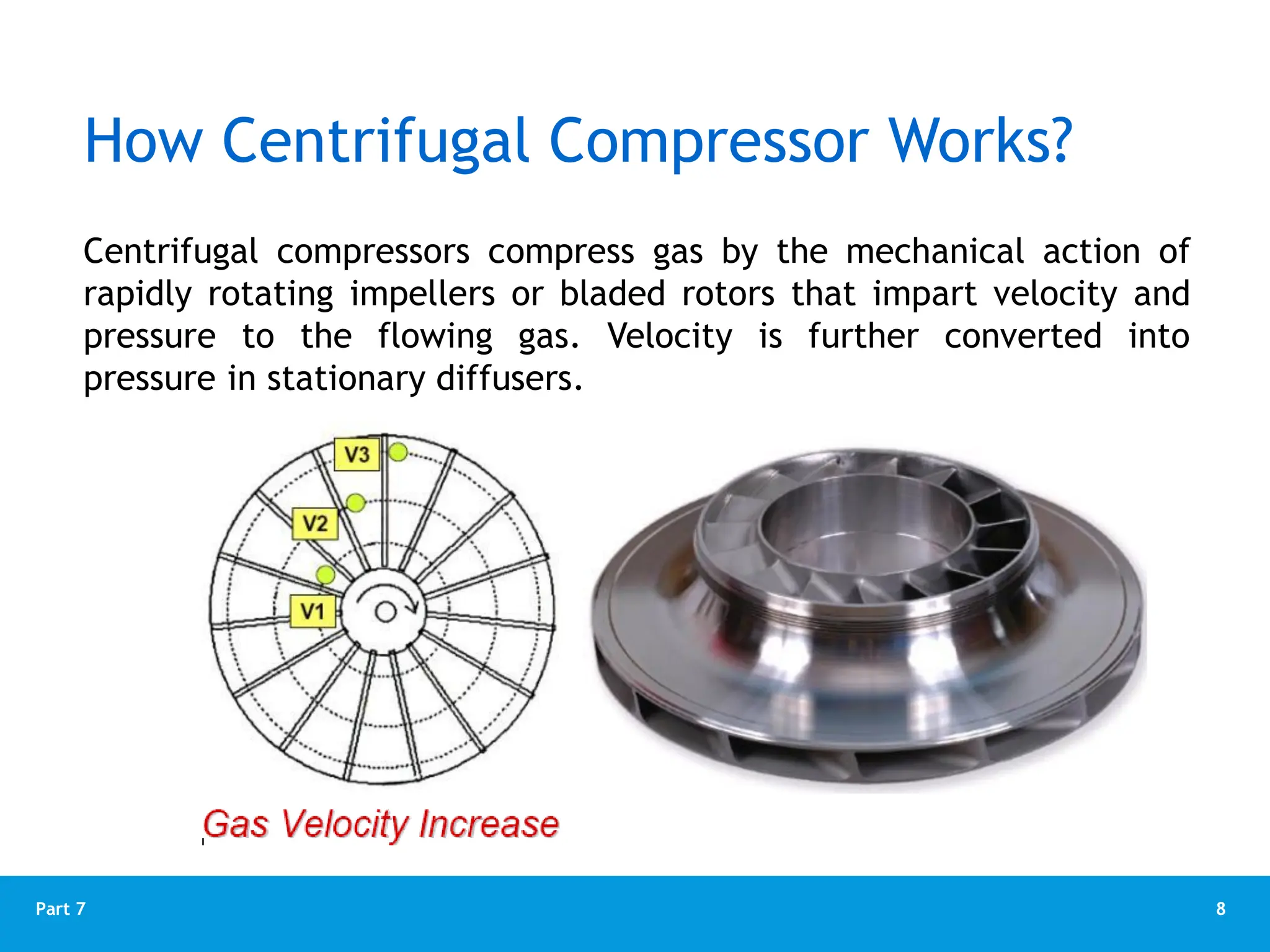

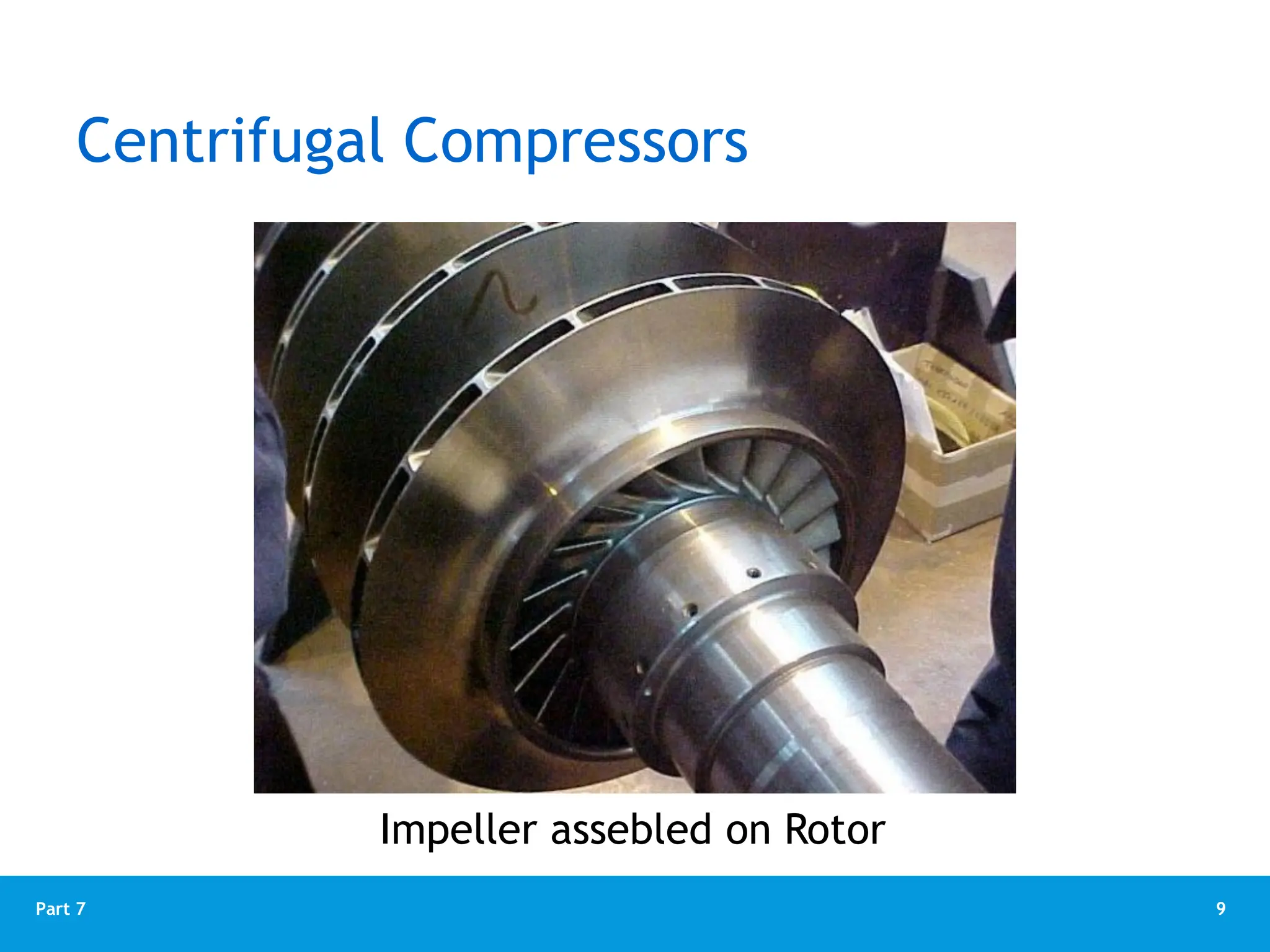

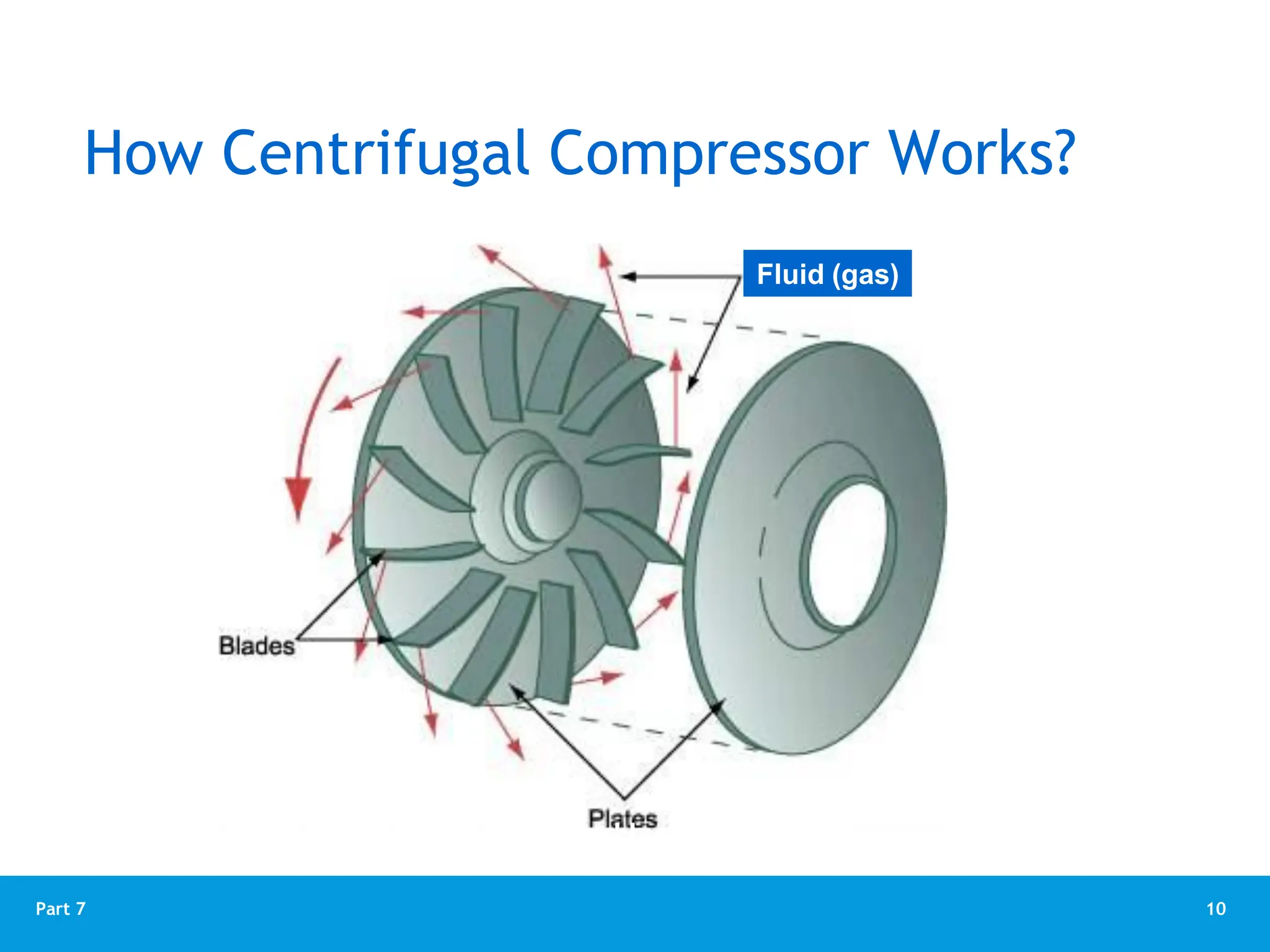

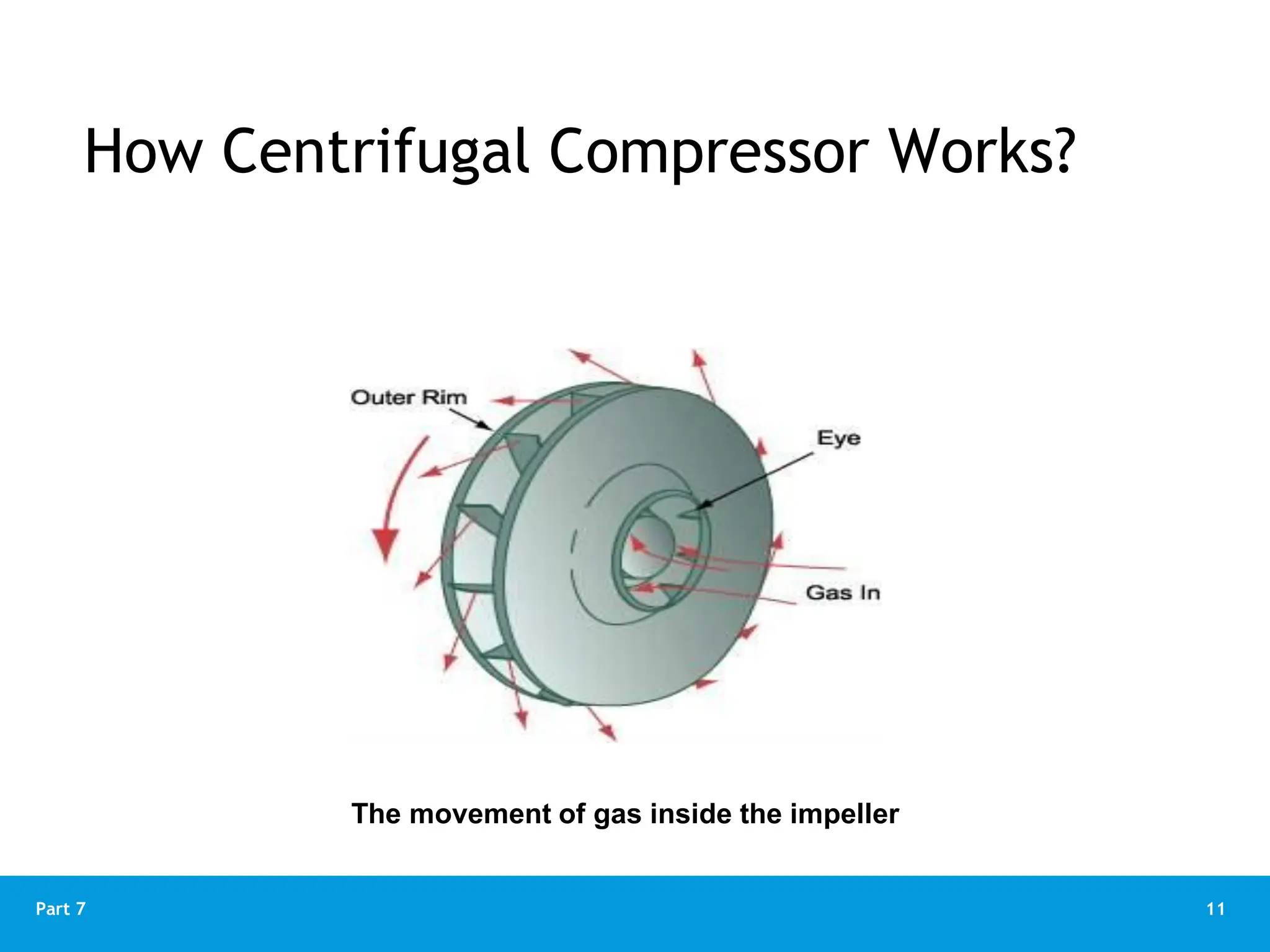

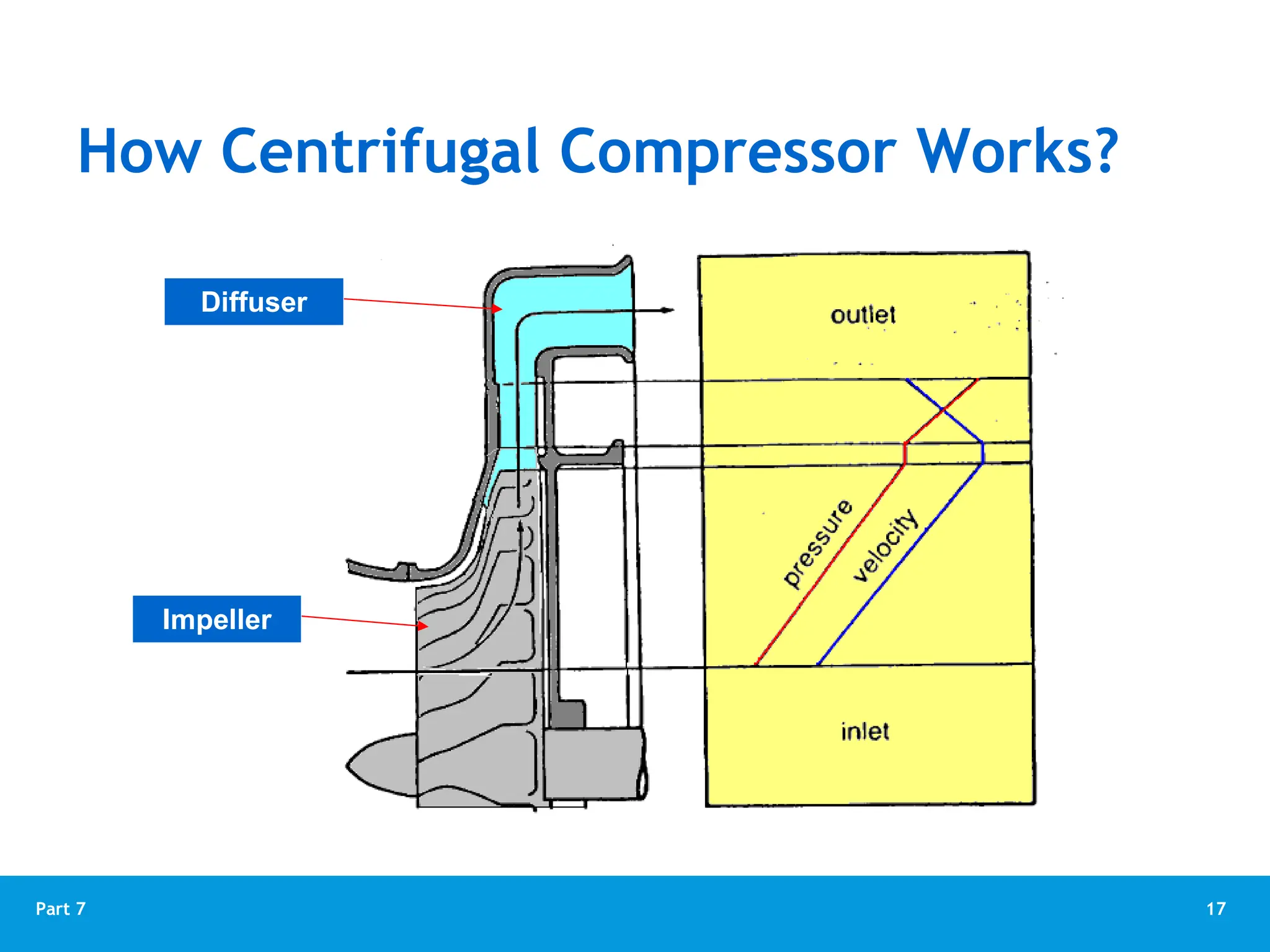

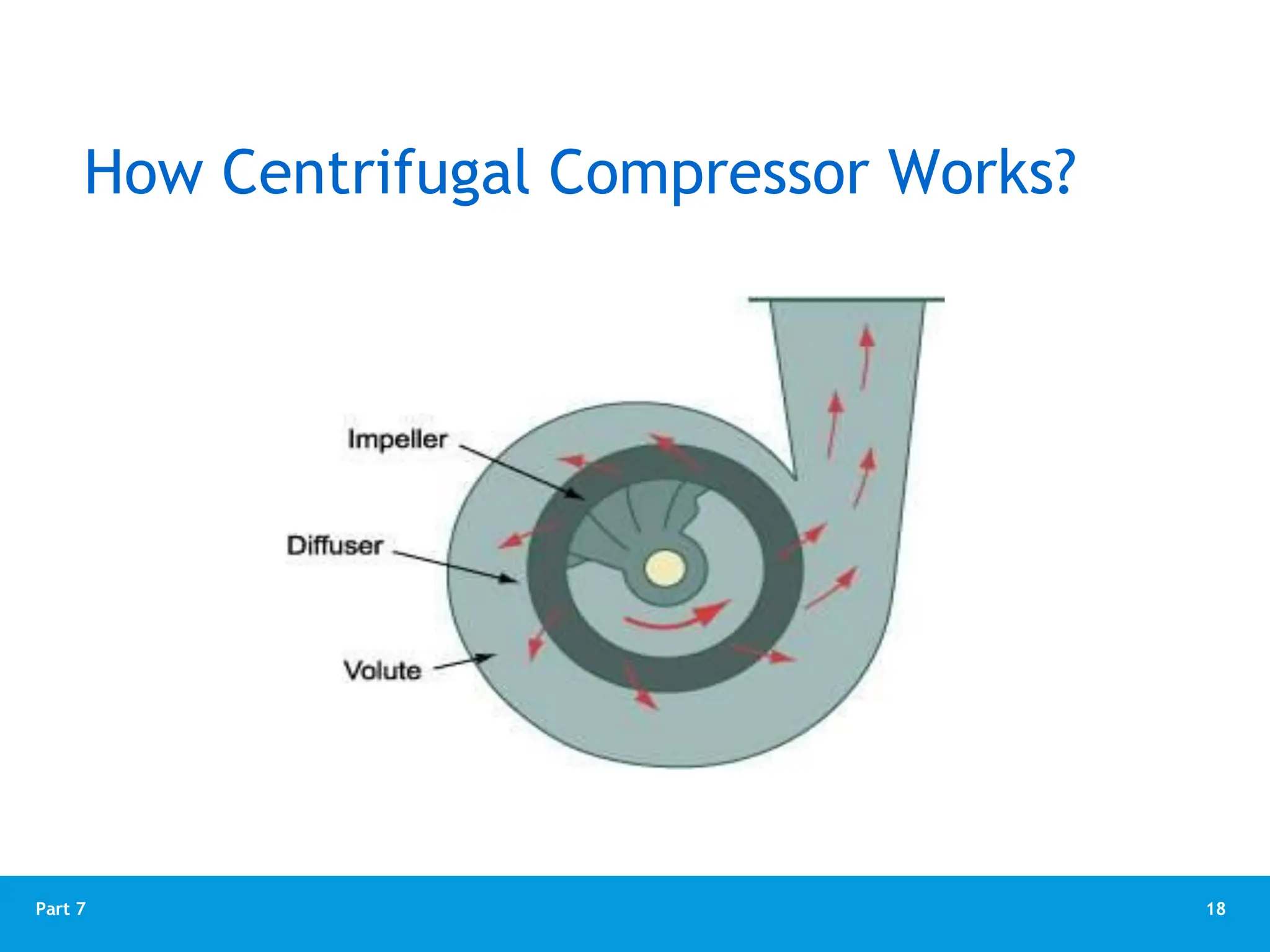

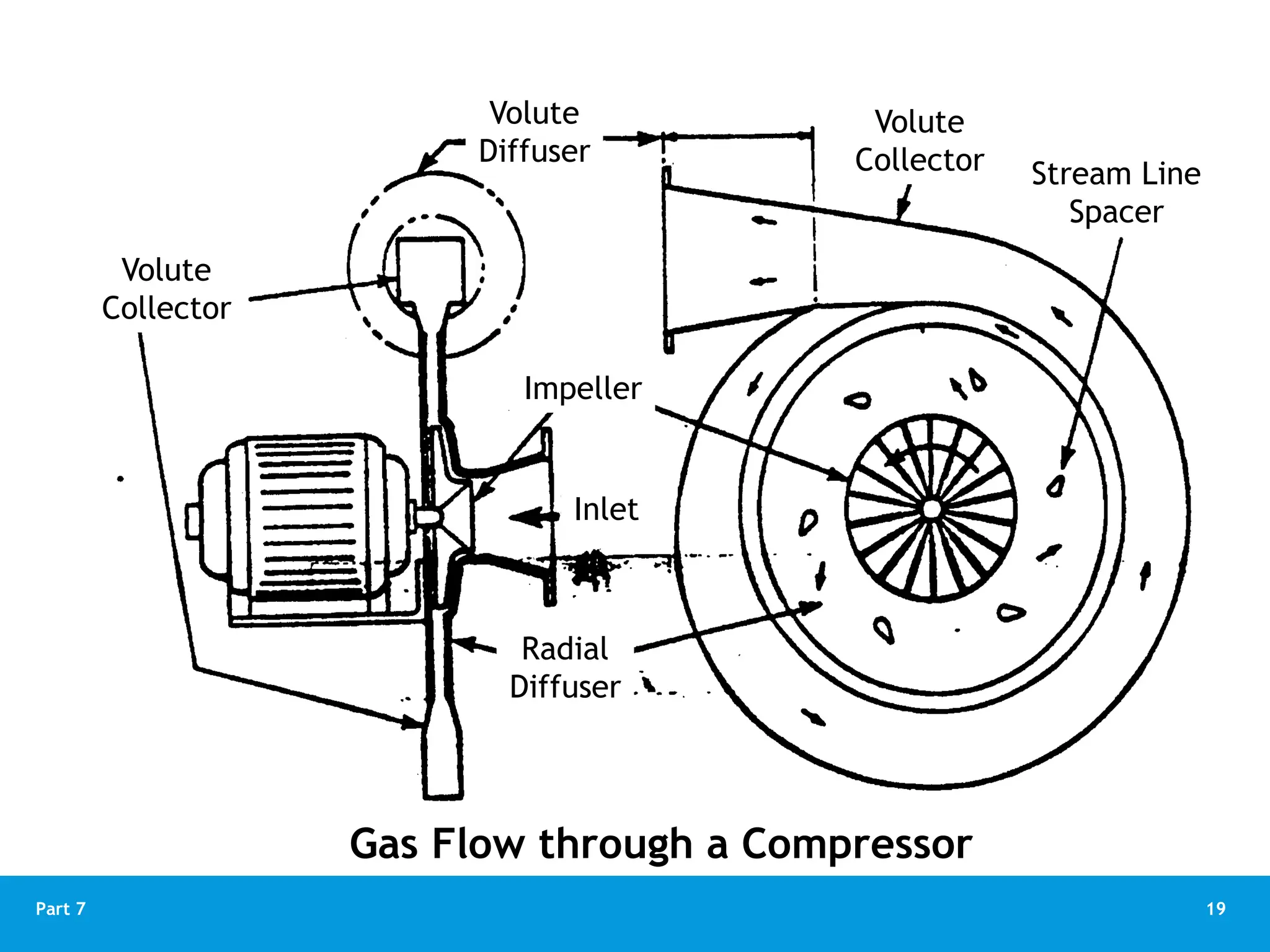

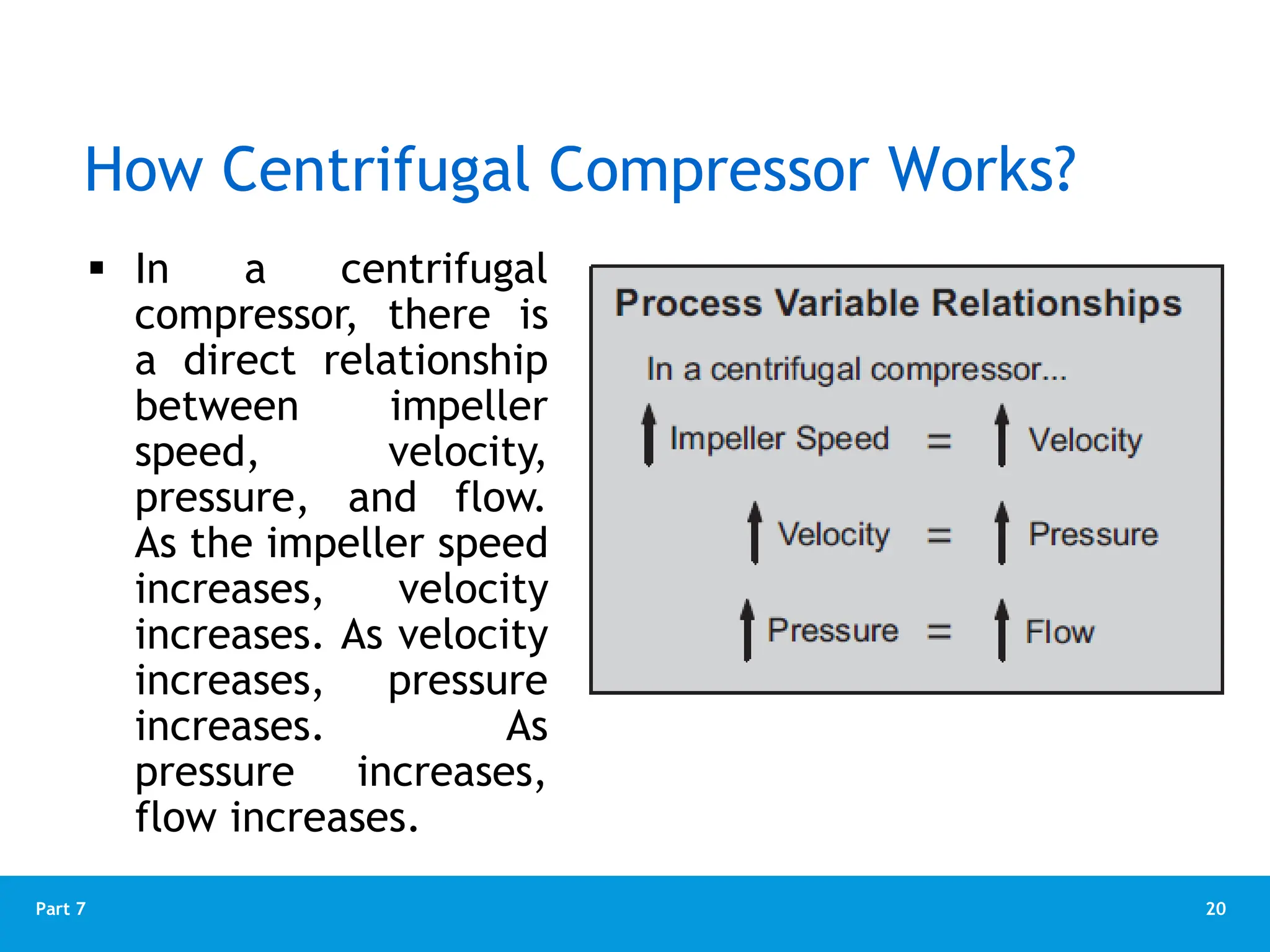

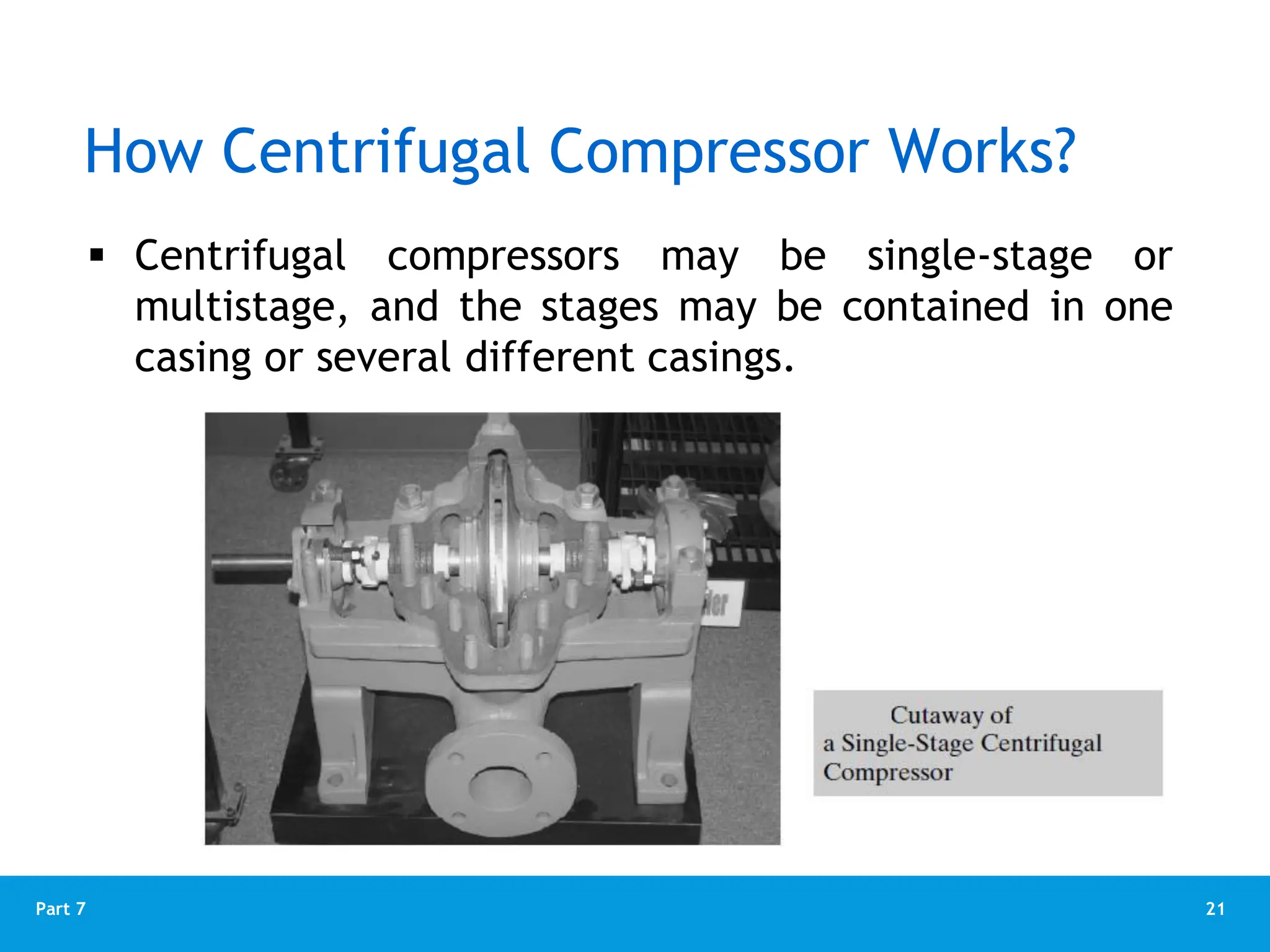

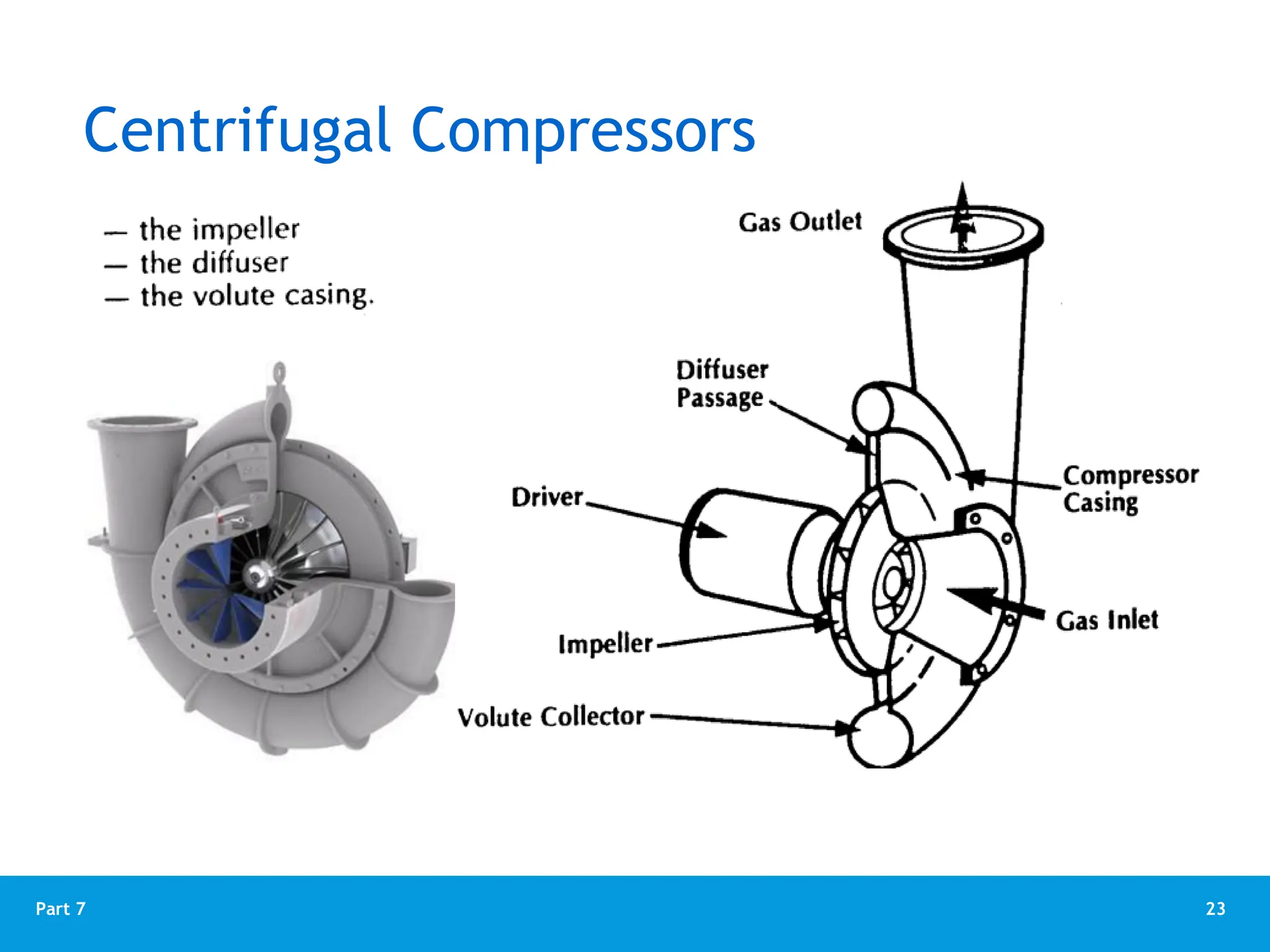

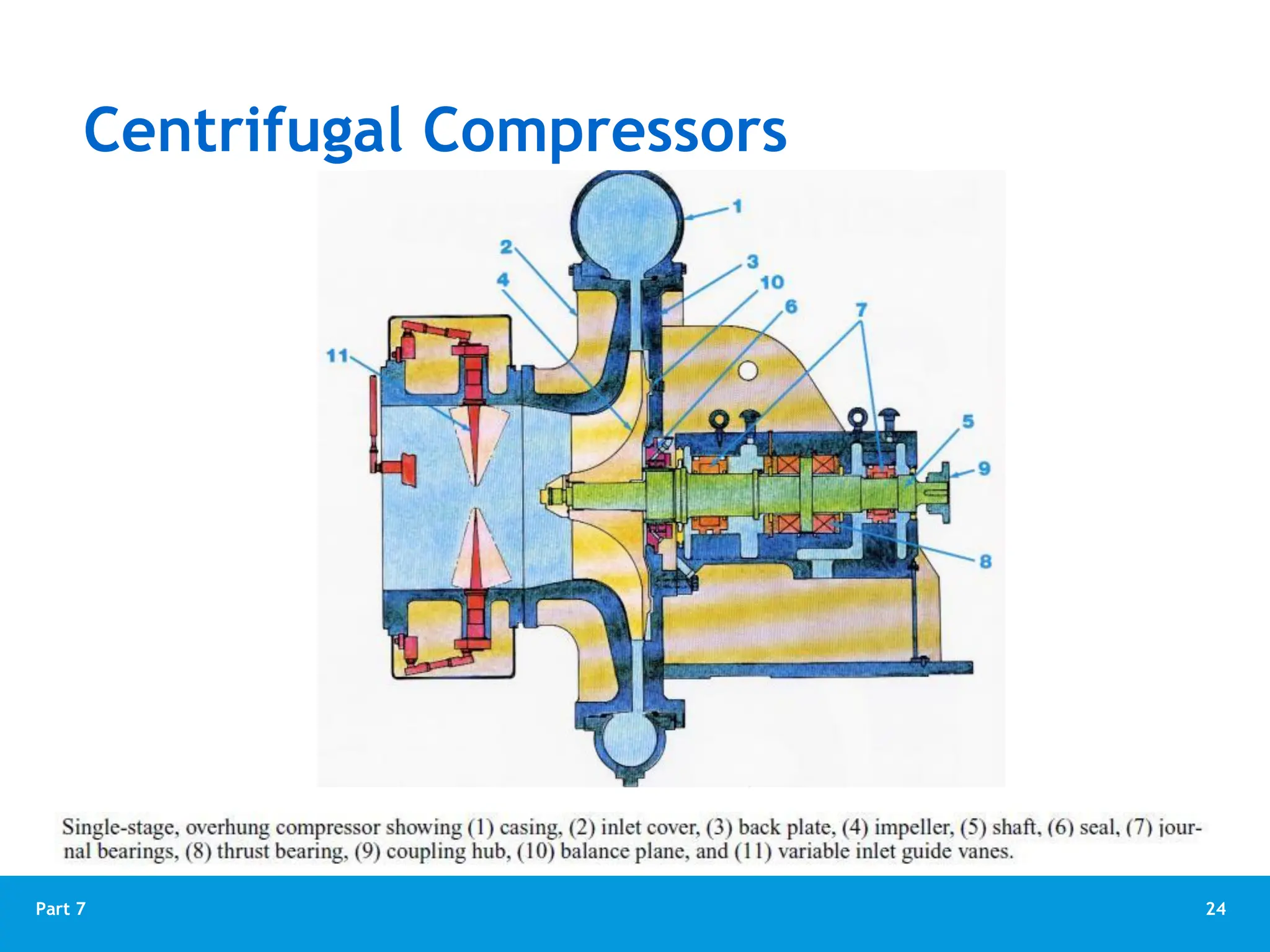

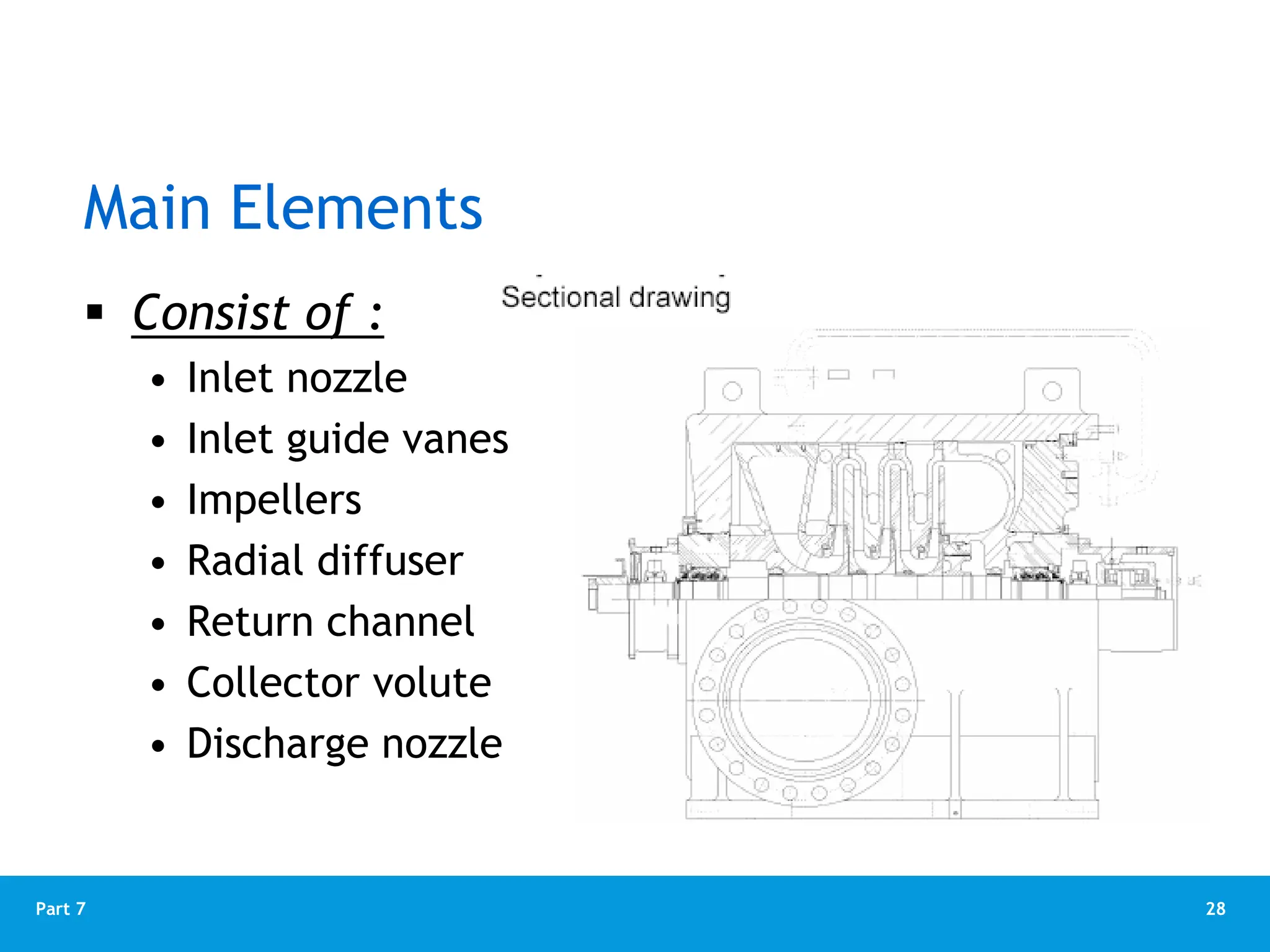

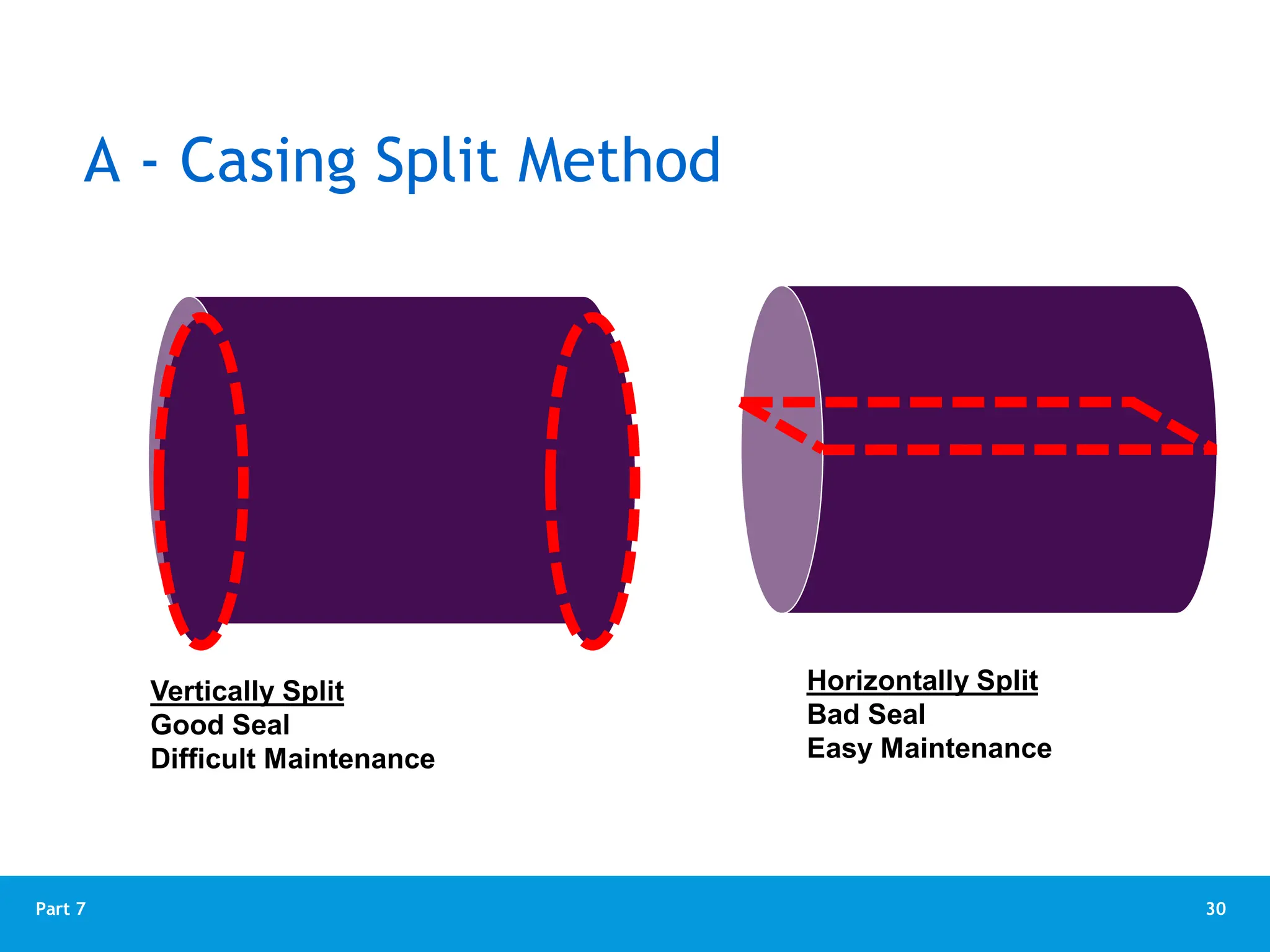

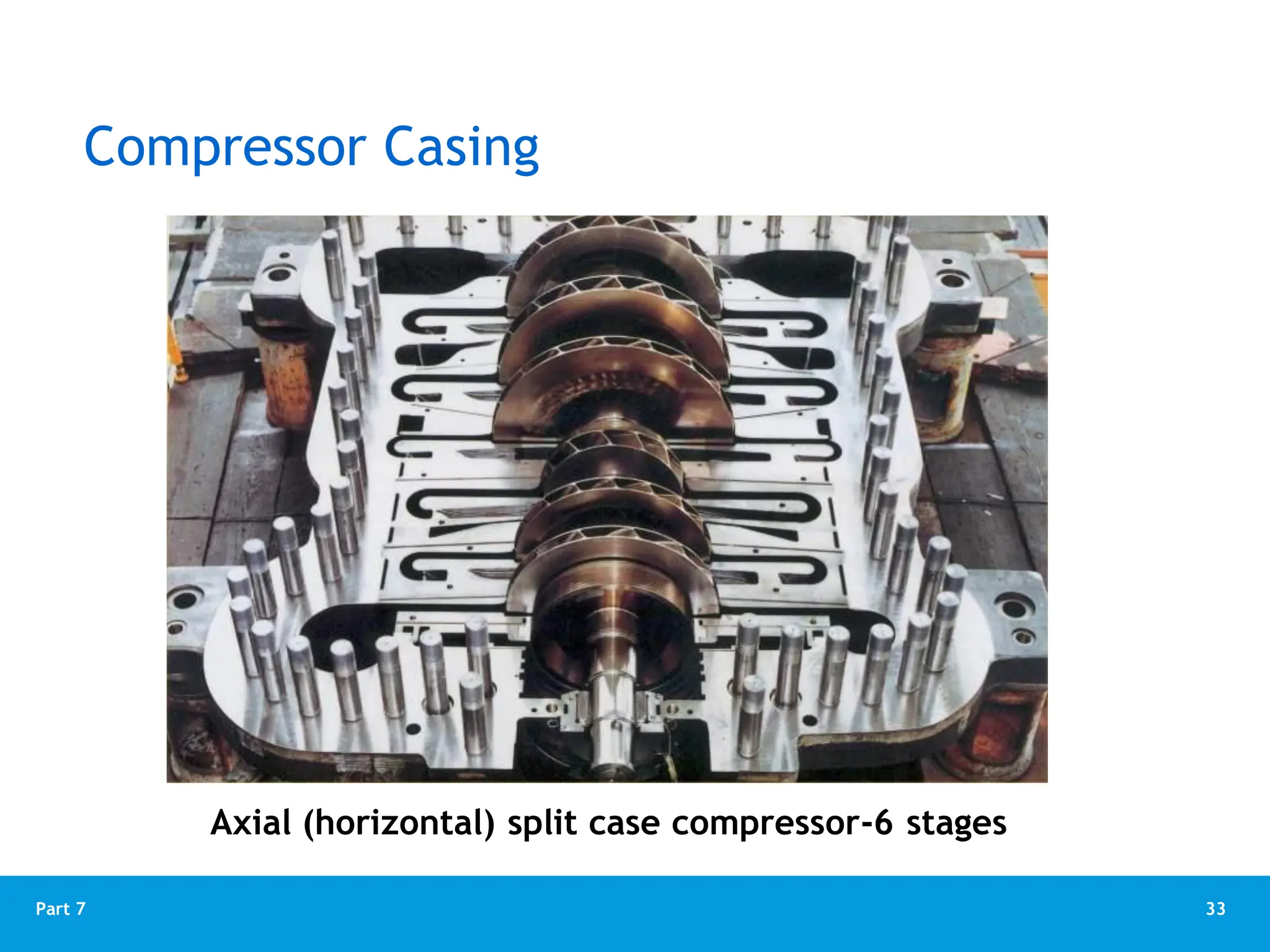

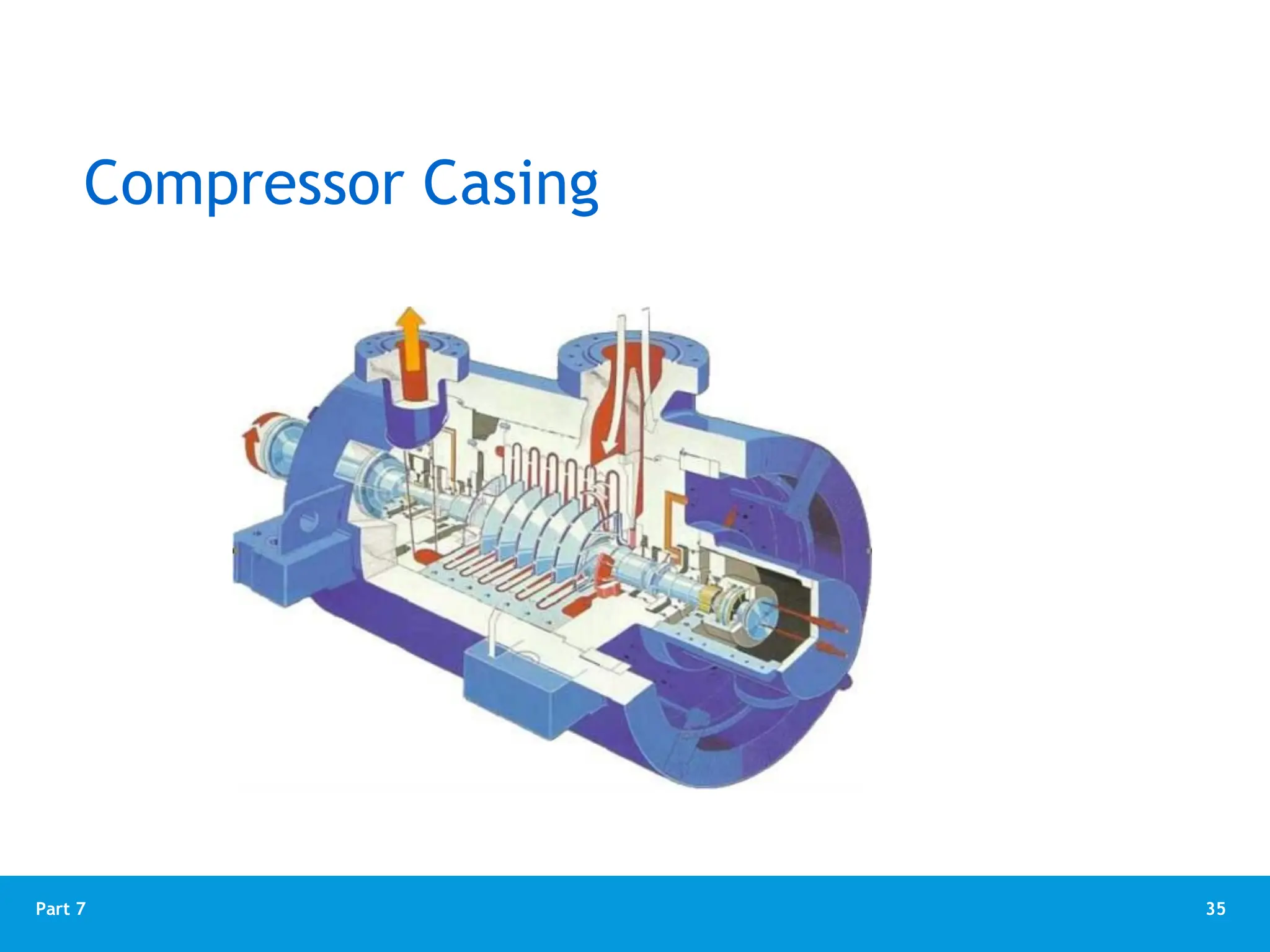

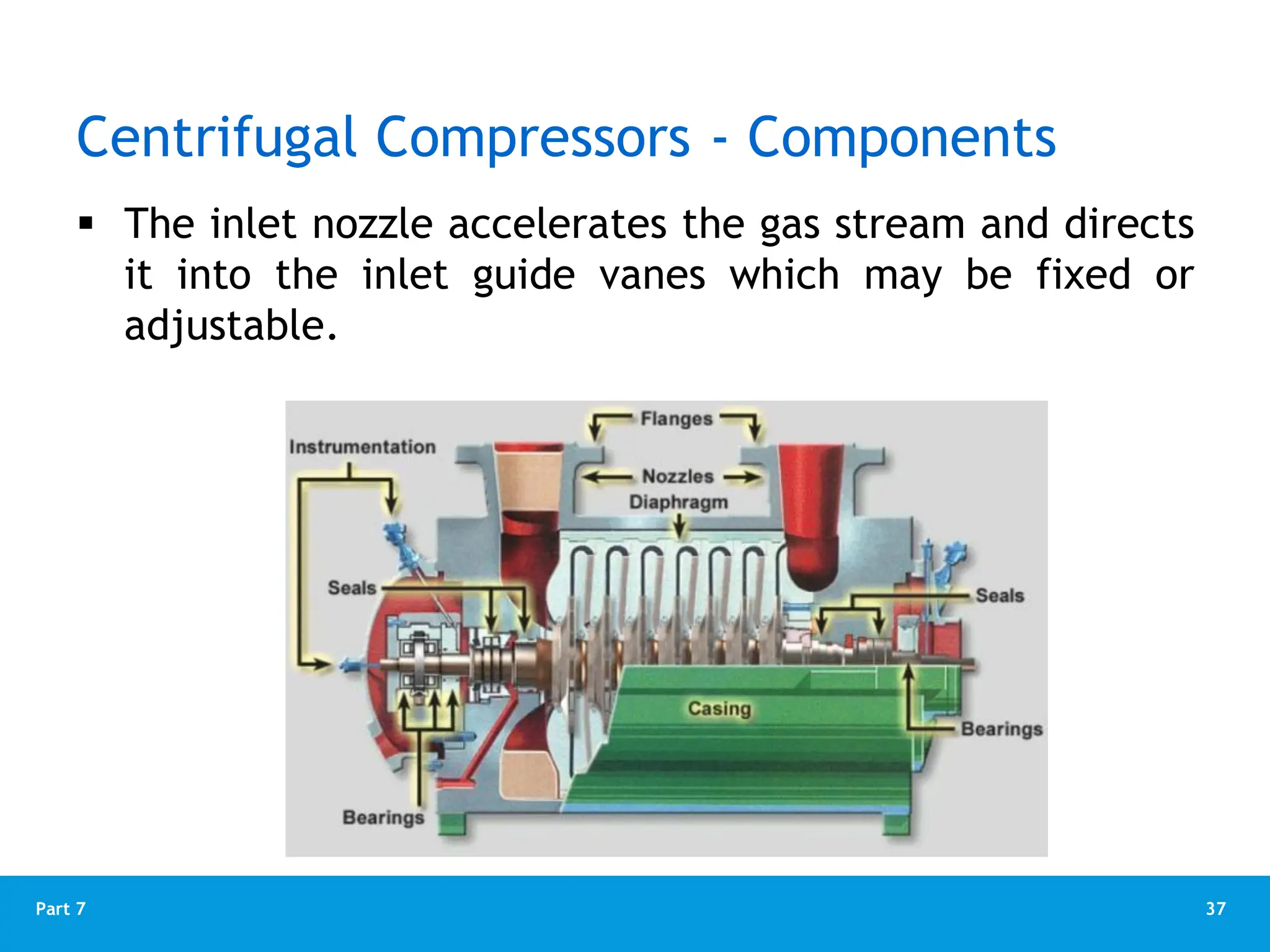

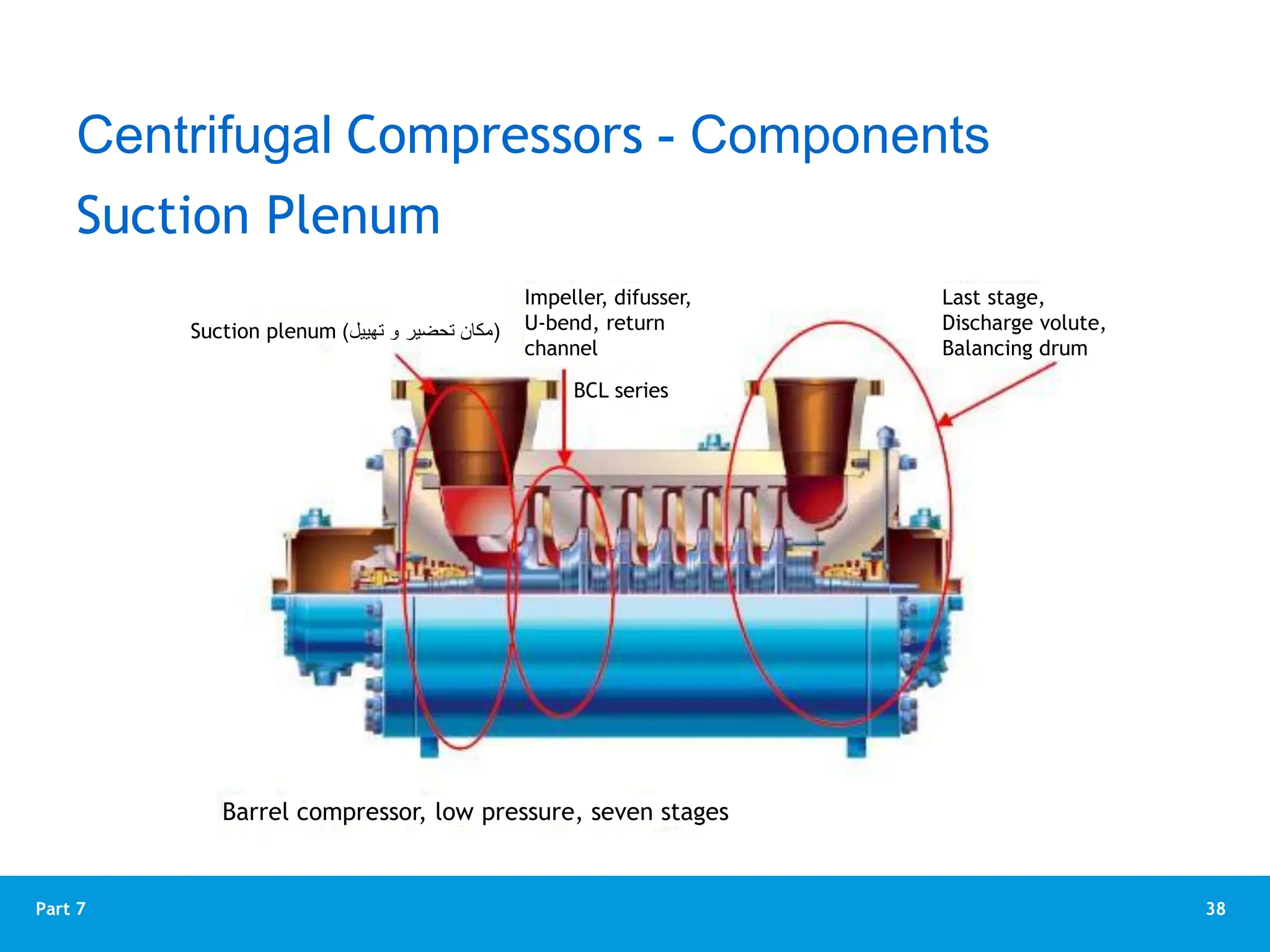

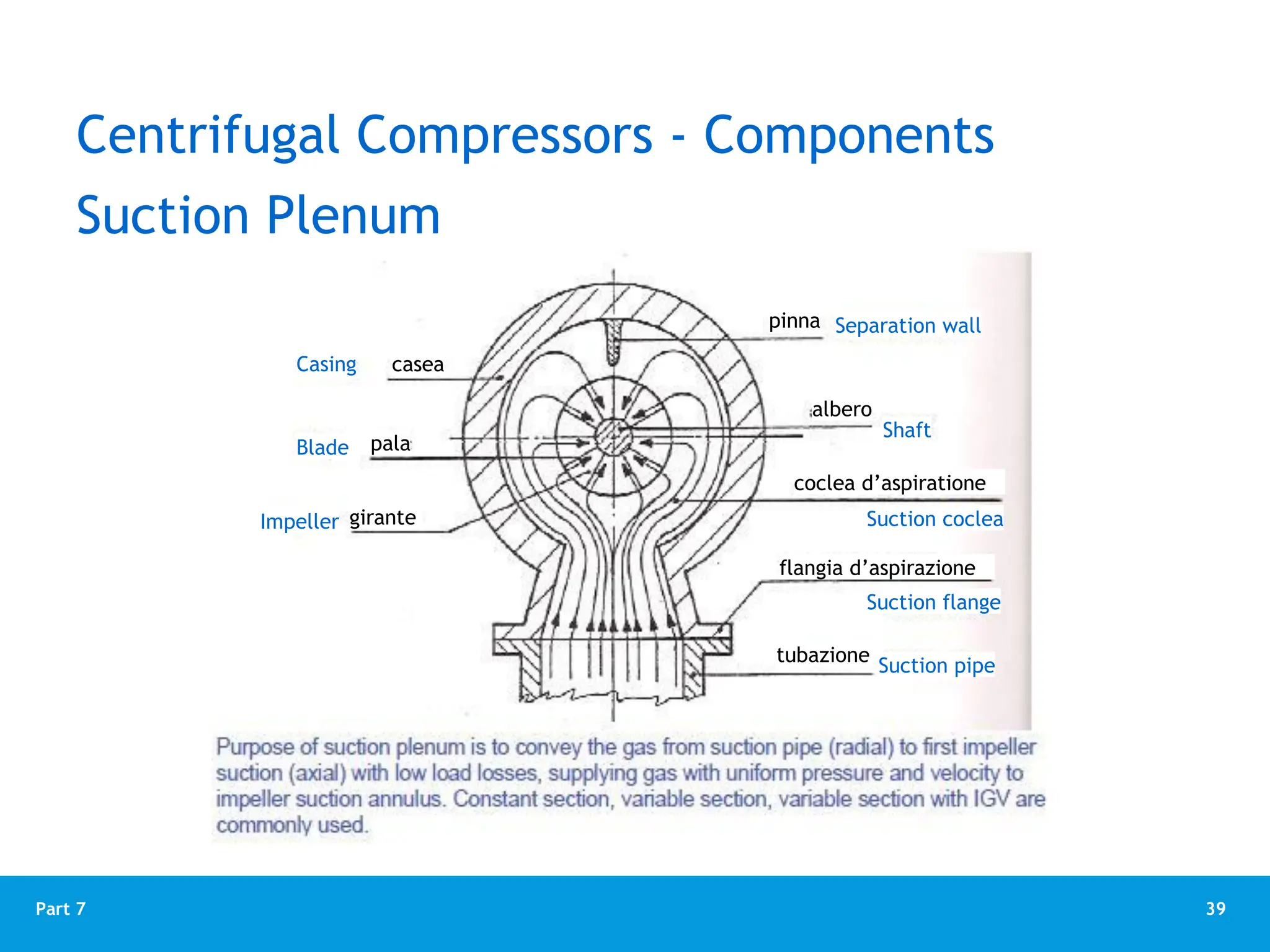

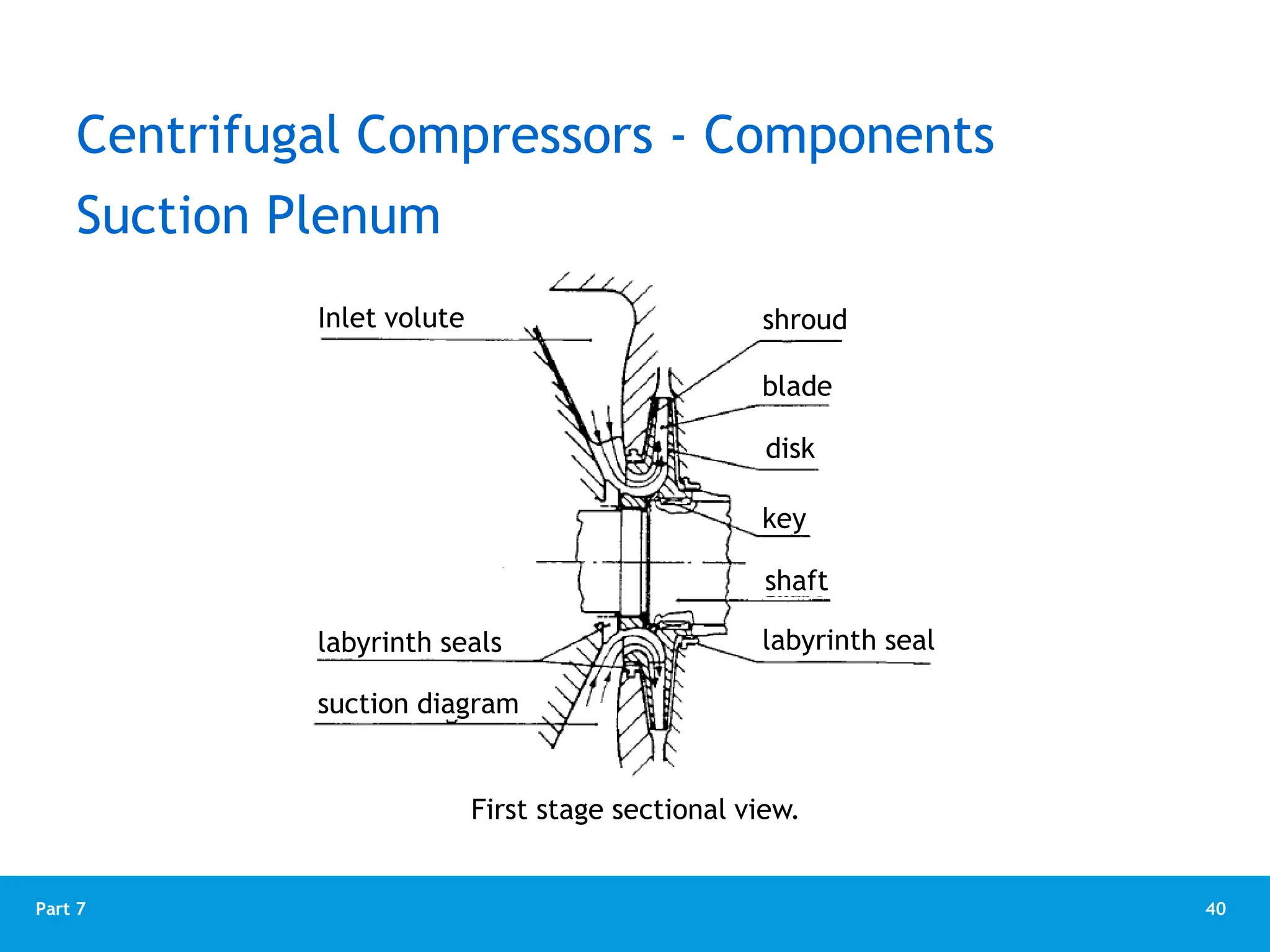

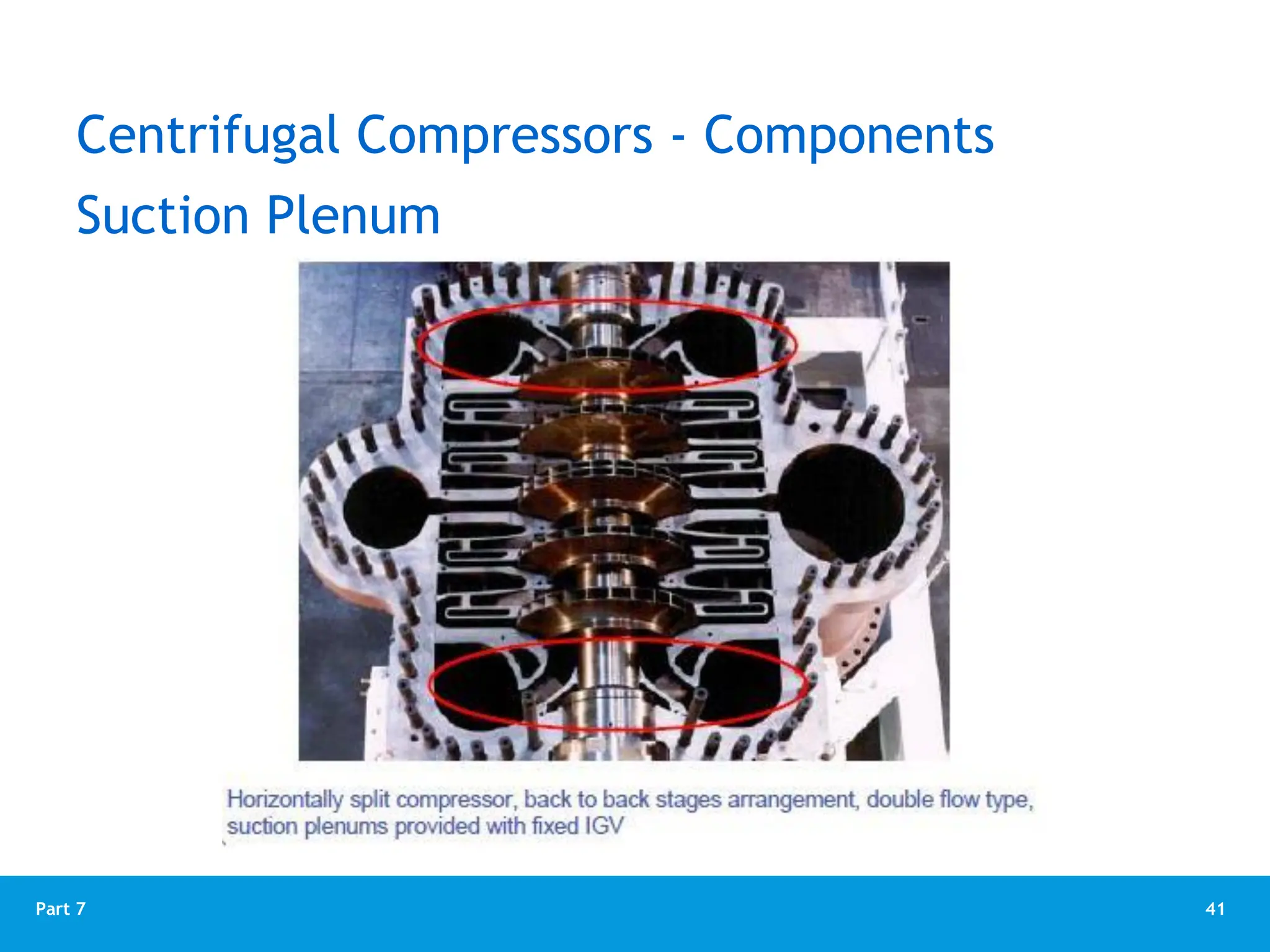

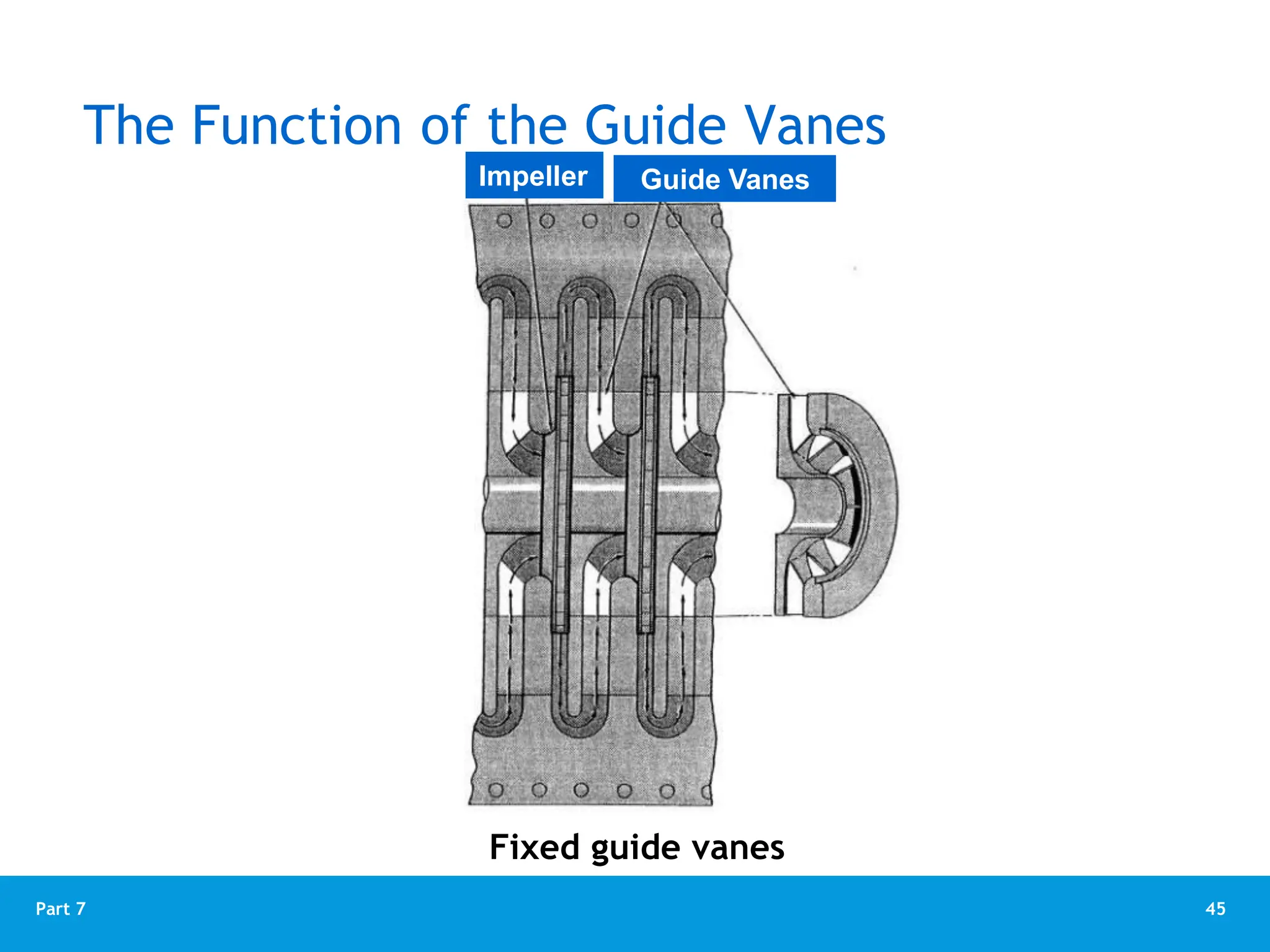

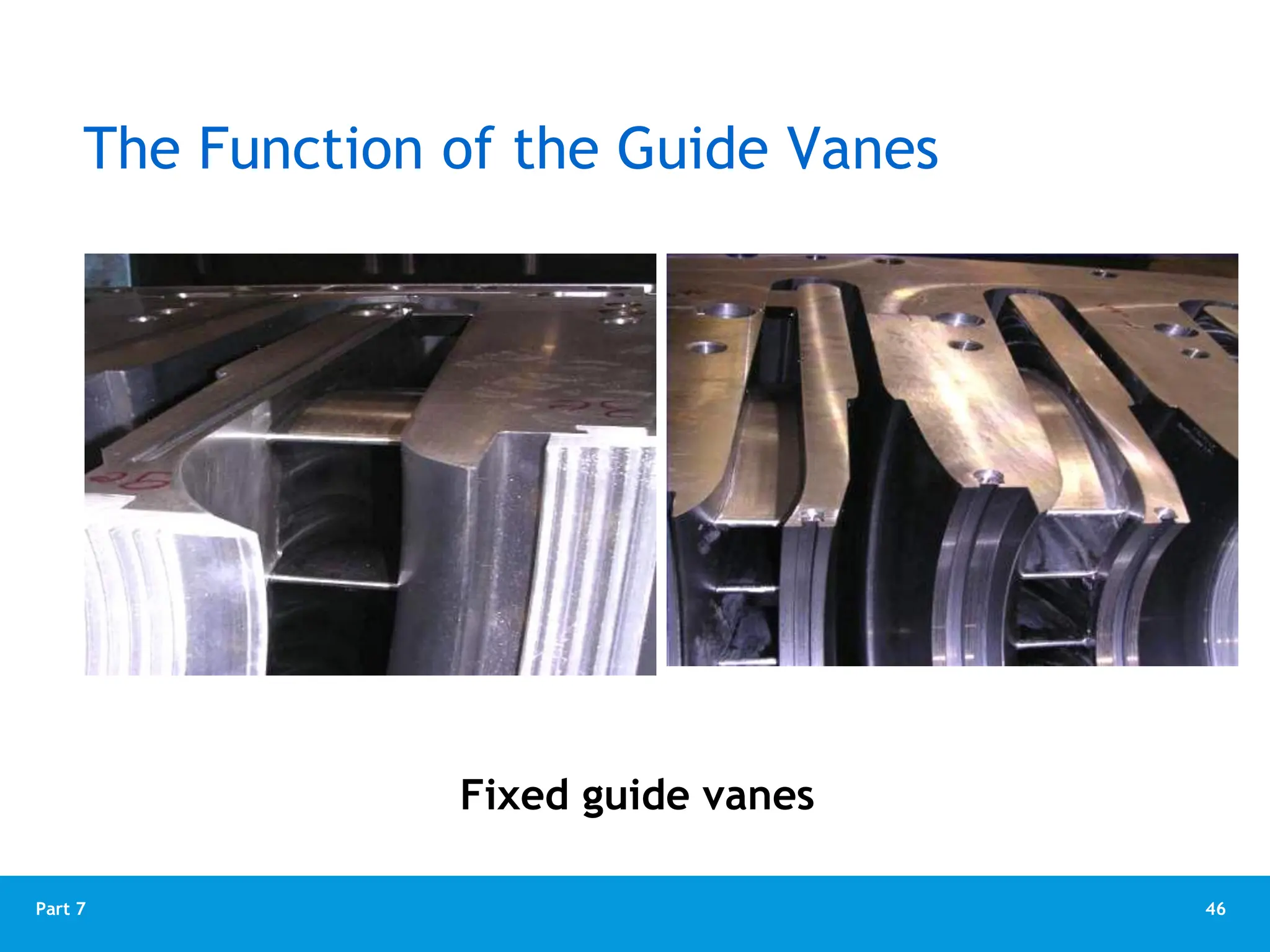

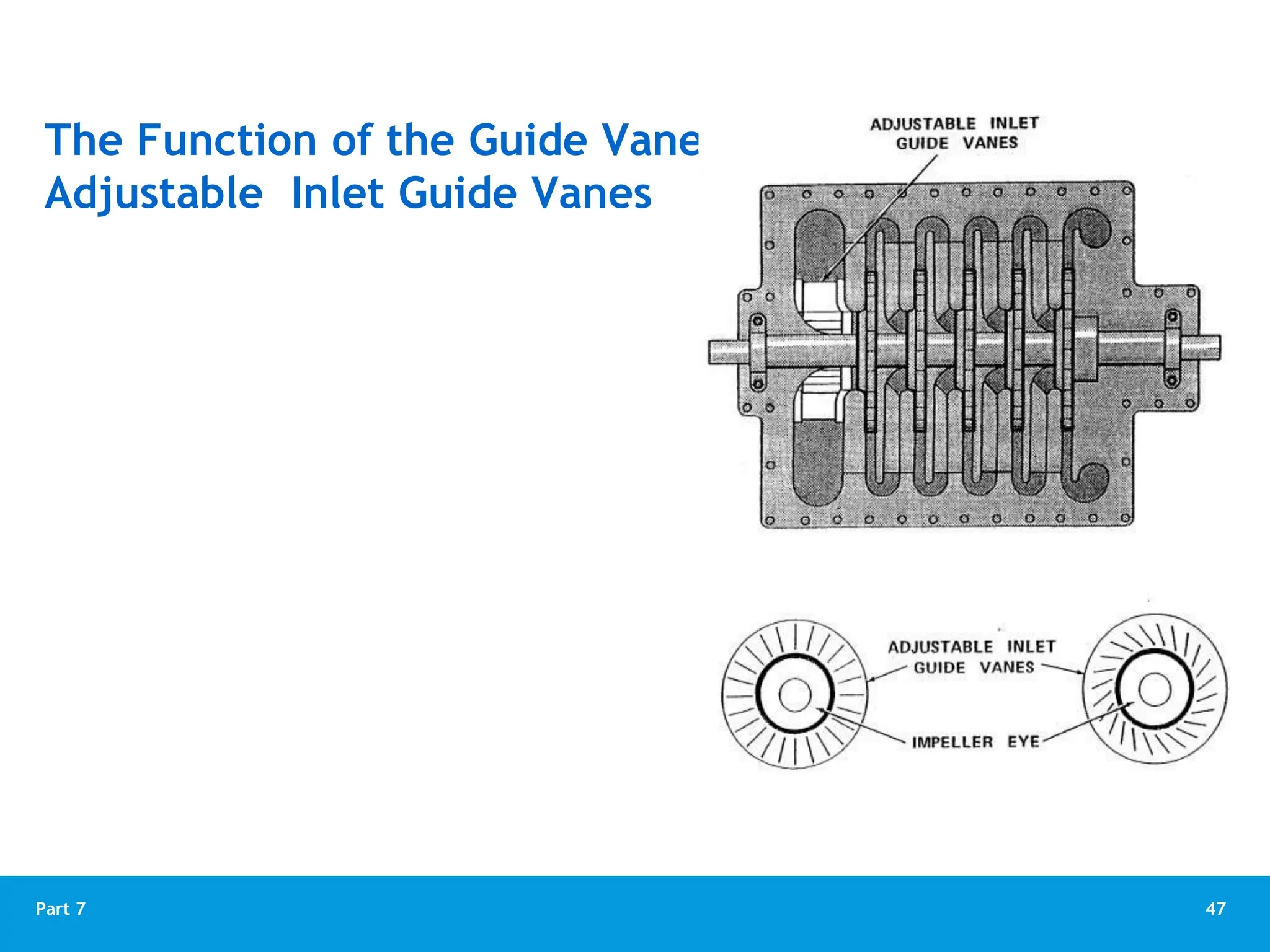

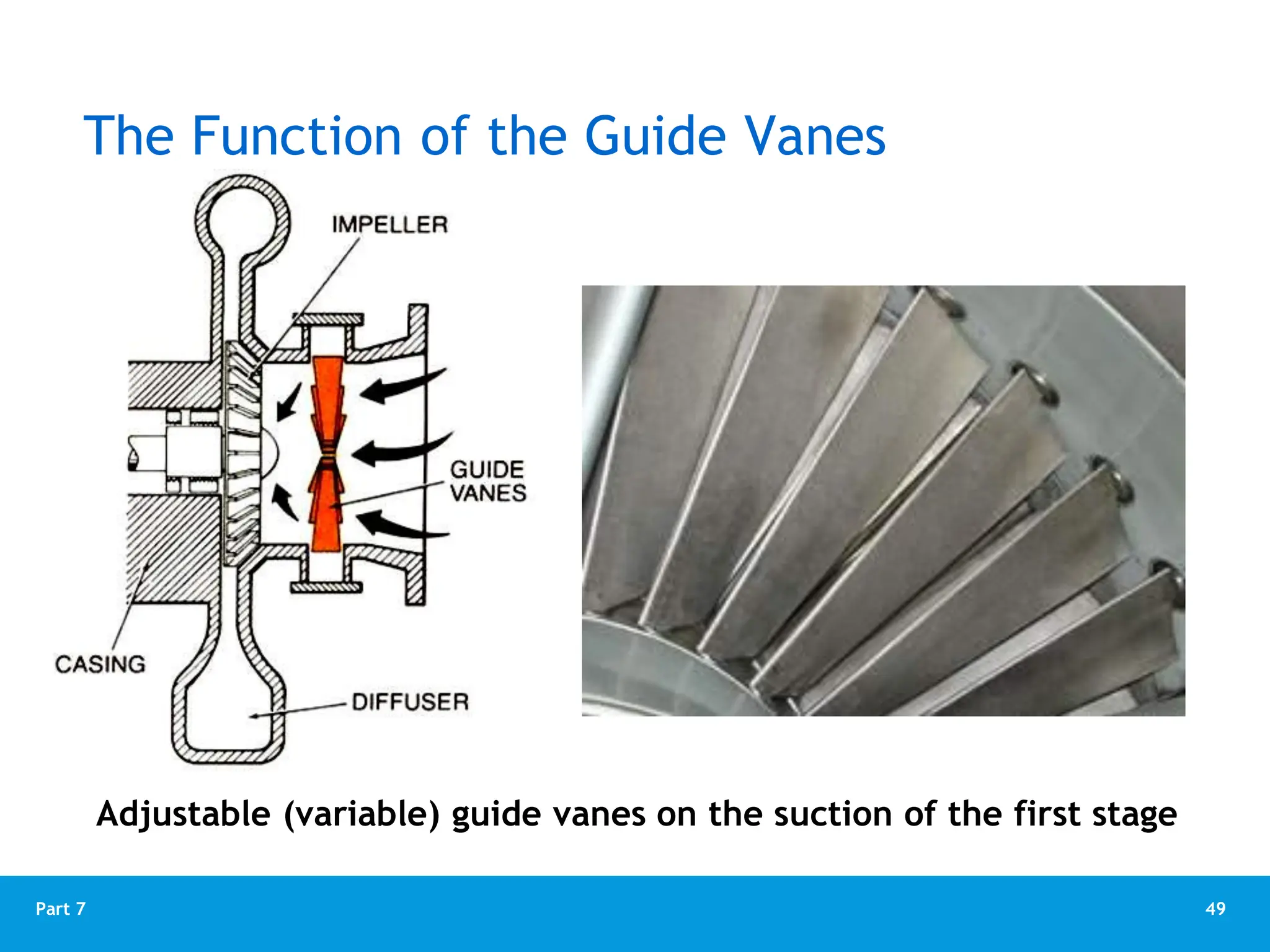

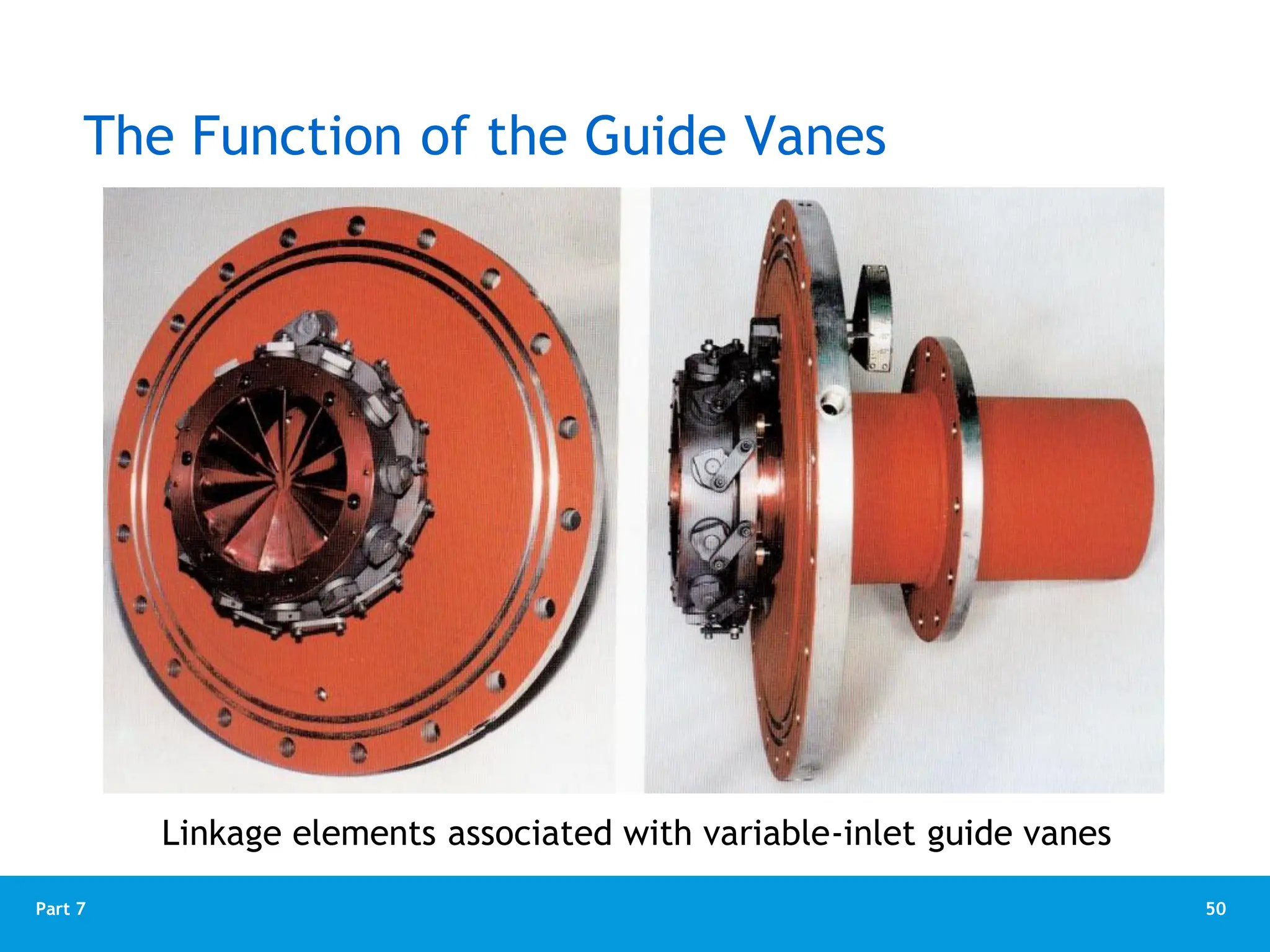

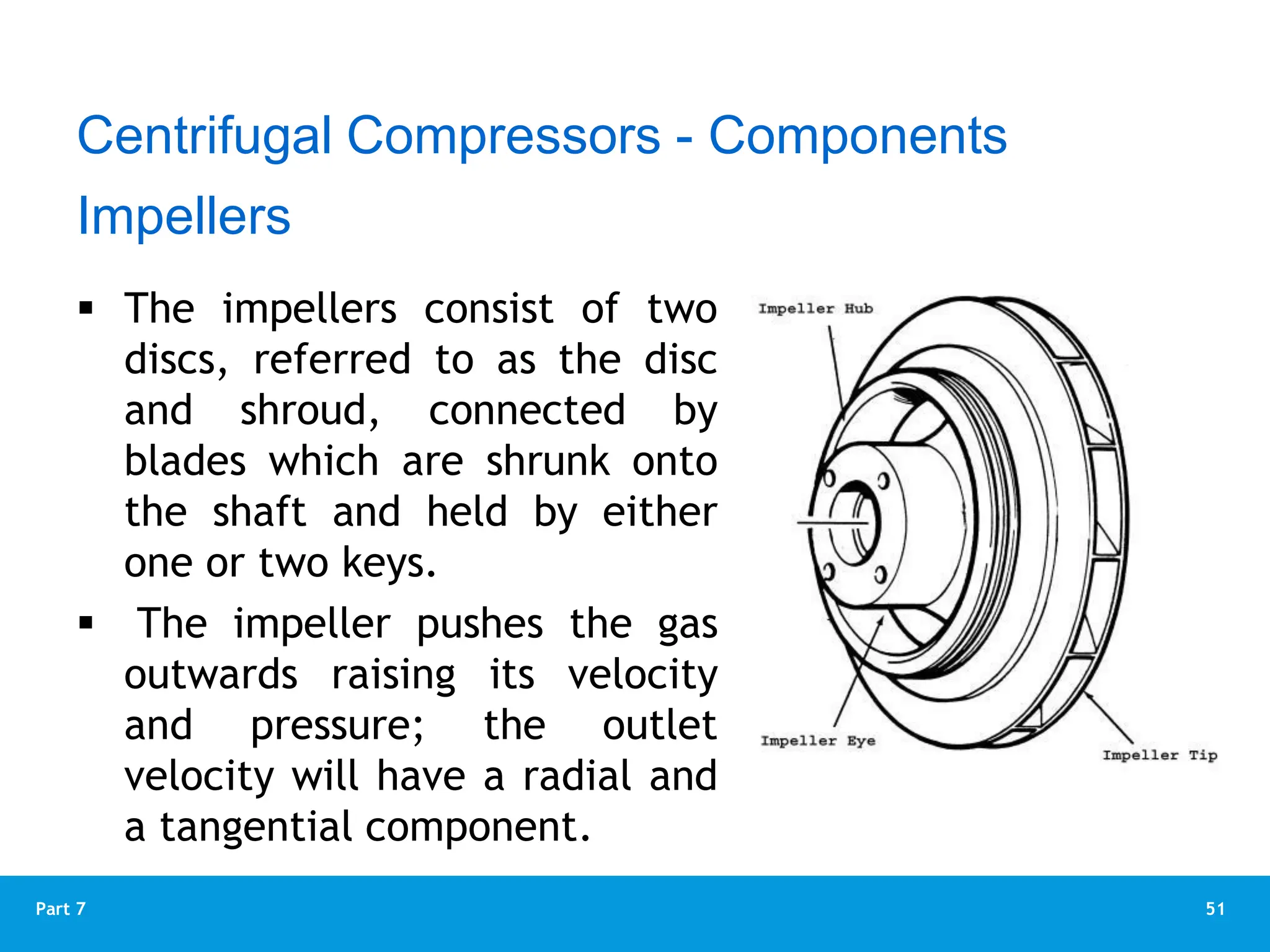

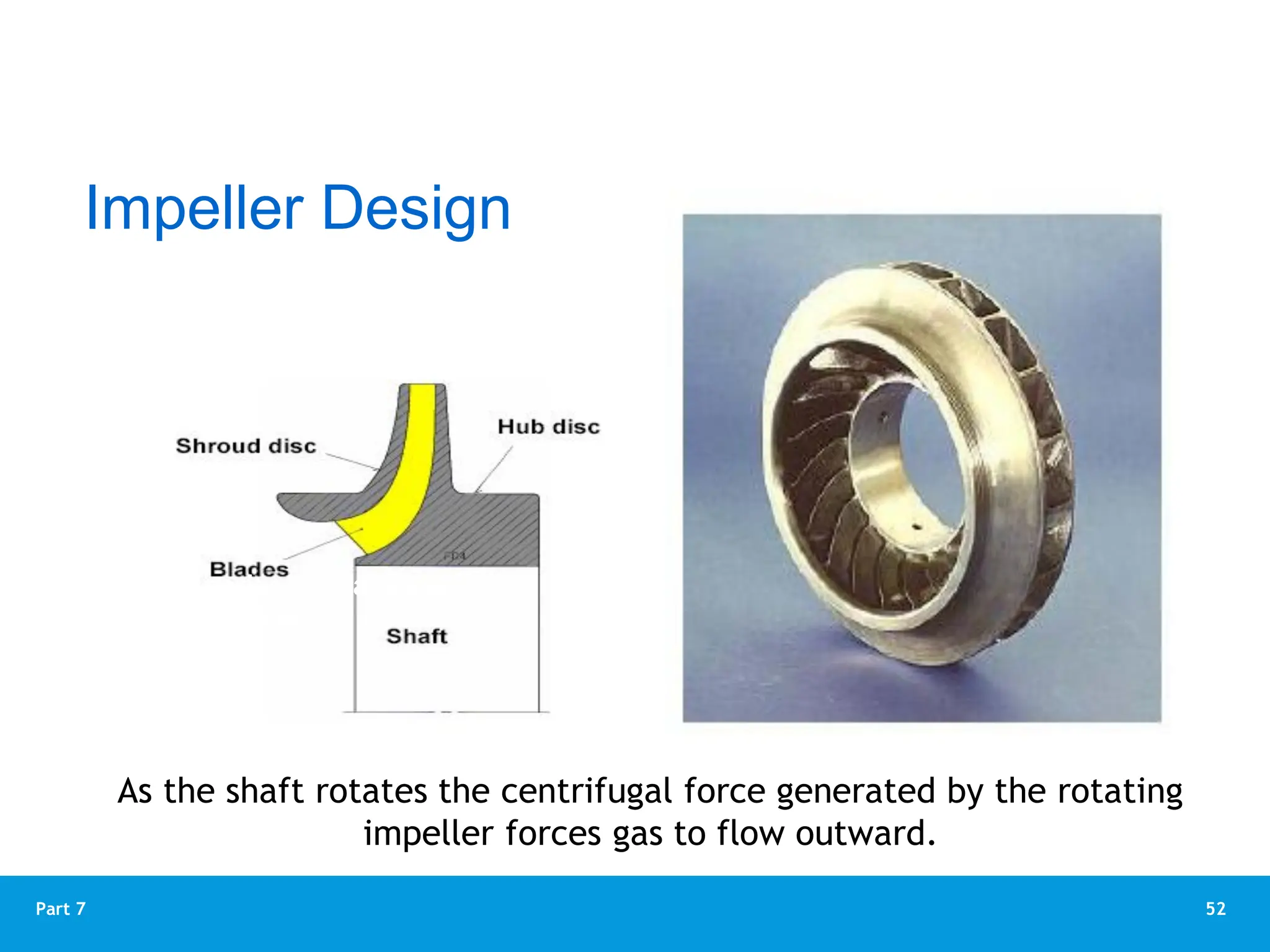

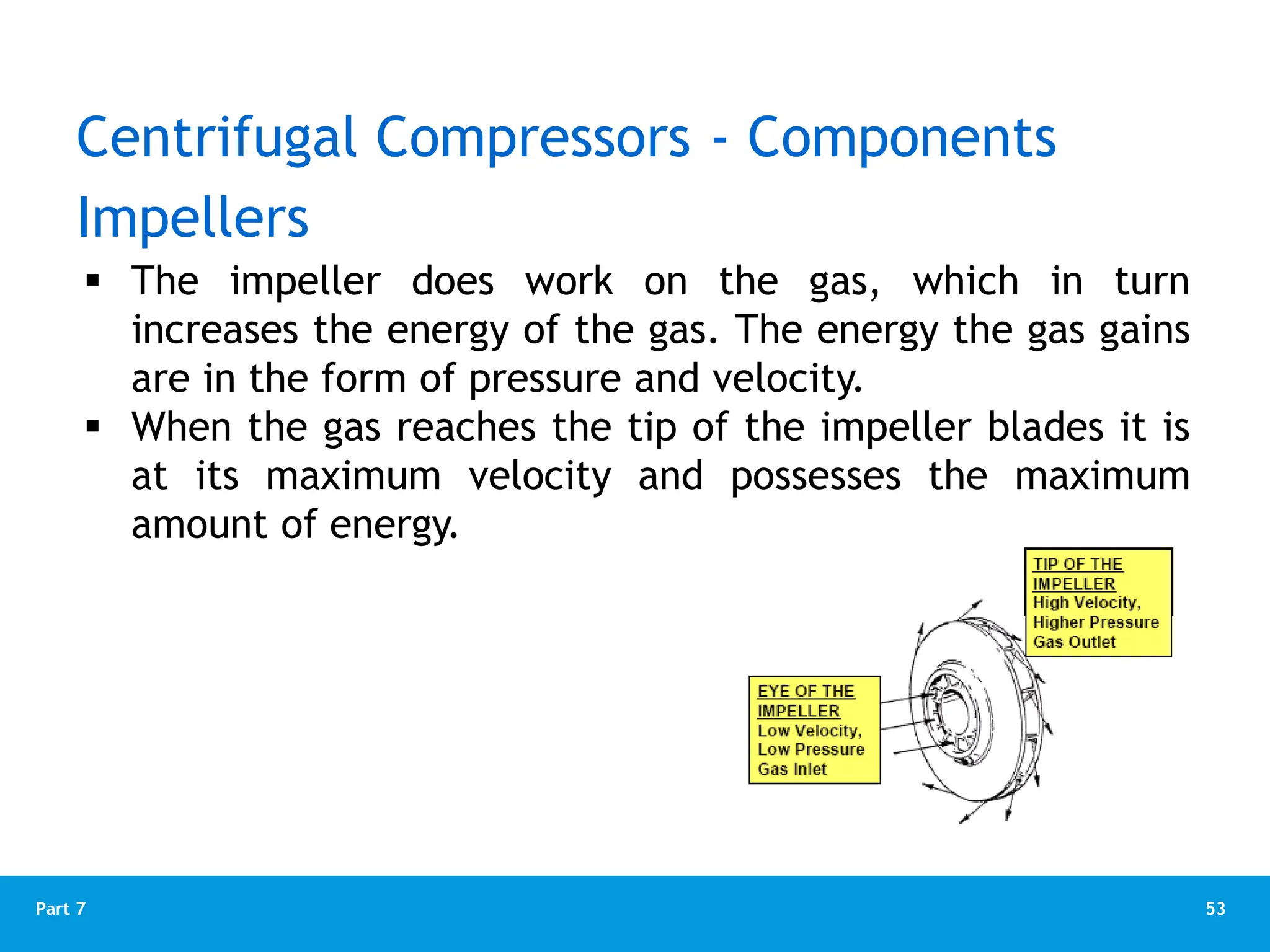

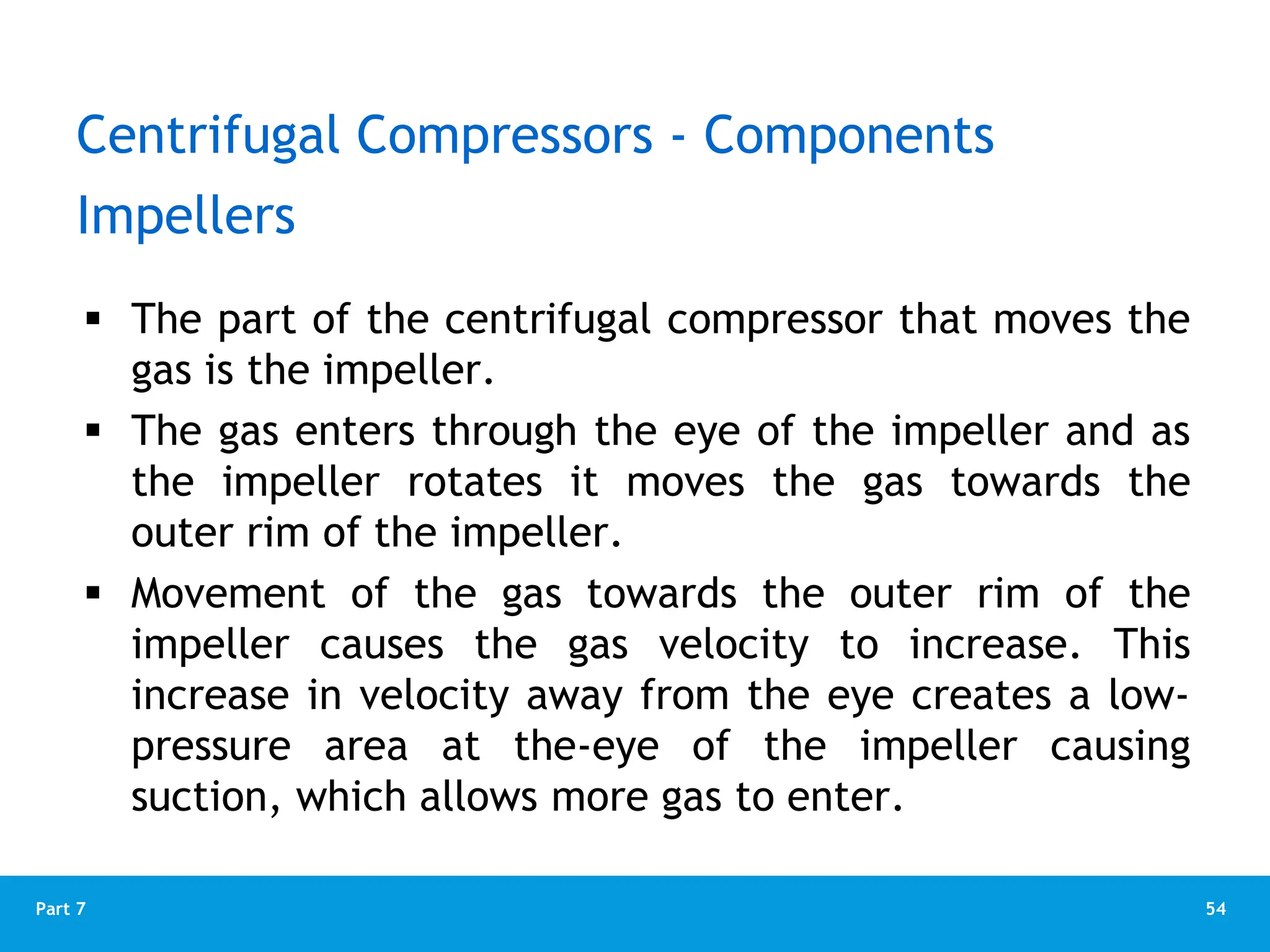

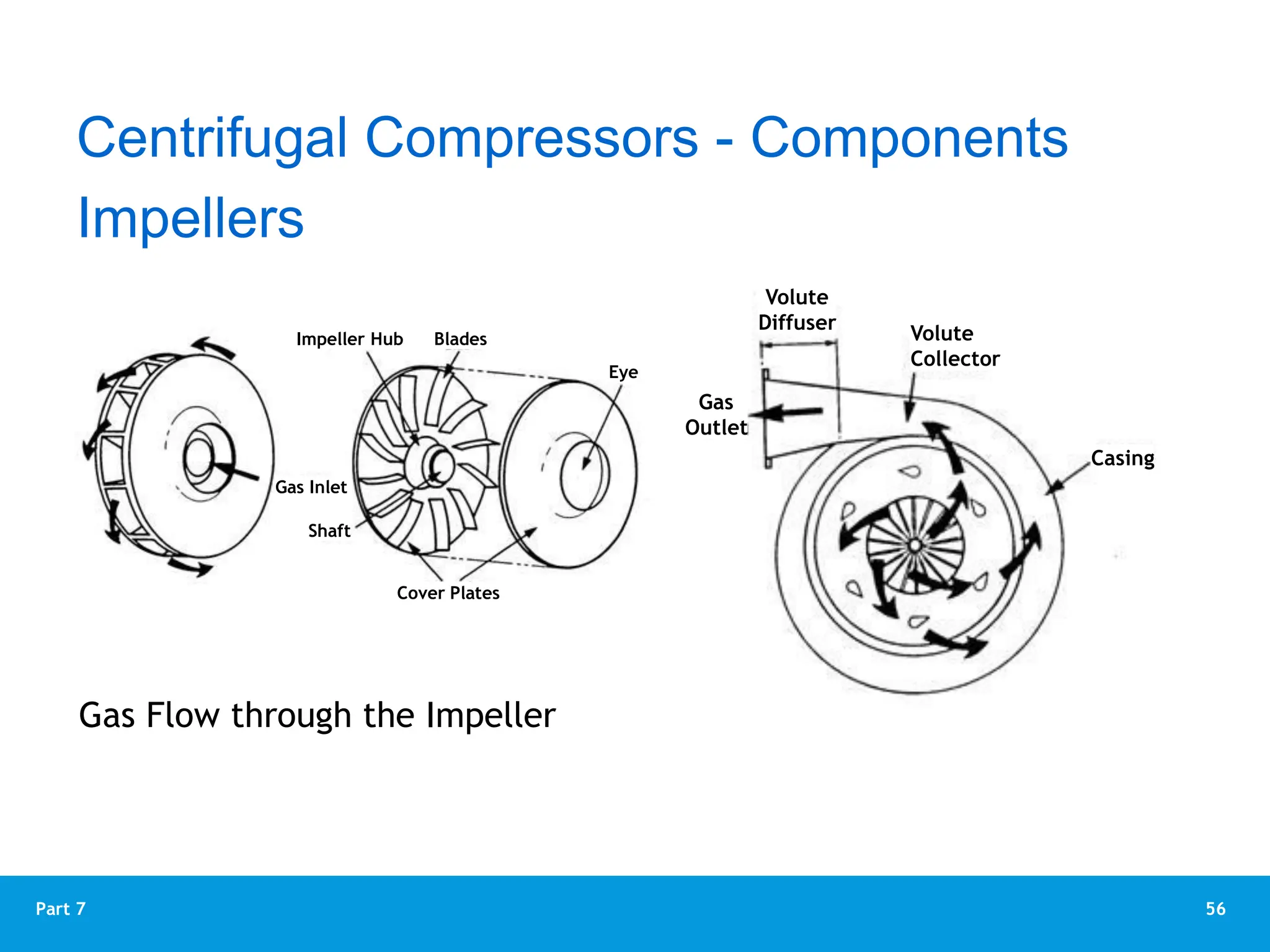

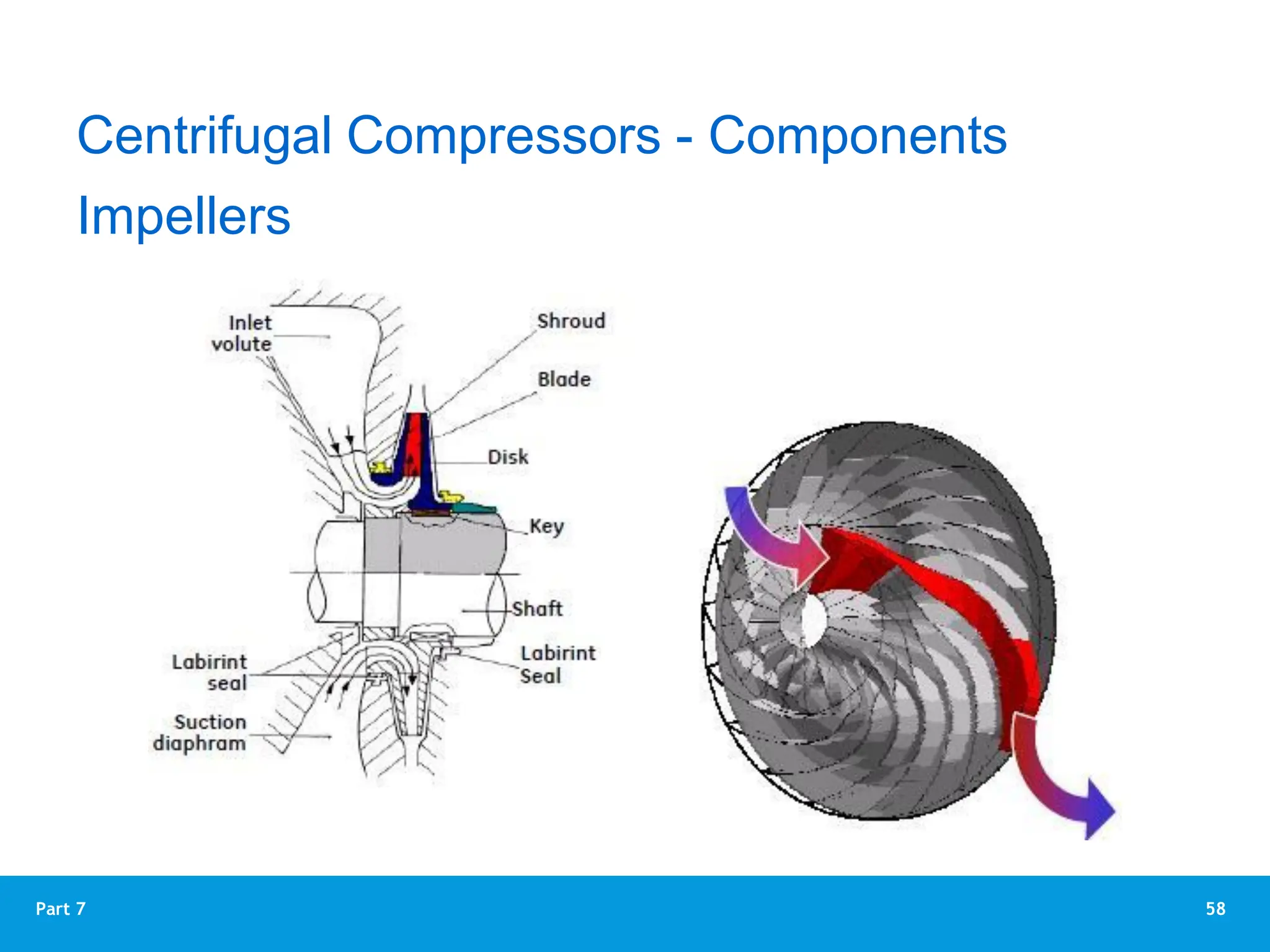

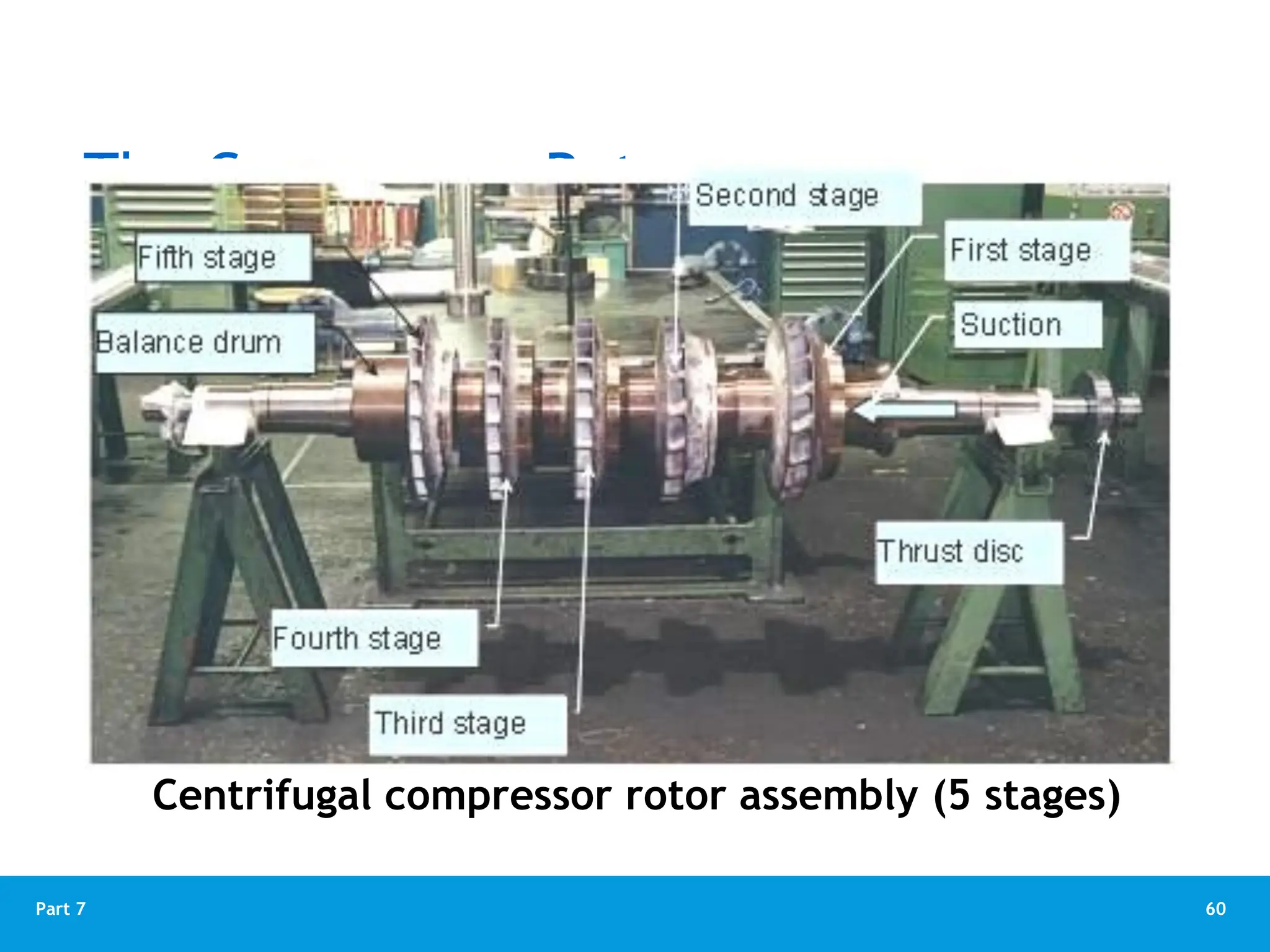

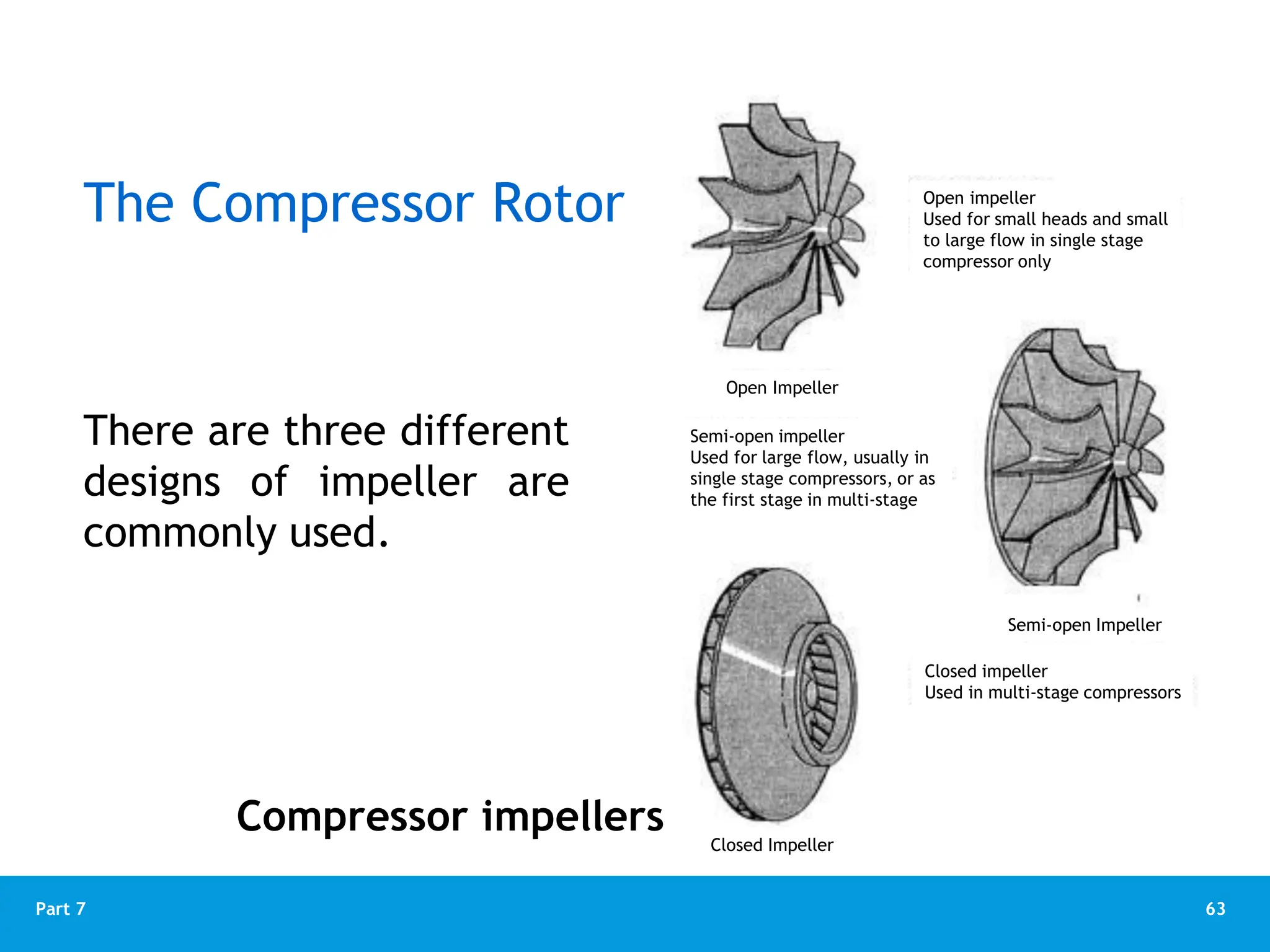

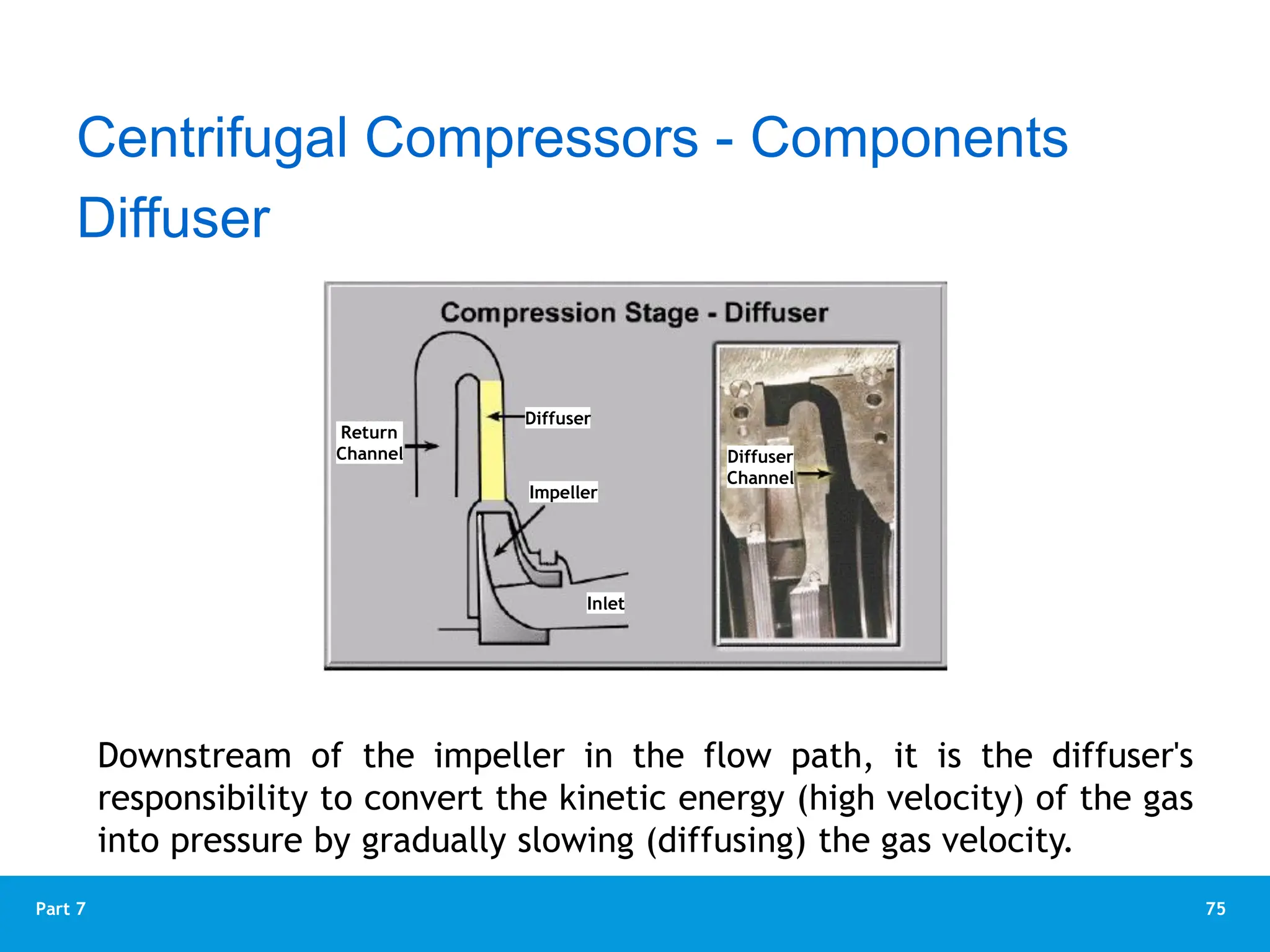

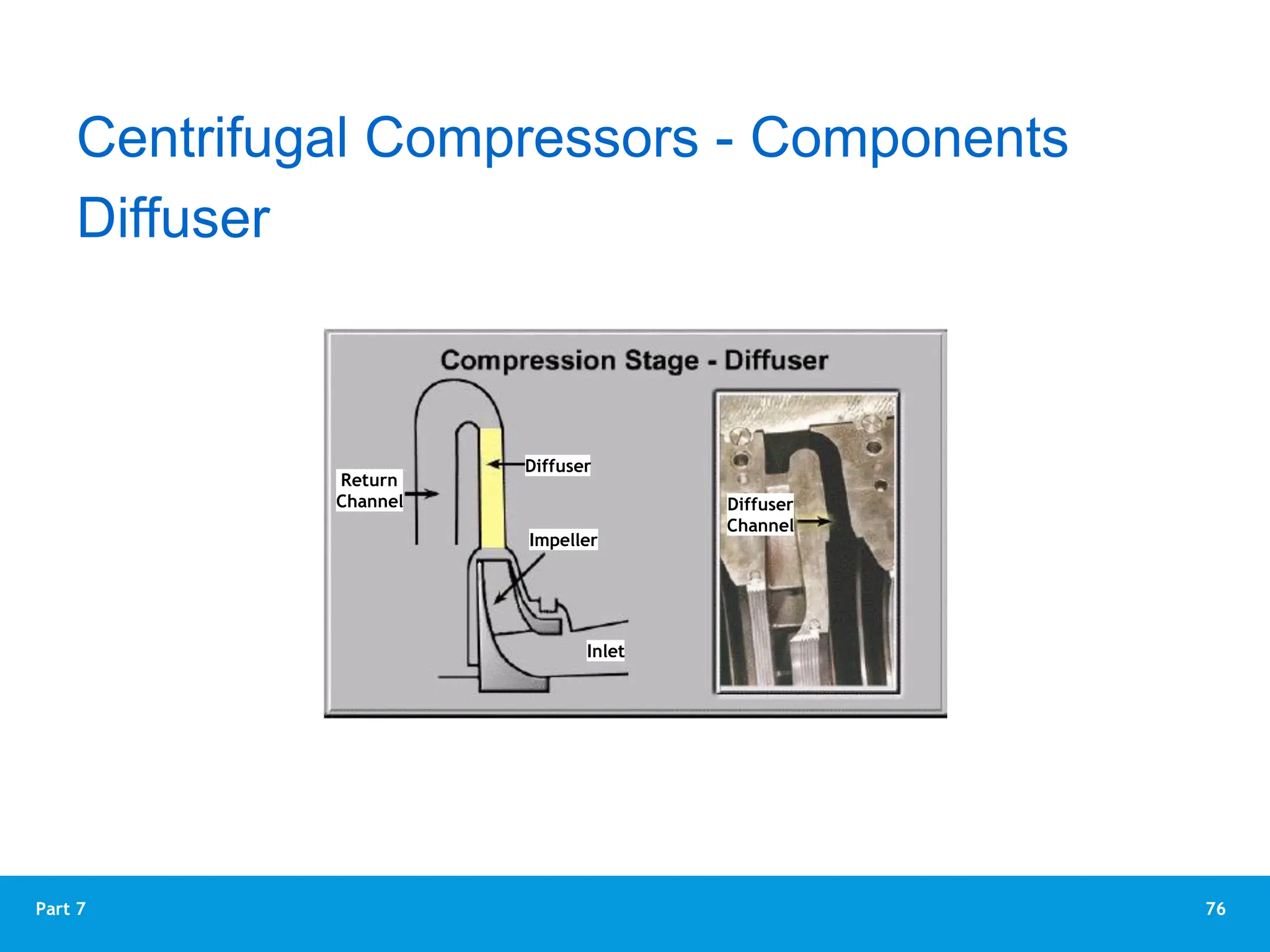

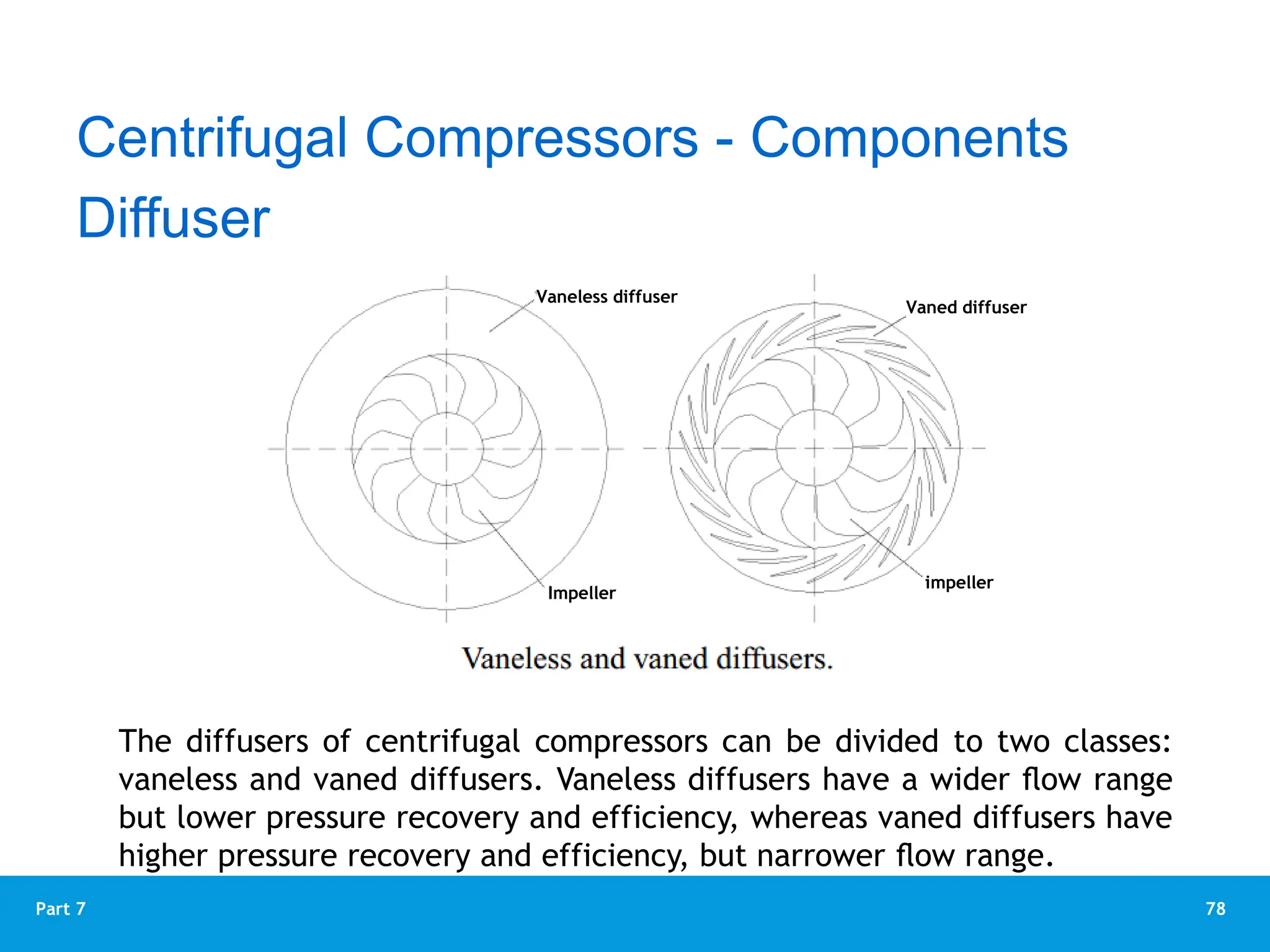

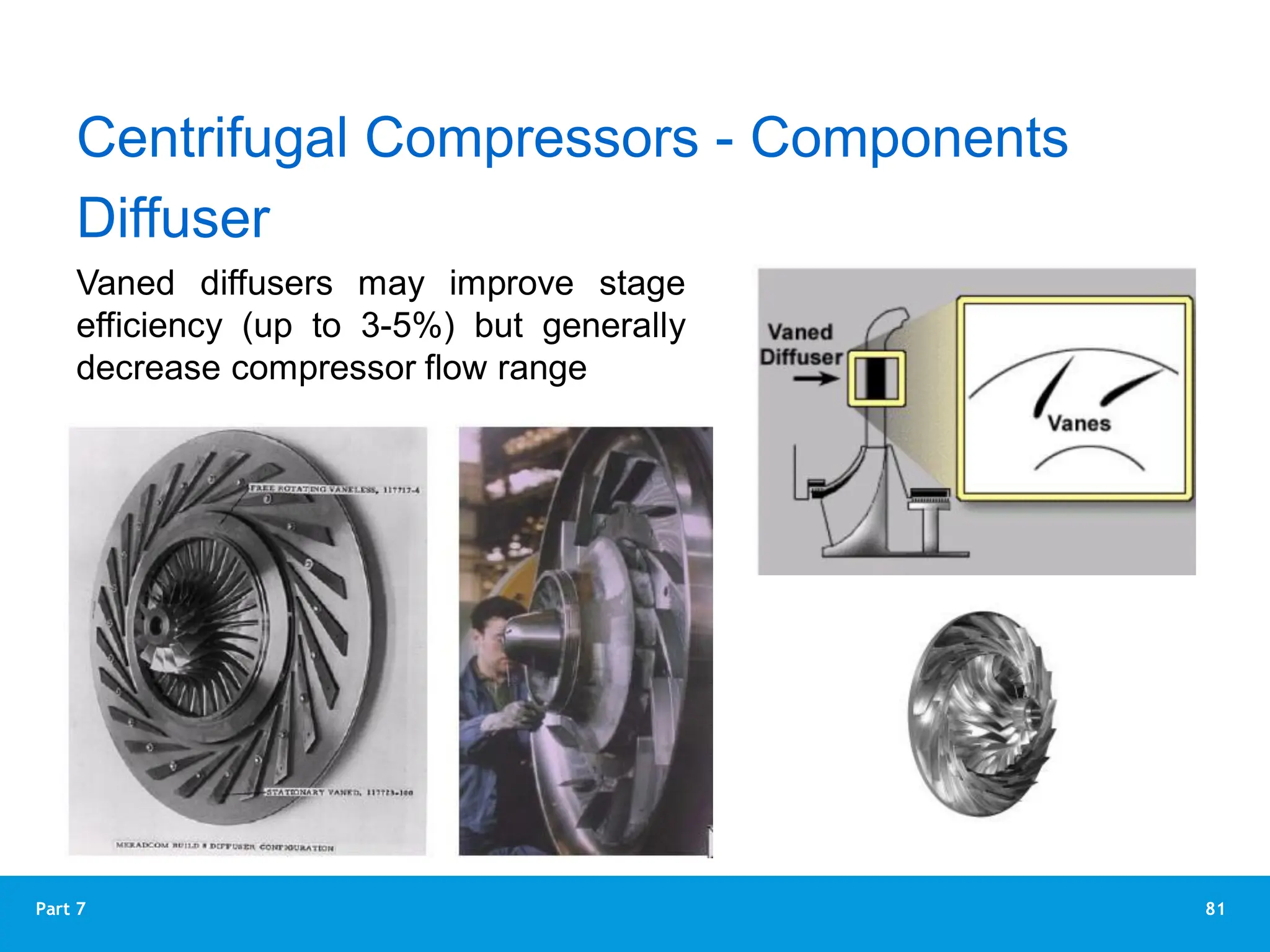

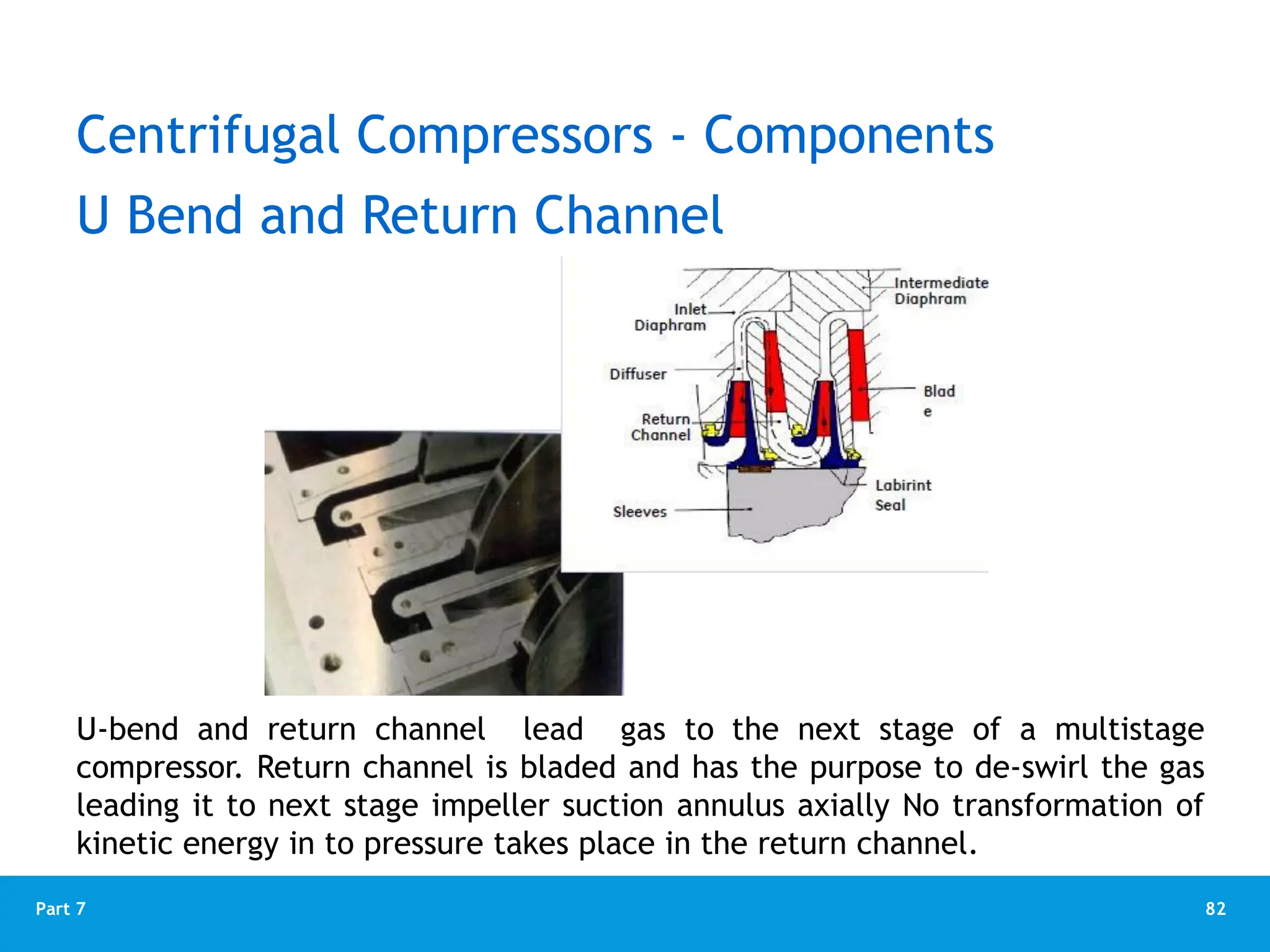

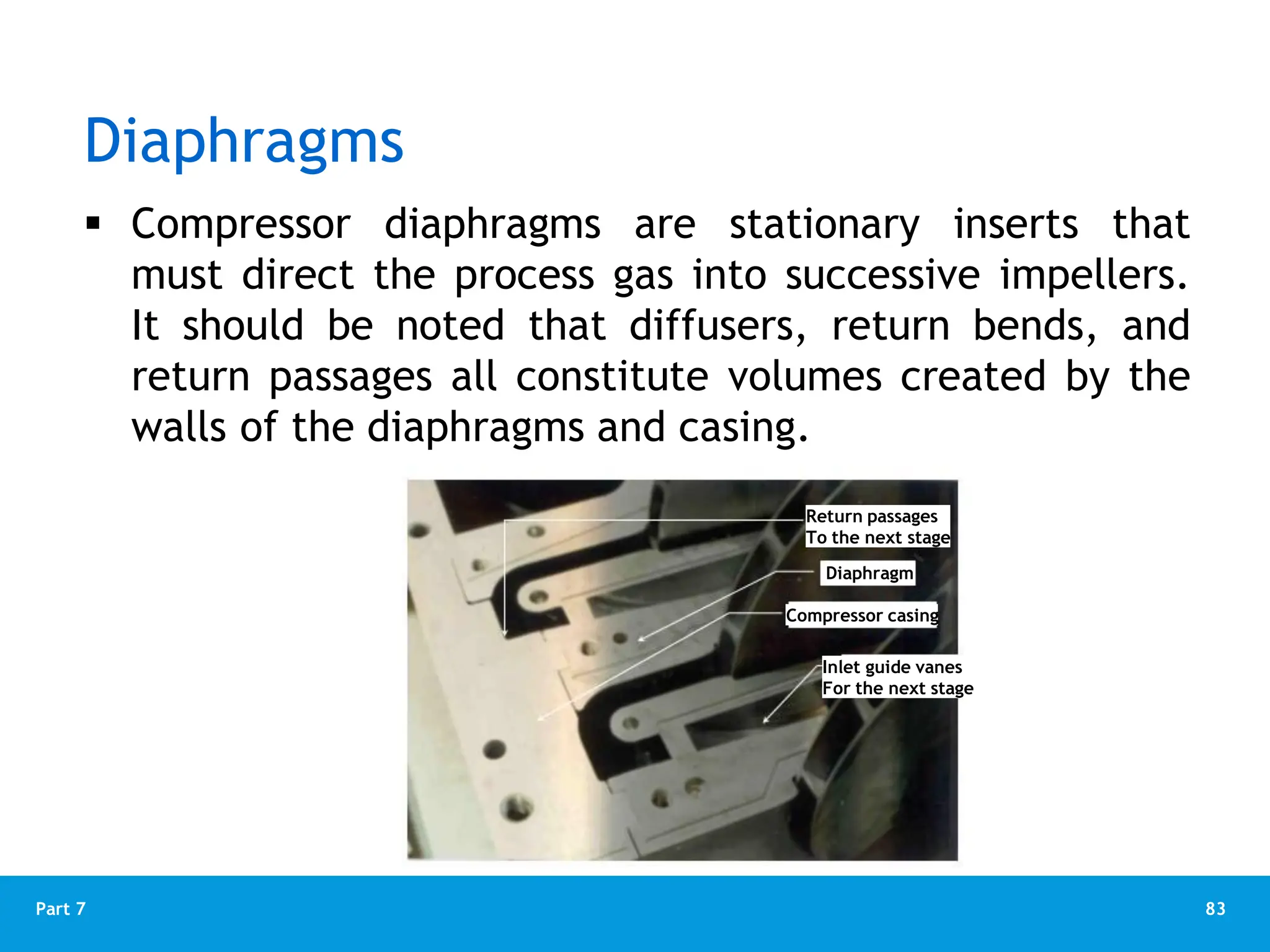

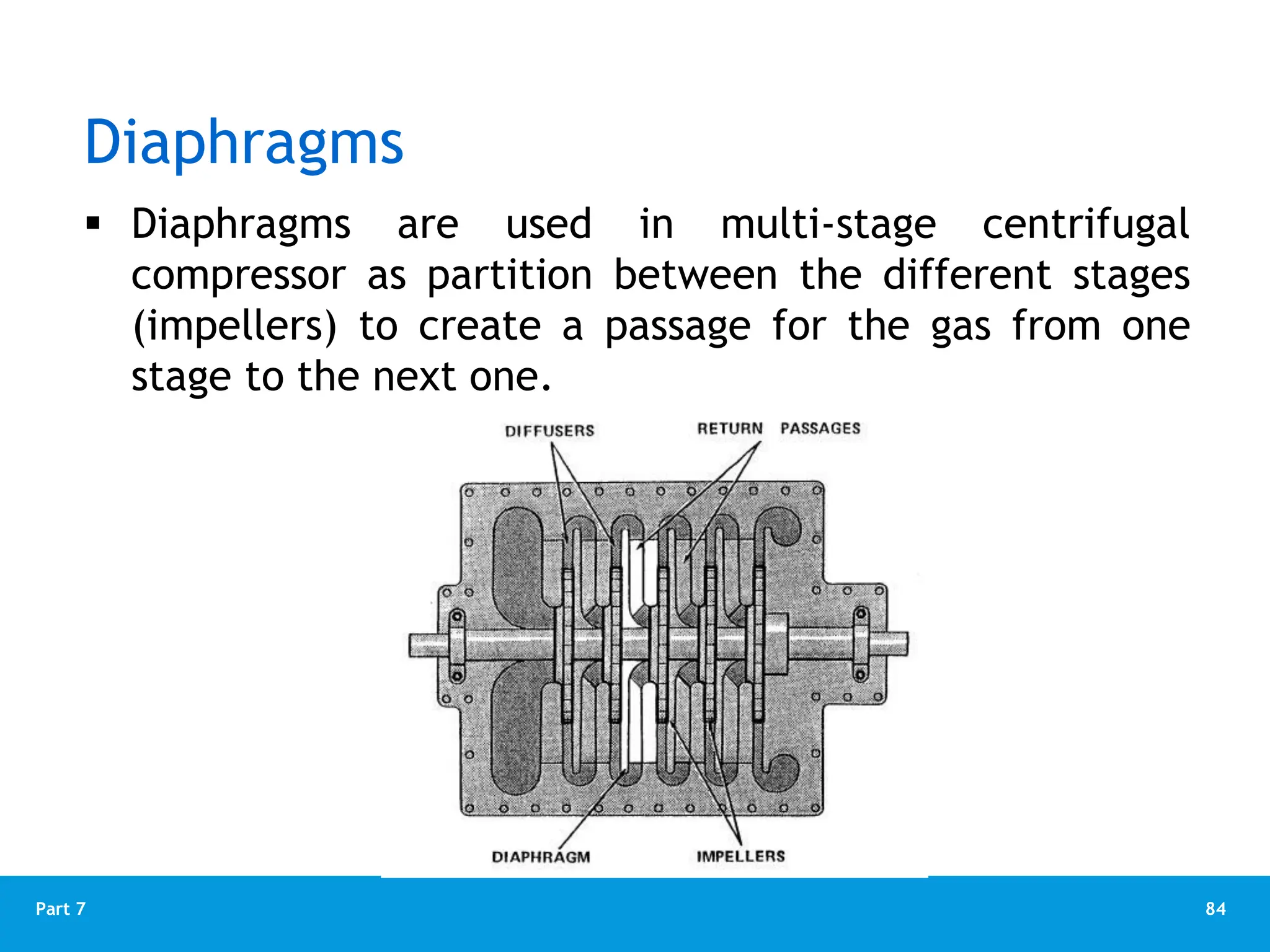

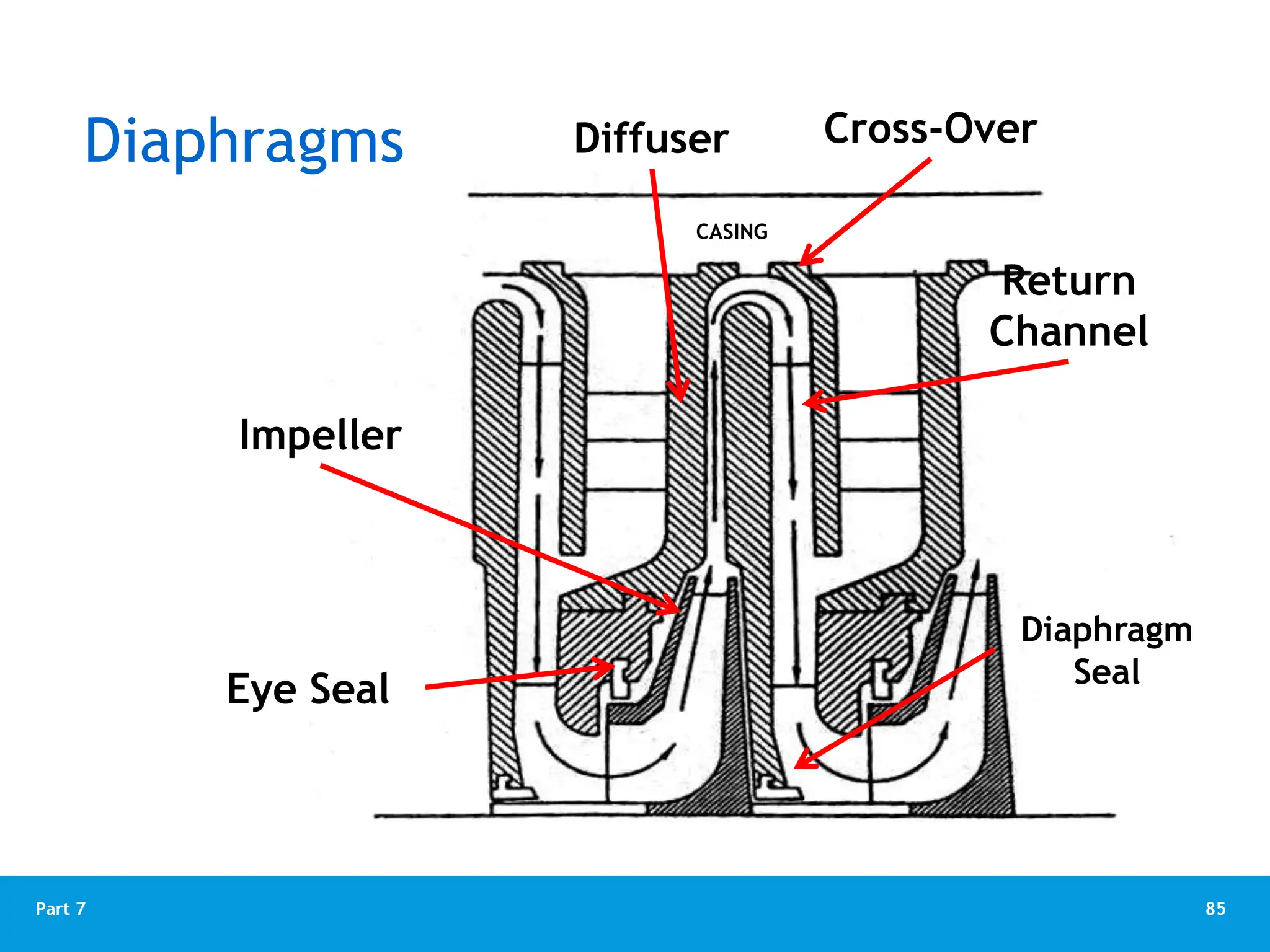

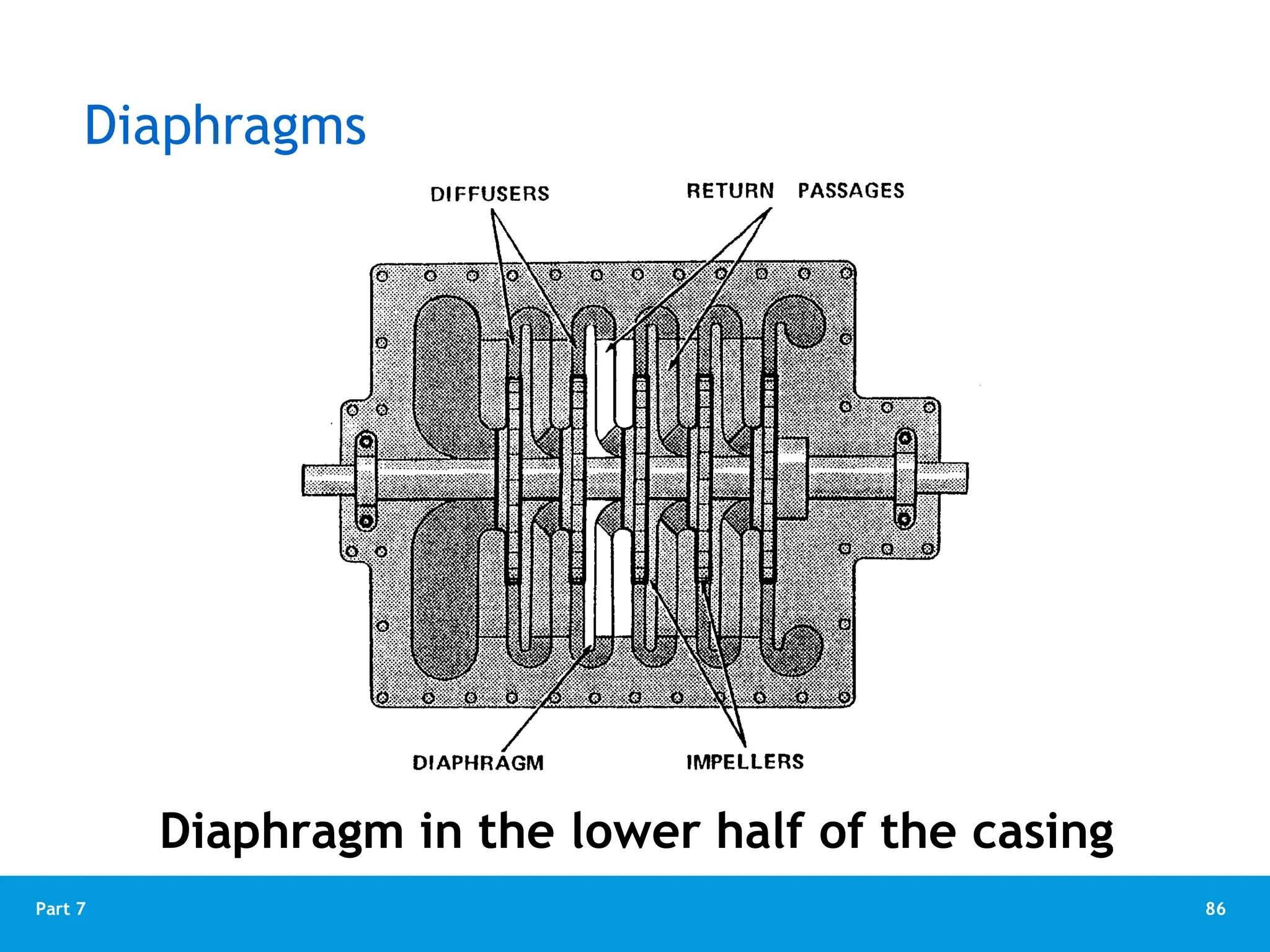

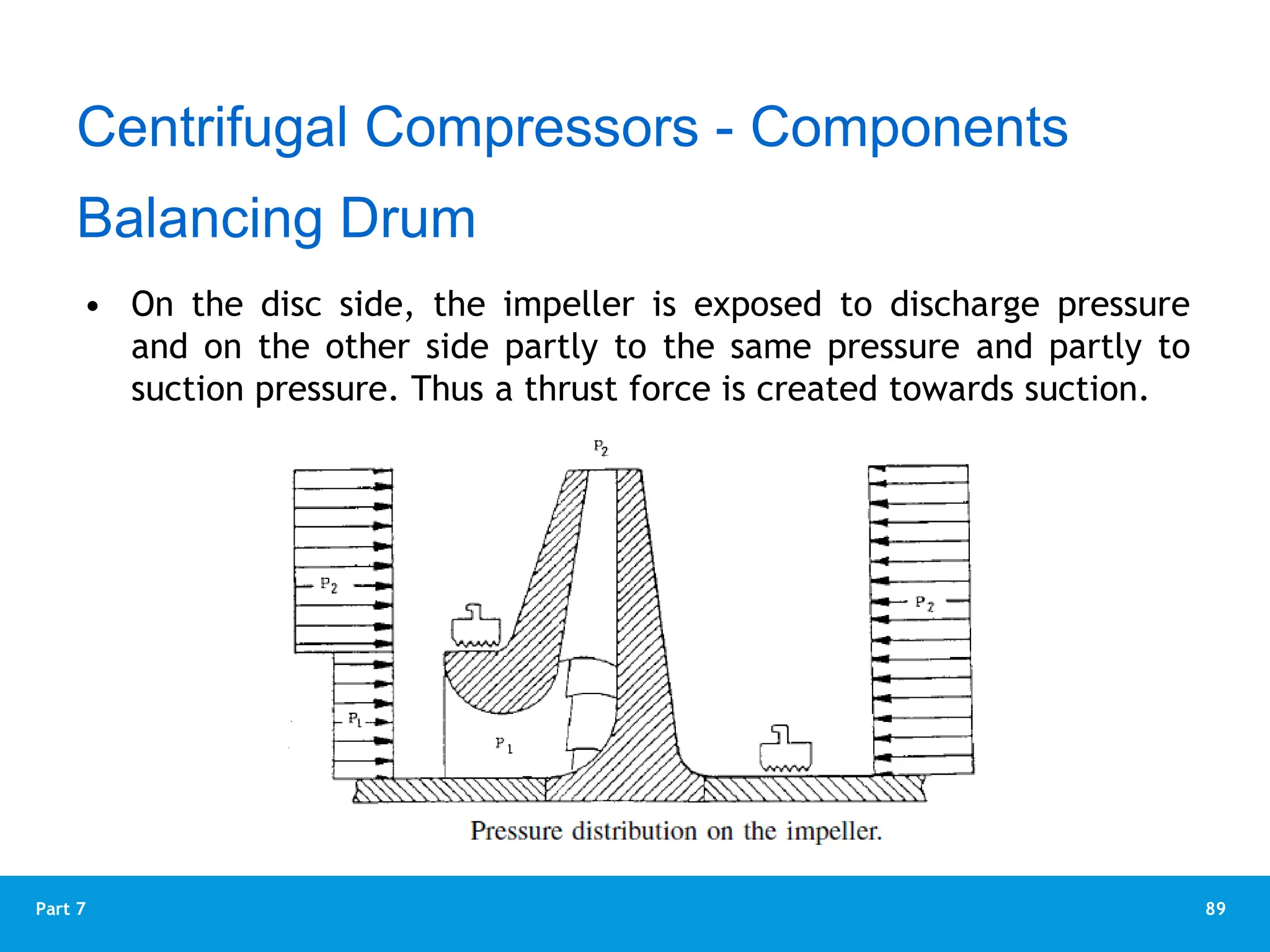

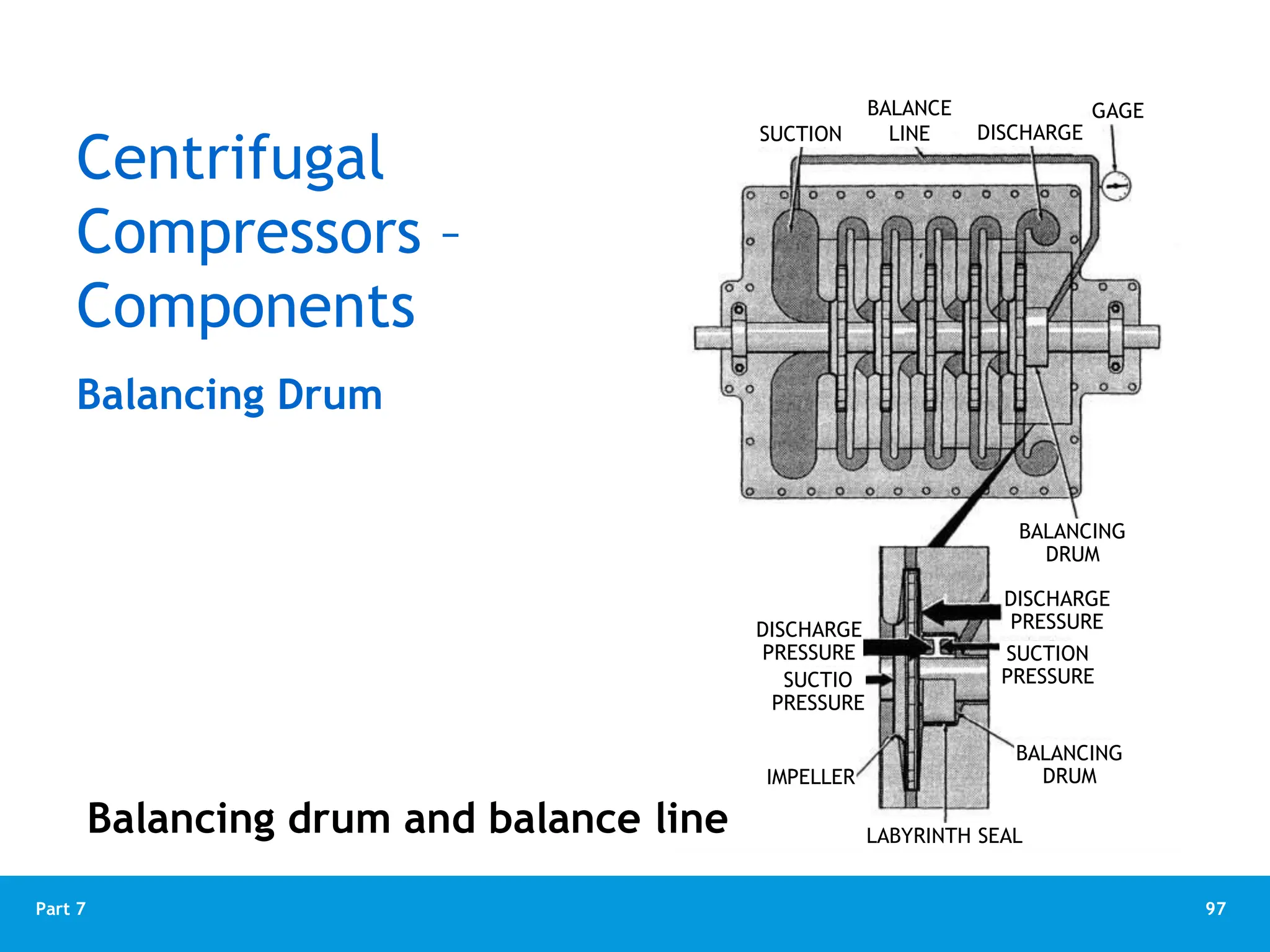

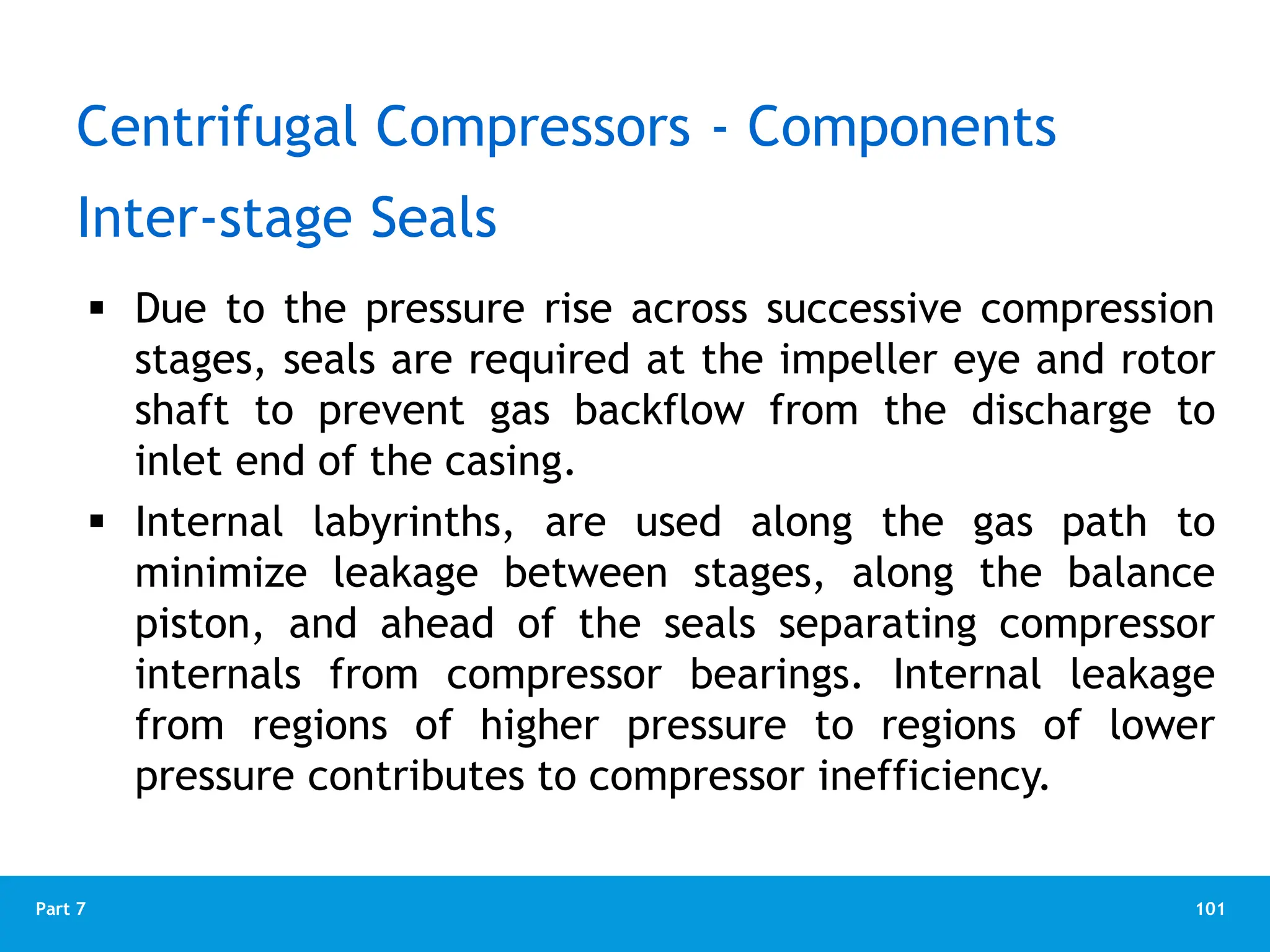

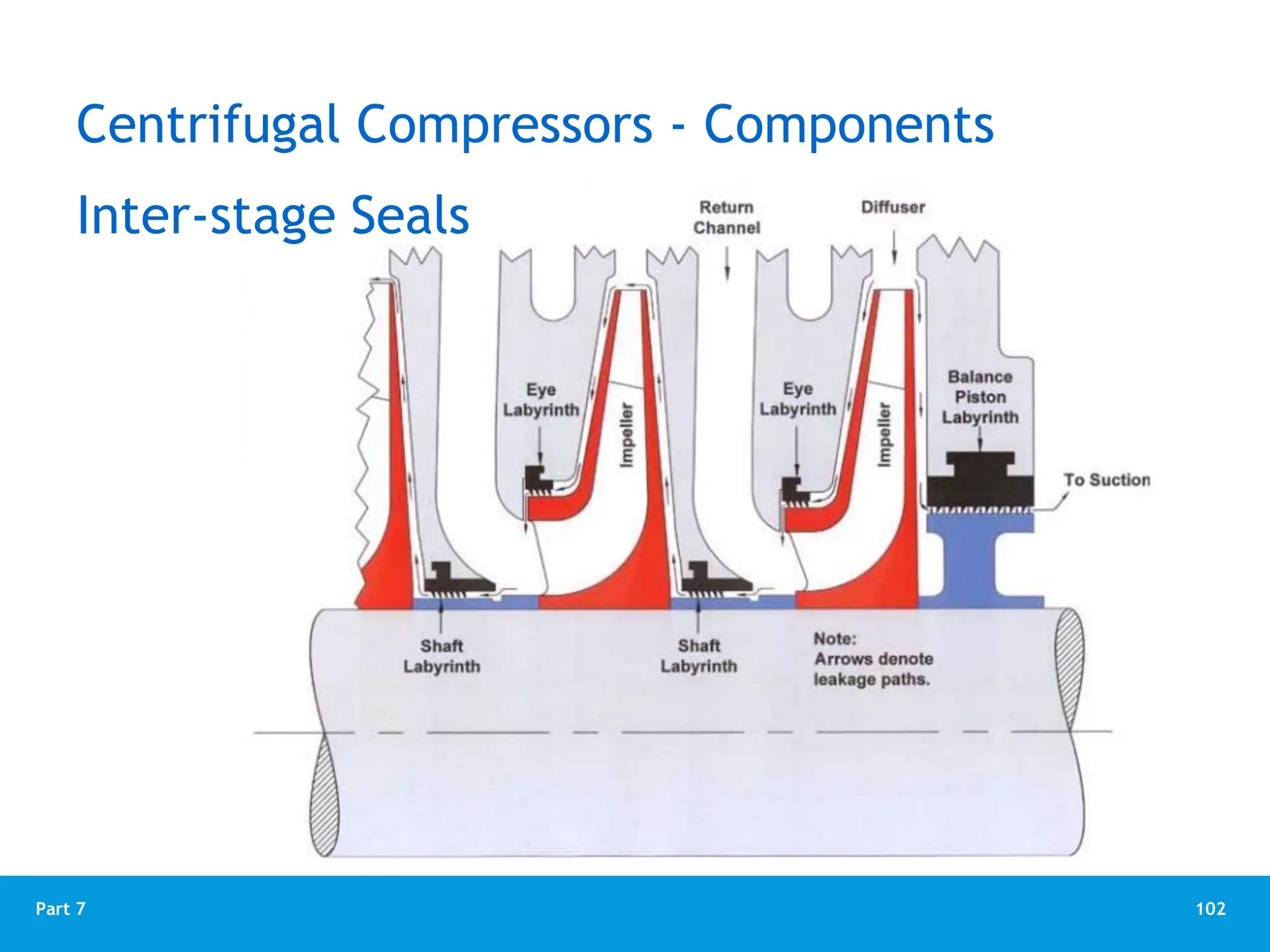

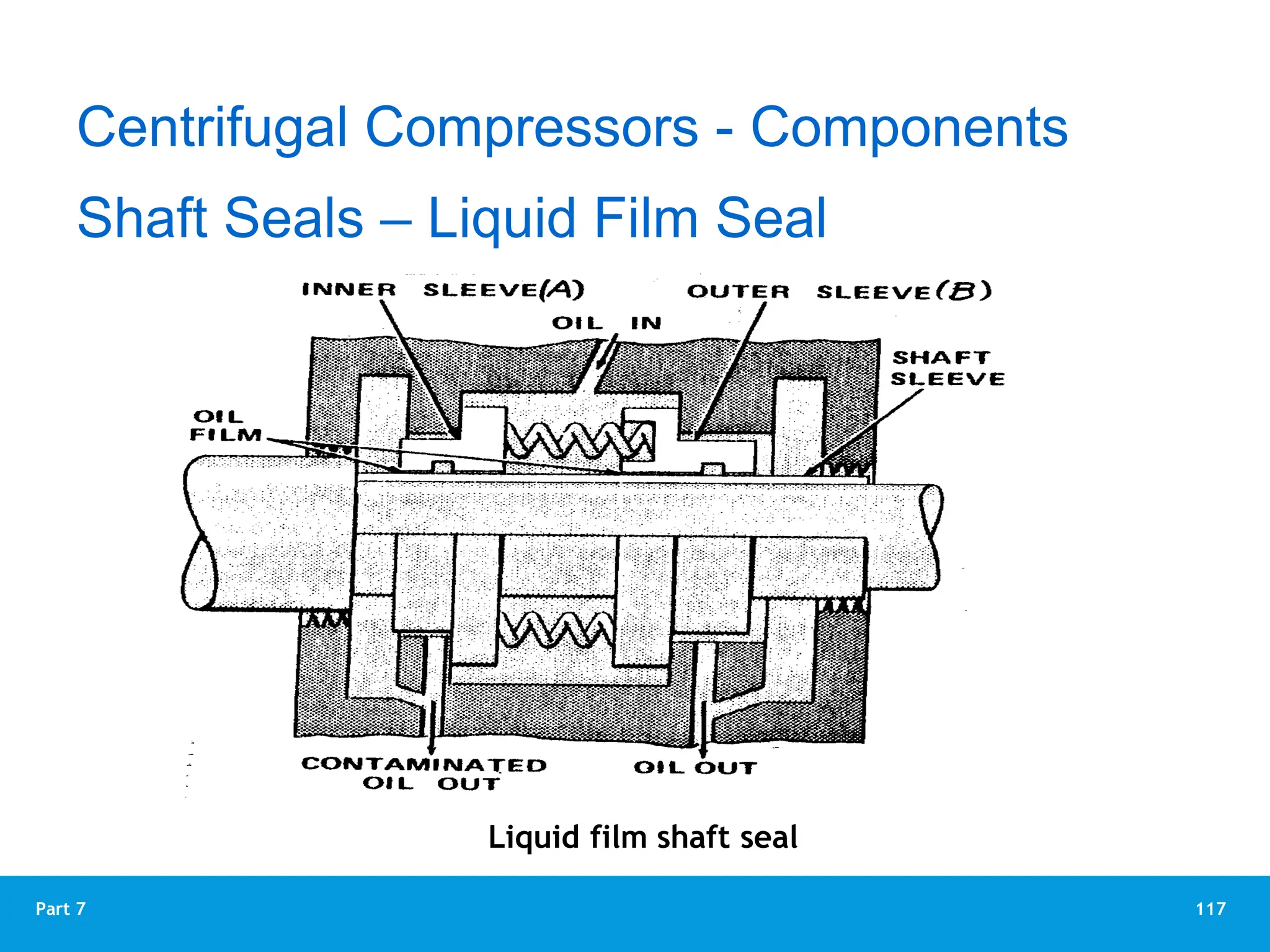

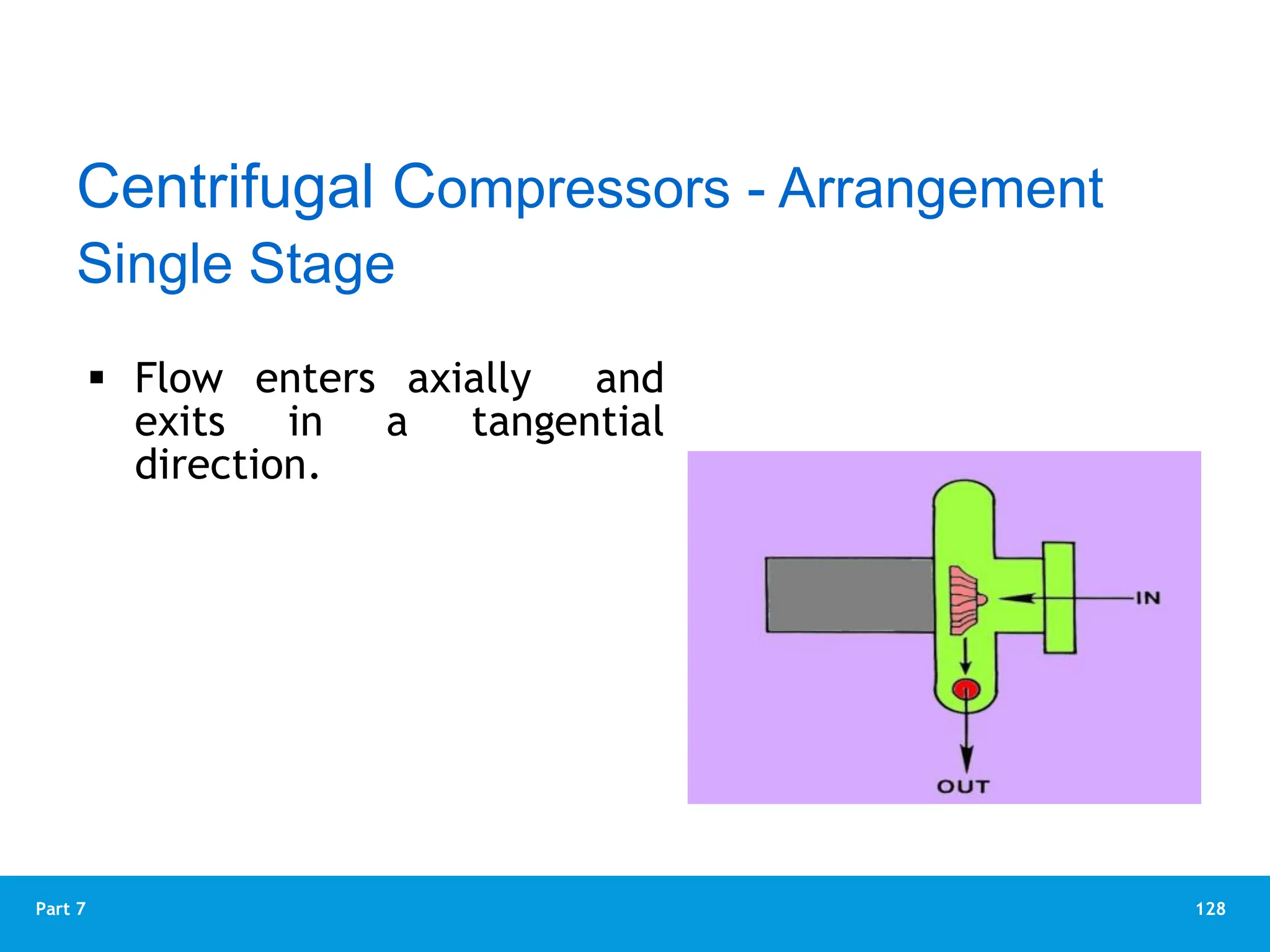

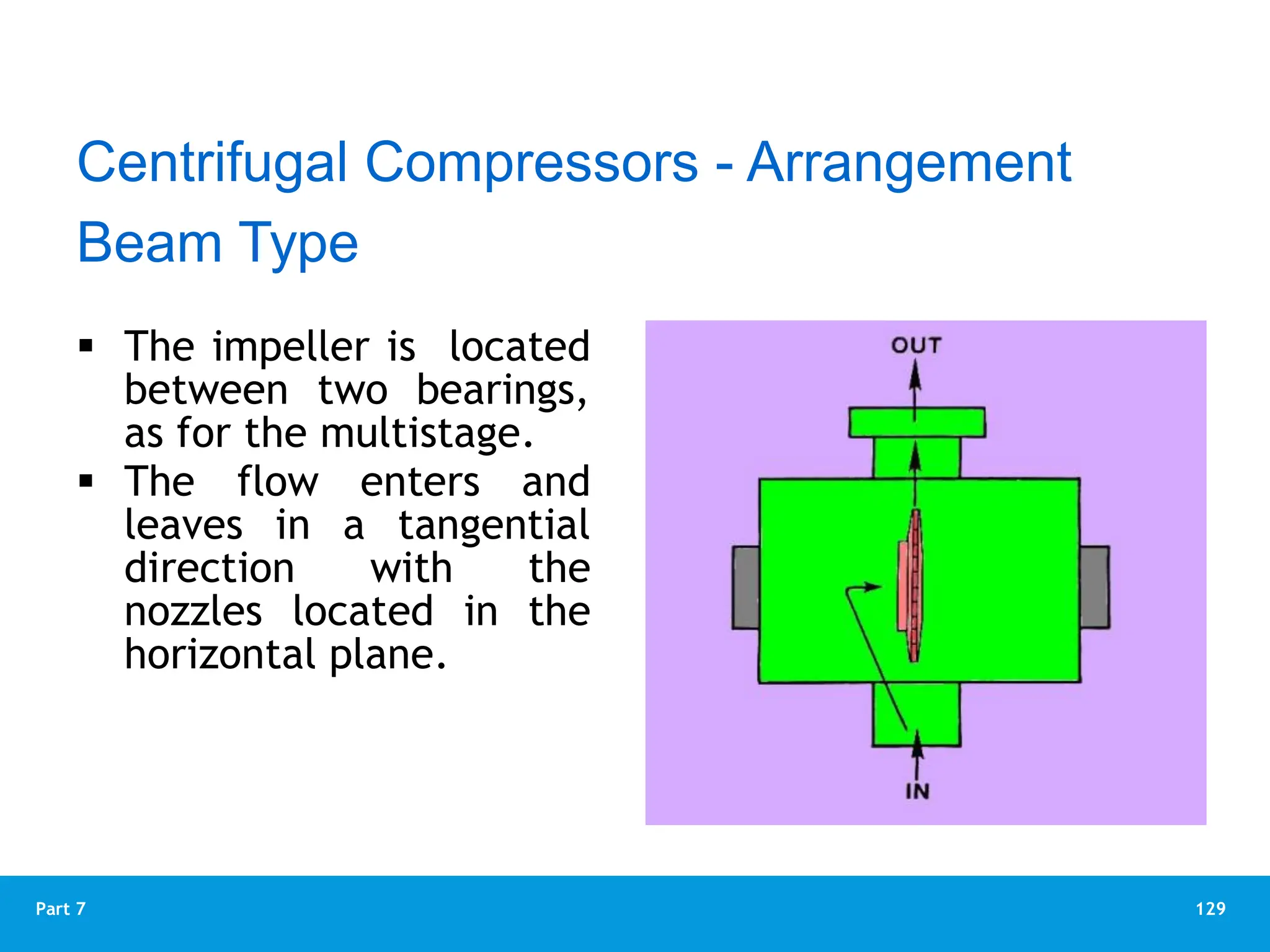

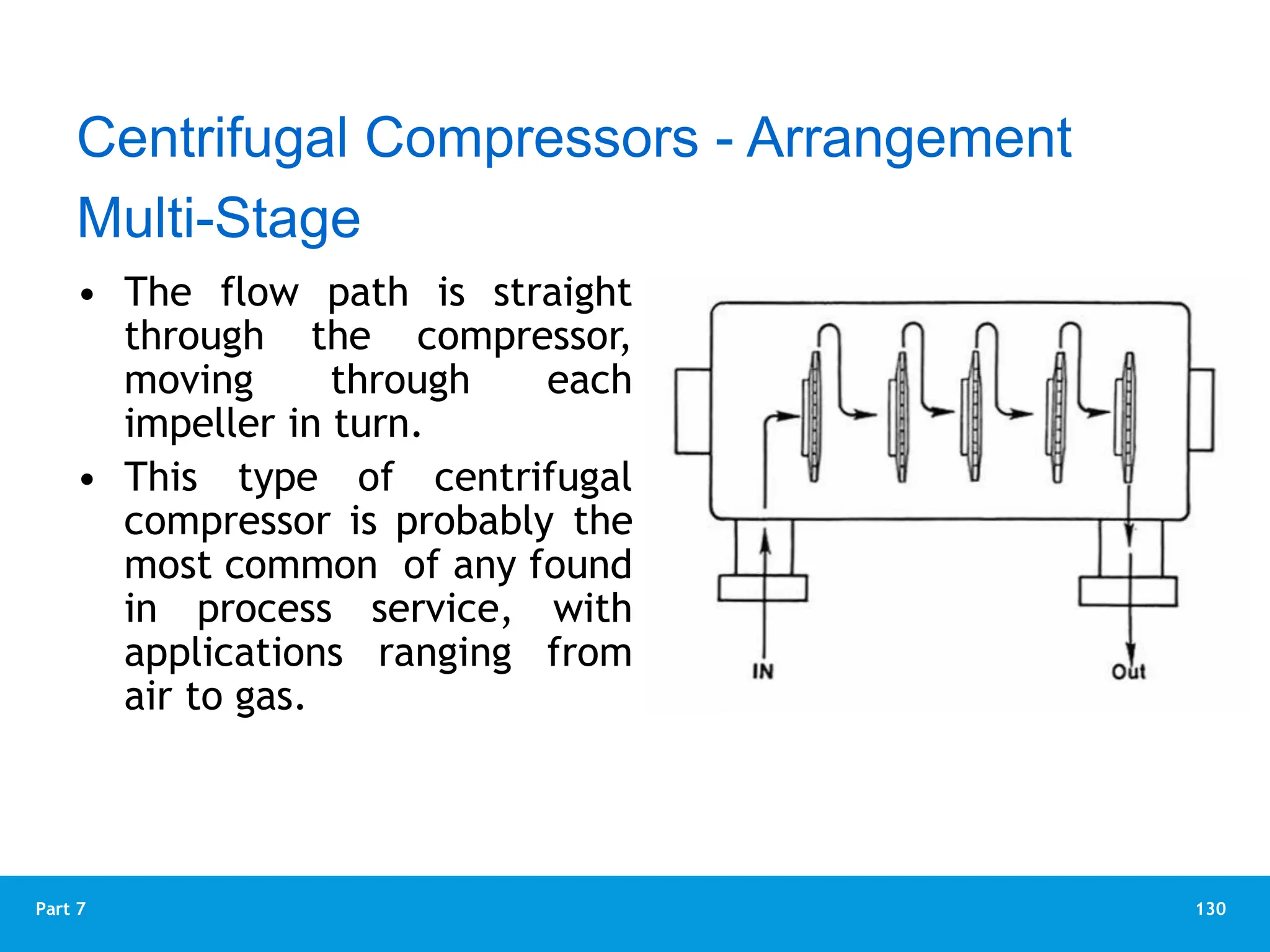

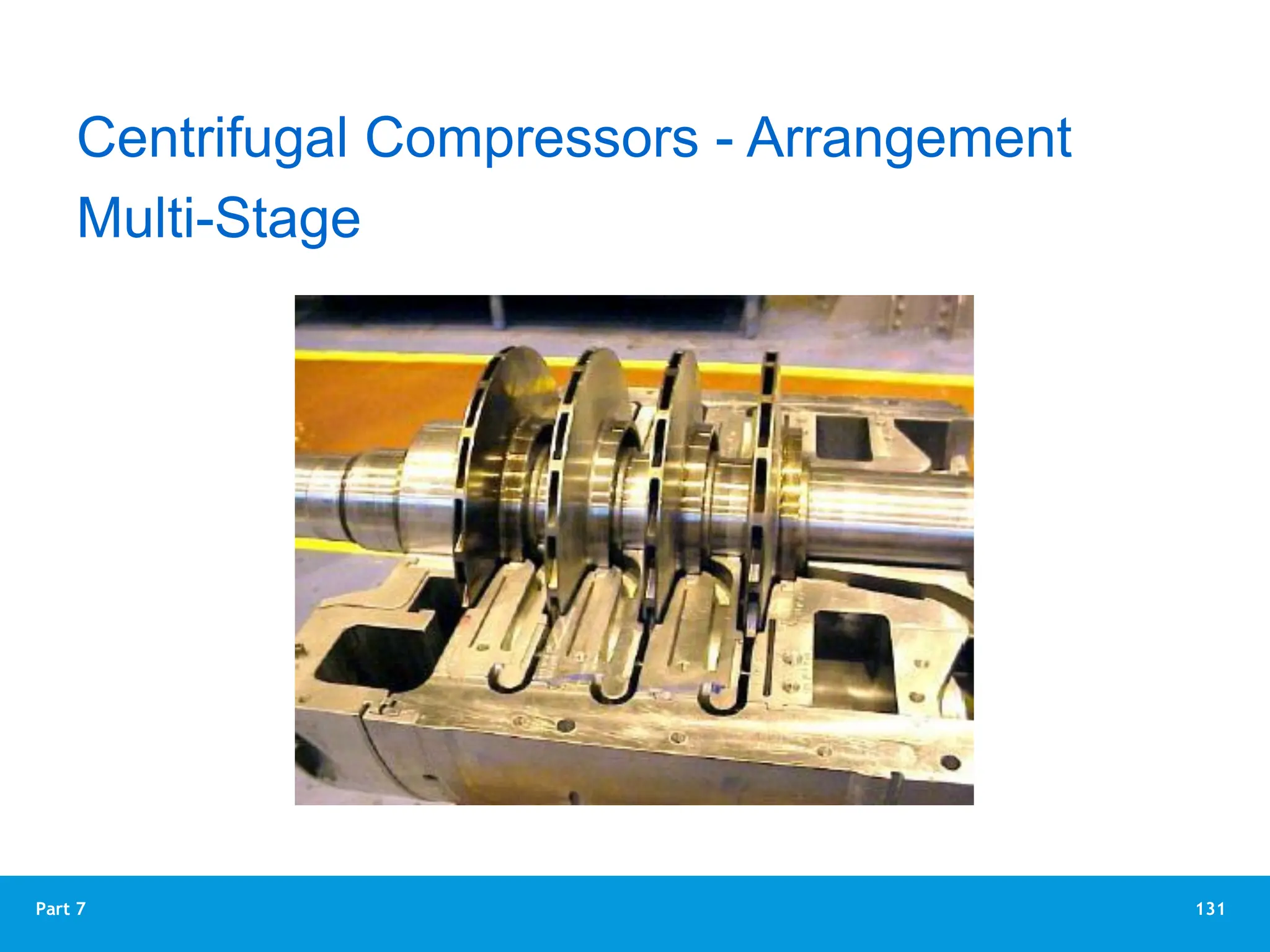

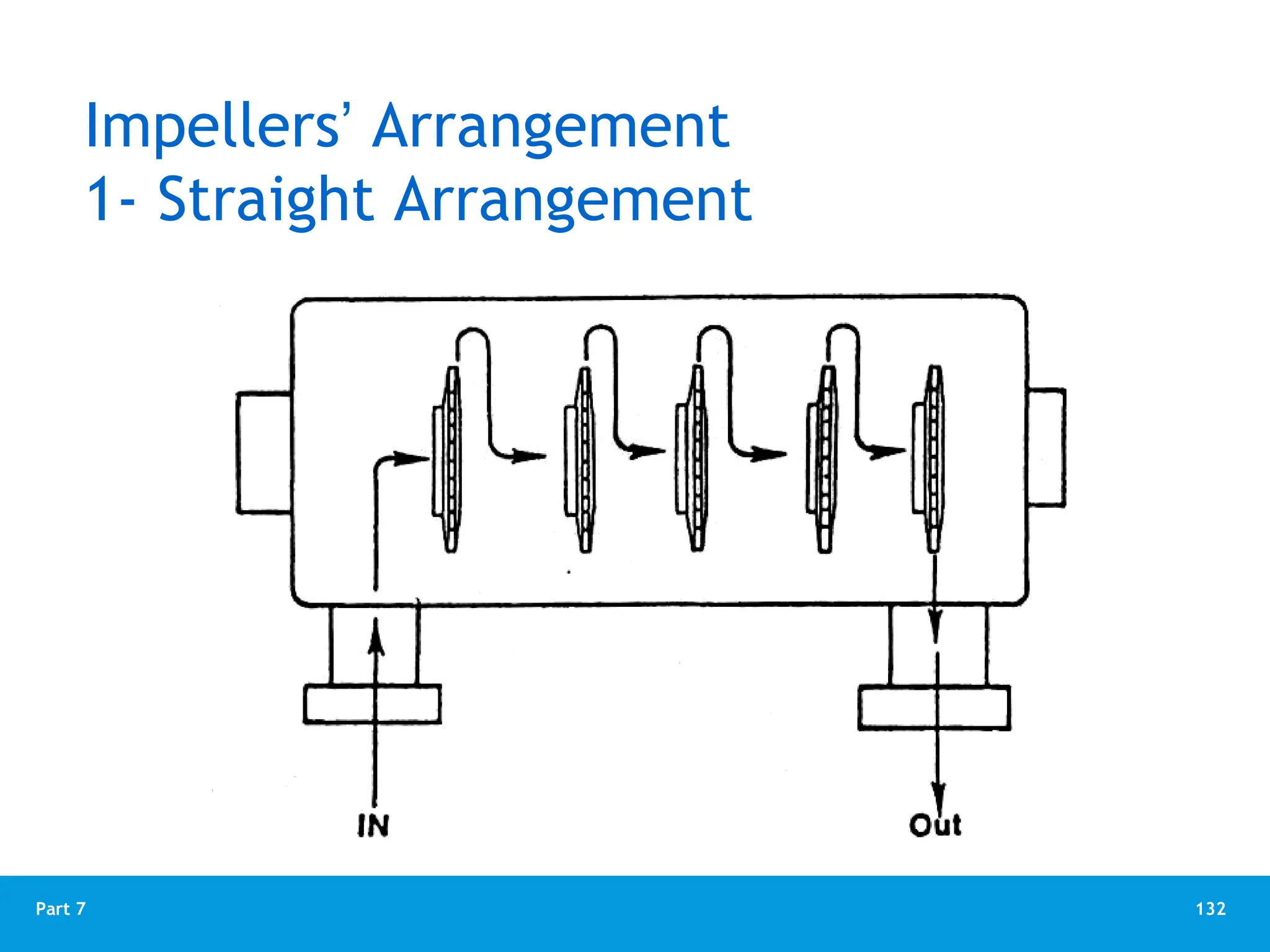

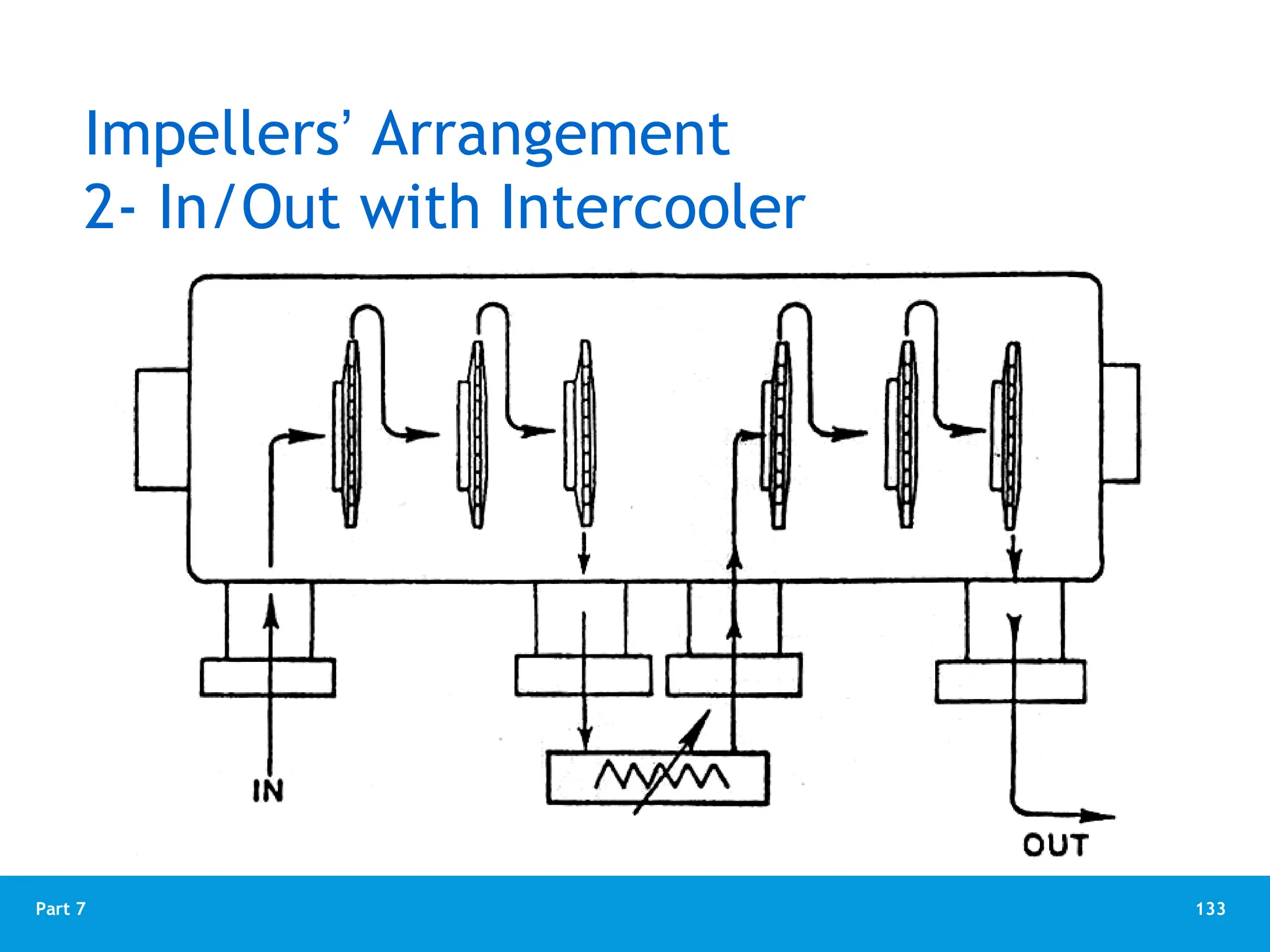

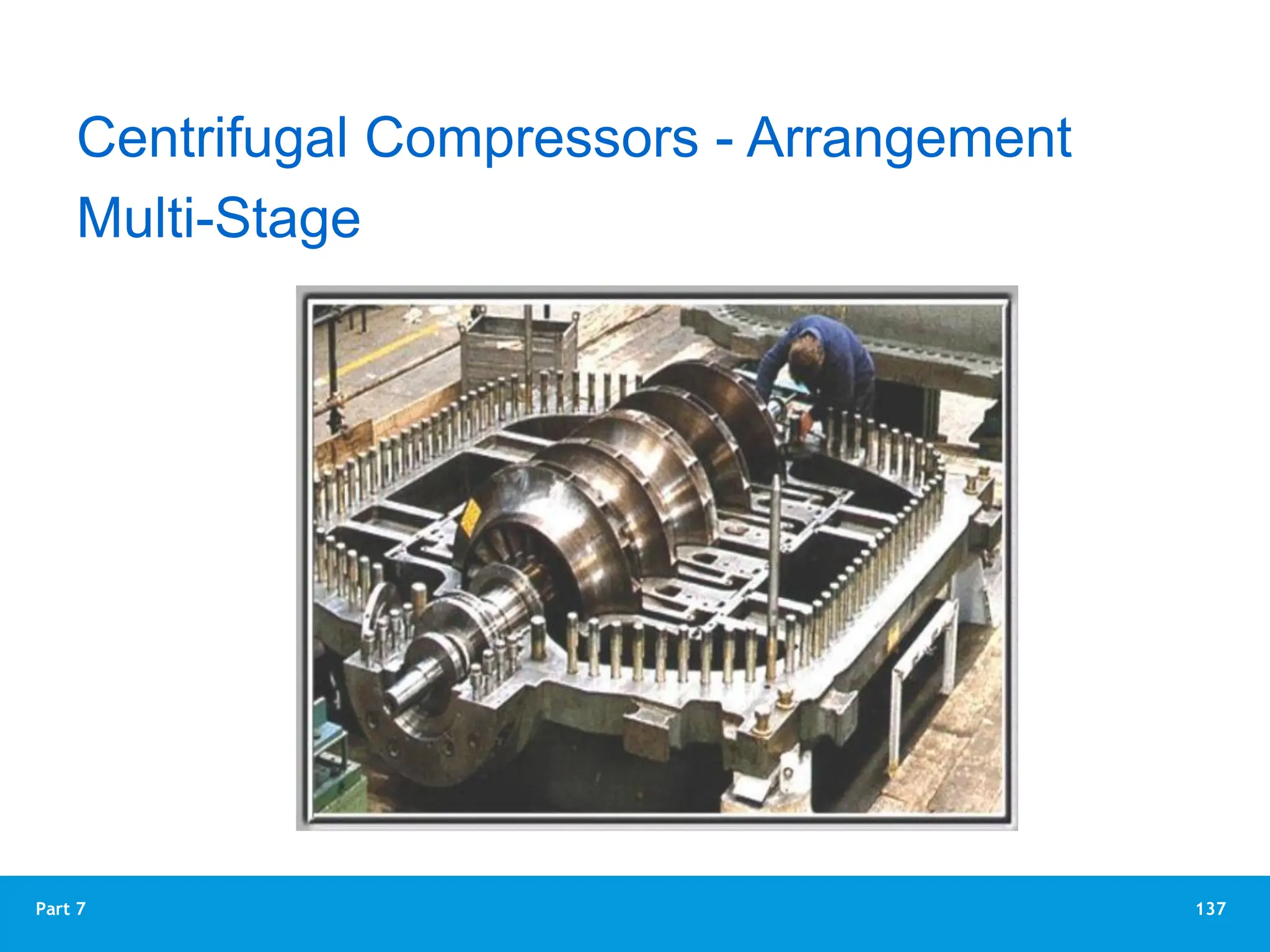

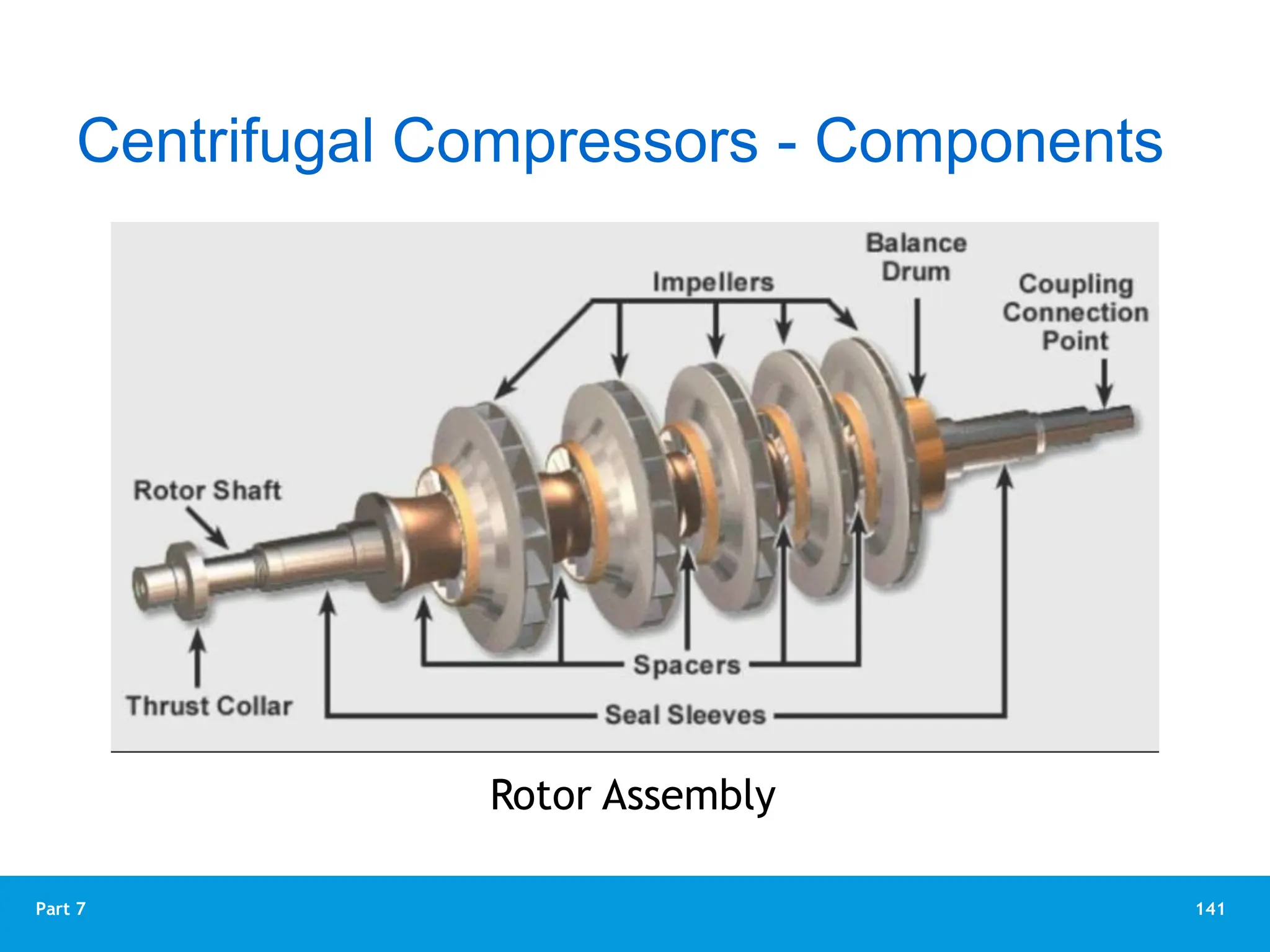

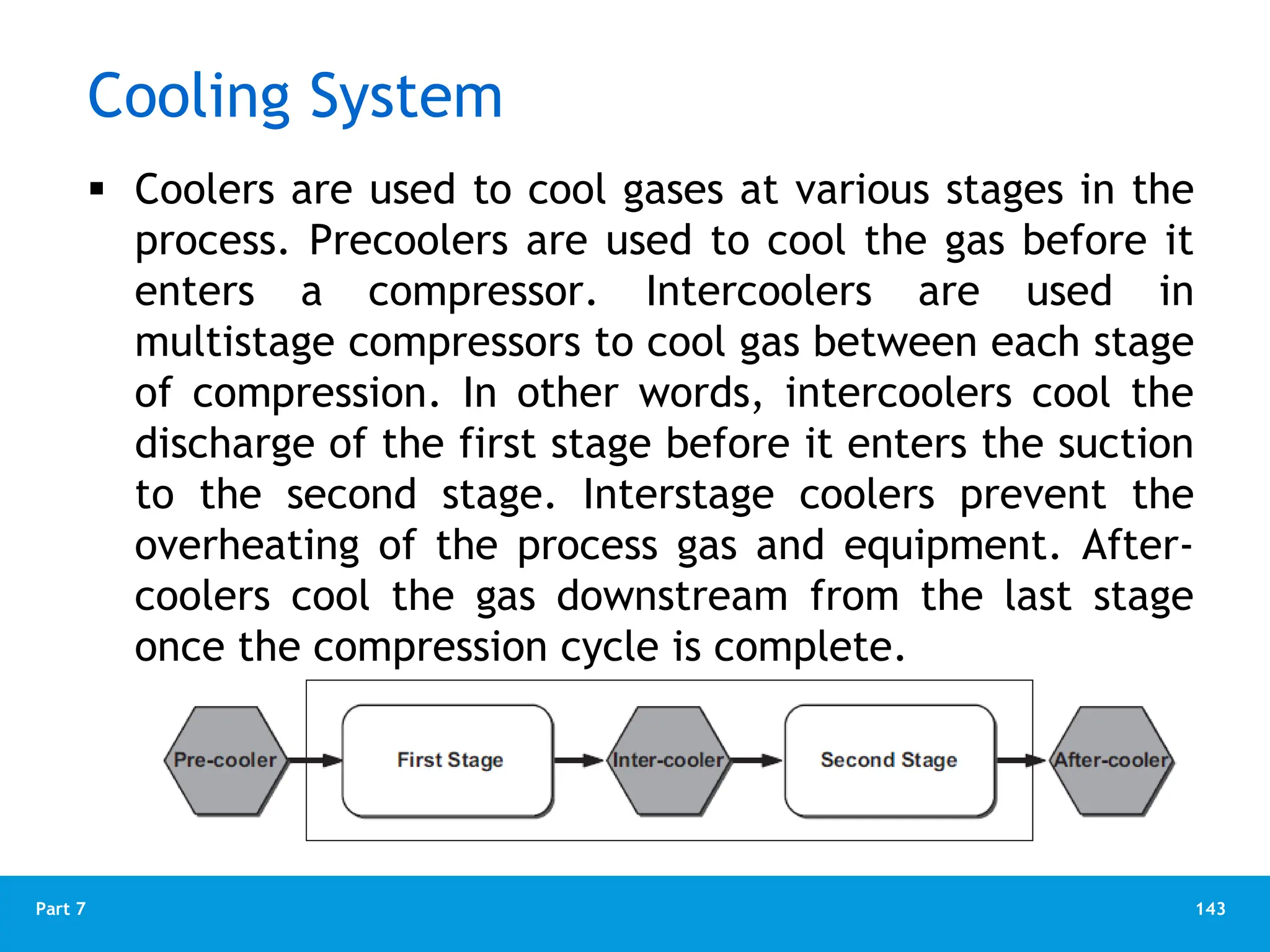

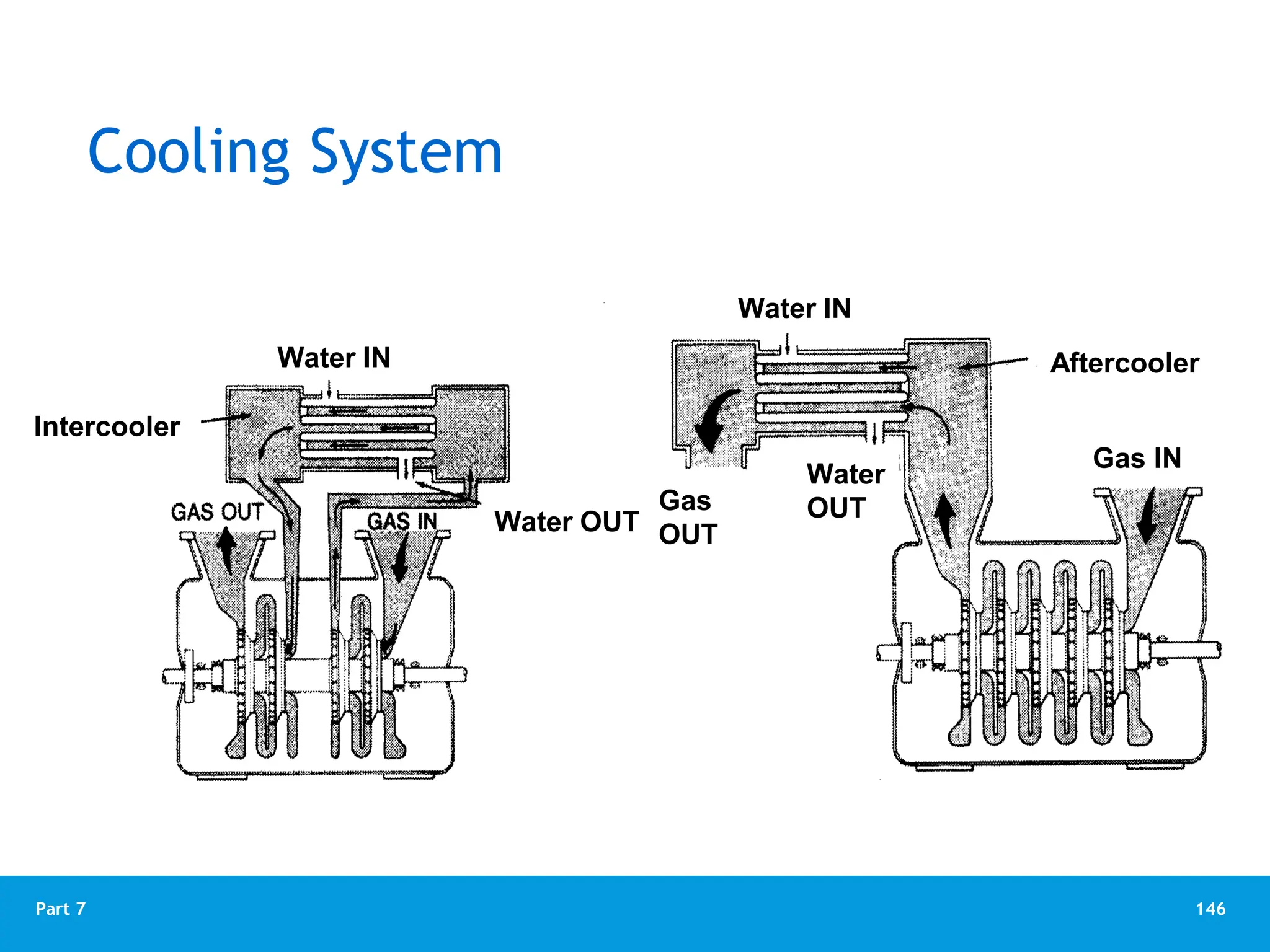

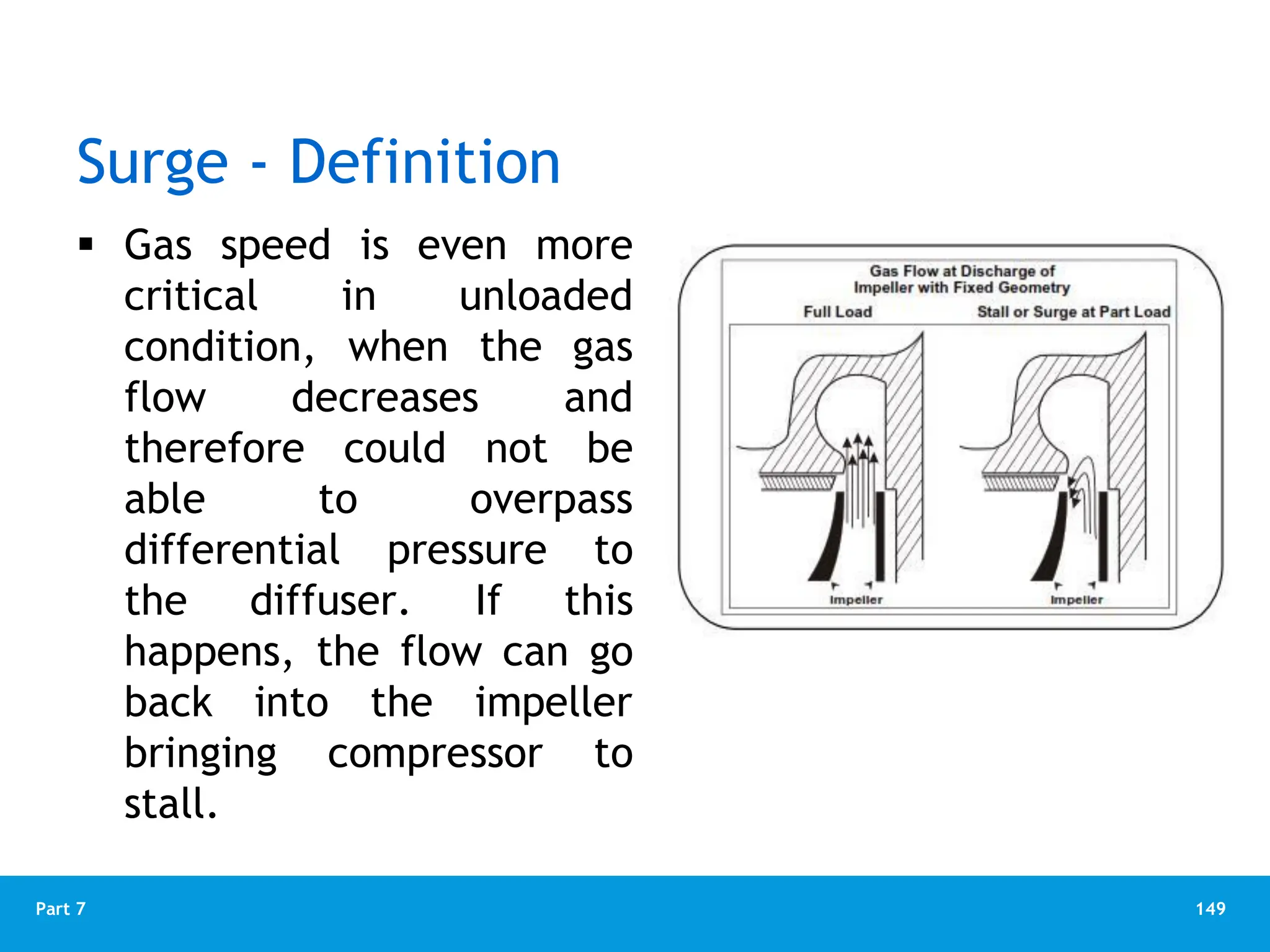

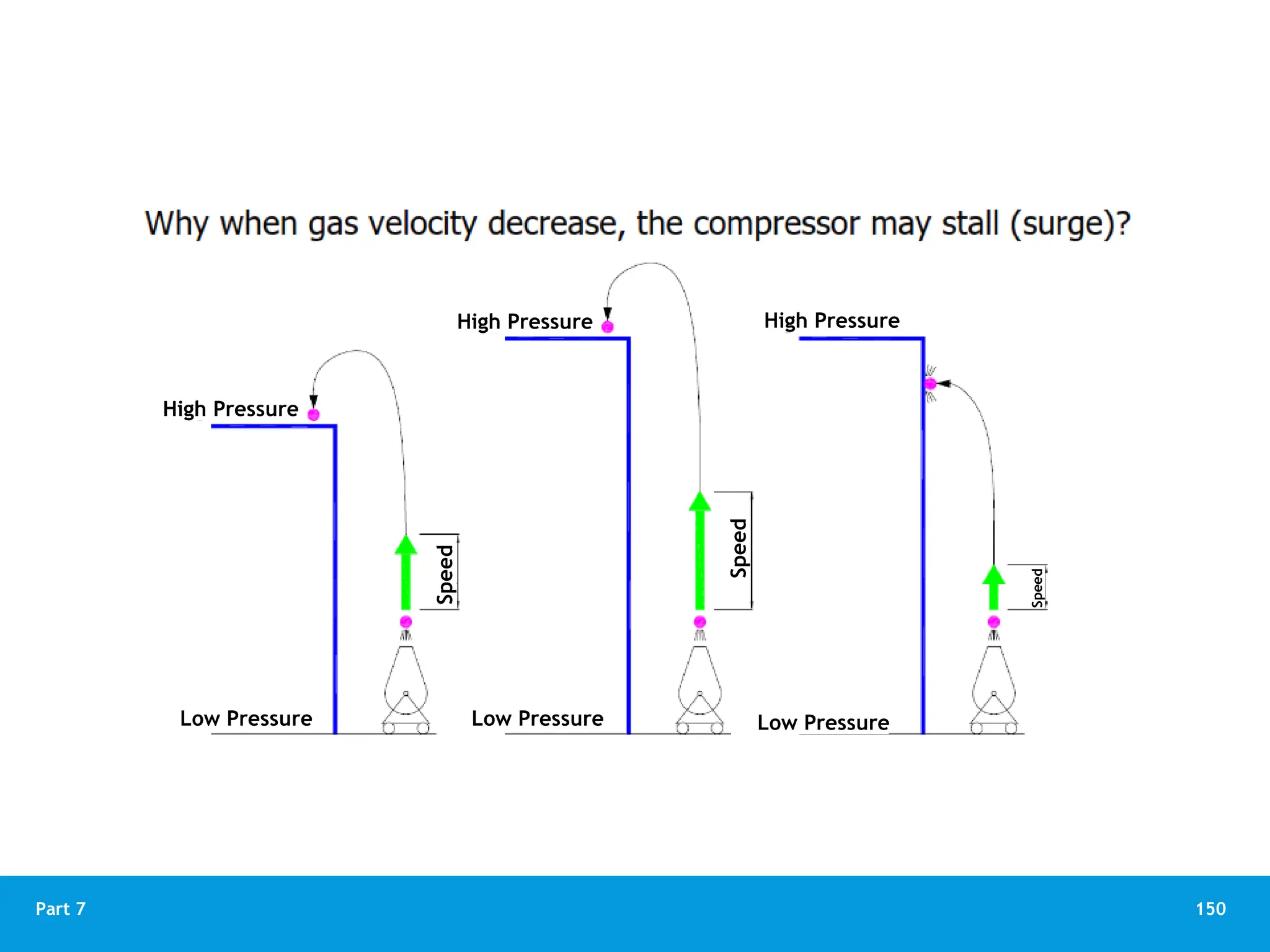

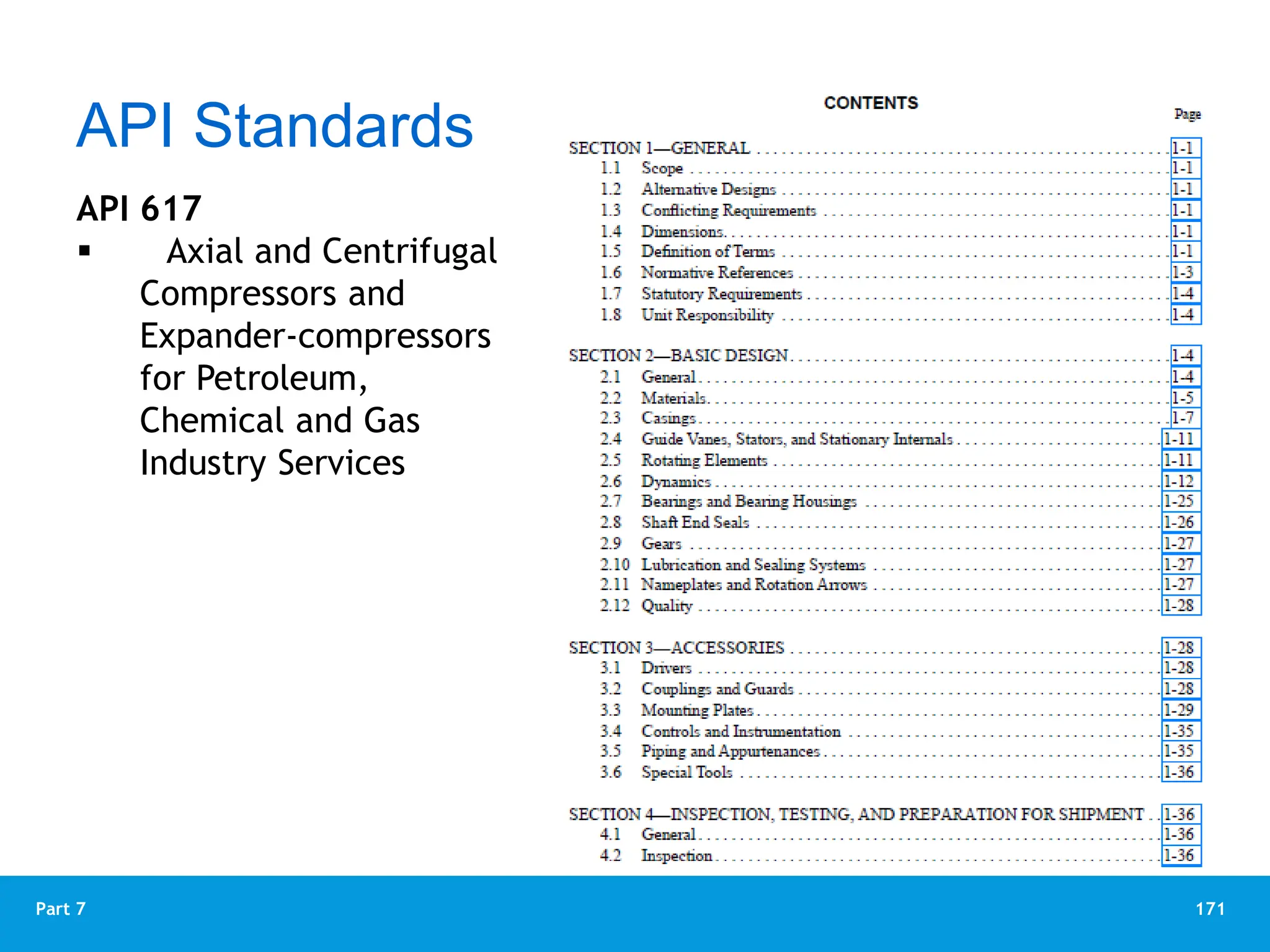

The document provides an in-depth overview of centrifugal compressors, which are devices that raise the pressure of gaseous fluids through the mechanical action of rotating impellers. It details the operations, components, and classifications of centrifugal compressors, emphasizing how they convert gas velocity into pressure and the significance of various components like the impeller, diffuser, and volute. Additionally, it discusses the design considerations and functionalities of guide vanes and casing configurations in enhancing compressor efficiency.