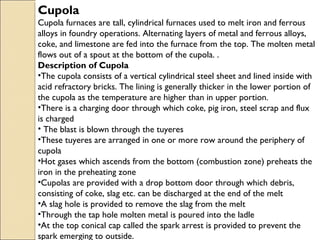

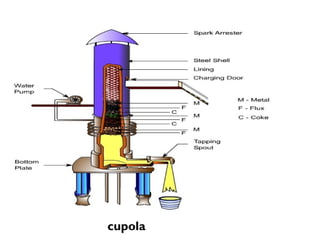

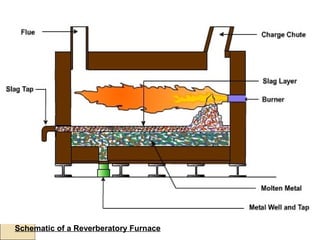

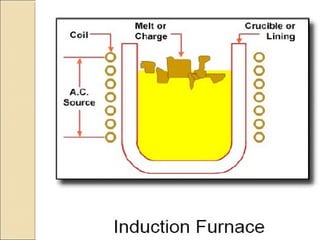

There are several types of furnaces used for melting metals in metal casting, with the choice depending on the type of metal and production needs. Crucible furnaces are small and suitable for batch processes, melting metal in crucibles heated indirectly. Cupola furnaces are tall cylinders that melt iron and alloys by layering them with coke and limestone and heating from the bottom. Reverberatory furnaces heat metal to melting through indirect radiation from burners on refractory walls. Induction furnaces use an induction coil powered by alternating current to generate a magnetic field and directly heat electrically conductive materials without contact.