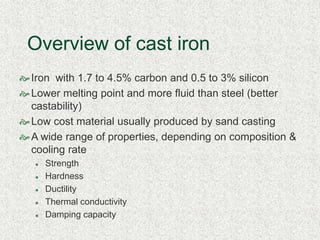

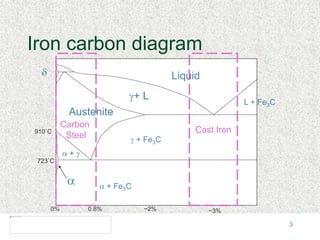

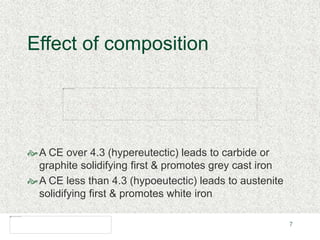

This document provides an overview of cast iron materials. It discusses the different types of cast iron including grey, white, ductile, and malleable cast irons. It describes how the microstructure and properties of cast iron depend on factors like composition, cooling rate, and heat treatment. It outlines the typical applications of different cast irons such as grey iron being used for engine blocks and brake drums due to its good machinability and wear resistance.