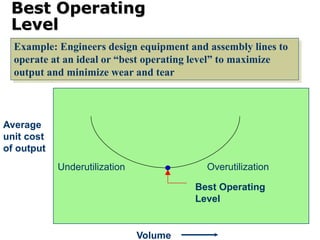

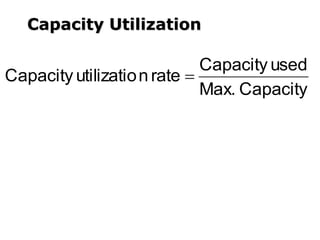

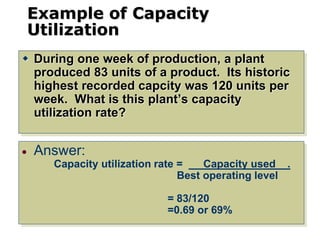

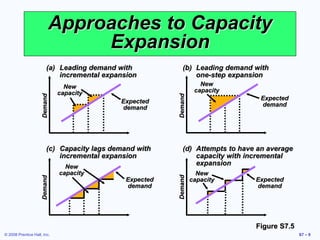

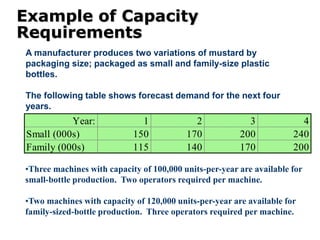

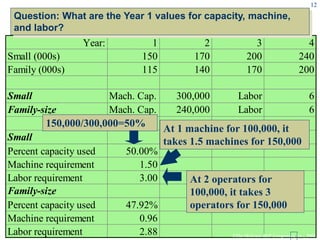

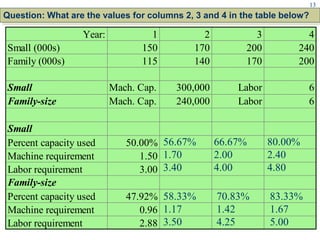

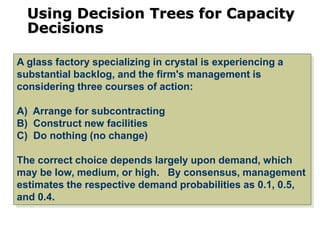

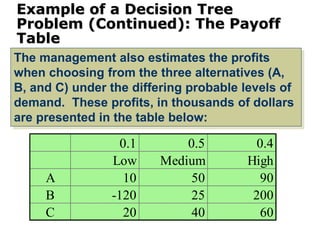

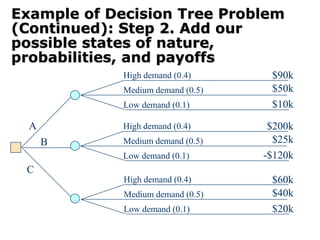

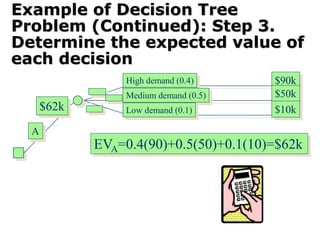

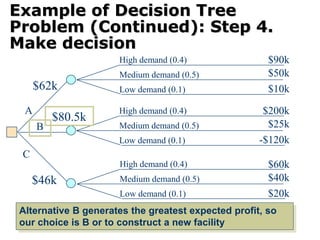

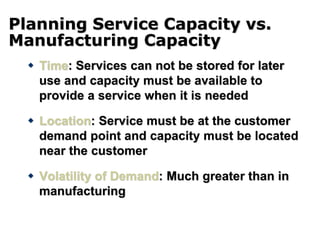

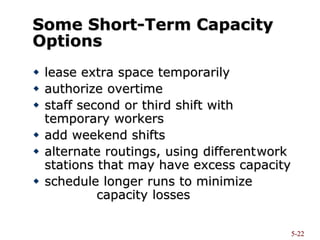

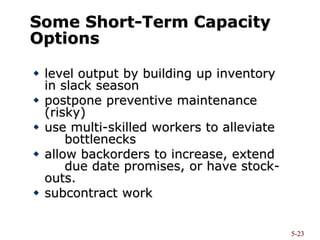

The document discusses strategic capacity planning and management. It defines capacity and strategic capacity planning as determining overall capacity levels of facilities, equipment, and labor force. It discusses determining a best operating level to maximize output while minimizing costs. It also covers capacity utilization rate calculations, approaches to capacity expansion, determining capacity requirements, and using decision trees to evaluate capacity decisions. Short-term capacity options like overtime, additional shifts, and subcontracting are also summarized.