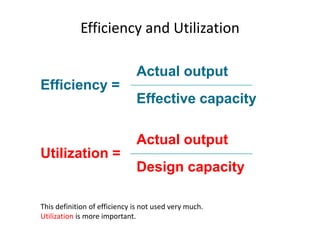

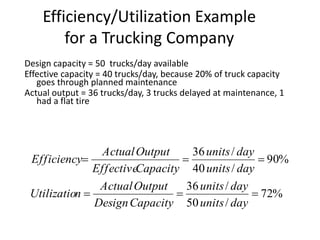

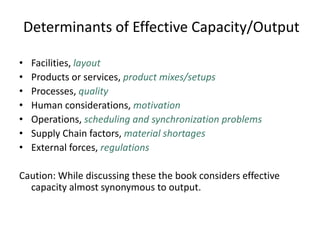

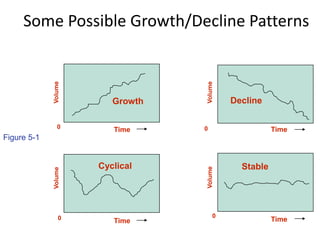

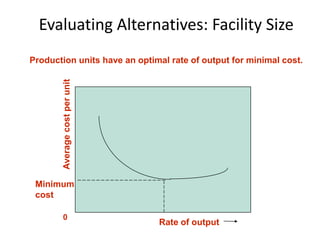

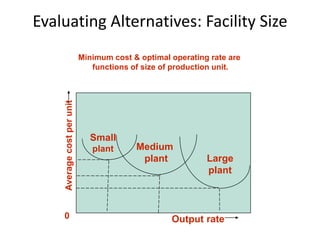

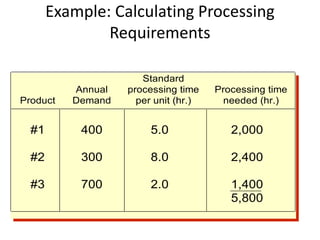

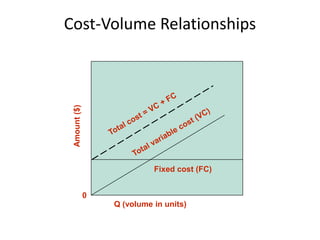

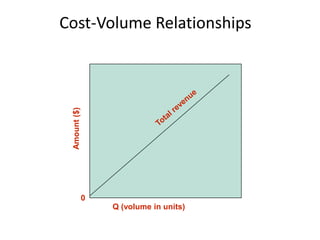

This document discusses capacity and capacity planning in operations management. It defines capacity as the ability to produce output within a time period. Capacity planning determines optimal resource utilization and plays a role in decision making. The document outlines different types of capacity like design, production, sustainable, and effective capacity. It also discusses factors that affect capacity planning like facilities, products, processes, and external forces. The goal of capacity planning is to meet current and future demands with minimal waste.