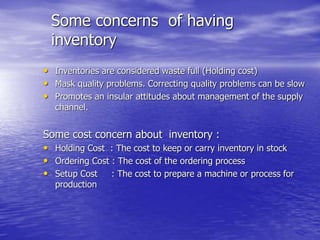

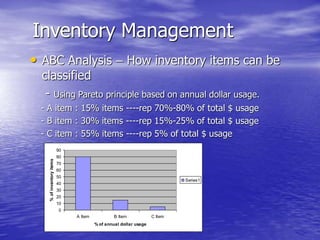

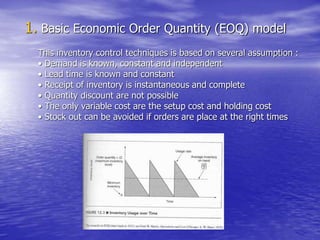

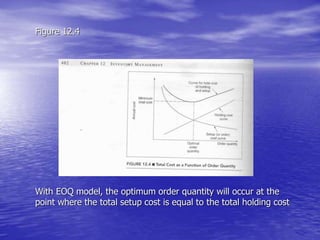

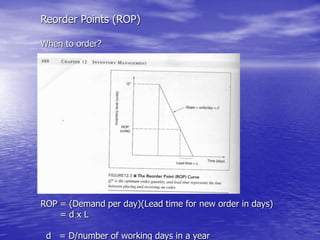

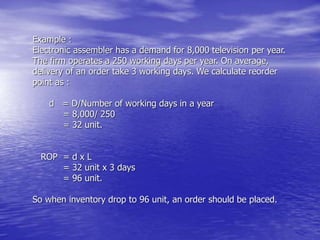

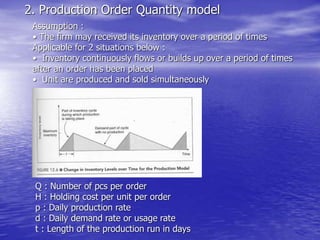

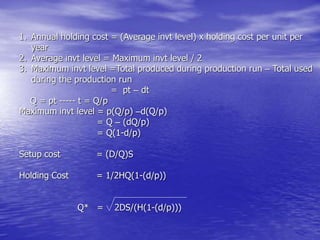

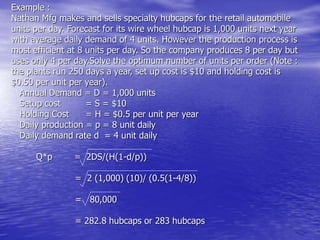

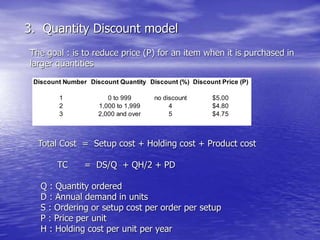

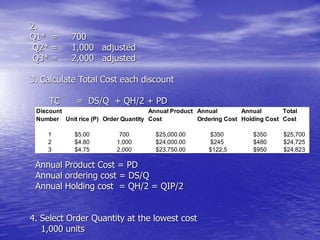

The document discusses inventory management. It describes the objectives of inventory management as understanding inventory functions and concerns, management techniques, and determining optimal order quantities. The key inventory costs discussed are holding, ordering, and setup costs. Different inventory models are introduced, including economic order quantity, production order quantity, and quantity discount models. Formulas are provided to calculate optimal order quantities that minimize total costs based on the different models.